The main brake cylinder on the VAZ-2106 is necessary to create high pressure in the pipe system and on the calipers. This pressure compresses the brake pads, which lock the discs. The brake system is one of the most important, so it must be maintained in good condition. If there is the slightest malfunction, repairs must be made. Quite often, the cause of a breakdown is the gas turbine engine, but before repairing it, you need to make sure that it is the one that is faulty.

Typical malfunctions of the brake system

Before repairing the master cylinder, make sure that the following problems are not present:

- Very often air gets into the hydraulic brake system. As a result, work efficiency decreases several times. Make sure there is no air at all. To do this, you need to bleed the system.

- Carefully examine all elements of the brake system for leaks. If there are any, then it is necessary to replace the damaged elements and completely bleed the system.

- Jamming of the working pistons or the turbocharger can occur due to uneven wear; the problem is solved by completely replacing the turbocharger.

- If the vacuum seal is broken, the brake pedal will be pressed with very great force.

- If the handbrake cable is jammed, the rear wheels may rotate tightly.

As soon as you make sure that all the above malfunctions are absent, you need to turn your attention to the brake cylinder. The cuffs and pistons may fail, resulting in brake fluid leakage. If the return springs are faulty or broken, the pressure in the system will be constantly high. And if there is fluid leakage on it, braking efficiency decreases several times.

GTZ malfunctions

Replacing the VAZ-2107 master brake cylinder is required when this part simply fails. You can determine the malfunction of the GTZ in the following ways:

The red warning light comes on, indicating a problem with the brake mechanism. This lamp comes on when the level in the brake cylinder reservoir drops below normal.

In this case, it is important to find out the reason for the decrease in fluid and, if necessary, add it. If the leak occurs due to a malfunction of the turbocharger, it should be replaced. Presence of leaks on the GTZ If, upon opening the hood, you can see signs of a fresh fluid leak on the GTZ, then it’s time to pay attention to repairing the mechanism

It is possible to repair the main brake cylinder of a VAZ-2107, but at the same time you can extend the life of the product for a short time, the quality of modern spare parts is to blame. If the product fails, or rather, the cuffs and oil seals have dried out, then experienced craftsmen recommend replacing the GTZ. Many desperate amateurs strive to find the answer to the question of how to repair the master brake cylinder, but subsequently everything ends with its replacement.

The GTZ for a VAZ-2107 costs about 500 rubles, so it makes no sense to spend time and money to repair it. Let’s find out in more detail how the GTZ is replaced with a VAZ-2107.

Features of replacing the GTZ

Replacing the mechanism in question will not take much time, so first you should purchase a new product, and then make sure you have a standard set of tools and a special pipe wrench. This key looks like this:

The list of standard tools includes:

- wrench set to “10”;

- wrench set to “13”;

- flat screwdriver.

Now let's start the workflow. The product is located directly under the hood in the engine compartment on the driver's side. The product looks like this:

- Initially, you should remove the remaining brake fluid from the reservoir.

- It is necessary to loosen the fastening clamps, and then disconnect the hoses of the fluid reservoir from the fittings.

- Using a special wrench, it is necessary to unscrew the threaded bushings that secure the steel tubes to the GTZ.

- Two nuts are unscrewed, with which the cylinder is secured to the vacuum booster housing.

- Now you can remove the device in question.

- After removing the old device, you can install a new GTZ. The protective plug should be removed from a newly purchased device and a new oil seal should be installed in its place. After installing the new product into the seats, it should be secured with fastening nuts.

- We use a clean medical syringe from which the needle should be removed. We fill the syringe with brake fluid and then fill the installed device with it.

- TJ should be poured until it goes into the holes. As soon as the mechanism, or rather, the system, is filled, you can begin screwing the tubes with a special key.

- Taking this opportunity, you can remove and clean the tank for refueling the TJ, if necessary. It’s easy to determine the need; to do this, you need to look inside the tank. If there is sediment, it is better to clean the tank and rubber hoses.

- We fill the reservoir with brake fluid, and then be sure to bleed the system.

This completes the procedure for replacing the main brake cylinder on a VAZ-2107. The procedure is not complicated, so even an inexperienced driver can cope with it. A serious malfunction is solved quickly and inexpensively, and the car owner can forget about this part for 3-5 years

The VAZ master brake cylinder has this name for a reason, so you should pay special attention to it if you detect the slightest sign of a malfunction

Signs of a broken master cylinder

The main signs characteristic of a breakdown of the main brake cylinder on a VAZ-2106 are the following:

- The presence of traces of brake fluid on the vacuum booster and inside it.

- The brakes cannot be pumped.

- Jamming and sinking of the brake pedal.

- The presence of jerks when pressing the brake pedal.

When repairing the master brake cylinder, there is no need to place the car on an inspection hole or overpass. Everything is done much simpler here. The master cylinder can be replaced by simply opening the hood.

But it’s best to pump the brakes on an overpass. Otherwise, you will need to lift the wheels one by one using a jack. If all work is carried out on a lift or inspection pit, you can not only bleed the system, but also at the same time adjust the tension of the handbrake cable.

Which cylinder to choose for installation

A driver who decides to replace the brake master cylinder will inevitably face the problem of choice. Practice shows that the best option is to install an original VAZ cylinder purchased from an official auto parts dealer. The original cylinder number in the catalog is 2101–350–500–8.

However, it is not always possible to find such a cylinder, even from official dealers. The fact is that the VAZ 2106 was discontinued a long time ago. And spare parts for this car are becoming increasingly rare on sale. If this is the situation, then it makes sense to look at the products of other manufacturers of cylinders for the VAZ classics. Here they are:

The products of these companies are in high demand among owners of "sixes", although the price of cylinders from these manufacturers is often unreasonably inflated.

I once had the opportunity to compare prices of brake cylinders from different manufacturers. That was six months ago, but I don’t think the situation has changed much since then. When I went to a spare parts store, I found an original VAZ cylinder on the counter, which cost 520 rubles. Nearby lay a Belmag worth 734 rubles. A little further along were the LPR and Fenox cylinders. LPR cost 820 rubles, and Fenox - 860. After talking with the seller, I found out that original VAZ cylinders and LPR cylinders are in greatest demand among people, despite their high cost. But for some reason the “Belmags” and “Phoenoxes” were not dismantled so actively.

Signs of cylinder failure and checking its serviceability

The driver should immediately check the brake cylinder if he notices any of the following warning signs:

- a light flashed on the dashboard, signaling that the level of brake fluid in the reservoir had decreased;

- the free play of the brake pedal has become longer or the pedal has generally begun to sink into the floor of the cabin;

- braking has become uneven: when you press the pedal, the car pulls to the side;

- it has become more difficult to brake: even if the pedal is completely recessed into the floor of the cabin, the car does not stop completely.

All these points indicate that there is something wrong with the drive cylinder, and you need to figure out this problem as soon as possible. Here's how to do it:

- The first and easiest way to diagnose a cylinder is a routine inspection. If brake fluid leaks are visible on the cylinder body, the problem has been found. When the seals in the cylinder lose their tightness, fluid begins to flow either to the vacuum booster or to the spar under the cylinder. In all these cases, the cylinder will have to be removed and disassembled;

There is another, more complex way to check the cylinder. Let us list its main stages.

- Using a 10mm open-end wrench, unscrew all the contour hoses from the cylinder. In their place, bolts of 8 are screwed in, which will serve as plugs.

How to remove the GTZ?

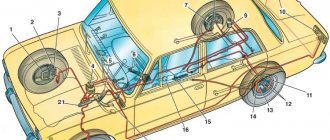

Replacing the master brake cylinder on “sixes” is carried out according to the following scheme:

- Use a bulb to completely drain the fluid from the expansion tank of the brake system.

- Loosen the clamps that secure the hoses coming from the brake fluid reservoir. Please note that if factory compression rings are installed, they may not need to be removed. It is enough to pull the hoses towards you with little effort.

- Using a special wrench, you need to unscrew the brake pipes from the master cylinder.

- Move these tubes so that they do not interfere with the work.

- Using a 13mm wrench, unscrew the two nuts that secure the device to the vacuum booster.

After all this work, you can completely remove the GTZ.

What is needed for pumping?

In order to carry out repairs without problems, you will need a set of standard tools and spare parts

Please note that it is advisable to install new fittings - on old ones the edges wear off very quickly and it is impossible to work with them

For repair you will need:

- A set of wrenches – open-end and socket wrenches for “8” and “10”.

- Balloon.

- Jack.

- Wheel chocks - at least two pieces.

- The supports are several wooden beams.

- Keys to "17" and "13".

- Special wrench “8” and “10” for unscrewing fittings and brake pipes.

You definitely need to purchase penetrating lubricant, prepare a small jar and a transparent tube. The inner diameter of the latter should be the same as the outer diameter of the bleeder fitting.

GTZ repair

To repair the master brake cylinder, you will need to do the following:

- There should be a clean rag on the table on which to place the brake master cylinder body.

- The mechanism has two pistons (that’s exactly how many circuits there are in the brake system). The pistons have slots in the lower parts that limit the stroke inside the cylinder. The pistons are secured using two locking bolts located in the slots.

- Remove the boot and unscrew the bolt that secures the first piston.

- If the piston does not come out under the influence of the spring, you need to lightly press on it so that it sinks a little in the cylinder. After this manipulation, the piston will come out of the cylinder without any problems.

- A similar action is performed for the second cylinder. Unscrew the bolt that secures the element. And in the same way the piston of the second circuit is removed.

- Be sure to place all the elements that you remove from the master cylinder in the order in which you removed them.

- Install new cuffs using the plastic cone included in the repair kit.

The design of the master brake cylinder on the VAZ-2106 is simple, there are only a few key elements in the design. But they affect the functioning of the entire braking system.

Be sure to make sure that the inner surface of the cylinder is perfectly mirror-like. If there are sinks or other damage, it is necessary to replace them - repair is useless. If the inside has taken the shape of an ellipse, then it is unlikely that you will be able to bleed the brake system, and even if you do, the new cuffs will not last long.

Replacing the master cylinder of the VAZ 2106 brakes

In the vast majority of cases, replacing the cylinder is the best repair option. The fact is that it is not always possible to find individual parts of brake cylinders (pistons, return springs, spacers, etc.) on sale. It is much more common to find sets of seals for cylinders on sale, but the quality of these seals sometimes leaves much to be desired. In addition, they are often counterfeited. That is why car owners prefer not to bother with repairing the old cylinder, but simply install a new one on their “six”. To do this, we will need the following tools:

- set of spanners;

- pliers;

- flat screwdriver;

- rags;

- medical syringe;

- canister of brake fluid (capacity 0.5 liters);

- 5 x 6 bolts (they will be used as plugs for the brake hoses).

On my own behalf, I can add that recently even original VAZ repair kits for seals for the master cylinder have become of very mediocre quality. Once I purchased such a kit and installed it in the leaking cylinder of my “six”. At first everything was fine, but six months later the leak resumed. As a result, I decided to buy a new cylinder, which is still in the car to this day. Three years have passed, and I have not yet noticed any new brake fluid leaks.

Sequence of work

When starting to replace the master cylinder, you should make sure that the car engine is completely cool. In addition, all brake fluid should be drained from the reservoir. The most convenient way to do this is with a medical syringe (if you don’t have one at hand, a medical bulb will do). Without these preparatory measures, it will not be possible to change the cylinder.

- Use an open-end wrench to unscrew the fastening nuts on the brake hoses. The hoses are carefully removed from the cylinder body. 8 bolts are screwed into the vacated sockets. They will serve as plugs and will not allow the brake fluid to leak out when tilting and removing the cylinder. The brake hoses are also sealed with 6mm bolts to prevent leakage.

Video: changing the brake cylinder on a “classic”

Disassembling the cylinder and installing a new repair kit

If the driver decides to do without replacing the cylinder and change only the sealing collars, then the cylinder will have to be disassembled. The sequence of actions is listed below.

- First, use a screwdriver to remove the rubber seal located in the cylinder body on the side of the mounting flange.

- Now the cylinder should be placed vertically in a vice. And using a 22-mm open-end wrench, slightly loosen the front plug. Use a 12 wrench to unscrew the limiting bolts located next to it.

Video: replacing the repair kit on a classic brake cylinder

Master Cylinder Assembly

Assembly is carried out in reverse order. If you have repaired the main brake cylinder of a VAZ-2106, then you must:

- Install new cuffs.

- Insert the secondary circuit piston and return spring into the cylinder. Before installing them, lubricate the inner surface of the cylinder with brake fluid.

- Secure the position with a bolt.

- Insert the primary circuit piston with the return spring and secure its position with a bolt.

After this, check the tightness of the fixing bolts and install the cylinder:

- Using two nuts, tighten onto the vacuum booster studs.

- Screw the tubes to the GTZ.

- Install the hoses and secure them with clamps.

After all the work has been done, you need to pour liquid into the expansion tank.

Where is the brake cylinder of the VAZ 2106

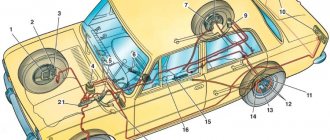

The brake master cylinder is installed in the engine compartment of the VAZ 2106, above the engine. The device is located about half a meter from the driver. Just above the cylinder there is a small expansion tank into which brake fluid is poured.

The brake cylinder is attached to the vacuum booster

The cylinder has an oblong shape. The body is made of high quality steel.

The brake cylinder has an oblong shape and a mounting flange with two holes

The housing has several threaded holes for screwing in contour brake pipes. This device is screwed directly to the brake booster using two 8mm bolts.

Main function of the cylinder

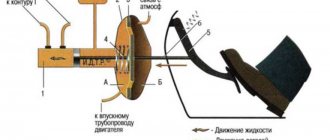

In short, the function of the master brake cylinder is reduced to the timely redistribution of brake fluid between several brake circuits. There are three such circuits on the “six”.

The “six” has three closed brake circuits

There is one circuit for each front wheel, plus a circuit for servicing the two rear wheels. It is from the master brake cylinder that the fluid comes, which then begins to put pressure on the wheel cylinders, forcing them to tightly compress the brake pads and stop the car. In addition, the master cylinder performs two additional functions:

- abductor function. If the brake fluid has not been completely used by the working cylinders, then the remainder goes back into the reservoir until the next braking;

- return function. When the driver stops braking and removes his foot from the pedal, the pedal rises to its original position under the action of the master cylinder.

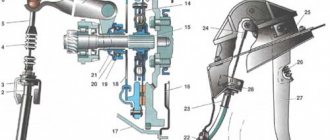

How the cylinder works and how it works

The VAZ 2106 drive cylinder has a lot of small parts, so at first glance the device seems very complex. Nevertheless, there is nothing complicated about it. Let's list the main elements.

The brake cylinder of the VAZ 2106 consists of 14 parts

- The case is steel with two internal chambers.

- Washer fixing the main fitting.

- Brake fluid drain fitting (it connects directly to the expansion tank).

- Union seal.

- Washer for the limit screw.

- Stopper screw for brake piston.

- Return spring.

- Support cap.

- Compensator spring.

- O-ring for the brake piston (there are 4 such rings in the cylinder).

- Spacer washer.

- Rear brake circuit piston.

- Small spacer washer.

- Front brake piston.

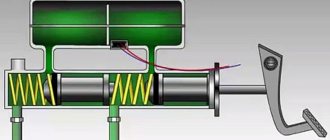

A steel plug is installed at one end of the cylinder body. The second end is equipped with a flange with mounting holes. And the master cylinder works as follows:

- Before pressing the pedal, the pistons stand in the cylinder body at the walls of their chambers. Each spacer ring is restrained by its own limiting screw, and the chambers themselves are filled with brake fluid;

- after the driver, by pressing the pedal, releases the entire free play of this pedal (this is approximately 7–8 mm), the pusher in the cylinder begins to put pressure on the main piston, moving it to the opposite wall of the chamber. At the same time, a special cuff blocks the hole through which the brake fluid goes into the reservoir;

- when the main piston reaches the opposite wall of the chamber and squeezes out all the liquid into the hoses, an additional piston is activated, which is responsible for increasing the pressure in the rear circuit. As a result, the pressure in all brake circuits increases almost simultaneously, which allows the driver to use both front and rear pads for braking;

- As soon as the driver releases the brakes, the springs return the pistons back to their starting point. If the pressure in the cylinder was too high and not all of the liquid was consumed, then its remains are drained into the tank through the outlet hose.

Video: principles of operation of brake cylinders

Bleeding the system

The procedure for bleeding the brake system of a VAZ-2106 (like any other car):

- Rear right and left wheels.

- Front right and left.

When working, you move from the far brake mechanism to the near one (relative to the GTZ). Your goal is to get rid of air jams. When pumping, carefully monitor the fluid level in the tank and top up if necessary.

The principle of operation of the master brake cylinder on the VAZ-2106 is that two pistons create pressure in the system. This pressure pushes out the calipers and sets the pads in motion. If there is even a little air in the system, the brakes will not work.

How to remove air from the brake system

When the driver changes the drive cylinder, air enters the brake system. It's almost inevitable. Air bubbles accumulate in the brake hoses, making normal braking difficult. So the driver will have to remove air from the system using the recommendations outlined below. It should be noted here that to perform this operation you will need the help of a partner.

- The front wheel of the car is jacked up and removed. Access to the brake fitting is provided. A piece of plastic tube is put on it. Its second end is directed into an empty bottle. Then the nut on the fitting is carefully unscrewed.

Video: bleeding classic brakes without the help of a partner

So, the brake cylinder on the “six” is an extremely important part, on the condition of which the life of the driver and passengers depends. But even a novice car enthusiast can change this part. No special skills or knowledge are required for this. All you need is to be able to hold a wrench in your hands and strictly follow the recommendations outlined above.

How it works?

When you press the brake pedal, the two pistons in the master cylinder begin to move forward, pushing the brake fluid lines. The resulting pressure acts on the brake pistons of the calipers, which are located on each wheel.

When you release the pedal, the springs push the pistons back, thereby returning them to their original position. After this, the fuel fluid that was in the lines returns to the expansion tank and fills the cylinders again. When heated, the liquid can expand, and to avoid excess pressure, there are two holes that lead to the expansion tank. An integral part of the GTZ is the vacuum brake booster (VBR), which increases pressure and helps put pressure on the pistons, making life easier for the driver and making braking more productive.

How does a malfunction of the brake master cylinder manifest itself, as well as possible causes!

Despite the apparent simplicity and primitiveness of the GTZ, problems often arise in its work that can have very dire consequences. Problems in the operation of the system can be recognized by the following signs:

- You press the brake pedal, but the car stops very slowly and inefficiently. The culprits for this phenomenon may be cuffs that have become “stiff” or leaky. Also, a malfunction of the VUT can manifest itself in a similar way; it could be a crack in the membrane or depressurization of the joints of the hose that removes engine vacuum.

- The pedal travel is very short. Most likely, the compensation hole is clogged; the liquid inside the cylinder simply has nowhere to go and excessive resistance arises. The second option is deformation of the rubber seals, which have swollen and blocked the passage.

- The pedal has to be pressed with great effort. This can happen as a result of deformation or partial destruction of the rubber piston seals.

- The pads get hot and do not open completely; they do not release the discs or drums. There are several options here; it could be a jammed piston, a clogged bypass hole, or other reasons that impede the movement of the fuel fluid in the brake system.

- The brake pedal falls. This is perhaps the most common phenomenon that most of us have encountered. When you press the brake pedal, it seems to fall through, there is no feeling of pressure or resistance, and the braking itself occurs at the very end of its movement. This happens when there is critical wear on the cuff, as a result of which the liquid easily passes through the piston and returns to the expansion chamber. Simply put, the cylinder “bypasses” the fuel fluid. The failure of the brake pedal can also be observed if the system is airtight, that is, leaky, or depressurization has occurred on one of the brake cylinders.

There are other symptoms indicating a malfunction of the gas turbine engine.

- When braking at speed, the car pulls to the side. This happens when one of the circuits or brake cylinders on the wheel is faulty.

- The appearance of a squeaking or knocking noise during braking. It could also be pads that are time to be replaced, but it happens that the problem is in the GTZ.

- The pads can jam, heat up and heat up the brake disc on a particular wheel.