- ➡️ Check while driving

- ➡️ Springs

- ➡️ Manufacturers of OP

An important element of a car suspension is the struts and support bearing (OP). It is installed in the front or rear pillar, or rather in the upper support. The bearing ensures mobility and at the same time rigidity of the connection between the shock absorber and the car body.

Front support

The strut effectively dampens vibrations that occur when the car moves on uneven roads. This allows you to reduce the load on the steering, chassis, suspension, and transmission.

The connection between the shock absorber and the car body must remain movable when the wheel is turned. To do this, it is necessary to install an intermediate rolling element between the shock absorber and the body shell, which is subjected to high loads and fails after a certain period of time.

Rear support

The name “support” indicates the main functional purpose of the part. It is this one, located inside the support, that rests on the car body.

The unit ensures smooth running and appropriate controllability of the machine. In addition, the rear wheels receive greater stability on the road. The design and arrangement of the support bearing allows it to withstand fairly high axial and radial loads.

It is important to know:

There is no OP as a rolling element on the rear shock absorber support, since there is no need to rotate the strut.

A little about the design of the car suspension

Let's talk about the suspension design

— almost all mass-produced cars now use the so-called MacPherson suspension, named after its inventor. An important element of the suspension are shock absorber struts.

MacPherson strut is also called the “swinging candle”

due to its design features. The device contains a spring, a damper and a shock absorber on one axis, which absorbs the energy of vertical vibrations of the car, ensuring a smooth ride.

The upper part of the rack is attached to the body

car using a special rubber bushing - the upper support. These undercarriage components transfer variable vertical load from the wheels to the body during operation.

In the front supports

In addition, a rolling element is required, a strut bearing, which allows the strut to rotate. By design, the support in the front of the car differs from the rear in that a strut bearing is installed there.

Replacing a bearing with a separate element

If the support itself is in order, and the fault concerns only the bearing, it can be replaced separately. To do this, remove the rack with the support (the process is described above) and deal with it separately.

Having disassembled the support (the design is different for everyone, but the principle is approximately the same), we inspect the bearing. As a rule, the balls are worn unevenly, there are burrs on the holder, and the seals are damaged.

It is possible that the problem can be solved with little blood

Although journal bearings can usually be disassembled and individual components can be accessed, there is no point in repairing them.

It is hardly profitable to tinker with the component parts of the support bearing, trying to repair them

Firstly, the bearing itself separately from the support is not that expensive.

Secondly, this is a critical unit, so replacing balls or seals using a makeshift method will not lead to anything good. Therefore, it is a clear replacement.

It is safest to replace the entire bearing

Whether to change bearings in pairs or not - there is no consensus. Typically, paired replacements are made more due to reinsurance. Experienced service station workers determine this need based on the general condition of the car’s suspension. It also happens that it is not practical to change the second bearing - why throw away a well-functioning part?

How to carry out work on an Opel Astra (video)

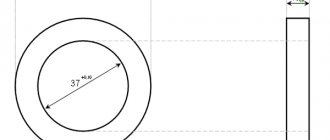

Support bearing

Strut support bearing (OP)

installed inside, between the front shock absorber rod mounting unit and the upper spring cup. As a rule, the design is an angular contact rolling bearing, but there are also sliding pairs made of metal bushings.

The strut support where the rear shock absorber rod rests

- consists of rubber bushings and a metal spacer, but can also be a solid rubber-metal part of the cup.

This “dual role” of the front support – rotation and thrust – and high loads lead to a certain amount of natural wear. After some (quite long) time, the upper support will need to be replaced.

How to replace the front strut support bearing

If the support bearing wears out or is destroyed, it must be completely replaced, since it can no longer be repaired. Replacing support bearings (strut supports) in two main ways:

- dismantling the entire rack along with the levers and other elements attached to it (after replacing the bearing there is no need to do a wheel alignment);

- Using special devices (strut nut remover, spring ties), first the strut is disconnected from the steering cam, and then the rest of the necessary elements (the more common method). In this case, after removal and reinstallation, it may be necessary to perform an alignment.

Signs of a faulty support bearing

“A good knock will make itself known”

- say drivers and auto mechanics. This is just about the support bearing - it lets you know about its malfunction with a characteristic metallic knock that occurs in the area of the front wheels. The knocking noise may intensify when driving on uneven roads, when turning, sharp accelerations, when the car is heavily loaded and at high speed.

Another signal

, which tells us about the wear of the strut bearing - knocking and crunching when the steering wheel is rotated while driving. An experienced driver will notice a change in the behavior of the car on the road, the appearance of a delay in the reaction to the rotation of the steering wheel, and a violation of the car’s stability on the course. The steering wheel may jam.

The mileage of the car can also be considered “signs” of failure.

Most bearing manufacturers estimate the product resource to be approximately 100 thousand km, quite high figures. But on our roads this value can be safely divided in two. So after 50 thousand km you can already expect a bearing failure. Although no one is immune from the fact that this will happen in 10 thousand.

Of course, knocking and crunching can also be caused by malfunction of other suspension elements. Therefore, it is advisable to carry out a full check of the chassis. But first you still need to check the support bearing.

In addition to wear, other problems are possible.

front support unit. Dull knocks when driving on uneven sections of the road may be a sign of wear on the rubber casing, or separation of the rubber from the metal. It can even be pierced through by the shock absorber.

It looks like there are signs of wear on the rear support:

squeaks and knocks (“suspension breakdowns”) in the rear suspension area. Moreover, there are no sounds when the car passes a round obstacle, and there are sounds when the rear wheel falls into a hole. A bumpy car can be caused by increased play in the parts of the support assembly.

Support bearings for replacement. How long can you travel?

Gentlemen! Need advice! Noise appears when the steering wheel is rotated (while standing still or when maneuvering at low speed). The servicemen installed the front support bearings for replacement. They are out of stock, they will be available in 2 weeks. But I am planning several long trips at this time. Isn't this fraught? According to the service technicians, there’s nothing to worry about, you can drive, except for the sound, there are no problems. Is this really true? Car Astra hatchback 2007 47000km

I had a 30,000 factory defect on the left side, they replaced it under warranty. You can eat, but it’s uncomfortable.

I plan to travel about 3000 km in these 2 weeks. I wonder if there will be negative consequences for the suspension due to such a mileage with “noisy” bearings, or is it not worth driving?

According to the specialists from Jenser, there are no problems. I drove about 3 thousand with such a defect while the new part was coming from the warehouse. So everything is ok!

Causes of malfunction of the rear and front supports

- Normal Wear

- When operating your machine, be prepared to experience more wear and tear on the bearings than the manufacturer claims. - Getting sand and dirt inside

- The fact is that the journal bearing is a type of rolling bearing, and it is not structurally designed to provide protection from the mentioned harmful factors. - Harsh driving style

- Driving on bad roads at high speed leads to excessive wear not only on the support bearing, but also on other elements of the car’s suspension. - Low quality of the part

- This is especially true for domestically produced bearings, in particular for VAZ cars.

The main cause of breakdowns

– a large load on the supports and the resulting wear. As already mentioned, driving on broken roads doubles your output. It is also accelerated by the ingress of water, dirt and dust into it. Water and dirt have a particularly negative effect on the condition of the OP, leading to wear of the components of the strut bearing.

You can fight this

washing and generously lubricating the bearing, at any opportunity. Thanks to this, the support bearing will be better protected from dirt. There is no such thing as too much lube!

A possible cause of failure is

and low quality parts, especially those made in China.

Chinese bearings have performed poorly.

“I bought Chinese bearings, they didn’t last long, so from now on I will only buy originals” - this is a typical review from the Internet.

Suspension breakdowns are dangerous for the rear support unit,

when the wheels fall into a hole, the vehicle moves with an overload.

The front support assembly does not like aggressive driving.

What is typical for the front support is that the failure of one part leads to accelerated wear and premature failure of other parts of the assembly.

How to determine that a support bearing is worn out and what the consequences are

The condition of the support bearings plays an important role in the stability of the suspension. Therefore, it is necessary to monitor their condition and eliminate any defects in a timely manner.

They are installed on the front pillars of the car. In addition, they are elements connecting the body and the pillars. As a rule, they are protected by a special cap, which is designed to protect against the accumulation of dirt.

The most important function of this element is to provide a movable connection between the body and the racks. Thanks to it, the front suspension is softer and the car's handling is improved.

And at the same time, a fairly large load always falls on the bearings. One of the main reasons for this is the quality of the roads of our vast homeland, which often leaves much to be desired. Potholes and potholes have a very bad effect not only on the condition of this element. But also on the functioning of all vehicle systems.

The support bearings themselves, although they essentially perform the same function, come in different types: - single-separated bearing; - a bearing whose inner or outer ring is built-in; — a bearing whose outer ring is detachable; - a bearing whose inner ring is detachable.

All of them are made of very durable alloys, which is why, as a rule, the service life of this part is quite impressive. But there are also many fakes on the market. Therefore, you should always try to purchase a bearing from a trusted manufacturer.

You can try to identify the malfunction of this element by ear. But it's quite difficult. The knock is very similar to the one that is heard when there is a problem in other car systems.

With slight bearing wear, you may not even notice any disturbances, such as deterioration in controllability and maneuverability. But when it is already quite shabby, you will understand it immediately, especially while driving on the highway.

Also, one of the consequences of bearing wear can be a violation of the car’s wheel alignment. In this case, if you encounter a hole on your way and fall into it, there is a risk of damaging the part so much that it will simply fall apart. This also very often causes the strut to pierce the body.

In order to diagnose the bearings yourself, you need to do a few simple manipulations. The first step is to turn off the engine and put the car on the handbrake. After which it will be necessary to remove the cap protecting it from the bearing. Then press down on the spare part. Here you will need an assistant who will have to rock the car a little at this time.

If at the same time you hear a knock and the strut starts to “walk”, then the bearing is already quite worn out. To avoid more serious problems, you should visit a car service center and replace the part.

Photos from Internet resources

Methods for checking the rear support assembly

We recommend reading 2 ways to diagnose the rear strut support assembly. It's good if someone helps you.

The first method (on the go), as for checking the front support bearings

- find your way on a road with bumps and obstacles;

- ride on uneven surfaces, changing the speed;

- accelerate, brake, turn on obstacles - load the rear supports.

Bumps and crunching sounds from the rear indicate that it is time to change the rear support.

A bad sign is malfunctions in the rear shock absorbers, “breakdowns” during these impacts.

The second method (on the site), as for checking the front supports

- it is necessary to install the car horizontally;

- put the vehicle on the handbrake;

- secure the wheels with wooden wedges;

- find the rear strut supports in the luggage compartment;

- remove the lining and protection, if necessary. Get to the rear shock absorber rod mounting nut;

- press the nut (upper element of the strut support) with your fingers;

- ask your friend to rock the back of the car. A knocking and crunching sound, the same as you heard when moving, or if the rod moves relative to the support (you can feel this with your hand), the condition of the system is unsatisfactory. The situation can only be corrected by installing a new one.

Re: Support bearings need replacement. How long can you travel?

In general, they just lubricated me and that’s it, they told me to drive calmly, I don’t know

You'll be gone for two weeks, nothing bad will happen. I traveled more. Turn on the music louder so that the knocking doesn't bother you

Thanks to all! I've already driven a thousand. I’ll post the results

Gee! And the dealer told me that I can ride as fast as I want! “What the hell is it knocking - we looked, we didn’t find any reason for replacement” - something like that.

What is the risk of final failure of this bearing?

If absolutely final, then wedge the wheel

Well, I changed it. Total: now 53150 km. They knocked lightly at 43,000. Loudly at 47,000. That is, you can drive up to 10,000 without any special consequences. But it’s better to change it early

I drove about 2500 km with a knock. It seems like nothing bad happened. My right one started knocking at 10 thousand km.

The right support bearing died after 4 months and 10 thousand kilometers. I could still drive, but the sound bothered me.

The support bearing is made so that it cannot jam. Even if it falls apart and grinds to dust, the steering wheel will simply spin like on a basin without power steering and with a hellish grinding noise. But it will spin!

yes. until the bearing jams at a speed of about 100 kilometers per hour! I would change it. bearings are not that expensive to replace until a wedge occurs. Then you’ll have to pour in a lot of money! (if you're alive)

How to extend service life

Even if you do not notice any problems with the suspension while driving, it is recommended to carry out regular (every 20 thousand km) checks of these components. Once a year, the rubber part of the support assembly is coated with silicone grease. Driving carefully and avoiding bad roads will also help protect your suspension components.

To increase the service life of the OP, if possible, technicians rinse it and replace the lubricant. If this part begins to deteriorate, it will need to be replaced; repair of the support bearing is impossible.

How to determine a faulty shock absorber support: basic methods

For repairs, in many cases, it is impossible to do without removing the shock absorber strut. This procedure takes a lot of time, and the camber and toe angles of the front wheels may be disrupted. In order not to make a mistake and not disassemble a completely serviceable unit, it is recommended to make sure in advance that the failure of the suspension consists of failure of the supporting part.

On level ground

This method is the simplest, but this work requires two people. You can find out about the malfunction as follows:

- Park the car on a level surface.

- Securely secure it with the parking brake.

- Open the hood.

- Remove the glass protection.

- Press the support device with your hand.

- The assistant must rock the car.

If play is felt in the support bearing, it will need to be replaced.

While driving

While driving the car, it is also a good idea to test the front or rear strut bearing. To do this, just drive over the speed bump, listening to the noise of the suspension. If a certain creaking or knocking noise is detected, then it is most likely time to change this part.

Attention! Sharp turns of the steering wheel while the car is moving will also allow you to audibly determine the malfunction of this part.

Steering wheel rotation

This test method is similar to the first diagnostic option, with the only difference being that the partner should not rock the car, but vigorously rotate the steering wheel from side to side. If, as a result of such a “research”, a significant gap is also felt in the mating elements, accompanied by metallic clicks, then the part will need to be replaced.

Why you shouldn’t delay repairs

When the OP has completely crumbled, you can continue moving. But driving with a damaged bearing dramatically accelerates the wear of other suspension parts. In addition, usually with this breakdown the geometry is disrupted - alignment and camber. This not only causes accelerated tire wear, but can significantly reduce the car's handling. This increases the risk of an accident. Therefore, it is not recommended to drive for a long time with damaged bearings.

Every car owner needs to know this.

The supports themselves do not require maintenance and last a long time. But it is necessary to change the worn-out part on time. A serviceable car is the key to safety on the road!

Recommendations for installing the wheel bearing

So, you have diagnosed a problem - the wheel bearing.

- First of all, I repeat, you should only buy a new wheel bearing from a trusted company; it is best to read reviews about the selected part. Take this issue seriously, because how long it will serve you depends on this stage. I have already told you how to choose and buy spare parts for a car.

- Most wheel bearings come with non-removable boots, under which there is grease, in which case you will not be able to check its quantity. But if you get an open bearing, be sure to check the amount of lubricant that the manufacturer supplied.

- Before installing the wheel bearing, make sure that the contact surfaces of the hub are not damaged, there are no burrs, dimples, burrs or signs of use. They could have formed during operation or pressing out the old bearing.

- On some cars, the wheel bearing comes together with the ABS ring (like on the Peugeot 307), so be careful when installing; some would-be masters install the bearing with the other side.

- Before pressing the bearing, lubricate the contact surfaces with a soap solution, this will make pressing the bearing easier.

- When installing the retaining ring, be careful not to damage the bearing boot.

- To install a wheel bearing, in most cases you need a special device - a press. Without it, it is extremely difficult to seat the bearing correctly and evenly in the hub. If in your case a press is required when replacing a bearing, then it is better to entrust this work to a trusted car service center.

Pressing in the wheel bearing using a press

Subscribe to our YandexZen

37 918