Today we will get acquainted with the stove and its structure on a VAZ 2110 car.

As you know, the heating system has a direct impact on the level of comfort. If in summer there is no special need for interior heating, then in autumn and winter it is problematic to imagine traveling without it. Theoretically, you can drive, but lower temperatures are unlikely to benefit your health.

Dismantling the heater

Device

Periodic malfunctions in the operation of the heating system for the VAZ 2110 are an ordinary and common thing. Therefore, the owners of this model from the Russian automaker have to dig around in their own garage every now and then or send the car for repairs to specialists from service stations.

Heater circuit diagram

To understand exactly how to carry out repair and preventative measures, you first need to familiarize yourself with the diagram of the stove and its components.

Element

Peculiarities

A fan is mounted on it. Both elements contribute to the injection of heated air into the cabin

The entire operation of the heating system is based on this component. Remove the radiator and the heater will not work. Interestingly, the new model stove does not have a valve that shut off the flow of coolant through the radiator. Older devices have a faucet. The faucet was removed in order to avoid leaks, which were common on old stoves. Plus, they got rid of the tap for faster and more efficient heating of the interior. Although many owners of new tens do not agree with this decision, therefore, during repairs, they install a faucet on the stove

In total, the stove has three of them. The first is responsible for air intake recirculation, the second is for opening and closing the heater duct, and the third is intended for control and is considered the most important

This element is responsible for the speed of blowing hot air into the cabin.

All elements, including additional valves, shields, fittings, are combined into a single unit. It, enclosed in a housing, is located in the engine compartment near the dashboard.

Air ducts

Air ducts are another block of the heating system. They come from the stove and perform several different functions at once:

- The interior is ventilated through central nozzles;

- Distribute the air through an appropriate distributor that supplies heat or air for ventilation;

- Another pair of air ducts serve to heat the rear row of seats;

- The system, which includes five nozzles at once, warms the feet;

- A pair of side air ducts take over the functions of heating the glass and partially heat the interior. This makes heating more efficient;

- A pair of nozzles are used for ventilation.

Electronic stove control

This electronic control unit operates directly from the passenger compartment. It consists of two main elements.

- Pen. Using the controller knob, the user sets the required temperature, which the stove then generates. Control is carried out by turning the knob in one direction or another, depending on what degree of heating you require at the moment.

- Temperature sensor. It is responsible for activating the stove when the temperature drops by more than 2 degrees compared to the value set on the controller. The sensor is equipped with a micro motor. When the handle is in position A, the micromotor in the stove block turns on, the damper is activated, thereby causing proper heating.

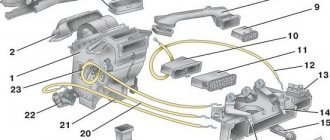

Control block

Before starting repairs of the entire stove, it is strongly recommended to check the condition of the sensor. You can find it near the heater lamp on the ceiling of the car. The device cannot be repaired. Replacement only.

How to repair the heating system of a VAZ 2112

An indispensable device for any car in cold weather is the stove. Sometimes it is necessary to replace the radiator heater on a VAZ 2112 with all the elements. The interior of the VAZ 2112 has built-in supply and exhaust ventilation. Air enters the cabin through special holes made in the windshield linings. Air can be supplied spontaneously or forcefully. In the second case, the supply is provided by the heater fan. It can exit the passenger compartment through cracks between the panels located inside the doors and holes in their ends. Built-in valves allow air to pass out and prevent it from getting in, which improves thermal insulation in the cabin. If necessary, the heater radiator preheats the air before entering the cabin.

What are the features of the VAZ 2112 heater radiator?

- The heater radiator of a VAZ 2112 car is located in a plastic casing under the dashboard in a horizontal position.

- The design consists of two rows of tubes made of aluminum with two plastic tanks pressed onto them. On the left there are two fittings: one for draining, the other for supplying coolant.

- The position of the dampers regulates the flow of part of the air that is taken in by the radiator. Its main flow passes by the radiator. If the damper is in its extreme positions, no air flows at all.

- A design feature is the absence of a tap, which should shut off the flow of coolant, which ensures constant heating of the heater radiator when the engine is running. In this case, the required temperature in the cabin is achieved faster, and the absence of a tap reduces the number of joints, places that can leak and create a lack of tightness in the entire system.

Dismantling the heater radiator of a VAZ 2112 car

If the heater radiator leaks, it must be replaced. Replacing the heater radiator in a VAZ 2112 begins with dismantling the entire dashboard and steering column. The work must be carried out carefully, which is due to the manufacture of most connectors from fragile plastic latches and clamps that can easily be broken. The radiator can be removed without dismantling the panel. Replacing the heater radiator on a VAZ 2112 is easier to do with the evaporator removed, but this requires preliminary depressurization of the main air conditioning system and removal of the refrigerant. The radiator removal instructions suggest:

Disconnect the battery.

- Disconnect the hoses installed on the heater bulkhead from the engine compartment side.

- Push the rubber seal on the partition into the interior of the cabin. To do this, you need to disconnect the edges of the seal from the edges of the hole in the partition.

- Remove the cover, the ashtray, the receiver, for the center pillar, and the front panels.

- Remove the heater and air conditioning control panel.

- Remove the electronic control unit without disconnecting it from the connector block.

Dismantling the control unit of a VAZ 2112 car

- Unscrew the bolts securing the left pillar to the base of the body and the bolts securing the ground wires; you do not need to completely remove the pillar.

- Unscrew the bolts that hold the right strut, then it is removed from the car.

- Use a Phillips screwdriver to unscrew the self-tapping screws that secure the stand to the front plastic panel from its reverse side.

- Remove the central air duct duct.

- Above the heater core, slightly shifted forward, there is a dividing damper, which must be removed along with the air duct section to increase the working space.

- Loosen the nuts on the studs that secure the left side of the evaporator housing.

- Unscrew the nut on the stud located near the upper pedal lever for controlling the throttle valve.

- Remove the bolts holding the lower right corner of the heater housing.

- Remove the heater lugs from the studs.

- Move part of the air conditioner evaporator housing to the side.

- Remove the heater from under the front panel; its general appearance is shown in the photo.

General view of the heater of the VAZ 2112 car

- Remove the clamps holding the heater pipes to the housing.

- Remove the radiator from the housing.

Design Features

For the VAZ 2110, it is possible to install two types of stoves - new and old. Regardless of the engine used (injection or carburetor), there are no fundamental differences in the designs of the stoves.

But what is the difference between the new and old type stoves? Let's try to figure it out.

- Radiator design. This is the main difference between the devices. Therefore, when replacing a radiator from an old one to a new one, be sure to take into account the installation nuances;

- The controller knob on stoves is slightly different. Old-style heaters have a main problem - they have been discontinued. They cannot be an analogue for 4 and 5 position controllers, which began to be equipped with dozens of them in the fall of 2003;

- The micro-gear motors for the stoves are different, starting in September of the same 2003. The difference lies in the shaft position sensors (resistors). Therefore, when making repairs, make sure that the devices are truly interchangeable and that you bought old-style resistors for your old stove, not new ones. Otherwise the gearmotor will not work.

Differences in design

The VAZ 2110 was equipped with stoves of the so-called new or old model. Both systems, including those on the VAZ, which has an injector instead of a carburetor, are not particularly different in design.

So, the immediate differences:

- The main difference between the new stove and the old one is in the design of the heater radiator. Therefore, if you are repairing a heating system and decide to install a new model instead of an old radiator, then take into account some nuances;

- In addition, the SAUO controller is also not exactly like that. 4 or 5 position controllers manufactured before the fall of 2003 have already been discontinued and are not suitable for new heater models;

- The micro-gearboxes are also different, starting from release in September 2003. They differ in resistors (shaft position sensors), so you need to check whether the resistor in the MMR model that you purchased is interchangeable.

MMR of the old type MMR of the new type

If you are planning a major overhaul of the stove, especially if you still have an outdated system, start by purchasing a new stove radiator (it is better to buy a copper one, it heats much better), and this will only improve the performance of the heater.

But the design of the VAZ injector stove is practically no different from carburetor cars.

The following is a breakdown of the following points:

- The engine block has a plug from which antifreeze is drained into some container;

- The frill is moved forward a little (a lengthy operation), the windshield wipers and everything that gets in the way are removed;

- The heater housing is removed. You should know that the body is divided into two parts. The front one is removed along with the fan;

- Next comes the cabin filter housing. It can be changed at the same time;

- The other part of the fan housing is removed;

- The clamps are loosened, the hoses are removed;

- Then, with some effort, the radiator is removed.

Assembly, as they say, is in reverse order. Just one more nuance: if you have an outdated stove, then pay attention to two points:

- When installing the plastic case, make sure that the pedal fits into the desired groove;

- Knowing the structure of all components, be sure to double-check their tightness.

Before adding antifreeze, do not forget to make sure that the engine block has a well-tightened plug. Be sure to make sure that the entire system is running smoothly and more efficiently than before.

Repair

As we have already noted, the design of stoves on dozens with carburetor and injection engines has practically no differences. Therefore, the repair instructions below are suitable for owners of a VAZ 2110 with both types of power units.

If you are planning to overhaul your old-style stove, we recommend starting with the purchase of a radiator. Use copper as it is more efficient and helps the heater work better.

To carry out repairs correctly, strictly follow the points presented in our instructions and rely on video materials.

- There is a plug on the engine block through which coolant is drained into any container. If you plan to use the same antifreeze or antifreeze again, choose clean containers.

- Next you need to move the frill forward. This process will take quite a long time, so be patient.

- Next, you need to remove the windshield wipers and get rid of as much as possible of everything that could interfere with the repair process.

- Remove the body of your stove. It is divided into two parts, which is important to know in advance. The front part of the stove body is removed directly along with the fan.

- After this comes the stage of dismantling the cabin filter. Check its current status. If the filter is dirty, this is an excellent reason to replace it.

- The next stage involves removing the second part of the housing.

- Loosen the clamps used on the hoses a little. This will allow you to easily remove the hoses.

- Having applied some effort, you can now finally remove the radiator from its seat.

The design and principle of operation of the cooling system of the “tens” engine.

Any cooling system is designed not only to cool parts, but also to perform some other functions, namely:

- ventilation and air conditioning, heating the air in the heating system;

- cooling air in the turbocharger;

- cooling the working fluid in the automatic transmission;

- cooling the lubricant, or rather the oil in this system.

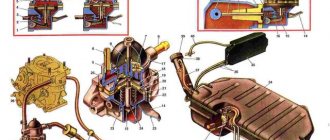

Design of the cooling system of the VAZ 2110 injection engine.

- Heater radiator

- Heater radiator steam hose

- Outlet hose

- Supply hose

- Coolant temperature sensor (in the cylinder head)

- Pump inlet hose

- Thermostat

- Charging hose

- Expansion tank plug

- Coolant level indicator sensor

- Expansion tank

- Outlet pipe

- Carburetor starter fluid chamber

- Radiator outlet hose

- Radiator inlet hose

- Radiator steam hose

- Left radiator tank

- Electric fan switch sensor

- Fan motor

- Electric fan impeller

- Right radiator tank

- Drain plug

- Electric fan shroud

- Timing belt

- Coolant pump impeller

- Coolant pump inlet pipe

- Coolant supply hose to throttle body

- Coolant drain hose from throttle pipe

- Exhaust coolant temperature sensor

- Radiator tubes

- Radiator core

The principle of operation of the cooling system of an injection engine.

If we talk directly about the cooling system of the VAZ 2110, then it is liquid, its circulation occurs forcibly, and is filled into the expansion tank.

The basis for creating the liquid used in this system is water combined with ethylene glycol. Such a liquid can freeze only at the lowest possible temperatures, and also create an elevated boiling point. By adding various additives to it, you can increase the service life of the oil seal, as well as slow down the process of corrosion of the system itself. Full filling of liquid requires the latter in a volume of 7.8 liters.

The movement of liquid throughout the cooling system of the VAZ 2110 injector is ensured by a centrifugal pump, which is fixed in the cylinder block and is activated by the timing belt.

As you know, the liquid gradually heats up from the friction of the working surfaces of the parts. And depending on the reached temperature of the liquid, the cooling system initially circulates in a small circle, and after heating it begins to move in a large circle. That is, when a certain heating point is reached, the thermostat is triggered, after which it opens and changes the direction of movement of the liquid. This process is already regulated by a pair of valves located in this thermostat. In it, the bypass valve regulates the movement of coolant in a small circle, and the main valve in a large circle. Thus, when one of these valves opens, the other closes, and vice versa.

Until the engine warms up well, the bypass valve is in the open position, and the coolant flows in a small circle through the cylinder block, throttle valve and heater radiator. This heating radiator is built directly into the engine cooling system, therefore, when liquid passes through it, the car interior is heated.

At the moment when the coolant is heated to 85°C, the main thermostat valve begins to open when the bypass valve closes. At this moment, the coolant flows simultaneously through both the small and large circles. And already at 102°C, the liquid enters the radiator, flowing only in a large circle. There, thanks to the flow of air from the outside, it is cooled.

It turns out that the injection system of the VAZ 2110 engine is designed in such a way that if the air flow does not cool the liquid well, then the fan is automatically turned on using a signal from the electronic control unit. And in the case of strong heating of the liquid, its volume begins to increase, and then its excess returns back to the expansion tank. This tank contains a valve that maintains the required pressure in the system.

It is necessary to monitor and check the coolant level only when the car’s power unit is cold. If you notice a regular decrease in it, be sure to check the entire system for leaks. Well, a complete replacement of the coolant in the VAZ 2110 injector must be done every 75,000 kilometers.

Car heating system design

The design of the heating system on the "ten"

Where is the VAZ heater control unit, heater tap, micromotor gearbox and other design elements of the old and new design, how to turn the heater on and off? First, let's talk about the device. As practice shows, owners of “ten” cars usually repair heating systems and other inoperative components of the car on their own.

Therefore, first you need to consider the design of the stove; below is a description of the main elements of the old and new-style systems:

- The VAZ 2110 stove is controlled by an electric motor. The VAZ 2110 heater fan is installed on the latter. These components are designed to pump hot air flow into the car interior.

- The next element of the circuit is the radiator, on which, in principle, the entire operation of the heating system is based. Without it, the operation of the unit will be impossible. It should be noted that the stove valve on the new model version is missing - it was dismantled in order to prevent possible leaks that often happened on old systems. In addition, removing the tap allowed the interior to be heated more quickly and efficiently. However, many “ten” owners today do not agree with such an engineering solution. Therefore, often, when tuning and modifying the VAZ 2110 stove with their own hands, “VAZ drivers” install the faucet back on their car.

- The stove on the VAZ is equipped with three dampers. One of them is responsible for air intake recirculation, the second ensures the opening and closing of the heating duct, and the third is necessary for controlling the system.

- The additional resistor of the VAZ 2110 heater (resistance) is essentially a regulator responsible for changing the speed of air flow inside the car.

Heating unit for VAZ 2110

As for secondary elements, such as valves, fittings, rheostat, shields, they are combined into one unit, installed in the body and located in the engine compartment. It can be found next to the control panel.

An equally important block of the heating system on any stove, including the VAZ 2110, are the air ducts that come from the unit and perform the following tasks:

- ventilation of the vehicle interior;

- air flow distribution via switch and distribution device;

- two air ducts serve as heating for the rear seats;

- five air ducts perform the function of heating the feet;

- On the sides there are air ducts designed to heat the windows and interior;

- Several more elements are designed for interior ventilation.

Air Ducts and Heater Controls

The electronic control system for the VAZ stove is located directly in the car’s interior and consists of several components:

- The switch itself. Using the knob, you can switch and set the desired temperature. The switch is adjusted by turning the knob to the right or left in accordance with the needs of the motorist.

- Temperature regulator. This element is designed to automatically turn on the heating system if the air temperature in the cabin drops by more than two degrees compared to the set parameter. The heater motor begins to function to heat the interior to the desired temperature, and the regulator itself is equipped with a micromotor. When the switch is set to position A, the micromotor is automatically activated, the damper is turned on, as a result of which the interior begins to heat up.

The main reasons for poor operation of an electric furnace

Before you can directly begin to find a solution to a problem, you need to be able to identify it quickly and effectively. First, it is advisable to consider the general structure of the furnace. So, the heater furnace consists of the following components:

- mounting block fuse;

- incendiary lock;

- ignition switch together with its unloading relay;

- a special switch that regulates the operating mode of the furnace electric motor;

- additionally built-in resistor;

- stove motor;

- heated rear window of the car, which contains a heater adjustment button with a light indicator;

- a special functional element for heating glass.

VAZ 2110 stove wiring diagram

One of the reasons for the malfunction of the electronic circuit of the furnace may be the lack of functional activity of the heater electric motor at both low and high speeds. In this situation, you must proceed as follows:

- First you should make sure that the fuse has not accidentally blown;

- If a blown fuse is detected, it will urgently need to be replaced with a new one.

Note. Before proceeding directly to replacing the old fuse with a new one, it is necessary to first and without fail establish the cause of the burnout. If this is not done, the service life of the new fuse will most likely be short.

- There may also be a break or damage to the wiring at the point of its connection;

- to eliminate the above reason, it is necessary to check the electrical circuit according to the furnace diagram;

- after which, it is necessary to eliminate the impulse, if it took place;

- if the heating switch does not function, then the most likely cause is a stuck pusher or burnt contacts;

- to accurately diagnose a switch malfunction, you need to check the voltage level at the side terminals while changing the position of the switch in space (to do this, it is enough to apply current to the main terminal);

- if during diagnostics a change in voltage is not detected when changing the position of the switch knob, then it must be urgently replaced;

- there are a huge number of possible reasons for the electric motor to fail to operate: broken electrical connections or armature winding, immobilized cleaning brush, oxidation and/or contamination of the armature commutator;

VAZ 2110 heater radiator diagram

- It’s not difficult to revive the movements of the brush again; just disassemble it and then clean it;

- restoring the wires will also not be difficult, because the main thing is to find the location of the defect;

- if several of the above provisions do not produce results, then there is only one way out - a complete replacement of the heater electric motor;

VAZ 2110 stove electrical diagram

- sometimes, which is extremely rare, the cause of the malfunction may be the mounting block;

- There are many reasons for the faulty state of the mounting block, but the main ones are: at the soldering site, a complete or partial break in the electrical circuit, fire of current-carrying paths;

- The circuit should be checked according to the furnace diagram, otherwise it will simply be impossible to detect breaks and faults;

- the final practically probable cause may be an internal break in the circuit of the auxiliary (additional) resistor (see How to replace the heater resistor on a VAZ 2110);

Operating principle of the stove

As for the operating principle, it is partially described above. As you know, a temperature controller is installed on the stream, designed to send information about the temperature, after which the heating system control unit activates the operation of the stove gear motor. The latter is responsible for opening or closing the damper, which is responsible for supplying air flow into the cabin. Further adjustment of the flow is carried out when the controller detects a change in temperature (video author - Fire Screen - Live).

Car chip tuning

Chip tuning is nothing more than reprogramming the engine control system. The entire farm is managed by a special controller. Changes in the operation of electronics are achieved by either completely replacing the memory chip or reprogramming it. This controller has been calibrated at the factory to the average machine performance. To be able to influence various characteristics, fuel consumption and much more, just change the calibration.

Programmers and electronics engineers who deal with these problems have created the necessary programs for chip tuning. Some of the most popular calibration settings are “sport” and “economy”. The first is designed for dynamic driving in the city or on the highway, with a slight increase in fuel consumption. The “economy” mode allows you to drive a car in city conditions more economically.

Typical faults

Below are the main malfunctions of heating systems:

- When the heating is turned on, hot air blows. In this case, there may be many reasons. It is necessary to diagnose the heater motor, gear motor, temperature controller on the ceiling, and the ACS controller. In some cases, the problem lies in the radiator, which, due to incorrect operation, cannot warm up the air flow that passes through it.

- Often the cause of incorrect operation of the heating system is dampers that are unable to open or close well. Since the damper is made of plastic, it tends to deform over time; in this case, installing a metal damper will solve the problem. To understand the condition of this element, you simply need to dismantle the deflector. Turn on the heating and try turning the controls - if the damper does not respond to your actions at all, then you need to look for the problem further.

- Fan failure can be determined by the absence of characteristic noise. But if there is no noise, the problem may be a failed fuse or oxidized wiring contacts. In order to get to the fan, you need to dismantle the so-called apron.

- In the engine compartment there is a radiator for the heating system, next to the fan. To remove the radiator, the fan will also need to be removed. If the radiator begins to leak, you will be able to see puddles of coolant under the floor mats; sometimes this problem is caused by bad clamps. One way or another, it is necessary to determine the location of the leak and solve the problem to restore the system's functionality.

- Many owners of "ten" are faced with such a problem as the lack of backlight on the heater control panel. Car enthusiasts associate the lack of lighting with stove malfunctions, but this is completely wrong. If there is no backlight, this may only be due to the wiring (video author - Aleks B).

Heater fuse

As you know, to protect electrical circuits from short circuits or overloads, a special fuse is used, which in case of any problems blows and de-energizes the circuit.

This device protects the power supply circuit of the heater motor; if overloaded, this fuse blows, which completely disables the interior heater. To get the stove running again, you need to replace the fuse with a new one, but to do this you need to know where it is.

Where is

The heater fuse is located in the fuse block under number F18 and has a rated current of 25A. It is necessary to install only a fuse of the same rating to avoid damaging the circuit in the event of a short circuit or overload.

DIY repair

Regardless of whether you have an injection “ten” or a carburetor, the repair procedure is carried out according to the same principle. If you decide to tune the system by adding new lighting, then the console will have to be disassembled. To provide improved illumination, it will be necessary to install diode bulbs instead of conventional lamps.

As for repairs, if it is necessary to replace the radiator, it is best to use a copper device, since it is more effective in itself:

- First, the antifreeze must be drained from the system through a special plug on the engine block.

- Then you need to move the frill forward - this step may take some time.

- Then you should dismantle the windshield wipers, as well as other elements that may interfere with the repair.

- After these steps, the housing of the heating system is removed - it is divided into 2 parts, the front one is dismantled with the fan itself.

- Next, you should remove the cabin filter element and check its condition. If you see that the filter is very dirty, then it should be changed.

- Then the second part of the heater housing is dismantled.

- Now you need to loosen the clamps on the pipes, after which you can remove the lines themselves.

- The last step is to remove the radiator and replace it with a new one. Subsequently, all steps must be repeated in reverse order for assembly.

Sorry, there are no surveys available at this time.

Common faults

Most often, the VAZ 2110 suffers in terms of heating because the heater adjustment, as they say, does not work. Regardless of the selected position of the temperature control knob, only cold or, conversely, only hot air blows from the heater.

The reasons for this phenomenon may have different origins. Among them:

Jamming of the MMR (micromotor-reducer) that controls the damper drive; The plastic damper (the first VAZ 2110 was equipped with these) has a destroyed seat, and due to jamming it is impossible to control it normally. If the gearbox is working, but the damper does not turn, you can most often hear peculiar clicks - this is the square shaft turning in the socket. For such a malfunction, there is only one treatment - replacing the old plastic damper with foam insulation with a new one. Better, more modern, metal, with a rubber seal

This one does not warp or warp like its plastic sister; To finally decide who to blame - the damper or the MMR, you still need to pay attention to its control unit. He is also among the “suspects”.

Video “Instructions for dismantling the heater radiator on a VAZ 2110”

How to replace the heater radiator on a domestic “ten” at home, see the video below (the author of the video is NlCKRUS).

On the VAZ 10th family, which includes the VAZ 2110-2112 models, the designers used an electronically controlled interior heating system, thanks to which the temperature set by the driver is maintained automatically.

On the VAZ-2110, instead of a manual heater control mechanism with a cable drive of the main elements - the coolant shut-off valve and dampers, an automatic heater control system (AHC) controller with a temperature sensor and a gearmotor that regulates the position of the dampers are used.

In such a stove, the valve for shutting off the antifreeze supply is no longer used, and the adjustment of the heater operating mode - “heating” or “ventilation” - is carried out by a central damper, which directs the air flow through the radiator or bypassing it.

VAZ 2110 heater blows cold, why?

Many owners of the “ten” complain that at some point the stove constantly blows cold air and no amount of turning the handles of the automatic heater control system can save the situation. There can be a lot of problems and malfunctions. For example, the ACS controller itself is faulty, the ceiling sensor or micro-geared motor is faulty and simply does not open or close the damper. Another reason is the air (air lock) in the heater radiator, which is simply not capable of heating the air passing through it. Below is a schematic representation of the VAZ 2110 heater device .

Heater dampers VAZ 2110

Often the cause of poor performance of the “tens” heater is the damper of the VAZ 2110 heater . The damper may not close tightly or open poorly. The heater flap itself is made of plastic, which can become warped and perform poorly over time. Many car owners buy a metal damper and change it themselves. How to check the functionality and evaluate the condition of the heater damper? Everything is quite simple, remove the central air duct deflector and there you have it - a damper! Let's look at the photo.

Next, carefully inspect the damper, turn on the stove, turn the controls on the ACS unit and see if the damper works at all. How does it move, does it fit tightly. If she does not respond to commands, then the problem may not be her at all. For one thing, you can see if the lever for redirecting the air flow from the glass to the feet works.

Heater fan VAZ 2110

It is quite simple to determine the performance of a stove fan by looking at the noise. If the fan motor burns out, then it naturally will no longer work. However, before rushing to change the stove fan, you need to make sure that the fuse has not blown. As we already wrote above, the fan of the VAZ 2110 stove is located not in the cabin, but in the engine compartment. To get to it, you will need to remove a special apron that separates the engine compartment from the heater housing, vacuum brake booster and windshield wiper mechanism. The actual photo is below for clarity.

How malfunctions manifest themselves

The automatic temperature maintenance system used on the VAZ-2110 is more convenient in terms of control, since the automatic control system does everything independently, but is less reliable than a mechanical cable drive. Moreover, problems are caused by the electronic and electrical components of the stove - the controller, temperature sensor and micromotor gearbox, the central damper, which regulates the air supply to the cabin from the outside.

Problems with the operation of the VAZ-2110 heater related to the damper:

- lack of temperature control (only hot or cold air comes from the stove) regardless of the position of the handle on the controller;

- insufficient air heating (even when setting the handle to the maximum temperature);

- squeaks, knocks and extraneous noises after setting the temperature.

The cause of such problems is the central damper of the VAZ-2110 stove, which is adjusted by the controller through a gearbox. The design of the stove includes another damper - air distribution into zones. It is controlled using a handle mounted on the central air supply deflector into the cabin, so malfunctions with this part are rare.

Where does the noise in the top ten come from?

The main sources of noise in the cabin of the 2110 and methods for eliminating them, schematically, are given below:

- noise from the engine compartment can be eliminated by insulating the engine shield and floor with special materials, of which there are plenty on sale;

- noise from wheels and from road gravel and dust can also be removed in several ways - with noise-insulating mastic, plastic fender liners coated with Bimast, or the combined use of both;

- Aerodynamic noise is the most difficult to eliminate, since in this case you will have to set all the gaps between the body panels and the hood, doors, and wings to their nominal value, and this is not so simple and not so effective.

Features of the design of the VAZ - 2110 stove damper

Note that VAZ-2110 of different years of manufacture uses heaters that differ in design:

1. Old-style stove damper

Old heaters use two central dampers, one of which blocks the flow of air into the cabin from the outside, and the second one redirects the air flow to the heater radiator or bypasses it. They are interconnected by drives and opened by a micromotor gearbox.

2. New sample

Principle of operation

The operating principle of such a control system is simple - the driver uses the left handle to set the desired temperature (completely cold or in the range from 16 to 28 degrees). Based on the set mode, the controller supplies power to the micromotor gearbox and it sets the dampers to the desired position.

Two-way communication is used between these elements - a position sensor is installed on the gearbox, which “informs” the controller about the opening angle. Thanks to the installed temperature sensor (located on the ceiling), the controller constantly monitors the degree of heating of the air in the cabin, based on which it adjusts the position of the damper to maintain the temperature set by the driver.

Causes of malfunctions

Depending on the design of the stove, the damper may cause a disruption in the efficient operation of the heater for the following reasons:

- deformation;

- wear of seals;

- deterioration or damage to control levers and rods;

- skew.

Deformation is a problem with old-style heaters. The first dampers of the VAZ-2110 stove were equipped with plastic elements that bent under the influence of temperature. Because of this, even when completely closed, cold air from outside leaks in and mixes with the heated air, and the efficiency of the stove decreases. Subsequently, the designers replaced the plastic flaps with aluminum ones and the problem with deformation disappeared.

To ensure tightness, the dampers have seals that reduce air leakage. Initially, foam rubber seals were used, which quickly wore out and became damaged. Later, foam rubber was replaced with rubber, but this only extended the service life of the seal; over time, the rubber ages, cracks and collapses.

On old-style stoves, rods and levers may break. On new heaters, there is another problem - wear on the edges of the square end of the gearbox, with which it is inserted into the groove made in the damper axis. As a result, the limit switch bypasses the groove, and the heater damper jams, although the gearmotor operates. The misalignment occurs due to the displacement of the damper axis in the mounting holes of the housing. Because of this, the damper warps and jams when opening.

Other reasons

The problems associated with stove control are described above. But the stove may not work or not function efficiently enough for other reasons:

- the appearance of an air lock in the heater radiator;

- radiator clogged;

- severe wear or breakdown of the fan motor;

- malfunction of the rheostat block of the control mechanism;

- damper deformation.

These malfunctions affect the performance of the stove. On the VAZ-2110 they occur less frequently than control system breakdowns, but they should also be taken into account. To identify the reason for the cessation of normal operation of the VAZ-2110 stove, determine why this could have happened. If the fan does not work, then to fix the problem, check it, the rheostat unit and the power circuit.

The stove blows cold air - the reason lies in the stove radiator (clogged, a plug has formed in it) or in the dampers (jammed in a position where the air flow bypasses the radiator).

The stove heats poorly and it is not possible to adjust the temperature - check the functionality of the controller, micro-reducer and temperature sensor.

To identify the cause and eliminate the decrease in stove productivity, move “from simple to complex.” First, check the functionality of the system elements located in the cabin (controller, temperature sensor), and then climb under the hood to diagnose the operation of the gearbox, dampers, and fan motor.

Diagnosis of the problem

If the reason why the VAZ-2110 stove does not work is the damper, it is not difficult to identify it. To do this, disassemble the central deflector, turn on the ignition and rotate the temperature setting knob to its extreme positions. In a working stove, the central damper will not knock and will completely open and close the air supply channel.

If the heater damper does not move or stops in a position that does not completely block the air passage, it may be stuck. You can verify this by pushing the valve with your hand or a long rod. If after this the damper returns to its normal position, then this is the reason why it is jammed. Through the mounting hole of the deflector, you can assess the condition of the damper and its seals. If the damper is deformed, its bend is clearly visible.

Step-by-step replacement process

- First, remove the doors, seats, bumper and front fenders. Also remove carpets, seat belts and sound insulation.

- Protect your car windows. Sparks from grinders and welding can damage them. It is also advisable to cover the doorway with cardboard so that nothing gets into the interior.

- Disconnect the negative terminal of the battery.

- Place the vehicle on a pit or tipper.

- Attach the new threshold and use a marker to mark the lines along which you will cut the old one.

Use a grinder to cut through the previously marked areas.We core all the contact welding points along the edges at the top and bottom of the threshold. Next, we drill out the points, and then use a body knife to separate the metals from each other.

After you have separated the threshold, remove it and evaluate the condition of the bottom, amplifiers and connectors. If necessary, cut off rotten parts of amplifiers, connectors, or remove them entirely.

- Cut out the required pieces from the repair parts and weld them in place.

- Prime all welds and repair inserts with epoxy primer, having previously “filled” the abrasive with a scratch to create conditions for good adhesion of the materials.

- Cut the butt pieces to size and drill holes for welding along the edges at the top and bottom of the threshold.

We clean all welds, grind the threshold with abrasive and apply epoxy primer. - We apply sealant to the non-facial welds, putty on the facial seams and paint. You can also apply an anti-corrosion agent, for example, Body Autoflex, before painting.

- After all the work has been done, anticorrosive the hidden cavities with Movil or Pushsal.

Repair and restoration of the stove damper

The deformed heater damper of the VAZ-2110 cannot be repaired; it only needs to be replaced. In this case, it is better to purchase a replacement metal part that is not so susceptible to temperature effects.

Whatever heater is installed on the VAZ-2110, to carry out repair work, the heater must be completely disassembled. In this case, the process of dismantling and disassembling depends on the design of the stove.

A positive aspect of the heater design on the VAZ - 2101 is its location - to get to it and the dampers you can from the engine compartment and you don’t have to remove the front panel.

Disassembling an old-style stove

For example, let's look at how to disassemble an old-style heater:

- Remove the terminal from the battery.

- We remove the windshield wipers, the seal, remove the air intake near the windshield (“jabot”) from the car, in the process you will need to disconnect the windshield washer nozzle tubes.

- We dismantle the insulation that separates the stove body from the engine compartment.

- We remove the gear motor.

- We divide the housing of the stove and air filter into two halves. To do this, unscrew the coupling bolts around the perimeter of the housings and remove the mounting brackets.

- Disconnect the fan power wires.

- Remove the outer half of the air filter and heater housing (along with the fan).

- We dismantle the inner part of the fan housing.

After this you will have access to the dampers. If you are only planning to repair or replace the heater dampers, there is no need to drain the antifreeze, since the heater radiator will remain in place and will not be removed.

Before removing the dampers, carefully inspect and remember their position and the way they are engaged. Further actions depend on the nature of the damage. Deformed damper parts cannot be repaired and only need to be replaced. As for damaged rods and levers, try to repair them or simply replace them. The damaged seal is replaced.

When assembling the stove, pay special attention to the engagement of the dampers. Do it as it was before disassembly, otherwise the dampers will not work correctly, which will affect the performance of the heater.

Disassembly and repair of a new type heater

The new model stoves are disassembled differently:

- disconnect the battery terminal, drain the antifreeze;

- dismantle the frill and insulation;

- disconnect the power wires of the fan and micromotor gearbox;

- unscrew the fasteners that secure the stove body to the body;

- disconnect the coolant supply pipes to the heater radiator;

- We remove the heater from the car along with the filter housing.

After this, we disassemble the stove body, dividing it into two halves, after first disconnecting the air filter housing and removing the mounting brackets. Next, we change or repair the damper, assemble the heater and install it on the car.

Note that the general algorithms of work are indicated above, but in reality, dismantling the stove is not so easy, since many fasteners are located in hard-to-reach places, sometimes you have to disconnect or remove elements that make it difficult or interfering with the removal of the unit.

Self-repair of the underbody of a VAZ-2110 car

The car body is subject to corrosion over the years, and it begins to rust especially quickly if you do not take care of it and do not apply an anti-corrosion coating. How quickly body parts begin to rust also largely depends on the quality of the iron, factory processing; over time, the car requires repairs to the underbody, sills, side members, wheel arches, and so on.

Rusted sills and a rotten bottom are a fairly common problem on VAZ-2110 cars, and since such work in a car service center is quite expensive, many car owners try to repair the car with their own hands. You can patch holes in the body and bring the car back to normal by yourself using various methods; there are non-welding methods, but basically all car owners try to make repairs using welding.

- When preparing iron for patches, it is necessary to take into account its thickness - metal that is too thin will be fragile, and a thick sheet is poorly welded and is more difficult to process.

- Although electric welding is cheaper to use, it is better to weld metal using a semi-automatic machine - it is easier to use, and the weld is smoother and more accurate.

- When cutting pieces of metal and installing patches, the part being installed must fit exactly in size.

- When replacing the bottom, the weld seam cannot be continuous, since it has high rigidity, and insufficient elasticity negatively affects the strength of the body.

And if you undertake to repair the body with your own hands, you should be patient, carefully, slowly, carry out all the necessary operations, sparing no time and effort on processing the metal and cleaning it from rust. Poor quality preparation and weak anti-corrosion treatment leads to the rapid appearance of corrosion, which negatively affects the service life of body parts.

Device diagram with all explanations

The operation diagram of the VAZ-2110 stove can tell the motorist about the presence of recirculation in it, in other words, moving air flows circulate inside the car without taking new volumes of air from the street. Thanks to this, dust and unpleasant odors, which are present in large quantities in the street air, do not enter the unit. However, it is worth noting the main drawback of such a system - the windows fog up too quickly. Experts recommend opening windows often (at a comfortable temperature outside). Otherwise, the stagnant air will negatively affect the health of everyone involved in driving this car. Due to the complexity of repair, the gearmotor must be completely replaced in case of malfunctions.

Disadvantages of the heater in the VAZ-2110

The main disadvantages, as a result of which car owners are forced to improve and modernize the heating unit:

- Weak air flow to the side mirrors and driver's feet. This problem often occurs during normal operation of the heating unit.

- Often consumers encounter a leak on a radiator device. The unit is equipped with a special tap, which wears out over time and begins to leak coolant. The faucet requires repair, but often the problem can only be solved by replacing the radiator assembly.

- The central air duct of the system includes two parts that are not sealed together. From the radiator device, this blower must supply a heat flow to the feet of the passengers sitting in the rear. If we take into account all the bends, then this is at least 2.5 meters. Of course, the heat flow does not reach the rear passengers.

Symptoms of a heater malfunction

The main signs by which you can identify problems with the heating unit:

- The temperature mode of the heater is not regulated. The problem usually lies in the control unit or in the operation of the heater dampers.

- The sensor located on the ceiling does not function. It is designed to determine the temperature inside the car.

- The heating unit does not function; only cold air flow is supplied to the vehicle interior.

- The side windows of the car or the feet of the driver and passengers are blown with hot air ineffectively.

- The volume of refrigerant in the cooling system decreases. The problem can manifest itself covertly or overtly. In the latter case, a leak can be noticed from the lines of the heating system or radiator device.

- The heating unit functions, but is very noisy.

The channel In Sandro's garage spoke in detail about replacing the electric motor of the heating unit on the "ten".