The VAZ "Seven" drive is carried out to the rear axle, which has a rather complex device. The most common failure of this unit is wear of the axle bearing. The external manifestations of such a malfunction on a VAZ 2107 car consist of a characteristic hum while driving. If the unit is not replaced on time, the bearing may be destroyed while driving and the wheel may jam.

Elimination of this malfunction of the rear axle on a VAZ 2107 car can be done in two ways. In the first case, the assembly is repaired with the installation of a new bearing; in the second case, the entire assembly is replaced. List of necessary tools and devices:

- a set of wrenches and screwdrivers;

- device for dismantling the unit from the rear axle;

- blowtorch or industrial hair dryer;

- device for removing the bearing thrust ring;

- pliers;

- mandrel for installing the retaining ring.

The listed devices are usually used at service stations. In garage conditions, slightly different techniques are used that do not require so much special equipment.

Rear axle axle shaft of a VAZ 2107 - removal and installation

We replace the axle shaft with bearing on a VAZ 2107 when it is deformed or the bearing is severely worn, which is expressed in noticeable axial play of the suspended wheel. The axle shaft seal must be replaced if oil is detected in the rear wheel brake mechanism, as well as in any case when replacing the axle shaft.

Removing the rear axle axle shaft from a VAZ 2107 1. Place the VAZ 2107 on an inspection hole or overpass (see “Preparation of the VAZ 2107 for maintenance and repair”). 2. Remove the brake drum (see “Rear wheel brake pads - replacement”). 3. Using a jack, we additionally lift the rear axle on the side of the axle shaft being replaced to prevent oil from leaking out of the beam. 4. Rotate the axle shaft until the large diameter holes in its flange coincide with the two nuts securing the brake shield. 5. Using a 17 mm socket wrench with an extension, unscrew the nuts and remove the spring washers.

Similarly, unscrew the remaining two nuts.

6. It is more convenient to remove the axle shaft from a VAZ 2107 with a special puller, but if it is not available, you can use the removed wheel. We secure it with two bolts with the outer side to the axle shaft flange, but do not fully tighten the bolts to ensure the inertia force of the wheel. With a sharp movement towards ourselves, we pull out the axle bearing from the flange of the rear axle beam.

7. After unscrewing the bolts, remove the wheel and take out the axle shaft. There is a rubber O-ring between the beam flange and the brake shield, do not lose it.

8. Using sliding pliers or another suitable tool, remove the axle shaft seal from the hole in the beam flange.

Installing the rear axle axle oil seal on a VAZ 2107 1. Before installing a new oil seal, apply grease to its seating surface and working edge. 2. Install the axle shaft oil seal into the hole in the beam flange (with the spring inside the beam) and with light blows of a hammer, press the axle shaft oil seal through a bushing of suitable diameter.

3. Install the axle shaft and other parts in the reverse order of their removal. When doing this, be careful not to damage the oil seal with the splined end of the axle shaft. 4. We check the oil level in the rear axle on a VAZ 2107 car, add oil if necessary (see “Rear axle of a VAZ 2107 car - checking the level and changing the oil”).

What you need for work

Replacing the rear axle shaft seal of a VAZ 2107

The diagnosis has been made and the owner of the “Seven” decides to change the part himself. What is needed to carry out the work correctly?

- Hammer.

- Chisel.

- Electric angle grinder, popularly called an angle grinder.

- 80 or slightly less centimeters of pipe with an internal diameter of 32 millimeters.

- Socket head No. 32 and wrench No. 17.

- Open-end wrench No. 10.

- Engine oil: motor or transmission oil, 100 grams.

- Lithium grease.

- An anvil or an object that can replace it.

- Blowtorch or other similar type of torch.

- New working bearing.

- Locking bushing and a set of seals for the axle shaft.

- Jack.

- Stop shoes.

- Mount.

- Rags.

The design solution of the classic Zhiguli models is simple. It will not be difficult to understand the system. Take the instruction manual, it clearly describes what is where. In order to change a part, it is not at all necessary to stand on an inspection hole or lift the car with a truck crane. Although these devices can significantly facilitate and speed up the operation.

Features of the replacement

When replacing a VAZ-2107 axle shaft, you must adhere to certain rules that will help speed up the work process:

When cutting off an old bearing using a grinder, the main thing is not to damage the surface of the axle shaft. Therefore, you only saw the outer part together with the separator. There is no need to cut the inner ring completely; make several small cuts on it. You can finally split it by installing a chisel and applying several sharp blows with a hammer. Install the new bearing onto the axle shaft with a hammer

Please note that you cannot hit the bearing race, in which case it may collapse or become deformed. It is for this purpose that a piece of tube is used, which is put on the axle shaft

It is not recommended to heat the bearing housing, as it may lose its properties. If the metal is annealed, its ductility will increase significantly and its hardness will decrease.

When carrying out work, try not to damage the axle shaft. Use a hammer as carefully as possible, because it is very easy to destroy metal parts. The work does not require high qualifications or special equipment, so it can be done in the garage with your own hands. The main thing is to comply with all the requirements described above.

Views: 2

RESTORING THE OPERATION OF THE UNIT

To fix the problem, you need to remove the old retaining ring. If a special device is not available, then the operation can be performed using a grinder. The ring is carefully cut off without damaging the axle shaft. This part is for single use and must be replaced every time the unit is repaired. The new bearing is put on the axle and secured with a new ring, which is preheated.

Repairing a component such as an axle shaft on a VAZ 2107 does not take much time from an experienced specialist. At the same time, going to a service station does not always guarantee a good result; often, in the absence of special devices, they simply knock down the ring with a sledgehammer, which leads to runout and rapid destruction of the bearing.

How to check and replace a VAZ-2107 axle shaft

Measuring the axial free play of the axle shaft on a car

The axial free play of the axle shaft can be measured on a vehicle both with the wheel and brake drum removed and without them removed. In the first case, the measurement is more accurate.

rice. 1 |

For what:

– remove the caps from the rear wheels and loosen the bolts securing them;

– place stops under the front wheels and lift the rear axle;

– release the parking brake and set the gear shift lever to neutral;

– remove the wheels and brake drums;

– screw device 02.7834.9504 to the axle shaft;

– pass the indicator leg extension 1 through one of the two large holes of the axle shaft until it stops in the brake shield or oil deflector and secure the indicator;

– take measurements with an indicator, applying a force of about 49 N (5 kgf) to the axle flange in both directions, along the axis of the rear axle. Free play should not exceed 0.7 mm. Measure the free play of the axle shaft without removing the wheel and brake drum as described above, taking into account the following features:

– secure device 02.7834.9504 using one of the holes for the wheel bolts;

– pass the leg of the indicator extension through another hole for the wheel mounting bolt;

– the force applied to the wheel along the axis of the rear axle should be about 98 N (10 kgf), the free play of the axle shaft should be up to 0.7 mm.

Replacing the axle shaft and its cuff

We hang the rear of the car on tripods, remove the rear wheel and brake drum. Using a jack, we lift the disassembled edge of the rear axle beam so that after removing the axle shaft, the oil does not spill out.

| 1. Using a “17” socket, unscrew the four nuts through the holes in the axle shaft flange. | 2. Remove the elastic washers with tweezers. |

| 3. We attach an impact puller to the axle shaft flange and knock the axle shaft out of the beam. Instead of this device, you can use the removed wheel. We install it with the reverse side on two bolts and with a sharp movement pull out the axle shaft. | 4. The axle shaft is removed along with the oil deflector, mounting plate, bearing and locking ring. |

| 5. A rubber O-ring is installed between the beam flange and the brake shield. | 6. Using sliding pliers, remove the axle shaft cuff from its socket in the rear axle beam. |

| 7. Using light blows of a hammer on the socket head (a piece of pipe of suitable diameter), press in a new cuff. | In case of deformation of the axle shaft, large radial and axial clearances in the bearing, displacement of the locking ring, wear of the splines, the axle shaft must be replaced as an assembly. Replacing the bearing and snap ring alone is not recommended. Install the axle shaft in the reverse order of removal. Before installation, lubricate the working surfaces of the cuff with Litol-24 lubricant. |

Anti-lock braking system (ABS)

| GENERAL INFORMATION |

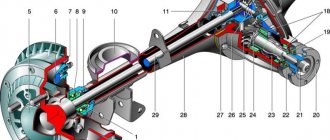

| The front wheel sensors are located in the steering knuckles as shown. They control the speed of the car's wheels through ring gears mounted on the front drives. |

| The rear wheel sensors are attached to the rear axle carrier as shown. |

REPLACEMENT OF ABS ELEMENTSREPLACEMENT OF ANGULAR SPEED SENSORS OF FRONT WHEELSRemoval

PERFORMANCE ORDER 1. Disconnect the ground cable from the battery. 2. Raise and place the front of the vehicle on stands. 3. Remove the wheel, allowing access to the sensor cable.

4. Remove the plug connection in the wheel housing from the holder and unplug it using a screwdriver.

5. If there are several plug connections, find out which one belongs to the ABS sensor.

6. Disconnect the cable from the mount.

7

Unscrew the sensor mounting bolt with a socket wrench and carefully separate it with a screwdriver. Installation

Installation

PERFORMANCE ORDER 1. Tighten the fastening bolt to a torque of 9 Nm. 2. Be careful not to twist the sensor cable. The cable is marked with a white line. 3

When tightening the cable mounting bolts, pay attention to the different tightening torques. 4

The lower cable fastening bolt is fastened with a torque of 27 Nm, the upper cable with a torque of 6 Nm

4. The lower cable fastening bolt is fastened with a torque of 27 Nm, the upper cable with a torque of 6 Nm.

5

Make sure that the speed sensor is not dirty or damaged.

6. After completing the work, set the ignition key to the operating position and check that the ABS warning light goes off.

REPLACING REAR WHEEL ANGULAR SPEED SENSORS Removal

| EXECUTION ORDER |

| 1. Disconnect the ground cable from the battery, lift and place the rear of the car on stands. |

| 2. Find the sensor cable and unplug the plug connection, disconnect the cable from the mount. |

| 3. Unscrew the sensor. The location of the sensor on the rear suspension is shown in the illustration. |

Installation

| EXECUTION ORDER |

| 1. Be careful not to twist the cable when connecting. For proper installation, the cable is marked with a white line. |

| 2. Tighten the sensor mounting bolts to a torque of 22 Nm, the cable mounting bolts to a torque of 27 Nm. |

INSTRUCTIONS ON WHEEL SPEED SENSORS Diagram explaining the principle of operation of the wheel speed sensor REPLACING THE FRONT WHEEL SENSOR ROTOR

| EXECUTION ORDER |

| 1. Remove the front hub as described in the appropriate section. |

| 2. Remove the rotor from the inside of the wheel hub. |

| 3. If the removed rotor is installed backwards, it is necessary to check the tooth surfaces. They must not be damaged. |

| 4. When installing, tighten the bolts to a torque of 18 Nm. |

REPLACING THE REAR WHEEL SENSOR ROTOR

| EXECUTION ORDER |

| 1. Raise and place the rear of the car on stands. |

| 2. Remove the rear drive as described in the appropriate section. |

| 3. Remove and install the gear rotor in connection with replacing the drive bearing. |

| 4. The specified work is also described in the Chapter Brake system |

Axle shaft seal VAZ 2107 number

Dear visitors of the “Cars” website! We will be very grateful for your comments on the video clip “Axle seal VAZ 2107 number”; registration is not required for this. We also ask you to let us know if you have any problems playing the video.

tormoza nado bylo pomyt benzinom i kistockoi :

There are a lot of similar videos, they are not interesting. I watched the video from Oleg, it was very interesting and I became interested in repairing the car myself:

Is there one seal or on both sides?

It’s obvious that this is not the first time you’ve changed the oil seal... but damn, was it really difficult to tap the mudguards and knock the snow off the arch? It’s not pleasant to sit in this melted puddle of shit and dig in the dirt... It’s better to hammer the oil seal into the seat with a pipe of the same diameter as it, otherwise it may not press evenly. I don’t know how, but I wipe the seat seat dry and lubricate it with sealant.

With this amount of oil, this wheel will not slow down all winter and all spring. During emergency braking on a winter surface without the clutch depressed, due to the non-braking of one wheel, it can spin through the differential so much that before you have time to react, it will turn 180 degrees, and depending on your luck.

very useful video, everything is accessible and clearly explained and shown

I unscrewed these 4 bolts, but the axle shaft cannot be removed

The brake drums are stuck, can you tell me how to remove them?

Doesn't look like butter. It looks like a brake. By the way, my oil seal cracked and everything was covered in oil. It slows down with oil, and how. The pads stick. The wheel blocked at the slightest braking, although I thoroughly wiped off all the oil with a rag from both the pads and the drum. I had to take it apart and wash it again. I came across some acetone soap.

Hello, can you show me how to replace the front oil seal on the third engine?

But it was impossible to remove the mess from the fender liner... everything flows straight onto your hands and onto the pads... I never do that... to pick around in the dirt...

but a rubber band is still needed, like a seal before putting the axle shaft back

They say that before you remove the axle shaft, you need to set the marks so that you can put it back exactly as it was, otherwise there will be vibration. Any opinions???

Thank you

Excellent video, but at the end, when tightening the wheel bolts... we pull all the way, I’ve already changed two axle shafts, it seems like I’m not strong, but the thread breaks right away. And I can’t even count how many bolts I’ve torn off in 10 years... I wish I had a Dino key a long time ago bought it So pull it carefully

after replacement, oil still continues to flow, everything was pressed in exactly, the assumption is that there is a gap in the cavity where the oil seal was pressed in. How to solve this problem? maybe someone knows

bit nado rovnomerno, inache budet tech , kak na video

Why didn’t I wash everything from oil there and put a drum in?

Handsome man. I'll go try it myself. In the service they want 1000 for work:

try hammering it in with a mallet, it’s better and easier, you can hit the top of a pointed mallet with a hammer. verified

Types of auto parts

Axle shafts for cars are divided into two types according to the degree of loading:

- Completely unloaded (placed mainly on buses and trucks).

- Semi-unloaded (installed on passenger car models).

By design, the drive shaft can be:

- Waferless.

- Flange.

According to their location, there are rear and front axle shafts. For a VAZ 2107 car, you can purchase an original or non-original drive. Analogs are sold at a more reasonable price.

Depending on the manufacturer, drive shafts are:

- Imported.

- Domestic.

Depending on the condition, you can buy a new or used spare part for the VAZ 2107.

Depending on the place of purchase, the drives are:

All about replacing the VAZ 2107 axle shaft

An axle shaft is a part of a rear-wheel drive car that transmits rotation from the rear axle gearbox to the wheels. The rear part cannot be repaired, therefore, when worn out, they are replaced with new ones. Along with the axle shaft, the rear axle shaft bearing and its seal must also be replaced. These parts are also consumables and cannot be repaired under any circumstances.

The VAZ 2107 axle shaft must be replaced in the following cases:>

- The axle shaft is deformed (bent). At the same time, it makes noise in the form of a knock in the rear of the car when moving.

- The locking sleeve no longer fulfills its role

- Bearing seat bored

- The threads for mounting the wheels on the flange are heavily worn

- The axle splines are also worn

Replacement of the axle shaft can be carried out both in the garage and in an open area, provided there is a flat and clean area.

When purchasing an axle shaft, purchase a new bearing, axle shaft seal and a new locking sleeve in advance.

Procedure:

We carry out preparatory activities. Why: put the car on a flat horizontal surface, engage first gear and place wheel chocks under the front wheels. Also, loosen the wheel bolts on the side from which we are going to replace the axle shaft. Loosening the bolts should be done using the “criss-cross” method. We lift the wheel with a jack, place bricks or stumps under the car as support, completely unscrew the wheel bolts and remove the wheel.

Unscrew the drum guides and remove the drum. If the drum is stuck, take a rubber hammer and gently hit it around the entire circumference to knock it off the brake pads. Note: If the drum does not come off after hammering, you can dismantle it in another way. To do this, lift the second wheel, place a support under it and start the engine. Engage second gear and accelerate the engine to 1500 rpm

After this procedure, the ram usually “comes to life” and removing it is no longer difficult. Attention! Do not perform this operation if one of the wheels is on the ground. Thus, the car may fall from the support and damage the part of the bridge that is being repaired.

Also, such a violation can lead to premature wear of the clutch disc.

Take a 17mm socket wrench and unscrew the bolts that secure the axle shaft. They should be unscrewed using the “crosswise” method. Then you need to pull the axle shaft out of the bridge with your hands. Note: in cases where it is difficult to pull out the axle shaft by hand, you can use a wheel. To do this, bolt the wheel with the back side to the axle shaft and pull out the axle shaft, holding the wheel with your hands.

Now press the bearing onto the new axle shaft. This is done using a special press. If there is none, then you can contact the nearest car service center that has the appropriate equipment. Replace the oil seal on the axle shaft and install the axle shaft in the bridge (Replacing the axle shaft oil seal on a VAZ 2107). Tighten the axle shaft mounting bolts and install the drum in place. Tighten the drum guides. The guides should be screwed in carefully, without tearing off any sharp edges. Because, in the future, removing the drum can become a very problematic task and will require a lot of effort and time. Install the wheel and hand tighten the wheel bolts as far as possible. Then lower the car and tighten the wheel bolts further.

The new axle shaft is checked while driving. To do this you need to listen to the sounds. If the sounds that arose before the repair disappeared, then replacing the axle shaft on a VAZ 2107 was successful.

Good luck on the roads!

Some advice from experienced motorists

Very often we are faced with the fact that the brake drum cannot be removed by any effort.

There is a way to dismantle it, but it is a little dangerous and requires special care and attention

- Make sure the car is securely immobilized and secured.

- Depress the clutch pedal and engage 2nd gear.

- Start the engine, gently accelerating for a while.

- Press the brake pedal periodically.

- The inertial force should cause the drum to move out of place, making it easier to remove.

To protect your eyes, cover the bearing being removed with auxiliary material, such as rags, soft rags, etc. Or wear special safety glasses.

When the locking sleeve heats up, wrap the bearing in a rag or rag. This manipulation will help avoid overheating, which can cause the lubricant to leak from the part.

In parallel with replacing the bearing, the car enthusiast is able to inspect some important components of the car: brake pads and cylinders, axle shafts, etc.

How to Determine a Bearing Failure

The VAZ-2107 axle bearing wears out during operation, and sometimes the seat underneath it breaks. Malfunctions of this element can be determined by several signs:

- A humming noise appears from the rear axle. Sometimes it turns into crackling and squeaking. Moreover, the higher the speed, the louder these sounds. This should not be confused with a similar hum that can be heard when the rear axle gears wear out.

- The balls fall out and the separator is destroyed; the axle shaft jumps out of its seat when moving.

- Increased play of the rear wheels. Diagnostics is quite simple; you just need to place the car on a jack and rock the wheel several times. A knocking sound and free movement indicate that there is a malfunction.

- Sometimes the rear wheels jam, which can result in a serious accident.

The design of the VAZ-2107 axle bearing is simple and reliable; it can last for quite a long time. But if the car experiences very heavy loads, moves on bad roads, or the bearing is made of low-quality material, the service life is significantly reduced. The bearing cannot be repaired; it will only need to be replaced. In case of deformation and excessive wear, new mechanisms must be installed.

Diagnostics

To check the wheel bearings, you need to put the car on the handbrake and put wheel chocks under the rear wheels. When it is firmly fixed, you need to lift the front wheel using a jack and install a reliable stop under the lower arm. After which, of course, remove the jack. To ensure complete safety, it is better to install a stop under the car body parts, which will protect against accidental falling when the vehicle slips from the stop.

Safety precautions are often overlooked; unfortunately, they are very necessary when diagnosing defects in the front hub.

. Next, holding the top and bottom of the wheel with your hands, you need to perform a reciprocating movement, while no knocking should be heard or play should be felt. You should also spin the wheel several times.

If there are problems with the bearings, grinding, creaking, knocking and other unacceptable sounds will be heard.

How to correctly replace the rear axle bearing on a VAZ 2101

Cases when it is necessary to replace the rear axle bearing of a VAZ 2107 occur less often than a breakdown with replacement of the front bearings. The operating conditions of the vehicle are very important here. The repair itself is not complicated and it is quite possible to do it yourself, which will save you on a trip to a car service center.

Kit, VAZ 2107 axle shaft bearing with retaining ring and oil seal

Long-term operation of a vehicle with this malfunction can lead to negative consequences and more expensive repairs. The fact is that the destruction of the bearing cage will lead to a misalignment of the axle shaft, and the displaced brake drum will rub against the brake pads.

Purpose

The bearing is located on the axle shaft, inside the rear axle. It ensures rotation of the axle shaft, its centering, and also supports the weight of the car. From here we conclude that the more often we carry loads and the greater their mass, the more often we will have to change the bearing.

Symptoms of a problem

Cases of axle shaft failure are extremely rare, unlike bearings. The main sign of a faulty rear axle bearing is a hum in the area of the rear axle wheel. In this case, its intensity will depend on the speed of movement. With significant wear, a creaking or grinding sound will be heard. Sometimes the bearing simply jams and it begins to rotate in the seat, and this leads to wear and tear and expensive repairs. The reason for its failure can be not only significant and frequent loads, but also simply a significant service life. Bearing diagnostics

Tools

1. socket wrench 17;2. mount;3. hammer;4. flat screwdriver;5. chisel;6. bearing number 6306 or 180306 (designation of a sealed bearing). Has the article number - 6306.2RS, 099407, 2101-2403080;7. stuffing box.

Replacing the rear wheel bearing

Before starting work, we carry out standard actions to secure it, jack up the car and remove the wheel. Next: 1. remove the brake disc;2. through the holes of the axle shaft, unscrew its fastenings using a 17;3 socket head. remove the axle shaft by prying it with a pry bar;4. cut the locking ring;5. through the holes that unscrewed the axle shaft, we knock down the bearing;

If the bearing is very “stuck”, it can be cut off with a grinder or removed after heating.

Don't remove the pads, I removed them to replace them.

We take out the oil seal and clean the seat

Next, assembly proceeds in the reverse order: • install the oil seal; • stuff the bearing onto the axle shaft; • install the locking ring; • put the axle shaft in place.

Useful little things

1. Do not remove the pads, this will only increase the operating time.2. It is better to heat the locking ring when installing.3. It is better to stuff the bearing with a piece of pipe measuring 32 (overall dimensions of the rear axle shaft bearing: d=30 mm, D=72 mm, B=19 mm).4. Use safety glasses when working with an angle grinder. Here is a video of how to replace the rear axle bearing of a VAZ 2107:

Sequencing

- The car is jacked up, and the wheel is removed using socket wrenches, behind which there is a worn bearing.

- The brake disc and pads are removed.

- Now you need to unscrew the axle shaft itself with a 17 socket wrench.

The axle shaft is unscrewed with a 17 socket wrench - To remove it from its seat, you can use a crank.

It should be inserted between the brake cylinder and the rear of the axle and used as a lever to push the axle out. Pushing out the axle shaft using a crank - Now you need to remove the bearing from the axle shaft.

Often it turns out to be tightly welded to it, so you have to literally cut it off with a grinder. This must be done by first clamping the axle shaft in a vice. The old bearing is cut off with a grinder - Once the old bearing is removed, the axle must be thoroughly wiped with a rag.

And then a new part and a retaining ring are put on the axle shaft. Installing a new axle bearing - Now, using a medium-sized flat-head screwdriver, you need to remove the worn oil seal from the seat.

The old oil seal is removed with a screwdriver - As soon as it is removed, a new oil seal is installed in its place (it is most convenient to drive it into the seat with a 32 socket head).

- The axle shaft with a new bearing is installed back into the seat and the entire assembly is reassembled.

Illusory repair possibilities

It should be said right away that repairing throttle position sensors is extremely rare. Firstly, the part itself, even the most expensive one, costs only a few dollars, and it makes sense to spend the money. Secondly, in most cases it is simply impossible to make repairs, for example, to restore a worn-out base layer. However, in some models you can slightly shift the resistive tracks relative to the slider and thereby extend the life of the device.

So, there is a special screw on the sensors. With its help, the position of the tracks is fixed. If they are already worn out, then you should loosen this same screw, this will change the location of the slider a little, and you can be a little patient with replacing the device. But don't count on long-term respite. Naturally, we remember that the contactless sensor cannot be repaired. This completes the adjustment, repair and replacement of the throttle position sensor, now you can operate the car for several more years and not even think about such issues.

To check the supply voltage, disconnect the wire block from the sensor. Turn on the ignition and use a tester to measure the voltage between terminals “A” and “B” of the wire block. The supply voltage should be about 5V. To check the sensor, we connect the block of wires to it and, with the ignition on, measure the voltage (the wires of the block can be pierced with thin needles connected to the terminals of a voltmeter) between the sensor terminals “B” (“ground”) and “C” (slider) - it should not be more than 0.7V. Turning the plastic sector of the drive by hand, fully open the throttle valve and measure the voltage again - it should be more than 4V. Turning off the ignition, disconnect the wire block and connect an ohmmeter between terminals “C” and “A” (or “B”) of the sensor. Slowly turning the drive sector, we monitor the readings of the tester arrow. There should be no jumps in the needle throughout the entire working range. To replace the sensor, remove the throttle body from the receiver studs without disconnecting the coolant inlet and outlet hoses from it (see Removing the throttle body).

Using a Phillips screwdriver, unscrew the two screws securing the sensor to the throttle body...

...and remove the sensor.

The sensor is marked 2112-1148200

Remove the sealing foam ring installed under the sensor.

Install the sensor on the throttle body in reverse order. In this case, the damper must be in the closed position. The tightening torque for the sensor mounting screws is 2 N•m.

The VAZ 2107 throttle sensor, together with a mass air flow sensor and oxygen concentration control, acts as an element that controls the supply of fuel to the combustion chamber depending on the position of the throttle valve. As with any repair to replace electronic fuel injection sensors, they must be checked for functionality. To check, you will need a regular multimeter with the function of measuring resistance in the power circuit and a set of standard tools.

To check the throttle sensor:

- Disconnect the package with wires from the sensor.

- The connector body will be marked. Connect the ohmmeter leads to terminals “B” and “C”. We open the throttle valve; for a working sensor, the resistance will increase from 2.7 to 8.2 kOhm.

- Next, we switch the multimeter to voltmeter mode and connect its negative terminal to engine ground, turn on the ignition in the circuit, and the positive probe will turn on. For a working sensor, the voltage should be approximately equal to 5V, if absent or significantly different from the norm, there is a malfunction in the power circuit or in the computer. After measuring the voltage, turn off the ignition.

After confirming that the throttle sensor is not working and deciding to replace it, you must:

- To remove the sensor, use a Phillips screwdriver to unscrew the two screws securing it to the throttle body and remove it.

- There will be a foam gasket between the sensor and the housing.

At this point, the repair work to check and remove the VAZ 2107 throttle sensor is completed. The installation must be carried out with the damper closed, aligning the protrusion of the damper axis with the groove on the sensor body.

Sources

- https://carnovato.ru/proverka-regulirovka-datchika-polozhenija-drosselnoj-zaslonki/

- https://www.autofizik.ru/VAZ/VAZ-210721047/features-of-repair-of-a-VAZ-2107-20-with-engine-VAZ-2104/checking-and-replacing-position-sensor-d

- https://remont-vaz2106.ru/datchik-drosselnoj-zaslonki-vaz-2107

Preparation

First of all, you will need to remove the rear wheels, brake drums and the axle shaft itself.

Place the car on a level surface (in case there is no pit or truck crane). The front wheels must be securely supported by chocks. Don’t forget that the “seven” has a rear-wheel drive and you can’t control its immobility by engaging a gear, it just won’t work. Using a jack, raise the rear of the car. Protect against accidental falls. You can place removed wheels, a metal canister or a safety bar under the body. Unscrew the bolts and remove the wheels. Use a 10mm end to twist the guides and remove the brake drums

You can help with a hammer, but be careful: you can only strike through a piece of wood. Wrench No. 17 removes the bolts securing the axle shaft and then removes it.

Most often at this stage, most mechanics are faced with the fact that it sits tightly in place and cannot be moved even a millimeter. In such cases, the following techniques may help:

- Install the wheel on a couple of bolts and use it to twitch the axle shaft several times. You need to make movements sharply in order to loosen the part.

- Spin it left and right several times until it loses immobility.

At this stage, the axle is inspected for distortions or deformations. Their presence is unacceptable.

Cost of spare parts

The price of a new rear axle bearing may vary slightly depending on the manufacturer (but everything is within reason). So, the product costs about 125 rubles per piece. More expensive ones are GPZ bearings. They are sold for 250 rubles. A set of bearings can be purchased for 450 rubles. At the same time, one piece sells for 300. As for the axle shaft seals, they can be purchased for 30-50 rubles. By the way, all these products are interchangeable on all classic VAZ models and on the Moskvich model 2141. This is a very big plus.

- Inner diameter – 30 millimeters.

- Length – 0.07 meters.

- Height – 0.02 meters.

- Width – 19 millimeters.

- External diameter – 72 millimeters.

- Product weight – 340 grams.

Causes of failure

Every part on a car tends to become unusable. Rear wheel bearings are no exception, but any part has characteristic operational features. If the operating conditions are met, the part can serve for years, which is confirmed by the driving experience of current older drivers.

The main reasons for bearing failure are:

- careless driving;

- incorrect installation of the product;

- water and dust getting inside the hub;

- leakage of lubricant;

- long service life.

If a VAZ-2107 car is often operated in aggressive conditions close to off-road, then the need to replace the rear wheel bearing will not take long to arrive.

It is especially important to take into account the fact that the famous “seven” is a rear-wheel drive car. But how can you determine that a wheel bearing has failed and needs to be replaced? Let's find out in more detail

Methods for determining whether a wheel bearing is faulty

Timely identification of a malfunction allows you to prevent unpleasant consequences that can provoke an emergency situation on the road. The part in question on the VAZ-2107 car plays an important role, since thanks to this product the wheel rotates easily. The car has 2 rear wheel bearings, one for each rear wheel.

The main way to determine the malfunction of an important part of the hub on a VAZ-2107 is to carry out the following manipulations:

- raise the rear of the car on a jack;

- swing the outer part of the wheel in different directions;

- if a knocking noise occurs and the wheel dangles, then the rear wheel bearing of the VAZ-2107 needs to be replaced.

If the car drives while turning corners and a squeaking noise appears, this also indicates the need for repair work. To replace the wheel bearing, you will need the following tools:

- jack;

- wrenches and screwdrivers;

- chisel and hammer;

- puller;

- Litol brand lubricant.

After making sure that you have a complete list of tools and materials for the work, you can begin replacement.

Replacing a faulty product

You must begin replacing the product by loosening the wheel bolts. This must be done before the rear of the car is jacked up. At the same time, do not forget to install stops under the front wheels.

- A jack is installed, then the rear side of the car where the bearing needs to be replaced is jacked up. Once the car is raised, you can install a safety stump in case the jack comes off.

- The wheel is removed, and then the drum. It should be remembered that you cannot put the car on the handbrake, otherwise you will not be able to remove the drum. To remove the drum, you need to unscrew two pins and insert them into the technological holes. When the pins are tightened, the drum is pulled out, after which it can be dismantled.

- Using a screwdriver, pry off the steel cap or protective cover. The 4 nuts securing the axle shaft are unscrewed.

- We use a special puller, with the help of which the hub is removed from the drive axle axle. If there is no puller, then you can use a regular chain or cable, attaching it to the axle shaft.

- It is necessary to remove the worn bearing from the axle shaft using a puller or grinder. To remove the bearing using a grinder, you need to cut the outer race on both sides.

We make a cut to remove the old part

- Before pressing in a new product, it is necessary to thoroughly lubricate the seat on the axle shaft and in the hub. The bearing must be pressed in using a locking sleeve.

- The bushing must be heated with a blowtorch, then put on the axle shaft and cooled with water.

Further actions are performed in the reverse order of removal

It is important not to forget that when replacing a bearing, the sealing seals must also be replaced.

The bearing must not be misaligned, which can lead to its failure on the very first day of operation. If you operate the car correctly and carefully, then you can forget about replacing the bearing for 2-5 years. You can also read about replacing the front wheel hub bearing.

Important points

The inner ring of the bearing is cut off with a chisel

Replacing a bearing is a difficult task, but it can be done. The main thing here is to avoid damage to the axle shaft when cutting off the bearing and distortions when installing a new part. In addition, you should take into account the fragility of the bearing rings and use the hammer with extreme caution. Otherwise, the procedure is quite within the capabilities of even a novice car enthusiast, who, by doing it with his own hands, can save a significant amount.