Applicability

| Brand | Model | Name according to auto catalog | Drawing |

| VAZ | VAZ-2108 | Hairpin | Engine / Engine |

| VAZ | VAZ-2110 | Hairpin | Engine / Engine |

| VAZ | VAZ-2111 | Hairpin | Engine / Engine |

| VAZ | VAZ-2112 | Hairpin | Engine / Engine |

| VAZ | VAZ-2115 | Hairpin | Engine / Engine |

| VAZ | VAZ-2110 | Hairpin | Engine / Engine |

| VAZ | VAZ-1118 "Kalina" | Hairpin | Engine / Engine |

| VAZ | VAZ-2110 | Hairpin | Engine / Engine |

| VAZ | VAZ-2115 | Hairpin | Engine / Engine |

| VAZ | VAZ-2114 | Hairpin | Engine / Engine |

Where else is the spare part used?

The parts data presented on this page is for informational purposes only.

Download price lists

To download price lists, you need to log in. If this is your first time on the site, please fill out the registration form.

Replacing the tension roller stud of a VAZ 2109

characteristics :

- Left thread length: 20mm;

- Thread length from right: 25 mm;

- Material: galvanized steel;

- Thread: M10;

- Thread pitch - 1.25.

Retail store at Uralmash, Baku Commissars St., 113. 8 (343) 221-35-35

02. By courier for orders over 2000 rubles, in Yekaterinburg from 20:00 to 22:00

Delivery only to the entrance. Additional +100 rubles to the apartment.

02.2. By courier for orders less than 2000 rubles, by EKB from 19:00 to 22:00

Delivery to the entrance or to the gate. To the door +100 rubles for the courier.

02.3. By courier outside the EKAD, up to 20 km, from 20 to 22 h

The manager will calculate the cost of delivery and notify you by phone or mail if your phone number is not available.

After sending, we will definitely send the TRACK NUMBER of the parcel.

On the official websites of the largest manufacturers of spare parts: SS20, Tehnoressor, Demfi, SEVI, online store illva.ru - IP Koroleva, recommended as a reliable supplier of original spare parts.

07. TC SDEK - careful and fast delivery

Recommended for light parcels! Inexpensive up to 10 kg and without queues, many delivery points in all large, medium and small cities, select the closest one to you on Yandex maps by entering SDEK in the search. After sending, we send you a tracking number. Fill in your full name in the Name field. Long distance payment upon receipt. Shipping is free.

05. TC "KIT" - a lot of branches

We recommend! delivery to more than 300 cities of Russia and the EAEU (Kazakhstan, Kyrgyzstan, Armenia, Belarus, Crimea). The delivery price can be checked with our manager or on the TK KIT website. After sending, we send you a tracking number. Delivery to TK KIT is FREE!

Low prices. We recommend for northern and eastern directions and Kazakhstan.

Delivery throughout Russia and the countries of Belarus, Kazakhstan, and China.

Fill in your full name and indicate the series and passport number in the comments to the order below. Delivery to TC Energia is FREE!

06. TC "Business Lines"

Prices are high with lots of markups! Attention!! TC DelLinii automatically includes services in the invoice - Insurance and Delivery by courier - but you may not be able to afford these services upon receipt, otherwise delivery with them will be twice as expensive! It is not profitable for her to carry small and inexpensive cargo. After sending the goods, we send you a tracking number. Please fill in your full name when ordering. In the comments to the order below, indicate the series and passport number. Payment for delivery upon receipt - the cost of sending this shopping center is indicated below.

09. TC “PEK” (series and passport number required)

Choose PEC only if there are no other options. The cost of PEC is relatively more expensive, and cargo in PEC is subject to inspection with violation of packaging, after which it is packed somehow, PEC charges various additional fees and, in general, delivery is more expensive. After sending, we send you a tracking number. Fill in your full name and indicate the series and passport number in the comments to the order. Below is the cost of the courier to the PEC branch.

Price list

- Special offers

- KAMAZ spare parts

- Spare parts KAMAZ-5490

- Spare parts MAZ, YaMZ

- ZIL spare parts

- Spare parts ZMZ, for GAZ vehicles

- Spare parts for Volzhanki cars

- Spare parts for Gazelists

- Spare parts for trucks Lawns

- Spare parts for GAZ-71 caterpillar

- Spare parts UAZ, UMZ

- Spare parts KrAZ, BelAZ

- Spare parts URAL

- Spare parts BUSES

- AMAZ spare parts

- IKARUS spare parts

- KAVZ spare parts

- LAZ spare parts

- LIAZ spare parts

- NEFAZ spare parts

- PAZ spare parts

- Other buses

- Tractors, computer equipment, attachments

- Tractors and walk-behind tractors

- Municipal vehicles

- Attachments and trailed equipment

- Spare parts for TRACTORS and SPECIAL EQUIPMENT

- JCB - spare parts for special equipment

- Truck crane (KS-3577, KS-4517, etc.)

- AMZ (A-01, A-41, D-440, D-442, D-447, D-461, D-467)

- Amkodor (TO-18, TO-28, TO-30, etc.)

- ATZ (T-4A, TT-4M)

- VgTZ (DT-75)

- VMTZ (D-120, D-144, D-130, D-145T)

- VTZ (T-25, T30A-80, VTZ-2048)

- LTZ (T-40, LTZ-55, LTZ-60)

- MKSM, UNC, DETVAN

- MTZ - spare parts for tractors

- OTZ (TDT-55)

- PTZ (K-700/701/702/703/704)

- KhTZ (T-150, MT-LB)

- ChTZ (T-130, T-170, B-10, B-12, B-170, T-10M, DET-250)

- YuMZ - spare parts for tractors

- Other special equipment and tractors

- RVD - high pressure hoses and sleeves

- MMZ spare parts and engines

- Spare parts for MMZ engines

- MMZ engines: D-242, D-243, D-245, D-246, D-260

- VAZ spare parts

Replacing the tension roller VAZ 2108, VAZ 2109

Many drivers often do not have time to delve into the design features and subtleties of repairing a particular vehicle component. And if the purpose and maintenance of the main elements (for example, the engine, radiator, bridge, battery and others) is not difficult, then problems may arise with smaller parts. So, in practice, few people know what a timing belt tensioner pulley is needed for, what its malfunction can lead to, and how to change it. The information in this article will fill your knowledge gaps.

Purpose

The tension roller is one of the main elements of the gas distribution mechanism. The quality of tension of the timing belt, which connects the engine crankshaft and the car generator, depends on its serviceability. As a result, the stability of the on-board network voltage and normal battery charge are ensured.

How it works? When the engine is turned off, the generator is immobilized, so the battery takes on the entire load. After starting the engine, the crankshaft (via the timing belt) transmits rotation to the generator rotor. From this moment on, the on-board network switches to a new power source.

The purpose of the roller is to maintain the belt tension at an optimal level. In case of strong constriction or, conversely, weakening of the latter, the following problems are possible:

— the appearance of unnecessary noise when the engine starts (for example, a squeaking or whistling belt); — a decrease in the voltage level, which leads to malfunctions of on-board devices and poor battery charging; — roller jamming. In this case, you definitely won’t go far.

How to determine the malfunction?

When the engine is running, the tension roller is in constant motion, in the mode of friction and load from the timing belt. Consequently, sooner or later it will expire and require replacement. The service life can be found in the factory operating instructions (most often it is about 40-50 thousand kilometers). But, as practice shows, replacement may be needed much earlier.

A breakdown can be diagnosed by the following signs:

— the appearance of defects on the bracket, bearings and other parts; - presence of play; — obvious abrasion of the roller; - grinding or squeaking. To check, remove the timing belt and rotate the roller by hand - it should make a slight rustling sound.

There should be no creaking or squeaking. If everything is quiet, try another experiment. Put the belt back in place and treat the inside of it with WD-40.

If the squeak (whistle) disappears, then the problem was most likely in the belt.

So, a serviceable tension roller should have no defects, signs of wear or play. And most importantly, it should rotate silently even when turned lightly by hand. Go ahead.

Should I change it myself or contact a professional?

Many car enthusiasts underestimate their strength and, at the first sign of a malfunction, go to a service station. The advantages of this method are undeniable - you receive a repaired car within 1-2 hours (without a queue) and do not worry about the repair (replacement) technology. On the other hand, you will have to spend some money on paying for the services of a specialist.

In fact, there is no need for such expenses. Replacing the tension roller with your own hands is a matter of 30-40 minutes. The main thing is to prepare the necessary tools, a workplace and follow the recommendations in the article.

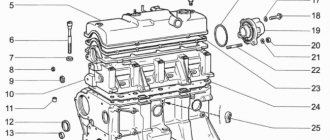

Auto catalog

- VAZ

- UAZ

- GAS

- AZLK

- IZH

- ZAZ

- ZIL

- LuAZ

- RAF

- BYD

- Chevrolet

- Daewoo

- Geely

- Great Wall

- Hyundai

- Lifan

- Tata

timing pulley stud thread

#1 nrgizer79

- Users

- 79 messages

- City: St. Petersburg

- Auto: 21099i

VAZ 21099 engineer 1.5l 8kl Background: During the next trip the engine started knocking. He stopped and began to study. It turned out that the fastening of the tension roller was loose, the belt slipped several teeth. I tried tightening the roller nut. It didn’t work out, the fastening became loose because the thread of the stud in the cylinder head was torn off and the stud was simply pushed out. I screwed the pin in the other way (the thread is longer there), adjusted the belt, tightened it, and drove home. Now I’m actually thinking: 1. Leave the pin with the longer side, but fill it with thread reducer (high-temperature); 2. Cut a 12mm thread and screw in the repair pin. The first option is “scaring” in that the “tenacity” of the thread restorer may not be enough and the stud will tear out again. The second, accordingly, is that the thread will be cut crookedly and the timing belt will move away (it’s very inconvenient to crawl up). Who has had this happen, who solved it and how long it has been working. PS: and ass. could something have gone wrong in the engine, it was knocking loudly, I almost turned gray when I heard it

- Top

#2 Sir YareG

thinks he is telling the “Truth”)) Fail

- City: Railway-City

- Interests: Depeche Mode & Cars!

- Auto: Behind The Wheel.

I have had ! Second option. A repair pin costs 10 rubles. The main thing is to cut the thread properly in the head.

- Top

#3 DIMAN

- City: M.O. Shchelkovo

- Car: VAZ 21061 sprint edition, GAZ 3102

* */ VFTS is not mine, I just charged the five!” (c) S. Brundza Stasis Brundza is so severe that he even goes to the bathhouse with a safety cage © Edgar

- Top

#4 nrgizer79

- City: St. Petersburg

- Auto: 21099i

If it `s not a secret. how they cut it, or rather how they drilled it out. Without drilling, the sword will not fit on M12. It seems like you can unscrew the front engine mount and jack it up, then use a drill to get to it. but this is in question. Well, or remove the entire head, which is of course worse!

- Top

#5 sim

- Car: VAZ 21099

I have the same problem! The thread in the engine is broken! The repair pin does not fit (( You need to drill and tap. Different services say different things. Some say that you need to remove the engine anyway, and someone says that you can drill and tap anyway. I wonder who how did you do it?

- Top

#6 lucky star

- City: SEAD

- Interests: Tuning vases of any complexity

- Car: VAZ 2108T

- Top

#7 Seryoga (kira)

- City: Moscow Maryino

- Car: VAZ 21093

- Top

#8 sim

- Car: VAZ 21099

- Top

#9 2bad4u

- Moscow city

- Interests: Striving for excellence

- Auto: none.

Men's Motors is a highly specialized professional service for the repair and maintenance of automobile engines.

- Top

#10 lexleb2008

- Auto: 21043

Timing roller pin of VAZ 2109 torn off

September 17, 2012 / Author admin / Category Timing belt repair / Comment

When replacing the timing belt, I encountered one problem: when the belt was already installed, it was necessary to fix the roller in the tensioned position of the belt. The nut that tightens the roller was not tightened and the stud began to rotate in the body of the block head. I had to remove the roller again, and after unscrewing the pin, it was discovered that the thread into which the pin was screwed was pulled out along with it. The force with which the fastening nut is tightened must be sufficient so that the roller cannot unscrew; repeated replacement of the belt, possibly mechanical stress, such as belt breakage due to failure of the pump or tension roller bearing, weaken the threaded connection.

The first thing that came to mind was the need to increase the diameter of the internal thread and install a stud with an enlarged thread. The old pin has a diameter of 10 mm, naturally we increase the thread to 12 mm. To do this, we use a tap with a diameter of 12 mm, pitch 1.7. For the first time we go through the thread with tap No. 1

and then with tap No. 2. Our carving is ready. Now a pin is needed. It should be 10 mm in diameter, since a tension roller cannot be installed on a 12 mm diameter, and the diameter of the thread that is screwed into the block head should be 12 mm. Any turner can easily make such a pin, but the first thing I did was go to an auto parts store, and they had such a pin on sale.

Similar articles

34 comments on “Repair pin. The repair pin of the tension roller has come out”

Maybe it's time for a pump.

It's not like there's no way out. To change the block because of one stud. Find a good craftsman or turner, I think.

Beer can washers for the roller. Look on YouTube about the shrinking belt, there is a lot of information

Friend. This will continue to cause problems. I would advise changing the head. Well, let's face these homemade products, the belt will break and the valves will bend

Stas, 8klop doesn’t bend the valve

Alexey, they say 1.5 is not oppressive, but 1.6 is oppressive. Idk

The valve does not bend either 1.5 or 1.6

Try to put the video from 1.5 16 cl

Alternatively, maybe take a ride

If washers do not help, then argon will help. And cut it again on the machine!

Stas, 1.6 has been running since 2012 on motors with new pistons

Gennady, ha I have a 2008

Yesterday, the washer under the roller was slightly ground off on one edge, now the belt will move in the other direction...

Make half-washers and give them a hand, I’ve been riding with them for three years now, everything is fire

I also had a belt slide down to the engine, put a 0.5mm washer, and it was in the center

Ivan, look on YouTube there are videos on how to make a channel Alexander Skripichenko master

They will press together and won’t go anywhere, the main thing is not to do it exactly in half, but to make it a little more than half. I have everything so far thank God))) good luck

Don't drive, come on! There is a thick ground washer between the roller and the wall of the block. The pin only presses the washer against the wall and the roller aligns parallel to it. And the belt is eating because the pulleys are worn out. Change the entire set of pulleys, roller and pump with belt. Everything will be fucked up!

Free forecast! Write!

The hairpin can be made of mild steel and bends. If the thread is cut crookedly, the pin can be bent, but this is definitely not easy to do

Andrey, This whole fucking thing started after I got a pin unscrewed while driving, well, I immediately replaced the timing belt, before that there was nothing like this even close... the pin was screwed in a little crookedly, it’s barely noticeable, the thick washer that was between the roller and the head was ground off a little Now the belt goes out.

Buy a new washer and tighten it

The hammer will help you, on the original stiletto it also led away, knocked a little and everything was fine..... the main thing is without fanaticism

Stas, he only bends 1.6 Grant engines, his timing belt is in a separate case, but the simple ones that went to 10-14 will never bend anything

Alexander, at least this makes me happy

Ivan, and in Tyr-Tyr-Net they advise putting cans under the roller, and for some it helps, but only for some and by chance, and not for everyone at once, but after two or three belts. Agree that it is cheaper to buy everything once than to change a new belt every week. Moreover, gears cost pennies. Just got a pump, and even then it’s worth 50 thousand, not that much money.

Belt care instructions

Above we listed the main reasons for timing belt wear, now we’ll add a few words about how to extend its service life.

- periodically (at least once a month) check the degree of belt tension and, if necessary, adjust it;

- before installing a new belt, treat all gear teeth with white spirit;

- avoid contact of gasoline and technical oils with the surface of the belt;

- replace the belt at least every 60,000 km (teared teeth and drops of oil on the belt significantly reduce this figure);

- periodically check the condition of the tension roller (if a whistle appears after replacing the belt, this means that the roller is already worn out and a new one should be purchased and installed).