In any modern automobile engine, continuous fault diagnosis and adjustment of adjustment data are carried out using electronic systems. All VAZ injection engines, including the eight-valve engine on the 2110, are equipped with an engine management system. Each of the important indicators is monitored using a mass of sensors, and the knock sensor is one of them.

Knock sensor VAZ 2110 - purpose of the device

Detonation is a rather unpleasant phenomenon caused by spontaneous uncontrolled combustion of fuel in the combustion chamber.

It can occur due to many reasons - low-quality fuel or inappropriate compression ratio, incorrect operation of spark plugs.

But basically, detonation occurs due to an incorrectly set ignition timing.

A knock sensor will help identify the occurrence of undesirable phenomena in engine operation.

It is in this case that the knock sensor will help to determine the occurrence of an undesirable process at the very initial stage and transmit information about the beginning of detonation to the electronic engine control unit. The ECU, in turn, will adjust the ignition timing automatically to counteract the incipient detonation.

Pros of a working sensor

A working knock sensor will completely relieve the engine from overheating, ensure fuel savings and optimal power and traction.

Operating principle and location

Ignition too early can result in engine overheating, detonation, loss of power and excessive fuel consumption. Too late - the same, but at the same time starting the engine, especially a cold one, is quite difficult.

The piezoelectric knock sensor converts vibrations and noise in the cylinder head into an electrical impulse and transmits this data to the electronic control unit - the greater the one-time pressure on the sensor (micro-explosion, increased vibration), the stronger the signal from it.

The VAZ-2110 is equipped with two types of knock sensors.

There are two types of knock sensors:

- resonant type;

- broadband sensor.

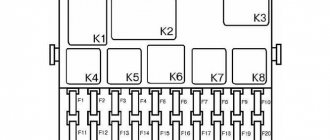

Knock sensor diagram.

The first type of sensor is configured to oscillate at a certain frequency, it is more accurate and is used on cars manufactured after 2002–2003 . A wideband sensor perceives the entire spectrum of frequencies and its readings are approximate, and the range of the transmitted signal is quite wide.

The two types of sensors are not interchangeable, and before checking and installing a new one, you must know exactly what type of sensor is installed on the engine.

The knock sensor on the VAZ-2112 is located on the front of the engine, next to the oil dipstick.

The sensor is screwed into the cylinder block on the left side under the spark plugs; its replacement and diagnostics take a few minutes.

ECU repair

As indicated above, it is impossible to accurately determine whether the unit is broken based on symptoms alone. Therefore, before repairs, it is necessary to diagnose the ECU, other units, systems and sensors, and check the wiring. When it is definitely established that the cause is in the ECU and it is not software in nature, repairs are made:

- Removing the block, checking the contacts.

- Opening and external inspection of the board to detect physical faults: breaks, damaged parts, etc.

- Replacement of damaged elements, restoration of soldering, tracks and other similar work.

- Voltage measurements, diagnostics.

- Assembly and sealing.

If the problem is software related, disassembling the unit may not be necessary. In some cases, flashing the ECU or, conversely, reverting to factory settings helps. But in any case, the exact cause can be detected only after high-quality diagnostics and testing with an oscilloscope.

If you suspect that the ECU is faulty, contact our partners for diagnostics. Specialists will determine the cause of the problems and, if necessary, repair the ECU (both software and hardware). You can find your nearest ADAKT partners on the map below.

We recommend watching

Symptoms of a problem

Before replacing the knock sensor, make sure that it is not working. Most often, sensor failure is due to an open circuit. This is expressed primarily in engine overheating and loss of power. In addition, the Check Engine warning light may come on when the load on the engine increases , the engine may stall and operate unstably regardless of speed.

When the knock sensor fails, the Check Engine light comes on.

Search

The easiest way to start troubleshooting is by reading the error codes. Depending on the type of error, we will take appropriate measures:

- code 0325 indicates that there is no contact in the sensor circuit, most likely the sensor connectors have oxidized, and in this case it is enough to ring its circuit and clean the contacts;

- with the same error, it is possible that the timing belt has slipped one tooth; it does not hurt to check the correct installation of the belt according to the marks;

- 0326, 0327 — low signal from the knock sensor, first let’s check the contacts and the tightening torque of the device fixing nut, it needs to be tightened with a force of 10–23 Nm, only then the sensor will work correctly;

- 0328 - the signal from the sensor exceeds the norm, this error basically indicates a malfunction of the sensor.

Depending on the manufacturer, the price of the sensor can be either 1200 rubles (Bosch, article number 2112–3855010 or 0 261 231 046 ), or 200–300 rubles for a domestically produced device. Their articles are 18.3855–01/18.3855 , 18.3855–01 and 2112–3855010 .

Stable operation of the 8-valve injector of the VAZ 2110 is ensured by a number of sensors. Each of them performs specific functions. Therefore, the failure of one regulator prevents the transfer of information to the electronic control unit. As a result, the ECU does not send signals to the power unit or transmits incorrect information.

Today, no one doubts that an injection engine demonstrates maximum efficiency and efficiency compared to a carburetor unit. Electronic fuel injection into the cylinders is one of the functions of the injector and provides it with a number of advantages.

Stable system operation, increased power and reliability are only possible if the electronics are functioning properly.

The functionality of the system is directly related to the huge number of sensors, which are the topic of this article, in particular:

- crankshaft sensor;

- speed;

- DTZHO;

- air regulator;

- turning on the fan;

- TPDZ;

- detonation.

Let us dwell in more detail on the listed, as well as some other regulators.

The engine control unit

All injection Ladas have a special unit that reads and processes readings from all sensors in the car system. This block is a small part made of plastic and metal, inside of which there is a microcircuit with many radio components. It is this block that sends signals to the fuel pump, injectors and ignition module, and also forms the ignition timing, controls the operation of fans, etc. This is a kind of car head unit.

Location

In all Lada models it is located in the cabin, in classic Lada models it is located under the glove box, in front-wheel drive Ladas the ECU is located under the center console. The location of the ECU can be called a problematic place in Lada Granta and Kalina cars, since the ECU is located under the heater radiator, which quite often exposes it to getting wet with antifreeze and disabling it. Many owners of these cars move the ECU under the glove box.

Symptoms of a problem

The unit does not have a malfunction as such; its failure may be associated with the failure of any of the sensors. For example, if one of the cylinders fails, the problem may lie not in the ignition module or coil, but in the key located in the ECU. Often a radio component that burns out inside the unit can affect the operation of any of the sensors.

Speed sensor

The device is located on the speedometer output shaft. If a malfunction occurs, the vehicle may not idle smoothly. The design is simple and reliable. The operating principle is based on the Hall effect. There were two types of meters installed on the ten - with a square and a round block.

When the speedometer needle jumps, it is recommended to check the device in question, since failure can affect the speed performance of the vehicle.

DTZO: temperature indicator

The regulator screws directly into the cooling system pipe. Located between the filter housing and the power unit. The task of the coolant sensor is as follows:

- when starting a cold engine – informing the system about the supply of an enriched mixture;

- if it overheats, turn on the fan to cool the radiator.

If we talk about carburetor engines, then one of the listed functions was performed by the choke. The measuring element (DTZO) plays an important role for the stable operation of the power unit. It is characterized by the following problems:

- violation of contacts;

- high probability of failure if the fan starts when the engine is cold;

- difficulty starting a hot engine;

- increased fuel consumption if the indicator fails.

Mass air flow sensor: air regulator

The tens electronic system needs information about the amount of air required. This is necessary to create the optimal volume of the warm-air mixture.

Considering the sensors of the VAZ 2110 injector 8 valves , it should be noted that the mass air flow sensor is the most sensitive of all devices.

A small amount of moisture or dust can cause damage. This must be taken into account during the car repair process. So, the sensor determines the volume of air before entering the system. The disadvantages of the device are:

- sensitivity to moisture and dust;

- malfunctions during operation of the power unit at idle speed;

- increased fuel consumption;

- difficulty starting the engine;

- at increased speeds and significant loads, the power unit may stop abruptly.

All of the above reasons are due to the fact that a mixture that is too lean (or rich) gets into the cylinders. The operating principle of the device in question is quite simple. There are several heating elements inside the structure, which “lose” temperature as air passes through. The more electricity used to heat these components, the more air enters the system.

Thus, the change in electrical power is directly related to air flow. The information is transmitted to the system, which turns on the appropriate modes and controls air flow.

Fan sensor

This tool is necessary for measuring temperature and then turning on a fan designed to cool the engine. Unlike other devices, it is reliable and has a long service life. The sensor is filled with a solid substance that expands as the temperature increases. By purchasing high-quality products, owners of the VAZ-2110 model will be able to forget about the need for replacement for a long time.

The task of the device in question is reduced to transmitting a signal to the computer as a result of pressing the gas pedal. Thus, the amount of fuel injected increases. The design of the regulator is quite reliable. Failure is indicated by jerking when pressing the accelerator pedal. Also, sometimes “failures” occur. A regular tester is used for testing.

If the damper is closed, the voltage is about 0.5 Volts. When you press the pedal as hard as possible, the voltage increases to 4 volts.

Knock sensor

The device is mounted on the cylinder block. Its function is reduced to transmitting information about detonation to the electronic control unit. As a result of increased detonation, the ECU (in accordance with the software) changes the operation of the power unit. Dozens of recent series have piezoceramic devices installed. Functionality testing is performed using a tester. To do this, you need to connect the meter to the contacts of the device and lightly knock. The measuring device should record voltage drops, which indicates proper operation.

There are other sensors, such as valve timing and a lambda probe, that can be installed on cars with 8 and 16 valves. To study the features of each device, it is recommended to use the instruction manual for the VAZ 2110 car.

Any modern car is equipped with many different sensors that allow the driver to know about the condition and performance of certain components. And the VAZ 2110 car is no exception; in this article we will talk about what sensors are used in it and what their location is.

As you know, the VAZ 2110 injector with 8 or 16 valves is significantly superior to the carburetor version in many ways. At least because in this case the supply of gasoline, as well as the combustible mixture, is regulated by electronics. Accordingly, the use of electronics implies the use of many different regulators and controllers. Their breakdown can lead to certain consequences, so the car owner should always know what certain regulators are responsible for. Below we consider almost all VAZ sensors that are in the top ten.

The power unit of the "tens" is controlled using the ECM - an electronic system. This system must always know how much air needs to be supplied for a certain volume of gasoline. These two parameters are closely related to each other, since with their help a combustible mixture with the required density is formed in the engine power unit. After the system determines the required volume of air, it begins to select the appropriate amount of gasoline. As for the regulator, it is responsible for the suction volumes.

Throttle controller

Designed for dosing fuel in cylinders. When you press the gas pedal on an injection engine, only the air damper mechanically opens. The amount of gasoline to create the working mixture changes according to a command from the ECU. This is what the throttle position sensor (TPS) is designed for.

The controller is a variable resistance, essentially the same as the volume control on a car radio. Only the voltage supplied to the control unit changes here. Roughly speaking, TPS converts the force of pressing the gas pedal into a certain electrical signal. It goes to the ECU, in which the voltage/fuel quantity relationship is hard-wired with great precision.

The signal amplitude varies from 0.7 to 4 V (with the damper fully open). The incoming gasoline also changes linearly. The TPS is installed directly on the throttle assembly.

Coolant temperature sensor

On the VAZ 2110, sensors can be used for different purposes, but most of them are mounted in the engine compartment. On an 8 or 16 valve engine, the fan sensor is a device designed to activate the fan. We are talking directly about a fan designed to cool a hot engine.

The controller turns on automatically when the power unit reaches a certain temperature. But it can also turn on when the engine is off. At first, this fact may be alarming for many owners of the “ten”, but there is nothing wrong with it, so there is no need to worry.

It is necessary to highlight the advantages of this controller:

- As practice has shown, the fan sensor is one of the most reliable vehicle devices, since its design is based on a solid filler. When the ambient temperature increases, this filler begins to expand.

- The design of this device also includes a special spring-loaded lever. Thanks to this component, no defects occur during the operation of the regulator.

- The device prevents sparks from appearing, which is especially important for ensuring vehicle safety.

- In fact, this type of regulator itself is reliable. If you buy a high-quality device, then in the future you will notice that it will function for quite a long time; you can forget about the need to replace it for the next few years.

Instructions for removing and replacing the computer

The need to dismantle the ECM unit 16 of the ten valve engine arises if repairs are necessary when faults are identified. The repair process itself will depend on what exactly happened in the operation of the ECU. For example, if the contacts on the module connector have oxidized, the unit must be dismantled to clean or replace them. If the reason lies in damage to the housing, then the device must be removed for replacement; if water has gotten inside, then the module should be removed in order to dry it. Only after you have dried the block can it be tested.

If the problem lies in the performance of the board and some burnt-out elements, then you can try to repair it yourself by re-soldering some components. But we would still recommend turning to specialists for help, especially if you have never encountered such a problem before (the author of the video about repairing the control controller is Vyacheslav Chistov).

Tools

To replace the module, you will need:

- socket head 10;

- ratchet handle;

- Phillips screwdriver.

Work sequence

Before dismantling the device, you should disconnect the negative terminal from the car battery:

- The vehicle must be placed on a flat surface, without slopes, and the parking brake must be set.

- The following stages of work are performed inside the car. You will need to carefully unplug the wire connector from the control box, but before doing so, you should unplug the latch.

- When you get directly to the powertrain control controller, using a wrench you will need to unscrew the two nuts that secure the module to the bar.

- After these nuts are unscrewed, you will need to move the bar itself slightly to the right side, this will allow it to be released from engagement.

- After completing these steps, the control controller can be dismantled. If you are replacing a device, then if it breaks down, you should replace the module with a similar one that was installed. That is, if you had a January 7.2 ECU, then the same module is installed. If the unit is subject to repair, it should be repaired and then reinstalled. The installation procedure is performed in the same way, only in reverse order.

Do not repair the control unit if you have never had to deal with such a task before!

Crankshaft regulator

Depending on the type of car, on a 16- and 8-valve engine, the location of all controllers may be different. However, all of these devices combine into one functioning system, and the crankshaft adjuster is no exception. Thanks to this controller, the electronic engine management system of the “tens” can independently determine at what point to supply gasoline and a spark through the spark plugs in order to ignite the combustible mixture. In fact, the design of the device is a magnet, as well as a coil of thin wire.

The crankshaft sensor has certain advantages:

- As practice shows, at “tens” this regulator can work for quite a long time. Its service life does not decrease even as a result of using the vehicle’s power unit under increased loads.

- The crankshaft adjuster works in conjunction with the crankshaft pulley.

- If the device fails, the engine may not be able to start. Or, if the regulator breaks down, the speed parameters will be reduced to 3.5 thousand per minute.

This controller is installed on the oil pump, actually at the very top of the shaft teeth. Or rather, one millimeter from the cloves. You can learn more about how to replace this controller yourself from the video below (the author of the video is the channel In Sandro’s Garage).

Coolant temperature indicator

Antifreeze or coolant is used to cool the engine. To ensure proper operation of the power unit, the coolant also has its own controller. In its functionality, this regulator is vaguely reminiscent of the choke that is equipped with 8- and 16-valve carburetor engines of the “ten” and other vehicles. The sensor itself is designed to monitor the temperature of the consumable.

Installing a new antifreeze sensor

In fact, this device also provides fuel regulation. If the power unit is running cold and has not yet warmed up, it will receive more gasoline for normal operation. Readings about the coolant temperature are displayed on the control panel in the vehicle interior. In accordance with these indicators, the driver will always be able to find out about the overheating of the unit by the way the sensor arrow on the dashboard begins to move into the red zone.

The antifreeze temperature sensor periodically fails; it is characterized by the following malfunctions:

- Loss of electrical contact inside the controller, resulting in its inoperability.

- The device is installed in such a way that it may be exposed to moving elements, particularly the accelerator pedal cable. It would be even more correct to say that the cable does not act on the sensor itself, but on its wires, which in fact can lose insulation as a result of long-term use.

- Often the regulator breaks down if the ventilation device starts to function on an engine that is not warmed up.

- If the motor is overheated, it may be difficult to start.

- If the fuel temperature controller fails, it can lead to increased gas mileage. If you encounter one of these problems, then to ensure normal operation of the car engine, you need to replace the controller. Detailed replacement instructions are presented in the video below (author - REPAIR VAZ 2110, 2111, 2112).

Gasoline level indicator

The fuel sensor of the VAZ-2110, like any other car, is a rheostat made of nichrome wire. Its moving contact is mechanically connected to a float, which is located in the tank on the surface of the gasoline. The fuel level changes, and along with it the resistance of the rheostat, which is recorded by the device on the panel.

In addition, there is an indication of the reserve amount of gasoline. It works thanks to the same float. In a certain position, it closes the contacts, which causes the warning lamp to turn on. The fuel gauge cannot be called an accurate and reliable device. However, these are the disadvantages of all mechanical sensors. The main malfunctions are associated with damage to the nichrome wire, which simply wears out due to the constant movement of the “runner”.

The sensor is naturally installed in the tank, and replacing it does not present any difficulties. True, you will have to remove the fuel pump and partially drain the fuel if the car is “filled to capacity.”

Speed sensor

8- and 16-valve “tens” are also equipped with a speed sensor. Thanks to this device, the electronic engine control system receives information about how fast the vehicle is moving. The sensor itself is installed on the vehicle's gearbox. As practice has shown, on VAZ 2110 cars this controller is characterized by fairly high reliability and a long service life.

But domestic developers could not do everything perfectly, so this device is characterized by several malfunctions:

- If a component fails or does not work correctly, then when idling, the power unit may turn off on its own.

- A failed regulator can partially affect the speed characteristics of the vehicle. Of course, if the device breaks down completely, the driver will not be able to know how fast it is moving.

Two speed controllers

Phase sensor

This sensor is not installed on 8-valve engines; it is present only on 16-valve versions of the “ten”. The main purpose of the controller is to provide the necessary data to the power unit control system. In accordance with these data, the system determines at what point in time and where to inject fuel, into which specific cylinder. Every owner of a VAZ 2110 should know where this device is located. If you open the engine compartment of the car, you will see that the regulator is located on the right side of the neck for filling the engine fluid.

In principle, if the regulator breaks, nothing bad will happen if you look at it from the point of view of the integrity of the vehicle. But failure of the controller will in any case provoke an increase in gasoline consumption. This is due to the fact that the electronic control system of the internal combustion engine will independently switch the gas distribution mechanism to standby mode. Accordingly, gasoline will begin to be supplied to all cylinders of the engine at once. And at first, the driver may not even know about it until he diagnoses the regulator or measures fuel consumption.

New phase sensor for VAZ 2110

Naturally, such a model of the domestic automobile industry as the “ten” is not the most modern and advanced car in terms of electronics. However, machines of this model are equipped with a wide variety of regulators and controllers. In this article, we did not talk about all the devices, but only about the most basic ones that every motorist should know about. You can find more detailed information in other articles on our website or in the service book for your car.

Idle speed control

Today, in urban environments, drivers simply cannot do without idling. Therefore, every car, including the VAZ 2110, is equipped with an idle speed sensor. Incorrect operation or failure of this regulator will significantly complicate driving, because it will cause the engine to stop even during the shortest stops. So if the controller fails, and this is not uncommon in VAZ 2110 cars, it needs to be changed as quickly as possible.

Removing the idle air control

The main purpose of this type of regulator is to support the speed required for normal operation of the power unit. Thanks to the device, the driver can always make a short stop as a result of changing the incoming air volume. As for the location, this controller is installed on the throttle line. In particular, we are talking about an anchor stepper motor, which is equipped with two windings.

When a corresponding signal is received on one of the windings, a special needle moves forward one step and backwards one step. Thanks to the worm gear, the device rotates, which is produced using a stepper motor, thus converting this movement into translational. The rod itself, namely its conical part, is located in the line through which the air flow is supplied.

Thanks to the functioning of the rod, the system adjusts the idle speed of the power unit. The rod from the device, as mentioned above, can be retracted or extended. In this case, it all depends on what kind of pulse will be supplied from the regulator. The controller itself allows you to adjust the frequency at which the engine crankshaft will rotate when the machine is stopped for a short time.

In addition, the controller controls the incoming air flow, which bypasses the throttle in the closed position. When the engine is warmed up, the regulator, by controlling the movement of the rod itself, at idle speed allows you to maintain the required crankshaft speed. In this case, the load and condition of the power unit do not play a role.

Mass air flow sensor

One of the most capricious and delicate sensors of the VAZ-2110 injector. However, it is also quite expensive. The sensor measures the amount of air passing through the car filter and transmits the data to the ECU, which, based on them, forms the optimal composition of the working mixture.

The main element of the VAZ-2110 air flow sensor is a platinum thread. It is used as a spiral, i.e. it is heated to a certain temperature and cooled by an air flow. The more it passes through the filter, the less the thread heats up. The flow meter is a high-speed device; it transmits data to the computer every 0.1 s.

A malfunction of the mass air flow sensor causes engine malfunction in all modes. In this case, characteristic symptoms will be:

- unstable idling;

- lack of engine power;

- poor dynamics;

- increased fuel consumption.

However, such malfunctions are also typical for damage to many other components, including VAZ-2110 sensors. The operating principle and purpose of the mass air flow sensor determine its location in the car. It is installed immediately behind the air filter.