Video: General structure of a passenger car in 3D. How does a car work? The structure of a car engine. Internal combustion engine (ICE) in 3D. General structure of a truck. Electrical equipment of a car: structure and main malfunctions

Nowadays, a car is no longer a luxury. Almost everyone can afford to buy it. But often very few people are familiar with the structure of a car, although it is very important for every driver to know what main parts, components and assemblies the vehicle consists of. First of all, this is necessary when some kind of car breakdown occurs, due to the fact that the owner is at least generally familiar with the design of the car, he can determine exactly where the malfunction occurred. There are a huge number of different brands and models of cars, but for the most part, all passenger cars have the same design. Let's analyze the structure of a passenger car.

Suspension

Windshield

Salon

Fuel system

Body

Transmission

Engine

Wheels and tires

Headlights

A passenger car consists of 5 main parts:

- body (supporting structure)

- chassis

- transmission

- internal combustion engine (gasoline or diesel)

- engine management system and electrical equipment

Body

Body

- that part of the car to which all other components are attached. It is worth noting that when cars first appeared, they did not have a body. All components were attached to the frame, which made the car quite heavy. To reduce weight, manufacturers abandoned the frame and replaced it with a body.

The body consists of four main parts:

- front spar

- rear spar

- engine compartment

- car roof

- hinged components

It should be noted that this division of parts is quite arbitrary, because all the parts are interconnected and form one structure. The suspension is supported by side members that are welded to the bottom. Doors, trunk lid, hood and fenders are more of a hinged component. It should also be noted that the rear fenders are attached directly to the body, but the front fenders are removable (it all depends on the manufacturer).

Brief overview of types of checkpoints

A gearbox or gearbox is one of the main parts of a car's transmission . Basically, checkpoints are usually divided into three types, namely:

• Manual Transmission. The principle of its operation is that the driver uses a lever to change gears, while constantly monitoring the engine load and vehicle speed;

• Automatic transmission eliminates the need to constantly monitor speed and load, and there is no need to constantly use the lever;

• A robotic gearbox is a semi-automatic type of gearbox that combines the properties of a manual and automatic gearbox.

In fact, there are many more types and subtypes of checkpoints. So, they distinguish Tiptronic

(based on an automatic transmission with a manual gearshift),

DSG

(equipped with 2 clutches, has an automatic shift drive and is a 6-speed gearbox) and

a variator

(continuously variable transmission).

Chassis

Chassis

consists of a huge number of a wide variety of components and assemblies, thanks to which the car has the ability to move. The main components of the chassis are:

- front suspension

- rear suspension

- wheels

- drive axles

Most often, manufacturers install front independent suspension on modern cars, because... it provides the best control, and also, most importantly, comfort. In an independent suspension, all wheels are attached to the body using their own mounting system, which ensures excellent vehicle control.

We must not forget about the now outdated, but still present in many cars, dependent suspension. The rear dependent suspension is basically a rigid beam or a drive axle, if, of course, we consider a rear-wheel drive car.

General structure of the car

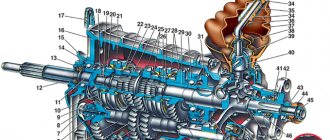

The block diagram of a rear-wheel drive car is shown in Fig. 6.1.1.

The car includes:

- engine 1;

- power train or transmission , which includes: clutch 5, gearbox 7, cardan drive 8, main gear and differential 11, axle shafts 10;

Rice. 6.1.1. Block diagram of a rear-wheel drive car: 1 - engine; 2 — fuel pedal; 3 - generator; 4 — clutch pedal; 5 — clutch; 6 — gear shift lever; 7 — gearbox; 8 — cardan transmission; 9 — wheel; 10 — axle shafts; 11 — main gear and differential; 12 — parking (hand) brake; 13 — main brake system; 14 — starter; 15 — power supply from battery; 16 — suspension; 17 — steering; 18 - hydraulic main

- chassis , which includes: front and rear suspension 16, wheels and tires 9;

- control mechanisms , consisting of steering 17, main 13 and parking 12 brake systems;

- electrical equipment , which includes sources of electric current (battery and generator), electrical consumers (ignition system, starting system, lighting and alarm devices, instrumentation, heating and ventilation systems, windshield wiper, windshield washer, etc.);

- monocoque body.

Front-wheel drive cars do not have a driveshaft or driveshaft box in the body, so the interior becomes more spacious and comfortable, and the vehicle weighs less.

Engine 1 (Fig. 6.1.1) is a machine that converts any type of energy (gasoline, gas, diesel fuel, electric charge) into rotational energy of a cranked engine.

Most modern cars are equipped with piston internal combustion engines (ICE), in which part of the energy released during fuel combustion in the cylinder is converted into mechanical work of rotation of the crankshaft (Fig. 6.1.2).

Displacement is a unit of measurement of engine volume equal to the product of the piston area by the length of its stroke and the number of cylinders. Displacement characterizes the power and size of the engine, expressed in liters or cubic centimeters.

To change the amount of fuel mixture supplied to the cylinder (to change engine power), use the fuel pedal (gas pedal) 2.

Rice. 6.1.2. Appearance of a modern engine: 1 — valve box cover; 2 — neck plug for filling oil into the engine; 3 — cylinder head; 4 - pulleys; 5 - drive belt; 6 - generator; 7 - crankcase; 8 - pallet; 9 — exhaust manifold

A flywheel with a toothed ring is installed on the crankshaft, which is the drive clutch disc 5.

Clutch 5 provides a permanent mechanical connection between the engine and the gearbox and is designed to briefly disable it for the time required to engage or shift gears.

The clutch (Fig. 6.1.3) consists of two friction clutches 1 and 3, pressed against each other by a spring 4. Drive disk 1 is mechanically connected to the engine crankshaft, driven disk 3 is connected to the drive shaft of the gearbox 14.

The clutch is turned on and off by the driver using pedal 8 (when the pedal is pressed, the clutch is disengaged). When you press the pedal, clutch discs 1 and 3 diverge, drive disc 1, connected to engine 13, rotates, but this rotation is not transmitted to driven disc 3 (the clutch is disengaged). The clutch must be disengaged during the period of engaging or shifting gears to ensure a shock-free connection of the gears in the gearbox.

When the pedal is smoothly released, the drive and driven disks engage smoothly. At the same time, due to slipping, the driving disk smoothly imposes rotation on the driven disk. It begins to rotate, transmitting torque to the input shaft of gearbox 14. Thus, the car can start moving smoothly from a standstill or continue moving in a new gear.

The gearbox serves to change the magnitude and direction of torque and transmit it from the engine to the drive wheels, as well as for long-term disconnection of the engine from the drive wheels while the vehicle is parked.

The gearbox can be mechanical (with manual gear shift) or automatic (torque converter, robotic or CVT).

Rice. 6.1.3. Clutch diagram: 1 - flywheel; 2 — clutch driven disc; 3 — pressure disk; 4 - spring; 5 — release levers; 6 — release bearing; 7 — clutch release fork; 8 — clutch pedal; 9 — clutch master cylinder; 10 - hydraulic fluid; 11 - pipeline; 12 — clutch slave cylinder; 13 — engine; 14 — drive shaft of the gearbox; 15 - gearbox

We recommend: Design and principle of operation of electric power steering

The manual gearbox (Fig. 6.1.4) is a gearbox with a stepwise variable gear ratio.

It contains:

- crankcase 12, which contains oil 13 for lubricating rubbing parts;

- input shaft 2 connected to clutch driven disc 1

- input shaft gear 3, which is permanently connected to the intermediate shaft gear;

- intermediate shaft 4 with a set of gears of different diameters;

- a secondary shaft 9 with a set of gears that can be moved using the gear shift fork 6;

- gear shift mechanism 8 with shift lever 7;

- synchronizers are devices that ensure equalization of gear rotation speeds during gear changes.

The driver changes gears using shift lever 7. Since the gearbox of a modern car has a large set of gears, by engaging different pairs of them (when engaging any gear), the driver also changes the overall gear ratio (gear ratio). The lower the gear, the lower the vehicle speed, but the greater the torque and vice versa.

When the engine is running, before turning on or shifting gears in a manual transmission, in order to shift gears without shock, you need to depress the clutch pedal (disengage the clutch).

Rice. 6.1.4. Manual gearbox: 1 — clutch; 2 - input shaft; 3 - drive gear; 4 - intermediate shaft; 5 — secondary shaft gear; 6 — gear shift fork; 7 — gear shift lever; 8 - switching device; 9 — secondary shaft; 10 — crosspiece; 11 — cardan transmission; 12 - crankcase; 13 - gearbox oil

The most common gear shift patterns in passenger cars are shown in Fig. 6.1.5.

Rice. 6.1.5. The most common gear shift patterns in passenger cars are 1 and 2, 3 and 4 - using the gear lever

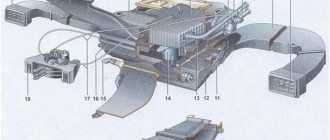

The automatic gearbox (Fig. 6.1.6) includes:

- The torque converter (2, 5, 4, 5, 9), which is directly connected to the engine, is filled with hydraulic fluid 10. The fluid is the medium for transmitting torque from the engine to the manual transmission. The principle of operation is as follows: with increasing engine speed, the revolutions of shaft 2 with blades 3 increase, which cause rotation of the hydraulic fluid 10. The rotating fluid begins to put pressure on the blades of the secondary shaft 4 and causes rotation of the secondary shaft. The torque converter essentially acts as a clutch;

- The manual gearbox 7 receives rotation from the torque converter, gear shifting in it is carried out by servo drives according to commands from the control unit 6.

Rice. 6.1.6. Automatic gearbox: 1 — engine; 2 - input shaft; 3 — blades of the input shaft; 4 — blades of the secondary shaft: 5 — secondary shaft; 6 — automatic transmission control unit; 7 — manual gearbox; 8 - output shaft

To control an automatic, robotic or CVT transmission, use the gear selector (Fig. 6.1.7).

Rice. 6.1.7. Typical diagrams of automatic gearbox selectors:

P - parking, mechanically blocks the gearbox; R - reverse gear, should only be engaged after the vehicle has come to a complete stop; N - neutral, in this position you can start the engine; D - drive, forward movement; S (D3) - low gear range, activated on roads with slight inclines. Engine braking is more effective than in position D; L (D2) - second range of low gears. Turns on on difficult road sections. Engine braking is even more effective

A cardan drive (in rear- and all-wheel drive vehicles) allows torque to be transmitted from the gearbox to the rear axle (main gear) when the vehicle is moving on a rough road (Fig. 6.1.8).

Rice. 6.1.8. Cardan transmission: 1 - front shaft; 2 — cross; 3 - support; 4 — cardan shaft; 5 - rear shaft

Main gear 5 serves to increase torque and transmit it at right angles to axle shaft 6 of the vehicle (Fig. 6.1.9).

The differential ensures that the drive wheels rotate at different speeds when the car turns and the wheels move on uneven roads.

Axle shafts 6 transmit torque to drive wheels 7.

The chassis ensures movement and smoothness. It includes a subframe, usually combined with the car body, to which elements of the front and rear axles with hubs and wheels 7 are attached via front and rear suspensions.

Mechanisms and parts of the chassis connect the wheels to the body, dampen its vibrations, perceive and transmit forces acting on the car.

While inside a passenger car, the driver and passengers experience slow vibrations with large amplitudes and fast vibrations with small amplitudes. Soft seat upholstery, rubber engine mounts, gearboxes, etc. protect against fast vibrations. Elastic suspension elements, wheels and tires protect against slow vibrations.

Rice. 6.1.9. Rear-wheel drive car: 1 - engine; 2 — clutch; 3 — gearbox; 4 — cardan transmission; 5 — main gear; 6 — axle shaft; 7 — wheel; 8 — spring suspension; 9 — spring suspension; 10 - steering

The suspension (Fig. 6.1.10) is designed to soften and dampen vibrations transmitted from road irregularities to the car body. Thanks to the wheel suspension, the body makes vertical, longitudinal, angular and transverse angular vibrations. All these vibrations determine the smoothness of the car. The suspension can be dependent or independent.

Dependent suspension (Fig. 6.1.10), when both wheels of one vehicle axle are connected to each other by a rigid beam (rear wheels). When one of the wheels hits an uneven road, the other one tilts at the same angle. Independent suspension, when the wheels of one axle of the car are not rigidly connected to each other. When hitting an uneven road, one of the wheels may change its position, but the position of the second wheel does not change.

Rice. 6.1.10. Diagram of operation of dependent (a) and independent (b) car wheel suspension

An elastic suspension element (spring or spring) serves to soften shocks and vibrations transmitted from the road to the body.

Rice. 6.1.11. Shock absorber diagram:

1 — car body; 2 — rod; 3 - cylinder; 4 — piston with valves; 5 — lever; 6 — lower eye; 7 — hydraulic fluid; 8 - upper eye

We recommend: What is better to choose between a CVT, manual, automatic and robotic gearbox

The damping element of the suspension - the shock absorber (Fig. 6.1.11) - is necessary to dampen body vibrations due to the resistance that occurs when fluid 7 flows through calibrated holes from cavity “A” to cavity “B” and back (hydraulic shock absorber). Gas shock absorbers can also be used, in which resistance occurs when gas is compressed. A vehicle's anti-roll bar is designed to improve handling and reduce vehicle roll when cornering. When turning, the car body presses one side of it to the ground, while the other side wants to go “away” from the ground. It’s the anti-roll bar, which, pressing one end to the ground, presses the other side of the car with the other, preventing him from getting away. And when a wheel hits an obstacle, the stabilizer rod twists and tries to return this wheel to its place.

Rice. 6.1.12. Steering diagram of the "gear-rack" type: 1 - wheels; 2 — rotary levers; 3 — steering rods; 4 — steering rack; 5- gear; 6-wheel steering

Steering (Fig. 6.1.12) is used to change the direction of movement of the vehicle using the steering wheel. When the steering wheel 6 rotates, the gear 5 rotates and moves the rack 4 in one direction or another. When moving, the rack changes the position of the rods 3 and the associated rotary levers 2. The wheels turn.

Rice. 6.1.13. Brake system: main - 1-6 and parking (manual) -7-10. Actuating brake devices: A - disc; B - drum type; 1 - main brake cylinder; 2 - piston; 3 - pipelines; 4 — hydraulic brake fluid; 5 — rod; 6 — brake pedal; 7 — hand brake lever; 8 - cable; 9 — equalizer; 10 - cable

The brake system (Fig. 6.1.13) serves to reduce the speed of rotation of the wheels due to the friction forces arising between the brake pads 11 and brake drums A or discs B, as well as to hold the car stationary in parking lots, on descents and ascents with the help of manual brake system (7-10). The driver controls the brake system using the brake pedal 6 of the main brake system and the parking-night (hand) brake lever 7.

The main brake system (1-6), as a rule, is multi-circuit, that is, when you press the brake pedal 6, the pistons 2 move, the pressure of the hydraulic brake fluid 4 is transmitted through pipelines 3 to the brake actuators A - for braking the front wheels and the brake actuators B - for braking the rear wheels. Systems A and B are independent of each other. If one circuit of the brake system fails, the other will continue to perform the braking function, although less effectively. The multi-circuit braking system increases traffic safety.

The electrical equipment of a car includes sources of electric current (battery, generator) and electrical consumers (starting and ignition systems, lighting, alarm devices, instrumentation, windshield wipers, windshield washers, heating, ventilation systems, etc.).

The battery energy is used when the engine is not running, the generator energy is generated only when the engine is running, it is used to recharge the battery and power other vehicle consumers.

body is rigid and load-bearing.

Transmission

Car transmission

is a set of mechanisms and units for transmitting torque from the engine to the drive wheels. Three main components can be distinguished from the components of the transmission:

- gearbox or simply gearbox (manual, robotic, automatic or CVT)

- drive axle or axles (depending on manufacturer)

- constant velocity joint or, to put it more simply, cardan transmission

In order to ensure smooth transmission of torque, a clutch is installed on the car, thanks to which the engine shaft is connected to the gearbox shaft. The gearbox itself is needed to change the gear ratio, as well as reduce the load on the engine itself. A cardan drive is necessary to connect the gearbox directly to the wheels or to the drive axle. And the drive axle itself is mounted in the gearbox housing if the car has front-wheel drive. If the car has rear-wheel drive, then the drive axle serves as the rear beam.

What does a car consist of?

Any passenger car contains the following components:

- engine

- transmission

- chassis

- electrical equipment

- body

This is the order in which a car is always discussed in any textbook on auto mechanics, and there is a reason for this: these components are arranged in order of importance.

Engine

The engine of a car is its main part. It drives the vehicle itself and simultaneously supplies energy to the service units. The engine is almost always located in the front, but sometimes it is also located in the rear (mainly on sports cars). The most common today is the internal combustion engine (ICE) - it burns fuel, converting thermal energy into kinetic energy (rotation). Engines are petrol, diesel and gas. In these three cases, the difference lies only in the type of fuel used and the characteristics of the engine operating cycle. By the way, you can put a diesel engine in the Niva. There are also electric car engines, but they are a minority, despite their undoubted advantages.

The engine torque must be realized as efficiently as possible, because when driving slowly, the engine cannot work slowly, and when driving quickly, it cannot work quickly. The transmission converts the engine's rotational speed, slowing it down or speeding it up. The transmission consists of a clutch, gearbox and final drive with a differential.

The clutch serves to mechanically separate the wheels and engine when vehicle movement is not required. The gearbox allows you to drive at different speeds at the same engine speed. It can be mechanical (manual) or automatic. In the first case, the gears are switched on by the driver himself using a special lever; in the second, the gears are selected automatically depending on the driving speed and the load on the car. The second option makes it easier to control, but the design of such a unit itself is much more complicated. The final drive sends torque directly to the wheels, and the differential allows them to rotate at different speeds (this is mainly needed when cornering).

Also, the composition of the transmission may vary depending on the type of drive. The engine can turn only the front wheels, only the rear wheels, or all wheels together. In the first case, rotation from the main gear goes through the axle shafts directly to the front wheels. In the second case (if the engine is in the front), a special driveshaft is added to the transmission, leading to the rear wheels through the entire car. On all-wheel drive vehicles (jeeps and crossovers), after the gearbox, another transfer case is installed, which distributes rotation between the front and rear wheels.

Chassis

It includes components directly related to movement - suspension, wheels, brake mechanisms. The car's suspension serves to smooth out the reactive moments that arise when driving over uneven surfaces, in other words, it makes the ride softer and smoother. In addition, the suspension eliminates and reduces body roll and tilt when cornering, keeping the car in a given horizontal position. The suspension includes shock absorbers and springs, as well as various levers and joints. The smoothness of the ride and overall behavior on the road depend on the characteristics of the suspension. Brakes are used to slow down and stop a car in various situations. They are located directly next to the wheels.

Electrical equipment

Electrical equipment is a very important equipment system. Nowadays, when there are more and more electronic assistants, the role of electrical equipment is becoming increasingly important. In its most general form, it consists of a battery, a generator, ignition systems, lighting, and control devices. Since various systems consume a lot of electricity, the engine, during its operation, rotates the generator, which supplies all consumers, and also charges the battery, which is used to start the engine.

We recommend: Car cooling system: purpose, types, description, photo, device

Body

The body is, roughly speaking, a metal box in which all of the above units are installed. The body, together with attached parts (doors, hood, wings) form the appearance of the car and protect the driver, passengers and all components from atmospheric influences. Almost all modern passenger cars are equipped with monocoque bodies, i.e. All components are installed on it, unlike trucks, for example, where a frame is used - a special element to which the engine, cabin, body, suspension, etc. are attached. The use of a monocoque body allows you to significantly, by 10-20%, reduce the total weight.

Of course, numerous pictures and books can give a more complete idea of the structure of the machine, but general theoretical knowledge in most cases is quite enough to understand, for example, that problems with electrical equipment can be the reason why the engine “troubles”, and knocks and rumbles When driving over uneven surfaces, this indicates a problem with the suspension. Therefore, the design of a car for “dummies”, despite the complexity of the systems and the abundance of car services, will always be able to help in a difficult situation.

In the twenty-first century, a car is no longer a luxury. Most likely, this is an urgent need. However, most vehicle owners simply do not have enough time to carefully study its components. Therefore, the design of a car for “dummies” allows you to become familiar with the fundamentally important points in the shortest possible time.

The simplest diagram of a car looks like this:

- top shell or ;

- chassis apparatus (transmission, control mechanisms, running gear);

- the power unit, which is the most important part of the car.

Answers on questions

What is an internal combustion engine?

An internal combustion engine is an engine in which fuel is burned directly in the working chamber (inside) of the engine. The internal combustion engine converts thermal energy from fuel combustion into mechanical work.

What is a gearbox?

A gearbox is a mechanism for changing the torque transmitted from the engine crankshaft to the drive wheels, for moving the car in reverse and for long-term disconnection of the engine from the transmission while the car is parked and when it is moving by inertia (coasting).

What is a car suspension?

Suspension is a set of parts, components and mechanisms that play the role of a connecting link between the car body and the road.

What is a body?

The body is an element of the supporting part that provides accommodation for passengers and cargo, and very often acts as a frame for securing the main units and components of the car.

Brief overview of types of motors

First of all, it is worth noting that the engine and motor are one and the same. Motors are often called internal combustion or electric engines. It is no secret that the engine serves as a source of energy to move the vehicle. Most cars have internal combustion engines , which can be roughly divided into:

• Piston engines, in which expanding gases during fuel combustion force the piston to move, which in turn drives the crankshaft of the car;

• In rotary engines, the same gases drive a rotating part, the rotor itself.

If you go deeper, there are a large number of types and subtypes of engines. Based on the type of fuel, engines can be divided into diesel, gasoline, gas and gas generators.

There are also gas turbine internal combustion engines, electric, orbital, rotary, rotary-vane, etc. Today, the most common is the piston internal combustion engine.

Engine management system and electrical equipment

The main elements of a car's electrical equipment include:

- rechargeable battery (or just battery)

- engine management system

- wiring

- alternator

- consumers of electricity itself

The rechargeable battery (AKB) is primarily designed to start the car engine itself. The battery is a permanent renewable source of energy. If the engine is not running, then it is thanks to the battery that all devices powered by electricity operate.

The generator is needed to constantly recharge the battery, as well as to maintain constant voltage in the on-board network.

Engine management system

consists of various sensors and an electronic control unit, which is abbreviated as ECU.

The electricity consumers mentioned above are:

- ignition system

- engine starting system

- tail lights

- headlights

- electric window lifts

- windscreen wipers

- as well as other electronic devices

We must not forget about the electrical wiring, which consists of a large number of wires. These wires make up the on-board network of the entire car, which connects together all sources, as well as consumers, of electricity.

Rigidity

Rigidity is the property of a car body to resist dynamic and static loads during operation. It directly affects handling.

The higher the stiffness, the better the car's handling.

Rigidity depends on the body type, overall geometry, number of doors, car size and windows. The fastening and position of the windshield and rear windows also plays an important role. They can increase stiffness by 20-40%. To further increase rigidity, various reinforcement struts are installed.

Hatchbacks, coupes and sedans are considered the most stable. Typically, this is a three-volume layout that has additional partitions between the luggage compartment and the engine. Insufficient rigidity is shown by station wagon, passenger, and minibus bodies.

There are two stiffness parameters - bending and torsion. For torsion, resistance is checked under pressure at opposite points relative to its longitudinal axis, for example, when hanging diagonally. As already mentioned, modern cars have a solid monocoque body. In such structures, rigidity is provided mainly by side members, transverse and longitudinal beams.