One of the main parts of the hydraulic drive of the clutch system, along with the main one, is the clutch slave cylinder. The main task of this device is to transfer the force generated when the pedal is pressed and coming from the master cylinder through a hose to parts that directly interact with the gearbox: the clutch fork and the release bearing.

Traditionally, the clutch slave cylinder is located on or next to the gearbox housing and is similar in its principle of operation and design in all car models, only the details differ: what the body, rod, etc. are made of.

To independently repair or replace this part, you need to understand the principle of its operation, the main components located in its body and the signs of possible malfunctions.

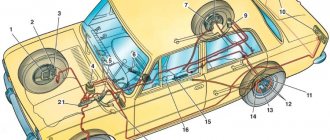

Hydraulic clutch drive device

The clutch release drive consists of:

- clutch pedal;

- clutch master cylinder (located in the chain immediately behind the pedal);

- The clutch slave cylinder moves the fork and pressure bearing;

- clutch release fork;

- pressure bearing;

- piping system (pipe)

The design of the clutch master cylinder is not particularly complicated: body, cylinder, piston, cuffs. The clutch master cylinder carries out the task of transmitting force from the pedal to the clutch slave cylinder using working fluid.

The principle of operation of the UAZ clutch

Clutch device

The main elements of the clutch, as is known, are:

- crankcase;

- release clutches;

- drive disk;

- driven disk.

One of the most important elements on which the reliability of the mechanism mainly depends is the master cylinder of the UAZ 3303 clutch. But we should not forget about the working cylinder, which plays a very important role. The cylinders are connected using a hose and tube.

The diaphragm spring, from which the entire design gets its name, is located in the drive disc housing. The support rings and pressure plate are also installed here. The spring is secured in such a way that its edges can have a strong influence on the pressure plate.

The structure of this system provides that the driven disk can come very close to the engine flywheel and even come into contact with it, and also transmit torque to the driven disk using friction linings. After this, the torque is transmitted to the gearbox. If it is necessary to temporarily disconnect the engine from the transmission, the UAZ 469 clutch release drive is used.

When you press the clutch pedal of the UAZ 469, the piston of the master cylinder begins to move forward. Because of this, the liquid is displaced and enters the working cylinder. After which she extends the piston with the rod. This rod acts on the shank of the fork, as a result of which it begins to turn and moves the release clutch. Thus, the ends of the petals of the diaphragm spring are pressed, the action of the spring on the pressure disk ends, and the supply of torque also stops.

Device location

To find the clutch slave cylinder on a VAZ classic, you need to look for it directly in the area where the gearbox is located. The device is attached with two bolts to the gearbox housing.

The mechanism can only be seen from below or in the very depths of the engine compartment on the driver’s side. Repair work related to dismantling and replacing the clutch slave cylinder can be carried out “from under the hood,” but it is much more convenient from an inspection hole or on an overpass. The video below shows the location of this unit. What function does this product perform and is it possible to do without it? We'll find out more about this later.

Features of operation

The operating principle is very simple. Below is a diagram where the slave cylinder is indicated by a green arrow.

According to this diagram, we can say that the RCS performs an important function, or rather, it activates the fork, which is connected to the clutch drum. The main element of the RCS, or rather the piston, is activated by the resulting fluid pressure coming from the main cylinder through the hose when the clutch pedal is pressed. The brake fluid pushes the piston, which in turn drives the fork, which acts on the drum, pushing the disc away from the flywheel. Many people wonder why brake fluid is used in the system? The reason is that brake fluid is incompressible, which is why it is used in such important systems as brakes and clutches.

When to replace the RCS

During the use of the unit, which happens very often, the product tends to fail. The main causes of breakdowns are chafing and wear of the cuffs, the appearance of cracks in them, which entails the leakage of liquid. Significant loss of fluid will cause the clutch system to malfunction. It is possible to repair a DCS that has become unusable, but it is easier and more efficient to replace it with a new one.

In order not to wait until the pressure in the clutch pedal disappears, you need to periodically inspect the unit. If there is a leak in the fuel fluid, it is necessary to immediately carry out the appropriate repairs on the VAZ 2107. Before carrying out repairs, you need to make sure that this particular element is faulty, since the main circulation system may also fail. The main signs of failure of the RCS are:

- decrease in the level of fuel fluid in the tank;

- visible brake fluid leaks from the device body or from under the rubber boot;

- “failures” of the clutch pedal, which can be periodic or constant;

- difficulty changing gears.

But most often the malfunction is determined by detecting a brake fluid leak.

Features of replacing the RCS

Replacing the VAZ 2107 clutch slave cylinder begins with the need to remove all fluid from the reservoir. Further actions are carried out in order:

- First you need to loosen the fastening nut that connects the hose to the cylinder. There is no need to unscrew the nut completely, just loosen it at this stage.

- Using pliers, you need to remove the tension spring.

- After this, you should unclench the cotter pin and remove it from the tip of the pusher.

- Using a key set to “12”, you need to unscrew the two bolts that secure the product to the gearbox housing.

- After unscrewing the bolts, you can disconnect the bracket from the cylinder, which is intended to secure the spring.

- Holding the working cylinder body, you should dismantle it. During dismantling, pay attention to the pusher, which is located in the fork.

- After disconnecting the product from the crankcase, you can continue unscrewing the nut connecting the hose to the device. After unscrewing the nut, brake fluid will begin to flow out of the hose, so you should prepare a special container in advance.

After the device is dismantled, it should be replaced with a new one, since repairing it is irrational. The cost of the product is insignificant, so it is easier to replace it with a new one than to try to carry out repairs. Installation of the product is carried out in the reverse order of removal. After installation, it is necessary to carry out the system bleeding procedure. In conclusion, it should be recalled that regular car maintenance helps prevent various unforeseen consequences along the way, such as the “disappearance” of the clutch.

This is interesting: Why did the oil pressure indicator light come on in a VAZ 2114/15 car: we are looking for reasons and solutions

DIY repair

So, the part has been removed and is ready for disassembly. First, unscrew the air bleed valve and remove the retaining ring. After disassembling the part, we inspect the condition of all elements - spring, piston, pusher and sealing rubber bands. They must not show any signs of mechanical damage. Next, we wash the insides of the element. There is no need to do this with aggressive liquids like gasoline and diesel fuel. Fill a medical syringe with hydraulic fluid and use pressure to clean out the dirt inside it.

Possible malfunctions and their diagnosis

Signs indicating malfunctions in the clutch drive can be diagnosed based on the following:

- The level in the clutch reservoir has dropped significantly, this indicates that brake fluid is leaking somewhere in the system; if the connecting pipes are intact, this may be due to worn cuffs or a faulty piston in the master cylinder.

- A visual inspection showed the presence of places where fluid was leaking: tubes, cuffs, etc.

- When pressed, periodic failures of the pedal occur, this indicates that there is air in the clutch drive, this happens when hoses are cracked or when the level in the reservoir drops below “nowhere”.

- When shifting gears, a characteristic sound is heard in the gearbox, reminiscent of a “crunch”; the cause may be a malfunction of the piston or spring of the master cylinder.

If the symptoms described above are present, you should not tighten and more carefully check all the parts responsible for the operation of the clutch drive. Otherwise, it may happen that postponing repair of the clutch master cylinder will lead to unpleasant consequences, the least of which could be repair of the gearbox.

Adjusting mechanisms

Parameters after adjustment

It is generally accepted that correct adjustment of the clutch can ensure its greatest reliability. First, you need to measure the amount of free play at the drive pedal, which disengages the clutch. If the clutch has a diaphragm spring, then the recommended value should be in the range from 5 to 30 mm. After pressing the pedal all the way, it is necessary to measure its full stroke, the recommended value of which should be approximately 16.5 centimeters. This size can be determined using an ordinary ruler.

If it is necessary to change the position of the pedal, we adjust the length of the pusher, which is located in the master cylinder. This adjustment is carried out as follows: unscrew the lock nut with a wrench, begin to rotate the rods, using pliers. This way, the desired pedal position is established, which will be more convenient. Ideally, a 13 key can be used for this operation.

It should be noted that the clutch with a diaphragm spring does not need to adjust the release mechanism, since the spring itself can provide optimal values. In other words, adjusting the clutch of the UAZ 469, UAZ loaf and UAZ Patriot will not be difficult. Clutch baskets can be purchased at specialized stores.

How to adjust the clutch rod on a VAZ 2106

After bleeding the working cylinder, it is necessary to adjust the clutch rod. To do this you will need:

- set of open-end wrenches;

- medium-sized caliper;

- pliers.

Adjustment sequence

Before you begin making adjustments, you should look at the machine's operating instructions . It is there that you can clarify all the necessary tolerances for the clutch rod and pedal.

- First, the clutch pedal play (also known as free play) is measured. The most convenient way to measure it is with a caliper. Normally it is 1–2 mm.

- If the free play exceeds two millimeters, then use a 10 mm open-end wrench to unscrew the nut located on the free play limiter. After this, you can turn the limiter itself and set the required free play of the pedal.

The free play of the clutch pedal is adjusted using the limit pin - Once the stop pin is installed properly, its nut is screwed into place.

- Now you need to measure the full amplitude of the pedal. It should be in the range from 24 to 34 mm. If the amplitude does not fall within these limits, the rod should be readjusted and then the measurements repeated.

Video: how to adjust the clutch drive

Causes and symptoms of GCS malfunction

As mentioned above, wear and tear of individual cylinder elements is inevitable over time. Also, premature failure of a part can be caused by untimely replacement of brake fluid, ruptures of seals, errors in assembling/installing individual spare parts from the repair kit, etc.

As a rule, the most serious damage can be considered when the mirror of the cylinder itself is heavily worn, scuffs, abrasions and other defects appear on the metal surface, and pockets of corrosion are visible. In such a situation, a conventional overhaul using a repair kit is often not possible. The only solution is to completely replace the clutch master cylinder.

The fact is that one of the properties of brake fluid is high penetrating ability. This means that fluid seeps through even the smallest scratches on the cylinder bore and/or piston. Replacing only the rubber seals does not help in this case.

We also recommend reading the article about whether there is a clutch in an automatic transmission. From this article you will learn what devices and mechanisms in an automatic transmission perform the clutch function, as well as how the clutch works in an automatic transmission.

Often, a high-quality GCS repair kit usually has both cuffs and a new piston. However, if there are scratches on the cylinder mirror, in this case the entire part needs to be replaced. For this reason, it is important to prevent critical wear and tear by paying attention to the slightest signs of failure of the main circulation system. As soon as a problem occurs in the cylinder, fluid can leak out of the system and its level decreases.

Also, the clutch pedal may work worse; while driving, the driver notices that the gear shifting process is disrupted as a result of clutch malfunctions. If there are problems with the cylinder, the clutch pedal may fall to the lower position (fall, stick), the pedal travel becomes tight, etc.

In this case, a visual inspection must be carried out immediately. First of all, you should check the level and condition of the brake fluid. You also need to inspect the cylinder itself. If there are obvious stains on the cylinder or the seals (cuffs) are wet, then a leak is obvious.

We also note that a common problem with the clutch master cylinder is active clogging of the holes in the reservoir cap. In order for the device to work properly, it is assumed that the fluid level in the cylinder reservoir constantly rises and then decreases.

In order for the level to rise and fall normally, there are special ventilation holes in the tank lid. In cases where the holes are clogged with dirt, the entire hydraulic drive malfunctions, the clutch pedal moves hard, the clutch pedal slowly returns to its original position, etc.

Symptoms of clutch malfunctions

As we have already noted, many drivers, when problems arise with the clutch, understand that the car has begun to behave strangely, but often get used to it without taking any active action. As a result, a minor breakdown develops into a serious one, leading to a situation where the car becomes immobilized.

If you know the main signs of a clutch malfunction, you can avoid such risks by carrying out timely repairs yourself or contacting the nearest service station or service center.

So, we will describe the main signs of possible clutch malfunctions and the specific unit responsible for the “wrong” behavior.

Maintenance

Get regular maintenance

To service the clutch basket of UAZ vehicles with a diaphragm spring, professional skills are not required. First of all, the clutch must be kept clean, regularly removing any dirt that has arisen. Bolted connections need to be tightened periodically.

It is necessary to constantly check the volume of working fluid that is in the master cylinder. It should be about 1.5 centimeters, but below the top edge of the cylinder. In this case, the tank is filled using the installed mesh filter. It is used to prevent the entry of unnecessary objects and substances. Typically, the UAZ 469 clutch slave cylinder does not require any additional, special manipulations.

Design

Unlike front-wheel drive foreign cars, on all-wheel drive UAZ Patriot vehicles the clutch slave cylinder (its adjustment is at the end of the article) is hydraulic and is controlled using fluid pressure, and not a cable. The design of this element includes several components. This:

- Frame. It is made of plastic or metal.

- Piston (working rod).

- A valve that releases air when the clutch system is bleeding (adjusting).

- Retaining ring.

- O-rings. Made from durable rubber.

- Return spring.

- Pusher. It affects the previous element.

Causes of breakdowns of the working cylinder of a car

The material from which the body of the part is made is important. Today, cylinders are made not only from steel or cast iron - as before. Aluminum and even polymer began to be used more often. However, such soft products will not be reliable.

Clutch rod repair is necessary for the following problems:

- leaks (occur due to wear of the O-rings or when the integrity of the connecting tubes is damaged);

- cracks on the body of the part;

- RCS spring failure.

The rod includes several components, each of which can be damaged. The pusher, piston, cuffs, spring - all these components are constantly under load, so the likelihood of them breaking is high.

Work performed when replacing the clutch master cylinder

The procedure required when replacing the clutch master cylinder is simple:

- Having unscrewed the tank, use a syringe to pump out the hydraulic fluid;

- disconnect the master cylinder from the clutch pedal, which is sometimes difficult;

- disconnect all hoses and plug those from which liquid is flowing;

- unscrew the nuts securing the cylinder to the car body;

- replace with a new clutch master cylinder and install in the reverse order;

- bleed the clutch system.

For the clutch bleeding procedure you will need:

- a suitable bleeding hose that fits tightly onto the air valve located on the working cylinder;

- container for draining hydraulic fluid;

- corresponding key for the valve;

- the liquid itself.

To pump, you should: remove the protective cap from the valve, put a hose in its place, the second end of which should be lowered into the liquid in the container. Have an assistant press the clutch pedal several times and then hold it down. After turning the valve 4-5 turns, let the liquid with air bubbles drain out and screw the valve back. After performing the same actions several times, you should pump the system until all air is removed from it.

We also recommend watching videos on the topic:

Some tips for repairing the master cylinder

Tip #1 . There is no need to completely drain the brake fluid from the hydraulic clutch when replacing the master cylinder (this is not at all necessary).

Tip #2 . To flush spare parts of the clutch master cylinder, it is not advisable to use the following products:

- kerosene;

- diesel fuel;

- petrol;

- mineral oils.

To avoid damage to clutch cylinder components, use only brake fluid.

Tip #3 . Before final assembly of the repaired GTZ, its spare parts must be lubricated.

Tip #4 . To process the piston, which interacts with the pusher, a special grease is used.

Tip #5 . After installing the master cylinder, it is imperative to bleed the hydraulic drive system.

Leveling up

After successful installation and assembly of the element, it is necessary to fill in new hydraulic fluid. The same one is used as for the brake system. After this, unscrew the air valve of the working cylinder several turns and press the clutch pedal 5-7 times. To avoid running to the salon several times, call an assistant who will bleed the system. Be careful - when you press the pedal, hydraulic fluid will flow out of the valve. Therefore, prepare the container first. This could be an ordinary mineral water bottle.

When should you not restore?

In some cases, repairs will not work. The working cylinder is replaced if the housing is damaged (cracks) or there is a large hole inside it. The latter may occur due to a faulty or defective rod. In case of any of these malfunctions, the UAZ clutch slave cylinder is replaced entirely with a new one. The cost of the element is about five hundred to six hundred rubles. The clutch master cylinder costs a little more - 750 rubles. The repair kit can be purchased at a price of 150 to 200 rubles. The amount is not impressive, so if you have limited time, it is better to immediately replace the element with a new assembly. After the clutch slave cylinder is installed, the UAZ needs to be “pumped”. This way we will eliminate all existing air pockets in the lines and adjust the normal pedal travel.

DIY replacement

First you need to drain the remaining liquid in the system. This can be done using a syringe. This operation is necessary to flush out dirt from the hydraulic drive system. On some models, access may be blocked by the cooling system expansion tank. For convenience, remove the container’s fastening nuts and remove the hose. It should be unscrewed with a 10mm wrench. Next, we dismantle the metal tube that comes from the clutch master cylinder. It can be copper or aluminum. After this, we remove the main cylinder, having previously unscrewed the two fastening nuts with a 13mm wrench. Using a 17 socket, you need to remove the hose that comes from the working cylinder. Next we will need the key for 13 again.

Using it, we unscrew the two bolts that secure the clutch slave cylinder. The UAZ is in neutral gear. The working cylinder itself on this car is mounted on the gearbox housing. To avoid damaging other elements, carefully disconnect the pushrod from the fork. If the hoses are removed “in weight” (that is, on the removed element), the cylinder can be secured with an adjustable wrench on one side, and on the other, unscrew the tube with a cape. But be careful, as mechanical stress may cause the rubber to crack.

Specifications

In the specifications for the master cylinder, manufacturers indicate the following parameters:

- side of the steering wheel (left, right) – important for asymmetric mounting,

- Is there a tank included (GCS can be sold with or without a tank),

- connection method (left, top, etc.) – help with selection if non-standard parts are installed in the hydraulic drive,

- body material: cast iron, aluminum, steel, polymer,

- dimensions of the body and structural elements (nozzle diameter, rod length).

These characteristics can be taken into account as auxiliary information when selecting a master cylinder for your car. Car enthusiasts pay special attention to manufacturing materials: the most common today are cast iron and aluminum, and there are also quite a few offers of cylinders with polymer bodies. Steel cases are quite rare, since steel combines high price and difficulty in processing.