Types of brake discs

Like any other automotive part, brake discs have undergone significant changes over time. Today, the auto parts market offers a huge range of discs, differing both in design and material. It is not surprising that the modern car owner gets lost among this diversity. Therefore, let's talk about disks in more detail.

About disc materials

The best materials for brake discs today are carbon and ceramics. A disk made from these materials has a high safety margin, and most importantly, it is extremely resistant to high temperatures.

Carbon-ceramic brake discs are highly reliable and expensive

In addition, carbon wheels weigh little (this is especially true for owners of racing cars, where every kilogram counts). Of course, such discs also have disadvantages, the main one of which is the price; not everyone can afford it. Additionally, these carbon wheels perform best under extreme loads and temperatures. And if the car owner’s driving style is far from aggressive, the wheels will not demonstrate all their advantages without preheating. Another popular material for brake discs is carbon steel. These are the discs that are installed on the “Seven” when it comes off the production line. The advantages of steel wheels are obvious: extremely low price. It's only cheaper for nothing. Disadvantages are also obvious: a tendency to corrosion, heavy weight and low wear resistance.

Design features of brake discs

By design, brake discs are divided into several large classes. Here they are:

- discs without ventilation;

- ventilated discs;

- solid discs;

- compound disks;

- radial discs.

Now let's take a closer look at each type of disk.

- A non-ventilated brake disc is a plain steel or carbon plate with no holes or recesses. In some cases, small notches may be present on the surface of this plate to improve air circulation near the surface of the rotating disk.

- Ventilated discs have holes. Most often they are through, but in some cases in their place there may be recesses of various shapes (so-called blind holes). The advantage of ventilated discs is obvious: they cool better, and therefore the brakes can work longer under extreme loads. In addition, such discs weigh little. But they also have a drawback: the strength of ventilated discs is significantly reduced due to perforation, which means their service life is also reduced.

- Solid discs are produced using casting. These are monolithic metal plates, which, after casting, are subjected to further heat treatment to obtain the required mechanical properties.

- A compound disc is a structure consisting of a ring and a hub. The ring can be either steel or cast iron. But the hub is always made of some light alloy, most often on an aluminum base. Recently, the demand for composite disks has increased significantly, which is not surprising. They weigh little, cool quickly, and are well ventilated. In addition, the operation of composite brake discs is cheaper for the car owner: if the ring becomes completely unusable, it is enough to simply replace it. In this case, the hub does not need to be changed, since it wears out much more slowly.

- Radial wheels began to be installed on passenger cars relatively recently. These are ventilated discs, but the ventilation system in them is not through holes, but long curved channels that start from the disc hub and diverge to its edges. The radial channel system provides strong air turbulence and maximum cooling of the brake disc. Radial discs are very durable and reliable, and their only drawback is their high price.

How to understand that the thickness of the brake disc is approaching a critical level

First of all, monitor the behavior of the car during braking, especially emergency braking. If there is a beating in the steering column, then it’s time to take a closer look at the brake discs. A visual inspection to determine the thickness of the brake disc should be carried out with the wheel removed.

The first thing to do is take a caliper and measure the thickness of the brake disc in several places. Why in different places? Because there is such a thing as uneven brake disc wear. It happens for various reasons.

When measuring brake discs, do not forget to pay attention to collars, deep scratches and other mechanical damage to the working surface of the brake disc. If they are, then it's time to think about repairing the brake disc.

Replacing brake discs on a VAZ 2107

Before starting repair work, you should decide on the necessary tools and consumables. Here's what we need:

- set of open-end wrenches;

- a set of mounting blades;

- set of spanners;

- jack;

- flat screwdriver;

- a set of two new brake discs and four brake pads.

Sequence of work

First you will have to make several preparatory operations. The car is installed on a flat surface. The rear wheels are secured with shoes and a hand brake. The front wheel, on which the disc is planned to be replaced, is jacked up and removed.

- After removing the wheel, access to the brake disc becomes available. But it is held in place by a caliper with brake pads, which will have to be removed. First, use an open-end wrench to unscrew the bracket with the brake fluid supply hose.

- After removing the bolt, the bracket is moved to the side and the nut on the hose itself is unscrewed with an open-end wrench. The hose is disconnected, and the hole in it is plugged with a 17mm bolt or other plug of suitable size so that the brake fluid does not leak out of the system.

- Now you need to unscrew the two mounting bolts holding the caliper to the steering knuckle. After removing the bolts, the caliper is carefully removed from the brake disc.

- The brake caliper has been removed, and access to the brake disc mount is completely open. One of the 19 bolts holding the car wheel is screwed into the hole on the brake disc hub (this bolt is indicated by a blue arrow in the picture). After this, the mounting blade is installed as shown in the photo (by installing the blade in this way, it can be used as a lever and keep the brake disc from turning). With the other hand, unscrew a pair of mounting bolts on the brake disc ring.

- After removing the bolts, the mounting ring is removed, and then the brake disc itself is removed.

- The removed disc is replaced with a new one, then the VAZ 2107 brake system is reassembled.

dismantling the brake mechanism of the front wheel of a VAZ 2107

| The brake mechanism of the front wheel of a VAZ 2107 car consists of a brake caliper, brake wheel cylinders, a brake disc and brake pads. We remove the brake caliper of the front brake mechanism from the VAZ 2107 to replace it, replace the working cylinder or brake disc. The work is shown using the example of the brake mechanism of the right wheel of a VAZ 2107 car. To disassemble the brake mechanism of a VAZ 2107 car, you will need an assistant, as well as a special 10 mm wrench for brake pipes, a transparent vinyl tube of a suitable diameter, a container for draining brake fluid, fresh brake liquid (see “Operating fluids used on VAZ 2107 vehicles”). Removing the front wheel brake mechanism from a VAZ 2107 car 1. We prepare the VAZ 2107 car for operations (see “Preparation of the VAZ 2107 car for maintenance and repair”). | Installing the front wheel brake mechanism on a VAZ 2107 car 1. We install the brake cylinder and brake caliper on a VAZ 2107 car in the reverse order. Attention The brake cylinders of the front wheels of the VAZ 2107 are not interchangeable. Do not mix up the brake cylinders during installation. 2. Before installing a new brake cylinder, press the latch and install the brake cylinder into the guide grooves of the brake caliper. Attention If it is difficult to install the new brake cylinder into the brake caliper, use a file to blunt the leading edge of the brake cylinder installation guide. 3. Press in the brake cylinder until the latch engages. 4. Replace the copper sealing washers with new ones (see “Brake hose of the front wheel of a VAZ 2107 car - replacement”). 5. After installing the brake caliper on the VAZ 2107 car and connecting the brake hose, pump the brakes from the side of the replaced brake cylinder (see “Hydraulic brake drive of the VAZ 2107 car - pumping and replacing brake fluid”). Attention We replace brake discs in pairs on both sides of the VAZ 2107. Periodically check the condition of the brake discs (see “Brake system of the VAZ 2107 - checking technical condition”) and replace the brake discs when worn, avoiding wear of the brake discs to a thickness of less than 9.5 mm , with increased lateral runout or in case of deep marks on the working surface. |

What you need to consider when installing rear disc brakes on a VAZ 2107

- Disc brakes are more efficient than drum brakes. Therefore, after installing disc brakes on the rear wheels, it is necessary to adjust the pressure regulator of the rear brake circuit, otherwise the rear brakes may operate earlier than the front ones, which may cause the rear axle to skid.

- To install disc brakes, you will have to carry out welding, milling and turning work, which will require special equipment. If it is not there, some of the work will have to be ordered externally.

- A car with a modified brake system (with disc brakes instead of drum brakes provided by the manufacturer) will not pass inspection.

- The requirements for the condition of the rear wheel hub bearings increase when installing disc brakes. The small amount of play allowed on drum brakes can cause damage.

- Tampering with the brake system is a dangerous step. If you are not confident in your capabilities, it is better to refuse to install disc brakes yourself or entrust the job to professionals.

What are the best pads to buy for the “seven”

And so, it is clear that you should not skimp on the reliability of the brakes, especially for a car designed in the middle of the last century and devoid of ABS and other bells and whistles to increase safety. Therefore, we recommend buying pads for the VAZ 2107 that best meet the following indicators:

- optimal friction coefficient both in “cold” mode and on warm brakes (0.35-0.45 according to GOST);

- high lining life and minimal wear of the brake disc.

- absence of uncomfortable sounds, creaks, vibrations when braking;

The last point is subjective in nature, since the pads creak due to the unsatisfactory condition of the brake system as a whole, disc wear, and poor caliper performance, which is also very important to take into account when independently replacing brake pads on a VAZ 2107. Under harsh operating conditions (under heavy loads and sudden braking) choose solid pads from companies: ATE, Ferodo

For more moderate city driving, which does not involve frequent overheating and large constant loads on the brake system, buy “softer” pads - Allied Nippon, Finwhale, TIIR

Under severe operating conditions (under heavy loads and sudden braking), choose solid pads from the following companies: ATE, Ferodo. For more moderate city driving, which does not involve frequent overheating and large constant loads on the brake system, buy “softer” pads - Allied Nippon, Finwhale, TIIR.

When purchasing, it is important to pay attention to the composition of the friction clutch; pads using large metal shavings, in the form of inclusions, can greatly wear out the disc, leaving grooves on it. It is best to buy pads with modern high-tech compounds that will protect the disc from premature wear

Basic faults

The most common malfunction of the VAZ 2107 brake system is the ineffectiveness of the braking itself. The driver himself can notice this malfunction by eye:

- when braking, the braking distance increases;

- The braking process itself takes longer than before.

This malfunction can be caused by a number of breakdowns:

- there are air pockets in the system;

- leakage of brake fluid;

- severe wear of the pads;

- cylinder failure.

Braking distance on dry pavement can be calculated using this scheme

In addition to ineffective braking, other malfunctions may also occur:

- strong grinding noise (noise) when squeezing the brake pedal;

- the car swerves to the sides when slowing down;

- softened brake pedal lowered;

- vibrations and jerking when pressing the pedal.

Any unusual sensations when pressing the brake pedal indicate a problem with the system.

Brake disc malfunctions and causes of their occurrence

The main problem with a brake disc is its wear. This process is inevitable, but can happen faster or slower, depending on your driving style.

First of all, wear involves “erasing” the working surface of the disk during operation, and this “erasure” can be either uniform or uneven. Uniform wear refers to the correct operation of the brake system, when the disc wears equally over the entire surface of the rim. Uneven wear includes various scratches and holes that appear on the disc due to driving with worn brake pads, their improper installation and sudden braking.

Replacing front pads on a VAZ 2107

If the front of your “seven” has factory brake pads, then you won’t have to worry about replacing them anytime soon. Such elements are maintained for at least 50 thousand km. during normal operation of the car, i.e. without constant sudden braking. If the pads are worn out, you can replace them yourself without visiting a service station. To carry out repair work you will need the following tools:

- Phillips and flathead screwdrivers;

- pliers;

- hammer.

To replace brake pads you will need a standard garage tool kit.

Dismantling

We remove the pads in the following order:

- Raise the front of the car using a jack, unscrew the wheel mount and remove it.

- Using a screwdriver or pliers, remove the two cotter pins holding the rods of the brake elements.

- Using a Phillips screwdriver, we push out the pad rods. If they are difficult to come out, you can use penetrating lubricant and lightly tap the screwdriver with a hammer.

- We take out the pad clamps.

- Brake elements often come out of their seats without problems. If difficulties arise, pry them through the holes with a screwdriver, resting against the brake cylinder.

- Remove the pads from the caliper.

Installation

We install new pads in the following order:

- We inspect the anthers of the working hydraulic cylinders. If the rubber element is damaged, replace it with a new one.

- We use a caliper to measure the thickness of the brake disc. For accuracy, we do this in several places. The thickness of the disk must be at least 9 mm. If this is not the case, the part needs to be replaced.

- Open the hood and unscrew the brake fluid reservoir cap.

- Use a rubber bulb to drain some of the brake fluid so that its level is below the maximum mark. We do this so that when the pistons are pressed into the cylinders, liquid does not flow out of the tank.

- Through the metal spacer, we rest the pry bar one by one against the cylinder pistons and press them all the way. If this is not done, then it will not be possible to install new parts due to the small distance between the brake disc and the piston.

- We mount the pads and other parts in the reverse order.

Video: replacing front brake pads on classic Zhiguli cars

Identifying faulty front brake pads on a VAZ 2107 and replacing them is a simple task and does not require special tools or skills. Any owner of this car will be able to cope with it, for which it will be enough to read the step-by-step instructions and follow them during the repair process.

Brake system VAZ 2101

Any car is equipped with a braking system, and the VAZ “kopek” is no exception. Its main purpose is to slow down or completely stop the vehicle at the right time. Since brakes can fail for various reasons, their performance and the condition of their components must be periodically monitored. Therefore, it is worth dwelling in more detail on the design of the braking system, problems and their elimination.

Brake system design

The Zhiguli brakes of the first model are made of working and parking systems. The first of them consists of the following elements:

- master brake cylinder (GTC);

- brake wheel cylinders (RTC);

- hydraulic drive reservoir;

- hoses and tubes;

- pressure regulator;

- brake pedal;

- brake mechanisms (pads, drums, brake disc).

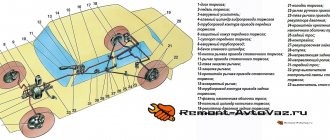

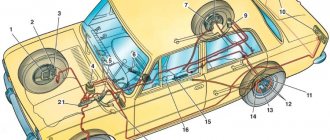

Diagram of the VAZ 2101 brake system: 1 - front brake protective casing; 2, 18 — pipelines connecting two cylinders of the front brake caliper; 3 - caliper; 4 — hydraulic drive reservoir; 5 — brake light switch; 6 — parking brake lever; 7 — adjusting eccentrics of the right rear brake; 8 — fitting for bleeding the hydraulic drive of the rear brakes; 9 — pressure regulator; 10 - brake light; 11 — rear brake wheel cylinder; 12 — lever for manual drive of the pads and expansion bar; 13 — adjusting eccentric of the left rear brake; 14 — brake pad; 15 — rear cable guide; 16 — guide roller; 17 — brake pedal; 19 — fitting for bleeding the hydraulic drive of the front brakes; 20 — brake disc; 21 - main cylinder

The parking brake (handbrake) is a mechanical system that acts on the rear pads. The handbrake is used when parking a car on a slope or on a descent, and also sometimes when starting off on a hill. In extreme situations, when the main braking system has stopped functioning, the handbrake will help stop the car.

Operating principle

The principle of operation of the VAZ 2101 brake system comes down to the following actions:

- When the brake pedal is applied, the pistons in the turbocharger move, which creates fluid pressure.

- The fluid rushes to the RTC located near the wheels.

- Under the influence of liquid pressure, the RTC pistons are set in motion, the pads of the front and rear mechanisms begin to move, as a result of which the discs and drums slow down.

- Slowing down the wheels leads to overall braking of the car.

- Braking stops after the pedal is released and the working fluid returns to the GTZ. This leads to a decrease in system pressure and loss of contact between the brake mechanisms.

The principle of operation of hydraulic brakes on the VAZ 2101

Brake system malfunctions

The VAZ 2101 is far from a new car and owners have to deal with malfunctions of certain systems and troubleshoot problems. The braking system is no exception.

Low brake efficiency

A decrease in the effectiveness of the braking system can be caused by the following reasons:

- violation of the tightness of the front or rear RTCs. In this case, it is necessary to inspect the hydraulic cylinders and replace worn-out parts, clean the brake elements from dirt, and bleed the brakes;

- presence of air in the system. The problem is solved by bleeding the hydraulic drive system;

- The lip seals in the GTZ have become unusable. Requires disassembly of the master cylinder and replacement of rubber rings with subsequent bleeding of the system;

If the sealing elements of the GTZ have become unusable, the cylinder will have to be completely disassembled for repair. - damage to flexible pipes. It is necessary to find the damaged element and replace it.

The wheels do not release the brakes completely

Brake pads may not fully release from the drums or rotors for a number of reasons:

- The compensation hole in the gas turbine engine is clogged. To eliminate the malfunction, it is necessary to clean the hole and bleed the system;

- The lip seals in the GTZ are swollen due to oil or fuel getting into the liquid. In this case, it will be necessary to flush the brake system with brake fluid and replace damaged elements, followed by bleeding the brakes;

- the piston element jams in the GTZ. You should check the functionality of the cylinder and, if necessary, replace it, and then bleed the brakes.

Braking of one of the wheel mechanisms when the brake pedal is depressed

Sometimes a malfunction occurs when one of the car’s wheels spontaneously brakes. The reasons for this phenomenon may be the following:

- The tension spring of the rear brake pads has failed. Inspection of the mechanism and elastic element is necessary;

- RTC malfunction due to piston sticking. This is possible when corrosion forms inside the cylinder, which requires disassembling the mechanism, cleaning and replacing worn-out parts. In case of significant damage, it is better to replace the cylinder completely;

- an increase in the size of lip seals due to fuel or lubricant entering the working environment. It is necessary to replace the cuffs and flush the system;

- There is no gap between the brake pads and the drum. The handbrake needs adjustment.

The car skidding or pulling to the side while pressing the brake pedal

If the car skids when you press the brake pedal, this indicates the following malfunctions:

- leakage of one of the RTCs. Replacement of cuffs and bleeding of the system is required;

Fluid leaks on the inside of the wheel indicate a leak in the brake system. - jamming of the piston element in the working cylinder. It is necessary to check the performance of the cylinder, eliminate malfunctions or replace the assembly part;

- a dent in the brake pipe, which led to blockage of the incoming fluid. The tube needs inspection and subsequent repair or replacement;

- The front wheel angles are not set correctly. Angle adjustment required.

Brakes squeal

There are times when the brakes squeak or make a squealing sound when you press the brake pedal. This may occur for the following reasons:

- The brake disc has uneven wear or excessive runout. The disc needs to be sanded, and if the thickness is less than 9 mm, it needs to be replaced;

- oil or liquid getting on the friction elements of the brake pads. It is necessary to clean the pads from dirt and eliminate the cause of leakage of lubricant or liquid;

- Excessive wear of brake pads. Elements that have become unusable need to be replaced.

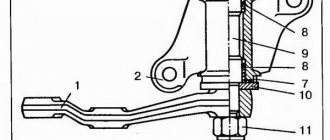

Front brake device for VAZ 2107

1 — fitting for bleeding the front brake drive; 2 — connecting tube of working cylinders; 3 — brake pad wear indicator wire; 4 — wheel cylinder piston; 5 — wheel cylinder clamp; 6 — brake pad lining; 7 - sealing ring; 8 — dust cap; 9 — pins for securing the pads; 10 — bolt securing the caliper to the bracket; 11 — steering knuckle; 12 — caliper mounting bracket; 13 — caliper; 14 — protective casing; 15 — cotter pin; 16 — pad pressure spring; 17 — brake pads; 18 — wheel cylinder; 19 — brake disc.

- Having disconnected the wires of the 3 front pad wear indicators from the plug connections of the wires, remove the cotter pins 15, and then the pins 9 with the springs, remove the springs 16 and the brake pads 17. Mark the pads so that during reassembly you can install them in their original places.

- Having straightened the locking plates, unscrew the two bolts 10 that secure the caliper to the bracket, and remove the caliper.

How to easily determine brake disc wear by visual inspection

Hi all! I think every motorist is interested in maintaining his own vehicle in good condition.

Moreover, special attention should be paid to the braking system. That is why the topic of our conversation will be how to determine the wear of brake discs

The purpose of the brakes is to ensure timely stopping or reducing the speed of the machine. Moreover, the brake must respond instantly to the driver pressing the corresponding pedal. The speed at which a car brakes directly depends on the current condition and serviceability of the brake system components in the form of pads and discs. The stopping of the machine is due to the work of the friction force. To ensure that the discs do not wear out during friction, high-quality and durable materials are used for their production. But they are not eternal either. Wear and tear comes sooner or later.

Caliper device

Let's move on. The front axle mechanisms are disk ones, consisting of calipers with the main brake elements - pads, and brake discs.

A caliper is a body with cylinders made in it for the pistons. This model has two of them, one for each block. The support structure is shown in the figure.

The caliper pistons have the form of a glass, which is placed in their cylinders, but they can move along it. To prevent fluid leakage, the pistons are equipped with o-rings.

Pads are small metal plates onto which linings made of friction material are glued.

The brake disc is made of metal for better adhesion to the surface of the pads; its side surfaces are well processed so that there are no protrusions or shells on them.

The VAZ 2107 brakes work like this: the fluid moves into the caliper cylinders, where it begins to push out the pistons. They come out of the cylinders, pressing the pads against the disc.

How to properly install pressure springs

This question has divided all professional car mechanics into two camps. Some argue that it is correct to install from the brake disc side, as shown on the left side of the screenshot below, others - from the brake cylinder side, as shown on the right.

The first ones say - there is no difference, the main thing is that they press the pads and do not let them “rumble”. The latter explain it this way: if you install “gulls” on the disc side, then with their edges they will press the brake element against the disc, increasing wear on the friction clutch. If you install it with the side facing the cylinders, they seem to move them apart; they do not come into contact with the disk, so there is no wear during movement.

If you think logically, then the second part of the people is right. The springs have a design in which they, with their rounded edges, attract the pads in the direction of their installation. Therefore, if you place the springs on the inside, their edges will slightly press them against the disk - they will wear out faster. If from the inside, then there will be no such effect.

Video on how to shoot a classic in a garage:

Installation of disc brakes on the rear axle of a VAZ 2107

As you know, the rear axle of the VAZ 2107 was initially equipped with drum brakes rather than disc brakes, which are not very efficient. In this regard, many car enthusiasts independently replace these brakes with disc brakes. Let's look at this procedure in more detail.

Sequencing

To work, we will need the tools listed in the list above. In addition to them, we will need a rust cleaning liquid. It's better if it's WD40.

- The car is jacked up and the rear wheels are removed. Provides access to the brake drums and rear axle shafts. The axle shafts are thoroughly wiped off from dirt using a rag, and if necessary, treated with WD40.

- The brake fluid from the system is drained into a previously prepared container. The pads are removed from the brake drum, then it is removed along with the axle shafts so that only the brake pipes remain.

- The mounting rings and wheel bearings located under the rings are removed from the axle shafts.

- Now the axle shafts are ground on a lathe so that their diameter matches the diameter of the selected brake disc (at this stage of the work, the car owner will need the help of a qualified turner). After this, holes are drilled in the axle shafts for the brake disc mounting bolts.

- The axle shafts improved in this way are installed back on the rear axle of the VAZ 2107. A brake disc is installed on top of them and screwed with a pair of mounting bolts as shown in the photographs above. After securing the discs, disc calipers with pads are installed on them, the rear wheels are installed in their regular places and the car is lowered from the jacks.

Video: setting rear disc brakes to “classic”

So, even a novice car enthusiast can change the front brake discs on a VAZ 2107. All that is required is the ability to use wrenches and a minimal understanding of how a disc brake system works. As for replacing rear drum brakes with disc brakes, it will not be possible to do this without the help of a qualified turner.

Tubes and hoses

Brake pipes and hoses of the braking system of the VAZ “kopek” are used both front and rear. Their purpose is to connect the GTZ and RTC to each other and supply brake fluid to them. Sometimes connecting elements become unusable, especially hoses, due to aging rubber.

Damage to the hose leads to fluid leakage and depressurization of the brake system.

The parts in question are attached using a threaded connection. There are no difficulties in replacing them. You just need to unscrew the fasteners on both sides, remove the worn element and install a new one in its place.

Video: replacing brake pipes and hoses on a “classic”

Installing the brake mechanism and bleeding the system

The restored caliper of a VAZ 2107 car is put on the disc and secured with bolts to the steering knuckle. The pads are inserted into the gap and fixed with guide springs; if necessary, parts are replaced with new ones. The brake hose and tube are installed in place, and the system is filled with fluid to the specified level. Repair of the brake mechanism ends with bleeding to remove it from the system.

This process on a VAZ 2107 car is carried out as follows: a hose of a suitable diameter is put on the nipple of the working cylinder. Its other end is lowered into a container with liquid. The assistant sits behind the wheel and presses the brake pedal several times and holds it in that position. Using the key, release the nipple and let out the air. We repeat this action until bubbles stop appearing in the container.

https://youtube.com/watch?v=n96SJyFwZJs

Article number and cost of good front brake discs for VAZ 2107 from third-party manufacturers

The best alternative options for original discs that do not require alteration of the brake mechanism are shown in the table below.

Table - Good analogues of the original front discs

| Manufacturer | vendor code | Approximate cost, ruble |

| Ferodo | DDF035 | 900-1300 |

| Remsa | 615600 | 1150-1500 |

| Brembo | 08255924 | 1200-1500 |

| ABS | 15025 | 720-950 |

| Road House | 615600 | 800-1100 |

How often should you change front pads?

Let's start with the fact that on the VAZ 2107 the front brakes are represented by a disc system, which in some ways is much better than a drum one, but that’s not about that now. There are 2 pads on each caliper at the front, which are responsible for effective braking of the car. The front brake pads of the VAZ 2107 have the following appearance, shown in the photo above.

Essentially, the products are a steel plate onto which a special friction layer is applied. It is this friction layer that is the basis for car braking. When this layer wears off, which depends not only on the frequency of use of the brake pedal, but also on the nature of driving, then the car owner urgently needs to replace the brake pads on the VAZ 2107. If this is not done in a timely manner, then you understand what the outcome may be.

How often it is necessary to change the parts in question depends on the following factors:

- condition of the brake system;

- character and driving habits;

- product manufacturer;

- regular maintenance.

But our mentality is such that we don’t pay attention to how often we need to change the pads, and we do it when it’s pressing. The reasons that indicate that the car requires repair work on the brake system are due to the following symptoms:

- the appearance of extraneous sounds when you press the brake pedal: creaking or grinding;

- to brake, you need to apply force;

- When braking, the car begins to skid.

Approximately, it is necessary to replace the front pads on a car every 25-30 thousand km. But this range is average, since someone can travel 50 thousand km without replacing products, but they can only do 10. Let’s look at what it is to replace the front brake pads of a VAZ 2107 in more detail.

Detailed description of replacing front pads on a VAZ 2107

Replacing pads on a VAZ 2107 is a simple process that needs to be taken seriously. First you need to purchase new products. You need to buy them as a set, and replacement should be done on both wheels at once. After this, make sure that you have a basic list of tools:

- screwdriver;

- hammer and chisel;

- pliers;

- standard set of wrenches;

- WD-40 lubricant;

- Brake Cleaner (optional).

Let's start the workflow:

- Initially, some of the fluid should be removed from the brake reservoir, which is done to prevent it from overflowing and entering the engine compartment.

- Place shoes under the wheels, then install a jack and lift the front end. Afterwards, the wheel is removed, and then the surface of the caliper is cleaned of dirt and dust.

- Using a thin screwdriver, remove the two visible cotter pins. These cotter pins are designed to hold the pad rods. The photo below shows the location of these two cotter pins.

- Using a screwdriver, you need to press out the pad rods. If your own efforts are not enough, then you can use a hammer and a punch.

- The products are additionally held by spring structures, which can be seen in the photo above. They also need to be dismantled, for which you need to use pliers.

- When the rods and springs are removed, you can begin to dismantle the products themselves. Usually the pads do not sit tightly, so you just need to pry them off with a screwdriver and remove them, as shown in the photo below.

- Once the pads are removed, it is recommended to clean the seat using special products, and you can begin installing new ones.

- To do this, using a mounting tool or a screwdriver, you need to separate both cylinders, thereby preparing a place for new (thicker) pads. At the same time, do not forget to monitor the level of the displaced liquid in the barrel and, if necessary, remove it.

After installing the new products in their places, install the rods and mounting springs in the reverse order. This completes the replacement of the front pads on the popular VAZ 2107 car. As you can see, there is nothing complicated at all. Everything is simple and clear, but the main thing is to perform all the steps in the order described above. After installing new system elements according to the instructions, there is no need to bleed the brakes.

If you decide to replace worn-out products, then it is recommended to purchase new ones from companies such as Ferodo, ATE or Nippon. They will last much longer and will also delight you with their quality and braking performance. If you still don’t know how to change the front brake pads on a Zhiguli, then this material will be a good help. And remember that you will always have time to overpay the mechanic at the service station, but only then will you not be able to gain invaluable experience in repairing your car.

Replacement steps

The entire replacement process can be divided into several stages:

- Removing wheels;

- Removing the old brake pad;

- Frame disassembly;

- Cleaning the hub and checking it;

- Removing coating from new disks;

- Runout check;

- Installation of new brake system elements.

Now let's talk about this in more detail.

Removing the wheel

In fact, dismantling the wheel for subsequent replacement of the brake elements is not difficult.

But a certain sequence of actions will have to be followed.

- Place a jack under the car.

- Lift it up so that it doesn't tip over, but still allows you to easily remove the wheels.

- Unscrew the wheel fasteners.

- Remove the hubcaps and the wheels themselves.

As you can see, the procedure is really simple, but it requires attention and accuracy.

Removing the pads

- Try to move the piston as far as possible from the brake mechanism. But do not exceed the distance beyond that which will allow you to comfortably remove the brake pads.

- Take out the block.

- To make the job easier, you can disassemble the brake frame. To do this, unscrew the two bolts securing the block and disconnect the device.

Hub

Dirty

Use alcohol-based solvents and metal brushes for cleaning. If cleaning is not performed, the operation of the brakes will be accompanied by beating - this should absolutely not be allowed.

Be sure to check the hub for runout. Normally it does not exceed 0.1 mm. There is a special tool for checking. If the indicator is within normal limits, then a full assembly is performed.

Working with new disks

Many owners of the “Ten” are interested in which brake discs are best to choose for the VAZ 2110. The question is quite logical.

New

Some take similar discs that partially fit the “ten”, sharpen them, and adjust the design. This is a dubious undertaking, since it requires serious skills in such a matter, additional time and financial costs. At the same time, it is far from a fact that such brakes will work better than those offered by the AvtoVAZ plant.

Do-it-yourself installation of rear disc brakes on a VAZ 2107

The procedure for replacing drum brakes with disc brakes is as follows:

- Remove the rear axle axle shafts. This procedure is described in the VAZ operating instructions.

- Clean the axle shafts and wash them in gasoline or kerosene (if you do not plan to use new ones instead).

- Drain the brake fluid from the system.

- Remove the rear brake parts, leaving only the brake pipes.

- Remove the retaining ring and wheel bearing. To remove the locking ring, a press is required, since it is designed for a tearing load of about 5 tons.

- You can do it differently: cut the retaining rings with a grinder. The cut should not be made completely so as not to damage the axle shaft, and then split the rings with a chisel and remove the bearings.

- Grind the axle shafts in accordance with the inner diameter of the brake disc. It is impossible to do this without a lathe, so it is better to seek help from a lathe.

- Also in the workshop it is necessary to make a bracket for mounting the caliper in accordance with the drawings.

- Before assembling the axle shafts, clean the parts and rinse with gasoline.

- Install the axle shaft boot, caliper bracket, compensating ring.

- Wash the axle bearing, lubricate it and press it onto the axle shaft using a piece of pipe. The bearing must be pressed to the landing stop on the axle shaft. The diameter of the pipe must be such that it rests against the inner ring of the bearing. The bearing is pressed in like this: the pipe is pressed against the ring, hitting its other edge with a hammer. It is unacceptable for the pipe to rest against the outer ring of the bearing - this will lead to its failure. It is necessary to push the bearing onto the axle shaft slowly, so as not to split the fragile steel of the bearing with impacts.

- Check the quality of the bearing fit on the axle shaft.

- Heat the retaining ring until red hot and install it on the axle shaft. If the ring does not fit tightly, it must be cut off and a new one installed. Most often, poor ring fit is caused by insufficient heating temperature. Therefore, to heat the half rings it is necessary to use a sufficiently powerful burner. A cold snap ring cannot be installed on the axle shaft.

- After the half-ring has cooled, install a spacer bored to match the diameter of the axle shaft and a brake disc.

- Place the axle shaft with the installed parts on the machine.

- Install the brake caliper.

- Connect the brake hoses.

- Fill with brake fluid and bleed the brakes.

Important: proper replacement of rear brakes with disc brakes involves altering the design of the parking brake. One of the parking brake options for rear disc brakes includes an additional brake cylinder, which prevents bleeding of the brakes when the handbrake is pulled on.

Therefore, before bleeding such a tuned brake system, it is necessary to remove the handbrake and hold it in a vertical position so that an air lock does not form in the GTZ.

To protect the brake hoses on upgraded rear brakes, you can use a simple design of large diameter rubber hose scraps secured with clamps.

After bleeding the brake system, you need to start adjusting the pressure regulator in the rear brake circuit. In the absence of a special stand, this can be done experimentally, periodically checking the operation of the brakes on an empty road. The wheels should brake evenly; it is unacceptable for the rear wheels to lock before the front ones.

Disk replacement process

All work should be carried out on a flat surface that is free from dust and dirt. The machine must be raised with a jack and secured in this position with metal supports. After the car has been fixed at a certain height, the brake system is dismantled and the piston is pressed out of the working cylinder.

The next stage of repair work in the system is to remove the brake pads. If access to the brake disc is very difficult, the caliper should be dismantled. Usually the disc is connected to the hub with 1-2 bolts, so dismantling it is not difficult. The seating surface must be cleaned of dirt and dust, since the new part may be installed incorrectly or may not fit tightly.

Replacement process using the example of BMW E39 (video):

The brake mechanism is supplied with factory lubricant and therefore does not require additional lubricants. There is no need to wipe the surface of the disk before installation, since a lack of lubrication can affect the tightness of the part to the hub. Installation of brake discs requires extreme care. Over-tightening the bolts can lead to radial runout, as can under-tightening. When installing, it is better to use a wrench with a dynamometer. The normal value is in the range of 100-120 Nm. After installation, it is better to check the vibration level using an indicator. This indicator is individual for each car brand and can be found on the Internet. If the indicators are outside the norm, you should tighten the bolts again.

After installing the brake discs, you need to clean their working surface from grease. If necessary, the caliper can also be replaced. If you are installing an old part, you must make sure that there is no rust or other mechanical damage on the surface of the mating flange. It is better to tighten all fasteners also using a wrench with a dynamometer. It is recommended to replace the brake pads together with the installation of other parts of the system.

REPLACING FRONT PADS FOR A VAZ 2107

If the front of your “seven” has factory brake pads, then you won’t have to worry about replacing them anytime soon. Such elements are maintained for at least 50 thousand km. during normal operation of the car, i.e. without constant sudden braking. If the pads are worn out, you can replace them yourself without visiting a service station. To carry out repair work you will need the following tools:

- Phillips and flathead screwdrivers;

- pliers;

- hammer.

To replace brake pads you will need a standard garage tool kit.

DISASSEMBLY

We remove the pads in the following order:

- Raise the front of the car using a jack, unscrew the wheel mount and remove it.

- Using a screwdriver or pliers, remove the two cotter pins holding the rods of the brake elements.

- Using a Phillips screwdriver, we push out the pad rods. If they are difficult to come out, you can use penetrating lubricant and lightly tap the screwdriver with a hammer.

- We take out the pad clamps.

- Brake elements often come out of their seats without problems. If difficulties arise, pry them through the holes with a screwdriver, resting against the brake cylinder.

- Remove the pads from the caliper.

INSTALLATION

We install new pads in the following order:

- We inspect the anthers of the working hydraulic cylinders. If the rubber element is damaged, replace it with a new one.

- We use a caliper to measure the thickness of the brake disc. For accuracy, we do this in several places. The thickness of the disk must be at least 9 mm. If this is not the case, the part needs to be replaced.

- Open the hood and unscrew the brake fluid reservoir cap.

- Use a rubber bulb to drain some of the brake fluid so that its level is below the maximum mark. We do this so that when the pistons are pressed into the cylinders, liquid does not flow out of the tank.

- Through the metal spacer, we rest the pry bar one by one against the cylinder pistons and press them all the way. If this is not done, then it will not be possible to install new parts due to the small distance between the brake disc and the piston.

- We mount the pads and other parts in the reverse order.

VIDEO: REPLACING FRONT BRAKE PADS ON CLASSIC ZHIGULI

Identifying faulty front brake pads on a VAZ 2107 and replacing them is a simple task and does not require special tools or skills. Any owner of this car will be able to cope with it, for which it will be enough to read the step-by-step instructions and follow them during the repair process.

Replacement process

The machine for repair work is installed on a straight, level surface. Use a jack to lift the required side and remove the wheel. In the opened space we free the disk for dismantling. Press the piston of the working cylinder to remove the caliper. First loosen the mounting bolts on it.

There is no need to disconnect the hydraulic pipes of the brake system; just move the unit to the side and pull it with a wire to any beam or rod. We unclench the brake pads and block them with a clamp.

In some assembly designs, dismantling is hindered by the caliper frame. It is enough to unscrew its fasteners and get rid of the obstacle. In most cases, the mounting bolt sticks and prevents removal from the hub. To weaken it, use WD-40 or brake fluid. Some machines have a pair of these bolts.

Having freed yourself from problematic hardware, you need to remove the stuck brake disc. Here you can also pre-use special fluids for corrosive areas. Then you need to apply one of the proven methods:

- Tapping with a wooden tip on the back side. This should be done with short sharp blows so as not to create problems.

- Using a wooden or rubber mallet, tap the reverse plane. This method is more gentle on the parts than using a heavier metal hammer.

- Apply a reverse hammer. To do this, you will need to buy or borrow this relatively rare but effective instrument.

- You can use a puller. However, you should feel the effort so as not to break the tool or disk, because in some cases stronger pullers can damage a heavily stuck part. Then you can forget about restoring the latter.

After getting rid of the old disk, we clean the surface from contaminants in the form of scale or dust. To do this, we use a metal brush or an attachment for power tools. Later we clean the surface with special liquids. If cleaning is not carried out, the new part may sit on the surface with large runout, which will lead to undesirable consequences.

Using a reverse hammer

We install the restored or new brake disc in the free space. The bolts for fastening it will need to be tightened with a force of 20 Nm, which a torque wrench will help with. The caliper will require increased force, which should be in the range of 100...120 Nm. Do not over-tighten the fasteners to avoid radial runout of the hub. The remaining elements of the unit are assembled in the reverse order of disassembly. Be sure to check the position of the hoses so that they are in their proper places.

The need for timely replacement

Before we begin to describe the actual process of replacing brake discs, let us recall that this is a condition for reliable operation of the brakes. In an extreme situation (and who can guarantee that it will not happen?!) There is a danger of failure of the most important element of the braking system.

The result will not be long in coming - an emergency situation

, fraught with many problems and serious danger to life.