The clutch on the VAZ 2110 is a critical component in the transmission structure. Simply put, it is the clutch that is responsible for creating the smoothest possible transition of torque from the crankshaft to the gearbox, and also provides the ability to “softly” shift gears.

If any problems arise in the operation of this unit, immediate repair of its components or replacement of the clutch as a whole is necessary. Next, we will look at in what cases replacement is necessary, how to replace the VAZ 2110 clutch yourself, which kit is better to choose, etc.

Choosing a clutch - articles and brands

VIS clutch kit for VAZ 2110-12: basket, disc, release bearing.

The driven disk must have part number 2110-1601130. This kit is produced by the VAZInterService (VIS) plant, the external distinctive features are a diaphragm with 12 blades, one-piece smooth friction linings of the driven disk, the disk itself has 6 damper springs. The quality of the original kit is so-so. The high level of imbalance of the driven disk exceeds the permissible limit by almost twice. In addition, the VIS kit is quite heavy compared to its competitors.

This was also reflected in the preferences of the public - only 6-8% of users buy this kit for 2.8 - 3 thousand rubles.

Analogs

This is the most common choice of tens!

In addition to the Togliatti VIS plant, on the shelves you can find a lot of clutch kits from a variety of manufacturers, both domestic and foreign. Among the latter, a huge share is Chinese counterfeit. In principle, the list of the most popular manufacturers looks something like this:

- German clutch LuK (Lamellen und Kupplungsbau), driven disc 320 030810, basket 2 D24 120 0252 10.

- Their fellow countrymen, Sachs.

- Also the Germans FINWHALE and QML.

- Turkish companies Starco, Mapa, Kraft (article 2110 W3200C B2240).

- VALEO, France, article number 21102 - 21103 - 21108 - 2111 - 2112 826622.

- HOLA, Holland.

- MecArm and PILENGA from Italy.

- South Korean company FORTECH.

Domestic factories from Naberezhnye Chelny and Tyumen, as well as the local Nachalo brand, are also quite widely represented, but the quality of their clutches is difficult to compare with German, say, kits. And now a few words about how to choose a high-quality clutch on a VAZ-2110 without resorting to laboratory tests.

Signs of malfunction and diagnostics of the release bearing of the VAZ 2114 (how the bearing makes noise and hums)

Direct diagnosis is to check the functionality and presence of the following signs of failure. Signs of a malfunction of the VAZ 2114 clutch release bearing, if detected, will require its replacement:

- When you press the clutch pedal, you hear a noise, hum or knocking (rolling, internal vibrations occur due to damage to the tracks with rolling elements, deformation of the cage or the clutch itself).

- A whistle when the clutch is engaged makes it clear that the quantity or quality of lubricant is not enough;

- The speed does not change or the pedal moves hard (occurs when the clutch has fallen apart, as well as if the ear of the release bearing is broken).

- Watch a video example of how the release bearing of a VAZ 2114 makes noise and hums, as well as how the check is carried out. You can also hear the noise of the bearing after disassembling the transmission after removing the VP.

Clutch selection

The manufacturer installed carburetor (2103 with a volume of 1.5 l) and injection (2106 with a volume of 1.6 l) engines on different VAZ 2107 models. Despite the external similarity, the clutch of these models has certain differences. The diameter of the basket pressure plate in both cases is 200 mm. But for the basket for 2103 the width of the pressure plate is 29 mm, and for 2106 it is 35 mm. Accordingly, the diameter of the driven disk for 2103 is 140 mm, and for 2106 - 130 mm.

Some car owners install a VAZ 2121 clutch on their VAZ 2107, which is noticeably stiffer and more reliable than the original one.

Clutches for the VAZ 2107 are produced by both domestic and foreign manufacturers

All VAZ models with rear wheel drive are suitable for clutch kits from classic cars of famous brands.

Table: clutch manufacturers for VAZ 2107

| A country | Manufacturer's brand | Advantages and disadvantages of clutch | Weight, kg | Price, rub |

| Germany | SACHS | Reinforced, so a little tough. Reviews are excellent | 4,982 | 2600 |

| France | VALEO | Great reviews, very popular | 4,322 | 2710 |

| Russia, Tolyatti | VAZInterService | Installed on the assembly line, good reviews | 4,200 | 1940 |

| Germany | LUK | There are dampers on the pressure and driven disks. Reviews are good | 5,503 | 2180 |

| Netherlands | HOLA | Noisy, short-lived, many negative reviews | 4,810 | 2060 |

| Germany | KRAFT | Soft, reliable. Reviews are good (many fakes) | 4, 684 | 1740 |

| Russia | TRIAL | Excessively hard. Reviews 50/50 | 4,790 | 1670 |

| Belarus | FENOX | Difficult, bad reviews | 6, 376 | 1910 |

| Türkiye | MAPA | Medium hardness, reviews 60/40 | 5,370 | 1640 |

| China | AUTOTECHNIK | Difficult, reviews are not very good | 7,196 | 2060 |

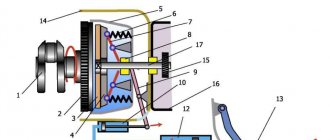

Operating principle and components

The clutch is single-plate, with a central pressure spring. Drive – cable. The housing is attached to the flywheel and pressure plate. There is also a driven disk.

For dozens, the “native” clutch system is VIS, and although many reviews criticize it, there are also many who believe that there is no better VIS (VAZINTERSERVICE) for VAZ.

The main components are:

- casing;

- Pressure and driven disks;

- Carter with bottom cover. It also has support planes with which the crankcase is attached to the frame;

- Release bearing for disengaging the clutch;

- Flywheel;

- Power plug;

- The cable lead that goes directly to the clutch pedal (far left).

This, in brief, is the clutch device of the VAZ 2110.

What you need to know

The release bearing is not the weakest link in the clutch system, but for some reason it is the one that causes problems and troubles.

coupling

Some car owners have gotten used to the whistle and simply ignore it. But this cannot continue for long, since untimely solution to the problem can lead to even more complex and expensive repairs. If the situation gets worse, then a simple replacement will not be enough for you.

The clutch serves to act on the leaf spring of the clutch basket. It is also called diaphragm, so don't be confused if you hear this designation. Due to this impact, the driven disk is disconnected from the flywheel and the pressure plate of the basket. This disengages the clutch.

If the squeezer is faulty, this can lead to various consequences:

- The clutch fork will be damaged;

- The integrity of the clutch spring petals will be compromised;

- The guide bushings are deformed.

In order not to pay twice, or even three times, promptly react to the appearance of a whistle in the clutch and try to quickly take action.

Clutch VAZ-2110

Clutch VAZ-2110.

Despite the fact that the ten clutch is primitive, like a cart wheel, it must meet many parameters in order to flawlessly perform its functions - high-quality transmission and complete interruption of the transmission of torque from the engine to the gearbox.

In addition (and few people know this), two types of clutches have been developed for the VAZ-2110:

- for cars with a carburetor or injection engine and a torque of 116 Nm (2110 and 2111);

- for 1.6-liter engines with a torque of 128.3 Nm (VAZ 2112).

You can distinguish a VAZ-2112 clutch by the hole in the slot of the petals and the damper springs.

Parameters and requirements

In addition, you should not discount the weight of the basket assembly, the weight of the driven disk and such an important factor (which our left foot will immediately feel) as the squeezing force.

And another standard is moving the pressure plate. This parameter should be 7.9-8.1 mm. The thickness of the driven disk is also important, not only in the free state, but also under load. The manufacturer must measure it under a load of 3.4 thousand N. As you can see, not everything is so simple with such a simple kit. Now let's listen to the reviews and reports of the expert laboratory.

Replacement

The procedure is not so simple, therefore, if you lack experience, it is not recommended to do it yourself. If you have enough skills and abilities, get to work.

- Disconnect the clamps and remove the release bearing along with the clutch.

- Remove the input shaft from the bearing.

- After fully releasing the clamps, remove the damaged bearing from the coupling.

- Install a new part, but first make sure of its quality. If the bearing moves freely, there is no need to worry, it works well.

- Lubricate the clutch and the release tool itself. This device loves high-quality lubrication. Then install it on a release sleeve that has been pre-treated with machine oil.

- Using special clamps, place the new element in its rightful place.

- The final stage will be reassembling and installing the gearbox in its original position.

The work can be considered completed. It is quite possible to do it yourself, but just do not forget about the accuracy and consistency of your actions.

A high-quality squeezer lasts a long time, so you won’t have to perform such operations regularly. Of course, provided that you have correctly replaced the old bearing and your clutch is functioning efficiently.

https://youtube.com/watch?v=d1bb0mbPPsA

Loading …

Dismantling

Most often you need to remove the gearbox, especially if you need a replacement rather than just an adjustment. It is not necessary to drain the oil from the box.

You also need:

- Disconnect the battery;

- Remove the air filter;

- Disconnect the wiring harness;

- Raise the car, then loosen the clutch drive nut (on the right) and unscrew it completely on the left;

- Remove the suspension arm, ball joint;

- Remove the lower engine protection;

- Disconnect the transmission linkage;

- Remove the clutch housing and inspect it carefully. The main defects that the crankcase may have are cracks, wear of the threads or paws with which it is attached. New threads can be cut, cracks can be welded, thus returning the crankcase to working condition;

- After jacking up the engine, remove the gearbox, gaining full access to the clutch elements.

It is also possible to replace the clutch without completely removing the gearbox:

After repairs, you may notice that the clutch is too tight. But this is easy to fix without disassembling the entire system - from the interior side, by adjusting the pedal travel.

Bearing removal

To remove this device, you will have to perform a series of sequential actions.

- Raise the car or drive it into a hole to gain access to the underbody of the car.

- Use appropriate tools to remove the gearbox.

- Squeeze the special clamps from the release bearing.

- Remove the element from the gearbox shaft.

- Press the locking tabs to remove the spring holder.

- After this, it will not be difficult for you to remove the damaged release bearing from the clutch.

The complexity of the process lies in the fact that in preparation for removing the release bearing it will be necessary to dismantle several components and mechanisms, such as:

- Accumulator battery;

- Clutch cable;

- Air filter box together with air flow sensor;

- Upper gearbox fixing bolts;

- The nut responsible for fixing the starter.

Basic clutch elements

Now let's look at what main elements are included in the design:

- VAZ-2112 clutch drive disc (usually called the “basket”). It is installed on the flywheel and secured with bolts.

- Driven disk. It stands inside the “basket” and is connected to the gearbox input shaft using a splined connection.

- The release bearing is an element that allows you to act on the petals of the basket. With its help, the slave disk is disconnected from the master disk.

- Clutch cable - allows you to transmit force from the pedal to the release bearing.

- The clutch pedal, which the driver operates with the force of his foot.

These are all the basic elements that are present in the design of a car clutch. It is worth noting that the “two-piece” uses a cable drive system, which is much cheaper than a hydraulic one. But it is much worse in terms of convenience - the pedal is tight, this is especially noticeable on older cars. And if you want the clutch on your car to be as soft as possible, change the cable in a timely manner, do not wait until it breaks.

Is noise a sign that replacement is needed?

In some cases, the noise occurs when the engine is started, and it persists until the car warms up, after which it disappears. In other cases, the noise returns every time you try to disengage the clutch.

The worst option is a grinding sound. This sound indicates that the element is rubbing against the leaf spring, and wear will form on the petals. If you are “lucky enough” to encounter such a situation, there is no time. Replacement needs to be done quickly.

By the way, there is no point in repairing it. Release bearings cannot be repaired, so the only solution is replacement.

Clutch on VAZ-2112

This is what the VAZ-2112 clutch diagram looks like in disassembly.

The clutch on any car, including the VAZ-2112, plays a very important role. So, without his participation it would simply be impossible to transmit torque from the engine to the gearbox.

Due to the fact that this element bears a large load, it can absolutely be called a consumable material, because its main elements require immediate replacement if they are severely worn.

Video about replacing the clutch on a VAZ 2110-2112 family

It is impossible to influence the condition of the clutch in any way, and it is also impossible to control its condition visually, so its malfunctions will only appear when one of the elements begins to fail.

Tool for replacement work

To make the work easier, you need to prepare all the tools in advance.

- Inspection hole or lift.

- Jack.

- Wheel chocks.

- Set of socket wrenches.

- Mount or extension tube.

Step-by-step work order

Replacing the clutch without removing the gearbox

Before proceeding directly to replacing the clutch, you need to remove the gearbox. How to do this quickly and efficiently is written in this article.

When the clutch is dismantled, we continue work:

- Using a spanner, unscrew the bolts securing the clutch housing.

Clutch basket assembly

We remove the dismantled bolts to the side.

Video “Replacing the release bearing”

This video shows the bearing replacement process. An experienced auto mechanic talks in detail not only about how to change this unit, but also describes the principle of its operation.

VAZ 2112 clutch disc replacement, basket, driven disc and release bearing VAZ

Replacing the clutch disc of a VAZ 2112 seems to many to be a very complicated process, and therefore they are afraid to do it themselves; they prefer to pay “professionals” to the service station (to tell the truth, not every professional there is). This article will prove the opposite to you and will help you learn step by step how to replace the clutch disc on a VAZ 2112 yourself. What actions to perform in what sequence and what should be taken into account.

Symptoms of a node malfunction

Before replacing the clutch on a VAZ-2112, you need to figure out whether it needs to be done at all.

Among the signs of malfunctions are the following:

- When you press the gas pedal, you can hear the engine picking up speed, but the car does not go faster. This indicates that the clutch is slipping, there is practically no connection between the driven and driving discs.

- Extraneous sounds are heard when the car moves - this may indicate the destruction of some system components. As a rule, at the same time as these sounds, the system also fails.

- A hum is heard when you lightly press the pedal - a clear sign of a faulty release bearing.

- The pedal falls through - most likely the VAZ-2112 clutch cable has broken. This is the most harmless thing that can happen.

- If the cable is intact, but the pedal falls and the clutch does not release, then the release bearing has collapsed. Unfortunately, this also happens sometimes.

Knowing all the signs of breakdowns, you can begin repairs. Replacing the clutch on a VAZ-2112 with your own hands is not difficult. You just need to know the order of the work.

When adjustment is needed

You need to send the car to the garage and start adjusting the clutch system of your VAZ 2110 as soon as you notice signs of deviation from the normal operation of the unit.

The clutch greatly affects the performance of the entire car. What can we say, without it you will not be able to engage a single gear. Therefore, you will not be able to go anywhere.

The pedal may be too tight or fall apart at the slightest pressure. Both situations indicate that the clutch needs to be adjusted.

In general, the work is carried out in two stages:

- Clutch travel is checked;

- The setup itself is carried out directly.

But the first thing you should start with is studying the most important tool for repairing all components, assemblies and mechanisms of the VAZ 2110. Of course, we are talking about the instruction manual. Open it at the clutch section, study the main nuances, understand the essence of the unit, its design, operating principle, and then become familiar with the adjustment process.

Now we will talk about two main setup steps.

Clutch installation and assembly

Replacing the clutch on a VAZ-2112 is carried out according to the following algorithm:

- Unscrew all the bolts that secure the basket to the flywheel. If you plan to install it again, then you need to unscrew the bolts evenly, crosswise. The main thing is not to damage the basket.

- Remove the basket and disk, install new elements in their place.

- Tighten all the bolts (be sure to use new ones, since the old ones are threaded) and install the guide sleeve.

- Tighten the bolts evenly, crosswise.

- Remove the old release bearing and install a new one.

- Reassemble everything in reverse order.

This is a short tutorial, but the hardest part is lifting and lowering the box, as it is quite heavy.

Installing a new element

When you have completed the entire range of dismantling work, you can move on to the final stage - installing a new component.

- The first thing to do is check the condition of the new clutch release bearing. For some reason, many car owners forget to make sure that the bearing that replaced the old one is actually in good working order. This is easy to check. Rotate the bearing, pull it in different directions. If there is no jamming during rotation, and there is also no play, then you bought a really serviceable, good release bearing.

- Insert the new part into the coupling. This must be done so that the protruding part of the inner ring is directed towards the coupling.

- After inserting the element, secure it using the holders.

- Before inserting the new release bearing onto the bushing (guide), do not forget to lubricate it with a grease. The layer of lubricant should be thin, do not overdo it.

- Secure the coupling and bearing using a spring lock.

- Place the gearbox and other dismantled elements in their rightful places.

- The entire repair process is completed by adjusting the clutch.

Do not ignore the most useful thing that you can need when repairing your favorite VAZ 2110 - the instruction manual. Literally everything a car owner needs to know is described in detail there. With its help, you can even perform complex repairs, the cost of which at a specialized service station would be prohibitive.

Source

Troubleshooting and Correction

Let's talk about how to detect malfunctions based on special signs, as well as correct them.

1. If the clutch is leading, the following may be to blame:

- Insufficient pedal travel, possibly too tight. Adjusting the drive will help;

- Deformations in the driven disk. If straightening is not possible, then the disk must be replaced;

- The driven disk hub periodically jams. You can try washing and then lubricating the splines on the input shaft. If they or the shaft are worn out, replacement is needed;

- Rivets are loose or friction linings are broken. In this case, it is best to change the casing along with the spring and disk;

- The pressure plate is warped or warped. Replacing the linings will help, but before that, check for any deviations in the end runout of this disk;

- Something is wrong with the cable. The cable needs to be tightened or replaced, depending on wear.

2. It slips, that is, it does not turn on. Possible reasons:

- The friction linings of the driven disc are burnt or worn. “Cure” by replacement;

- The surfaces of the flywheel and both disks are oily. These signs also indirectly indicate that it is time to change the engine and gearbox seals. You also need to check if there is any oil leakage through the bolts securing the flywheel. In this case, it is better to place them on sealant. And rinse the oily parts (white spirit is usually used);

- The drive jams. Check and replace what is damaged.

3. It works, but in jerks. This clutch operation can be caused by:

- Oil getting on surfaces, as mentioned above;

- Jamming in the drive. Trace the “chain”, troubleshoot;

- Deformations or damage in the pressure disk, requiring replacement of the casing along with the disk.

4. It makes a lot of noise when it turns on. Most likely, these are signs that the springs in the damper have broken. Replace the entire driven disk assembly.

5. It makes a lot of noise when it turns off. The first suspect is the release bearing. It can wear out, become damaged, and lose oil. Therefore, naturally, it is better to replace such a bearing.

6. During prolonged operation, the clutch may suddenly disengage. The reason most often is that the release bearing is stuck. It is located on the gearbox guide sleeve. A worn bearing must be replaced with a new one.

There are also other problems. For example, the clutch is very tight, or it disappears when overtaking. With such a problem, you can still slowly drive to the garage, but if the clutch is completely lost, you can’t go, you need to call a tow truck.

Let's look at how to properly dismantle it, repair it, and then reassemble it.

Replacing the clutch cable

Purchasing spare parts will cost quite a round sum, and for work at a service station they will charge the same amount. Therefore, it is better to deal with this problem yourself, saving your money.

Changing the cable is not that difficult. The only difficulty is pulling it from under the hood into the cabin. The hole is small, not very convenient, but everything can be solved and is quite doable. It only takes 5 minutes to secure the cable to the fork and pedal. The whole process will take about half an hour.

Replacing a release bearing is quite labor-intensive work, and in order to avoid having to deal with this again, experts strongly recommend replacing all parts of the clutch with new ones. After carefully reading this material, you can replace worn parts yourself.

Source

Replacing the clutch of a VAZ 2110

You should think about replacement in the following cases:

- After pressing the clutch pedal, a noticeable vibration appeared.

- The clutch “leads” - engine power drops for no reason.

- Incomplete launch. Motorists call this malfunction “clutch slipping.”

- Extraneous sounds in the form of jerks and clicks when starting.

- Unauthorized disengagement of the clutch.

If you find one of these defects, then you need to carry out repairs. If replacing parts (for example, a fork) can be done with your own hands, then finding the faulty part is quite difficult. The best solution would be a trip to a car service center for diagnostics. The service is inexpensive - about 300 rubles. But after checking, you will know what parts you need to buy. Replacement and repair are carried out using an inspection hole or a lift, and the second option is more practical. So, we have new parts, an inspection hole with a jack or a lift, an amplifier pipe (can be replaced with a regular mount) and a set of open-end and socket wrenches. We can begin.

The replacement takes place as follows:

We need to lift the front part of the VAZ 2110 and securely fix it on stands. When working with a pit, you need to install special stops for the rear pair of wheels. Removing the air filter to gain access to the gearbox. Next, we pull out the negative terminal from the battery - this is done to protect against short circuits and burning out all the car’s wiring. Next to the battery we find the air filter housing. We dismantle it so that there is access to the gearbox mountings to the engine.

Attention: the fastening bolts must be loosened, not completely twisted. Remove the wheel caps from the front wheels and then unscrew the nuts. The nuts on one wheel need to be removed, and on the other they only need to be loosened, since the wheels are removed sequentially. After making sure that the stands support the car, remove the front wheel - it is recommended to start with the left one

Removing the front wheels to access the vehicle's clutch. Next you need to remove the anti-roll bar protection. On older VAZ 2110 models it may not be available. Now unscrew the bolt that secures the stabilizer. The next step will be to shift the checkpoint. Now the fastening bolts under the hood can be unscrewed. It is also necessary to ensure free movement for the gearbox: remove the left mudguard, move the left strut behind the wheel drive, and release the left support from the fastenings. Now we need to remove two connectors from the gearbox. Next, pay attention to the plate, which is located to the right of the gearbox. It is a mount for jet thrust. Before dismantling, you need to mark the location for attaching the lever. This will make reassembly easier. All that remains is to unscrew the fastenings to the engine - 3 bolts and 1 nut. Removing the pillow. After this step you will have access to the clutch. The next step is to dismantle the rear cushion, which connects the engine and gearbox. Before removing the gearbox, you need to jack up the engine or use supports. Now the box can be moved to a distance for full access to the clutch. We unscrew the basket and remove the release bearing. Next, we change the necessary parts. Experts recommend performing a complete repair, that is, replacing the release bearing along with the clutch. Replacement of clutch basket parts.

Many motorists ask the question: “How much does it cost to change the clutch at a car service?” The answer is about 2 thousand rubles, while a set of a high-quality unit will cost you about the same amount.

Let's move on to withdrawal

To remove clutch discs from a VAZ 2112, perform the following steps:

- We install our car on the inspection pit (or whatever you have instead - an overpass, a lift)

- We remove the gearbox from the car, first disconnect the wires from the battery

- Without this we cannot get to the clutch, let me briefly remind you of the procedure:

- Draining the oil from the gearbox

- Removing the starter

- Disconnect the block with wires from the speed sensor by squeezing the spring clips to do this.

- We unscrew the bolt that secures the bracket holding the ignition module, then the bolts (there are two of them) securing the top of the gearbox to the engine

- Disconnect the wiring block located at the bottom of the car from the reverse sensor

- We unscrew the bolt of the clamp securing the shift rod bracket and pull it off the hinge, sliding it back

- Removing the wheel drives

- Instead of one of them, be sure to insert a plug so that the differential does not fall apart

- The plug should be tied so that it does not accidentally fall out during the process of removing the gearbox.

- It will be enough to pull the right drive out of the box and move it to the side, fasten it to the body with wire so that it does not interfere

- Then unscrew the bottom nut securing the box to the motor (it is located on the motor side)

- You should be careful, because on car models with a gasoline injection system, a bracket supporting the intake pipe is attached under this nut; it must be removed

- You can loosen the top nut of this bracket if you can’t just remove it

- After unscrewing the three bolts, remove the lower cover of the clutch housing

- Then we unscrew the lower left bolt, which also secures the gearbox to the engine, and hang the engine using a board or hoist

- Unscrew the nut of the left engine mount from below

- Then two nuts that secure the rear cushion to the engine

- Unscrew the bolts securing the rear engine mount to the gearbox

- We insert a screwdriver into the gap between the clutch housing and the engine block, and slide the box away from the guide bushings

- It is necessary to hold it

- We move the box as far back as possible so that the rear cover passes over the brace coming from the front suspension (its input shaft comes out of the clutch)

- When the input shaft is not released from the clutch, push the engine to the side

- We lower the front end of the gearbox and pull it out from under the car (you need an assistant here), photo below

Choosing which clutch is better to install on a VAZ 2110 car and why?

Any mechanic will tell you that with a properly tuned manual transmission, the components wear out almost evenly; this, so to speak, is an addition to the above. Most car repair shops that provide at least some kind of warranty refuse to replace the clutch piece by piece for fear of returns. Among the variety of kits, the editors of “Behind the Wheel” chose five manufacturers:

What indicators were compared?

To make it easier for our motorists to decide which clutch is best to install on their VAZ 2110, the publication’s specialists compared the following parameters:

Compliance of the mass of the part with the requirements of technical documentation - the weight indicator of the unit has a significant impact on torsional vibrations, as well as inertial transmission loads. All presented samples meet the standards, with the heaviest being Pilenga, and the lightest being KraftTech. We can conclude that if the kits are interchangeable, there will be no significant changes.

- Clutch safety factor - characterizes the ability of the internal combustion engine to transmit torque, taking into account the wear of the linings. Pilenga and KraftTech formally comply with modern VAZ standards (2.1), but for cars of the tenth series any set from the five presented is suitable. Only the first two models are suitable for Lada 2112 engines.

- Pressure plate imbalance level - acceptable values are in the range of 0.10-0.25 Ncm. Tests showed a complete discrepancy between these numbers of the VIS set. Valeo has a deviation of 20-25 percent, the rest fully meets the requirements.

- The level of imbalance of the driven disk - the indicator for all models turned out to be within the normal range, only in the Pilenga it is on the verge of what is permitted. The same kit did not meet the standards for squeezing force.

- The distance from the edge of the petals to the friction plane is an indicator characterizing the entire assembly. Exceeding the norm significantly reduces the service life of the car part. Here again, Pilenga’s indicators are unimportant.

It's time to choose

This time, the specialists of the Za Rulem editorial board were unable to find an ideal answer to the question of which clutch is best to install on the VAZ 2110 sedan. Perhaps the best performance in the top five was demonstrated by KraftTech and Luk, although the latter kit has insufficient torque. Valeo occupied the rightful middle - the balancing failed a little. The final list, where quality indicators are arranged in descending order, looks like this:

- KraftTech – there is no marking on the factory release bearing, but the thrust bearing is designated as X2200C; driven disk – Y 3200A B0206. Main features: four damper springs, there are 18 petals on the diaphragm spring. The box bears the designation: 2110 W3200C B2240.

- Luk – the kit does not include a release bearing, its marking is: SKF 500 063820; the pressure plate is branded 2 D24 120 0252 10, and the driven disk is branded 320 030810. The latter has marks for precise orientation during installation. The driven disk has six springs, the basket has 18 petals. The side is last marked.

- Valeo - marking is applied only to the bearing: Valeo SNR BB 126 18S50. The kit includes a mandrel for precise installation. The spring element of the pressure plate consists of 18 petals. There is a mark on the package - 21102-21103-21108-2111-2112 826622.

- VIS - there are no marked parts, the only special sign is the approval mark - AYA70. The pressure plate spring has 12 lobes, the driven disk has 4 large and 3 small damper springs. On the box: 2110-1601180.

- Pilenga - there are no markings or designations on the parts, but on the packaging it is noted: CK-P-4005 2110. The driven disk is equipped with 4 small and 4 large damper springs. The pressure plate spring includes 18 lobes.

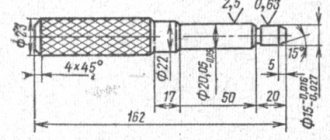

Briefly about the torque transmission mechanism on the “ten”

Volumes have already been written about the technical side of domestic cars, so here we will consider only the very “tops” of the friction unit design. The classic “ten” is equipped with a single-disc dry clutch with a diaphragm-type pressure spring. The main parameters are as follows:

- Disc size 200x140 mm.

- Backlash-free cable drive.

- The casing is connected to the flywheel with six bolts.

When should the clutch or its components be replaced? It depends on the driving style and the quality of the assembly. Some can drive more than 100 thousand kilometers without repair, while others install a new part every 15-20 thousand. If the pedal travel increases, as well as ring wear on the pressure spring petals is more than 0.8 mm, it is worth thinking about replacing the clutch.

The presence of scoring, cracking and uneven wear on the driven disk is unacceptable. A distance of less than 0.2 mm from the top edge of the trim to the rivets also indicates the need to install a new element.

Anyone interested in the question of which clutch is best to install on a VAZ 2110 car should take one point into account. On the “ten” you can install a clutch from the Lada 2112; the disc there is the same size, but due to the reinforced pressure spring it is capable of transmitting higher torque values. In this case, when pressing the pedal, you will have to apply more force, and, quite possibly, change the clutch drive cable more often.

In conclusion of this brief review, we cannot fail to mention the advisability of a comprehensive clutch replacement. No, if you have a lot of time and a wealth of practical experience that allows you to disassemble and reassemble the unit several times a week, then please - today you can change the release bearing, and in a week - the driven one. The fact is that it is not known how long the remaining structural elements last after replacing one of them. Therefore, change the kit right away - it’s cheaper and more reliable.

What is clutch?

Before you go to a car service center in Moscow or another city, try to figure out how to properly replace the clutch on a two-wheeler. As you can see, there is nothing complicated in the work procedure. You can complete all repairs yourself in a few hours.

The clutch is a mechanism that allows you to disconnect the engine crankshaft and the primary gearbox. As a result, the engine can work, the gearbox lever can be in a gear position, and the car will stand still.

A clutch is needed in order to change gears while the car is moving. If it were not there, then changing gears would be problematic - the lever is very difficult to move from one position to another. And all because the engine crankshaft and the wheels of the car are rigidly connected. And it is the clutch that allows for a kind of disconnection of the power units.

When repairing a car in a car service center in Moscow or any other city, you need to carefully ensure that the technicians complete all the work to the highest possible quality.

Recommendations for choosing a kit

A competent decision on the question of which clutch is best to install on a VAZ 2110 car is traditionally facilitated by the advice of experienced specialists. A few short but practical recommendations will come in handy, especially for novice motorists:

As already noted, it is better to replace the unit as a set. This is important if the machine already had an imported unit - the differences between the components can be significant.

- When replacing the coupling, tighten the mounting bolts one at a time to prevent warping of the basket casing. In this case, a centering mandrel should be used. After repair, you need to adjust the clutch in order to effectively use the power of the power unit.

- It is important not to confuse the position of the driven disk when installing it. If there are no marks on it, then just look at the disk from the side. The side where the damper springs protrude less is usually towards the flywheel. Incorrect installation threatens that during operation the springs will touch the flywheel bolts.

Source

How to choose the right one

Competent selection in 2022 begins with studying manufacturers’ offers. Knowing several factors will help determine which clutch is best installed on a VAZ.

- Precise car modification. The configuration of the clutch kit and its physical parameters depend on the type of car.

- Estimated price range. Depending on the desired cost, the user can navigate by company. The final price tag is considered an important factor - you shouldn’t count on the cheapest model.

- Method of operating the machine. With moderate driving under normal conditions, even simple modifications to the disc and drives will last quite a long time. If the car is used in racing mode or under critical overloads with frequent switching (this also includes training cars), you should buy high-quality products with a large margin of safety.

By taking into account all the parameters, the motorist can correctly select the required clutch model and install it on his car.

Which clutch kit to choose for Lada 2110?

Even experienced motorists treat the friction clutch with due respect, regularly inspecting and adjusting this unit. This fact is not surprising, because the comfort of driving a car fully depends on the quality functioning of the transmission.

to completely replace the clutch , but deciding which clutch is best to install on a VAZ 2110 is something he can do. The test results of specialists from the magazine “Behind the Wheel” will help you choose the right kit.

Dismantling the gearbox

The most important thing is to remove the gearbox. Therefore, it is best to carry out all work on an inspection hole or overpass - it’s really more convenient. Procedure:

- Remove the left wheel, unscrew the nuts from the ball joint and the tie rod end. You will need to move the box to the side; the drive on the left should come out without any problems.

- Loosen the nut securing the rocker and remove it from the gearbox shaft.

- Remove the starter, having first disconnected the battery and all wires from it.

- Unscrew the fastenings of the pillows holding the box. It is recommended to place a jack or reliable support under the gearbox housing before doing this.

- Disconnect the speedometer cable, disconnect the wires from the reverse sensor, as well as the ground bus.

- Unscrew the three bolts and nut that secure the gearbox housing to the engine block.

- Carefully move the box to the side; the right drive must be removed.

A little about how to properly remove the box:

- Firstly, you cannot remove both drives at once - replace one with a tube that will hold the differential.

- Secondly, it is imperative to drain the oil from the gearbox crankcase. By the way, why not replace it?

Replacement instructions

If you are still sure that the release bearing of the VAZ 2110 has failed, then you need to get to work without delaying for long, having first purchased the same new bearing and other components that will be needed during the work.

Tools

- a set of keys;

A set of keys

- Screwdriver Set;

- container for draining transmission fluid;

- rags;

- new transmission fluid (if we plan to replace it at the same time).

Stages

In order to get to the release bearing, you will need to partially or completely remove several fairly large components of the car.

Preliminary work

Unscrew the left nut and loosen the right one that secures the hub. After the wheels are loosened, we lift the car on a lift or jack it up until its front wheels leave the ground. During this procedure, observe safety precautions and place the vehicle only on very strong supports.

- We dismantle the wheels.

- Remove the motor protection.

- We loosen the fastening on the transmission drive rod (after marking the previous installation location in order to simplify the adjustment of the gear shift lever during assembly).

- We disconnect the gearshift drive rods from the gearbox.

- Turn off jet propulsion.

- We dismantle the starter.

- We dismantle the suspension arm and ball joint located on the left.

- Remove the cover on the clutch housing.

- Disable the speed meter.

- We remove the left drive, leave the right one in place, just loosen the hub nut on it.

- We hang the motor (after placing a reliable support under it), which will make it possible to prevent the motor from moving and a possible break in the heater hose. We unscrew the fastenings of the supports located on the gearbox and disconnect the clutch housing from the cylinder block. We move the box away from the engine and remove it.

Clutch on VAZ-2112

This is what the VAZ-2112 clutch diagram looks like in disassembly.

The clutch on any car, including the VAZ-2112, plays a very important role. So, without his participation it would simply be impossible to transmit torque from the engine to the gearbox.

The following two tabs change content below.

About the expert:

Fan-auto

All my life I have been surrounded by cars! First, in the village, already in the first grade, I was rushing around on a tractor through the fields, then there was JAVA, then a penny. Now I am a third-year student at the Polytechnic Faculty of Automotive Engineering. I work part-time as a car mechanic and help repair cars for all my friends.

Due to the fact that this element bears a large load, it can absolutely be called a consumable material, because its main elements require immediate replacement if they are severely worn.

Video about replacing the clutch on a VAZ 2110-2112 family

It is impossible to influence the condition of the clutch in any way, and it is also impossible to control its condition visually, so its malfunctions will only appear when one of the elements begins to fail.

Tool for replacement work

To make the work easier, you need to prepare all the tools in advance.

- Inspection hole or lift.

- Jack.

- Wheel chocks.

- Set of socket wrenches.

- Mount or extension tube.

Malfunctions

Any driver experiences an unpleasant feeling when the clutch pedal sinks to the floor. This can happen if the clutch cable breaks; it is also possible that the release fork breaks (this case is discussed in another article). The cable breaks more often on older cars that are used in extreme conditions or all year round.

The cable may become frayed, which affects the smoothness of the pedal and the operation of the clutch. This cable also requires replacement.

If the clutch cable is broken, you can drive your car to the repair site. You need to start the car in first gear and shift while driving. The following situation is possible: the cable broke while the gear was engaged, and the car stalled.

There is a possibility that it will be difficult to engage the neutral position. Then your car won’t even be able to roll off the roadway. The transmission is disengaged by rocking the car forward and backward and disengaging the transmission at the same time. You can jack up one of the wheels and spin it by hand, this will also help.

Even if the cable is not replaced, gear shifting is possible. It is possible to get to the service station, but such driving has a negative impact on the service life of the gearbox.

The cost of the spare part is low, about 300 rubles. The cost of replacing a cable in a car service is 400 rubles.