What kind of tuning does the G7 suspension undergo?

In general, the VAZ-2107 car is very similar to the already outdated “penny”. The latter is completely copied from the Fiat-124. Therefore, many motorists try to improve the design as much as possible in order to achieve higher performance. Tuning will allow you to achieve the following results:

- Improve ride smoothness.

- Significantly improve vehicle handling.

- Significantly improve stability when driving at high speed.

- Increase the durability and reliability of all structural elements.

The easiest way of tuning is to install higher quality products on the car, which are produced by foreign companies. In particular, this applies to shock absorbers, the fine selection of which can solve a lot of problems, as well as “tailor” the car to specific needs. You can make it either soft and smooth, or hard but more stable when driving at high speeds.

Replacing a broken spring

To replace the spring (which also cannot be repaired), you need to remove the shock absorber and disconnect it from the roll bar. After this, you need to loosen the screws of the lower arm, after that it is jacked up, then using a special puller we remove the ball pin.

Now you can slowly release the jack, as a result of which the spring weakens and is easily removed from the cup.

Attention! A new spring can be placed in the support bowl only by first tightening it with a special tie. After this, the lower arm is pressed in the same way, then its ball joint enters the steering knuckle

Then you can release the spring from the tie. Shown is a diagram of spring compression using a tie

After this, the lower arm is pressed in the same way, then its ball joint fits into the steering knuckle. Then you can release the spring from the tie. A diagram of spring compression using a tie is shown.

In conclusion, it must be said that a novice motorist is quite capable of monitoring the serviceability of the suspension, the main thing is that he has an overpass or a pit at his disposal.

The suspension of any car consists of many different parts that have different functions. One of these parts is a ball joint, which is a connecting part that allows the front wheels to rotate in different directions. If a part malfunctions, serious consequences can arise, so we will figure out how to check the ball joint of a VAZ 2107, and what may be needed for this.

Main components

The front suspension of the VAZ-2110 includes the following elements:

- Shock absorber strut with welded steering knuckle.

- The ball joint that connects the lower control arm to the wheel hub.

- A support bearing is a device mounted on the body. With its help, the stand rotates around its axis.

- Hub - with the help of this mechanism, the CV joint rotates and motion is transmitted to the wheel. Installed on the steering knuckle.

- The levers fix the suspension elements and do not allow them to move in the longitudinal direction.

Each suspension element has its own characteristics; when it fails, characteristic signs will appear. It is by them that you can determine the breakdown.

Front suspension device on the VAZ-2110 device, design

Front suspension VAZ-2110: device and design

Why a suspension is needed and what responsibility it bears, everyone knows from driving school, if not from school

Therefore, we will not focus on general maxims, but will immediately get down to business

The VAZ-2110 inherited from the eight and nine the MacPherson suspension, developed back in the 70s of the last century and tested on the experimental VAZ-2108.

Of course, adjustments were made to the design and today it looks like this:

As can be seen from the diagram, there is nothing complicated in the design, and there is nothing superfluous. The Spartan suspension of the tenth family is of the type of independent suspension with hydraulic shock absorbers, coil springs 7 on the lower (23) wishbones. The right and left levers are hinged, using silent blocks, connected by a stabilizer bar. A stabilizer is necessary to maintain vehicle stability in turns and during active maneuvering. It is a rod made of springy steel with a bend for the muffler.

Front pillar

The most important, expensive and maintenance-requiring unit is the front shock absorber strut (16).

There's a suspension strut hidden somewhere here!

In the lower part, the rack is attached to the steering knuckle 19 using two bolts, one of which (18) is eccentric. By turning this bolt and releasing nut 17, the camber angle of the front wheels is adjusted. The front spring rests on the support cup 6 from below and on the upper support cup 10. To prevent breakdown of the suspension, a compression damper 9 is installed on the shock absorber rod.

The stand itself rests on top of cup 12, which is assembled with a rotary bearing 11. The upper support is a separate unit, it is fixed to the body mudguard using three self-locking nuts. The support has some elasticity in order to absorb high-frequency vibrations and not transmit them to the body, and free rotation around its axis by the rack and the front steered wheel is ensured by the upper bearing 11 and the lower ball joint 1.

The front struts are oil-based and dismountable.

Front suspension springs.

Front strut supports.

Front strut shock absorbers and protective covers.

The working shock absorber is installed in the strut housing. If necessary or when choosing a different type of shock absorber (gas, gas-oil), it is always possible to remove it from the strut body, repair or replace it. It should be taken into account that the figure-eight shock absorber is not suitable for the ten, since the strut body on the 2110 is shorter, although the design looks identical.

Ball joint and lower control arm

It is the ball joint that takes on all the loads - braking, accelerating, longitudinal and transverse, and in addition, it is the lower point of support of the steering knuckle.

Ball joint fastening unit.

Support 1 is fixed on the lower arm using three blind bolts. When disassembling this unit, you need to be extremely careful, since the holes in the steering knuckle for the support mounting bolts are not through and if handled carelessly, you can easily tear off the heads or break the body of the bolt. If this happens, you will have to drill out the remaining bolt or change the steering knuckle. This is labor-intensive and expensive work.

Ball joint with cover.

Lower suspension arm with silent blocks.

Stretch marks

To prevent bending of the lower arm and relieve braking and accelerating loads from it, braces are attached to it, the second end of which is fixed through a silent block to the front suspension beam.

Front suspension of VAZ-2110.

The stretchers perform another important function: they help regulate the longitudinal inclination of the rotary axis. This angle greatly affects the stability of the vehicle and its behavior when maneuvering. Adjustment is carried out using washers installed at both ends of the stretcher.

Rounded fist

An equally important detail is the steering knuckle.

Steering knuckle and hub assembly.

It is he who is responsible for the safety and fixation of the wheel bearing. The bearing is held in the fist by two retaining rings. Bearing type: angular contact, double row. It does not require adjustment throughout the entire period of operation.

The hub itself is pressed into the inner race, and it is secured with a nut, and the nuts on the right and left are the same and have a right-hand thread.

conclusions

In short, this is how the VAZ-2110 suspension works. We examined only the basic elements of the design, but the essence is clear - repair and maintenance of the front suspension is not at all a complicated procedure, the main thing is to know its structure and promptly identify and eliminate faults. Take care of your suspension and let only smooth roads under your wheels!

https://youtube.com/watch?v=gS1brgDQlSk

A little about the generator and its improvement

The battery must be recharged while the vehicle is moving. At this time, all devices are powered by a generator. The voltage should be within 14 Volts. So, if you have too many electrical appliances and the voltage drops to about 11-12 Volts, then there is one way on how you can increase the power of the device by about 10%. Such a modification of the VAZ-2110 generator involves the installation of one diode. First of all, we need to disconnect the battery terminal, and then disconnect the wire marked “D”. Next, you need to remove the clamps from the back cover of the generator. After that you will see the voltage regulator. We need to thread the wires from the pre-prepared diode through the holes in the generator cover.

View gallery

After this we connect the wires. To do this, the “mother” is connected to the PH, and the “father” is connected to the standard wire. After that, we need to close the back cover and screw everything into place. This completes the modification of the VAZ-2110 generator. The voltage should rise to approximately 13 Volts, which is closer to normal. By the way, it is advisable to use a diode with a breakdown of no more than 20 V and a current of 5 Amps. As for the voltage drop, it should be within 0.6-0.7 Volts.

suspension

| Helical suspension (coilovers) allows you to easily adjust the car’s suspension to different operating conditions. But such adjustable shock absorbers have one big drawback - their high price (a set from 50,000 rubles). Want to save money? Try making homemade coilovers. |

| One of the popular ways of tuning a car is to lower it. To do this, the suspension is modified using different methods, for example, cutting off the springs (which is not recommended), installing a lowered suspension kit, installing air suspension, or using suspensions with adjustable clearance. I will dwell on the last method in more detail. |

| On the VAZ 2110 (and some other front-wheel drive cars), rubber silent blocks are used in the cross member of the front suspension. To change the characteristics of the suspension and handling, they can be replaced with rubber-metal hinges (popularly “daisies”). Let's look at this improvement in detail. |

| Car silent blocks are hinged elements that serve to connect parts of the front or rear suspension and dampen vibrations transmitted from one unit to another. Most often they are made of rubber, but for tuning enthusiasts they offer polyurethane silent blocks. Do you know what is better to choose polyurethane or rubber? |

| Buffers are interturn spacers made of durable and elastic material, designed to increase the stiffness of suspension springs. According to the manufacturers, these accessories can not only make the ride more comfortable, but also extend the life of the suspension and increase ground clearance. They claim that the installation of an auto-buffer is comparable in its characteristics to the installation of an additional shock absorber and gives the effect of an air suspension. Is this really so? |

| If the car falls into a deep hole, cracks in the paintwork may appear on the strut support. Most often, Kalina owners encounter this defect, but older VAZ models (2108-21099, 2110-15) are also no exception. To extend the life of the body, there are special protective spacers that can protect weak points from damage, as well as prevent the further spread of existing cracks. |

| For the first time at AvtoVAZ, negative camber of the rear wheels was used on the sports Kalina. Later, minus camber of -1 degree was used on Grant and the new Kalina. Do you know how to make negative camber on a VAZ with your own hands? |

| AvtoVAZ recommends installing wheels with a camber angle of 0 degrees. When the wheels are parallel to each other, good traction and stable driving are ensured. Do you know why they do negative camber and how it affects the behavior of the car? |

| Many car owners complain about insufficient handling due to weak body rigidity and suspension mounting points. This problem can be solved using an integrated approach to improving the driving performance of the car - installing a subframe. |

| On front-wheel drive VAZ cars, the rear suspension is semi-independent (torsion bar), which has its advantages and disadvantages. To change the characteristics of the car, the rear suspension is changed to independent. Do you know how complicated this process is and what impressions you get after such tuning? |

| At the front of the car, as a rule, an independent MacPherson-type suspension, double-wishbone or multi-link suspension is installed. But the rear suspension may have significant differences. Depending on the car and its operating conditions, the rear suspension is dependent, semi-independent or independent with a different number of levers. Each design has its own characteristics, advantages and disadvantages, and which one is better? |

Replacement of front struts of VAZ 2110, 2111 and 2112

| The front struts of the VAZ 2110 are designed to absorb shocks and impacts on the car body. Their approximate service life is 60-100 thousand km. mileage, and it largely depends on operating conditions. If you notice that the car has become less stable on the road, replacing the shock absorbers will most likely solve the problem. |

Design and purpose of the VAZ 2110 front suspension

Let's look at how the front suspension of the VAZ 2110 is designed, how well it complies with modern standards, what functions it provides, and what attention it requires.

Purpose

First of all, it is intended for fastening the wheels, and is also designed to provide shock absorption for the entire front of the car, its stability on the road while driving, the possibility of a number of wheel adjustments, namely along the axis of rotation (the angle of its longitudinal inclination), toe, camber.

VAZ 2110 front suspension assembly diagram

Main nodes

Let's talk about its device.

The most important element of the front suspension is its strut (hydraulic telescopic) - indispensable in the matter of shock absorption, that is, ensuring a comfortable ride, without much shaking (as far as possible) over bumps and potholes on our roads. It is thanks to the rack, or rather its steering knuckle with an upper bolt equipped with an eccentric washer and a belt, that makes it possible to change the camber of the wheel.

Telescopic strut of the front suspension of VAZ 2110

The following are installed on the rack:

- Special spring;

- Buffer limiting the compression stroke, made of polyurethane;

- Upper support. Its structure is as follows: it is attached to a stand, to which the mudguard is attached with self-locking nuts. Therefore, if you make repairs yourself, do not miss this moment - you cannot use ordinary nuts;

- A bearing that makes it possible to rotate the stand together with the wheels;

- A shock absorber in which a spring and a plunger are installed for better performance.

The ball joint combines the lower parts: the steering knuckle and the lever. The longitudinal braces, lower arms, and supports that the crossbar has are connected to each other by rubber-metal hinges. With the help of special washers, it becomes possible to adjust the longitudinal inclination of the turning axis. An angular contact, non-adjustable bearing secures the wheel hubs.

Ball joint VAZ 2110

The cross member is the rod to which the lower arms are connected. In the middle it is attached to the body, in which it is helped by rubber cushions. This, in short, is the design of the front suspension. Now let’s look at possible malfunctions, which in some cases can be fixed with your own hands, in others it is better to contact specialists.

Cross member VAZ 2110

Knock

If you hear a knock in the front suspension while driving, the main reasons may be:

- Faults in the rack;

- The bolts have become loose, the stretch marks or cushions with which the cross member is equipped may have worn out;

- The attachment to the body has become loose;

- The rubber parts have collapsed, and the knocking has a distinct “metallic” sound;

- A “limp” or even a broken spring knocks;

- Wear of hinges;

- Knocking due to wheel imbalance.

In principle, in any of the listed cases, repairing the VAZ 2110 front suspension, done by yourself, can help, during which you need to replace a worn part or (in the latter case, the reasons why a knock is heard) - balance the wheel.

Vehicle pull to the side

The car pulls to the side when driving straight. The reasons for this malfunction may include:

- Each spring has its own compression ratio. In this case, the spring that has lost its elasticity must be replaced;

- Tires have different pressures. We check and correct;

- The rubber element near one of the strut supports was destroyed. At the same time, a characteristic knocking sound is also heard while driving. The problem is solved by replacing this element;

- The wheel alignment angles are incorrect. Increased tire wear may be associated with this malfunction. If you can’t handle it yourself, it’s better to entrust this task to specialists.

Tire wear

This may be due to improper driving (rash acceleration, braking, exceeding the permissible load of the vehicle), or other reasons:

- violations of wheel alignment angles;

- high wear of the hinges;

- wheel imbalance.

Suspension check

Knowing the meaning and design of the suspension, you will be able to check its condition every time you inspect the machine on a pit (overpass) and perform maintenance.

Pay special attention to the condition of the protective covers on the ball joints. Check to see if any deformations, cracks or dents have appeared on the suspension due to shaking and bumps.

Be sure to check the condition of all rubber and rubber-to-metal parts, as well as the ball joint of each wheel. Remember: a malfunction noticed and corrected in time is much less evil than repairs when everything is already falling apart.

Suspension modifications

Many owners of the VAZ 2110 do not consider the factory suspension to be ideal, and tune it to improve stability and handling on the road.

Typical faults

The front suspension is characterized by certain breakdowns, which are determined by two phenomena:

They should be considered separately, since the reasons for their appearance are different.

Knocks

If you start to hear knocking noises coming from the front suspension, this could be caused by several reasons:

- The rack has certain faults;

- The ties on the cross member, the cushions are worn out or the bolts are loose;

- The attachment to the body was not strong enough;

- The springs have failed;

- The hinges are worn out;

- The rubber part of the suspension has broken its integrity. The knock should be clear, like the impact of metal on metal;

- Wheel alignment is out of balance.

If you do not hear a knock, but a noise, then the causes of front suspension problems may be as follows:

- The bolts that secure the stabilizer bar to the body have become loose;

- The rubber components in the strut support have collapsed;

- The rubber pads of the coupler or rod are worn out;

- The suspension spring has broken or violated its geometry;

- The wheels are unbalanced;

- The compression stroke buffer has collapsed.

Increased tire wear

If you are not a fan of fast acceleration, harsh braking, or do not overload the car, then the reasons for increased wear may be:

- The wheel alignment angles are incorrect;

- The hinges are worn out;

- Wheel balance is off.

Chassis 2110

The front suspension of the VAZ 2110 is independent, telescopic. It is based on hydraulic shock absorber struts and coil springs, as well as lower wishbones with braces and a stabilizer bar.

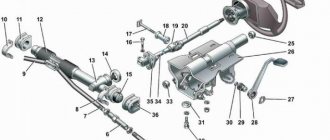

Telescopic stand

1 – compression valve body; 2 – compression valve discs; 3 – throttle disk of the compression valve; 4 – compression valve plate; 5 – compression valve spring; 6 – compression valve cage; 7 – recoil valve nut; 8 – recoil valve spring; 9 – recoil valve plate; 10 – recoil valve disc; 11 – throttle disk of the recoil valve; 12 – piston; 13 – bypass valve plate; 14 – bypass valve spring; 15 – plunger; 16 – plunger spring; 17 – rod guide bushing with a fluoroplastic layer; 18 – guide bushing cage; 19 – sealing ring of the rack housing; 20 – rod seal; 21 – oil seal cage; 22 – gasket of the rod protective ring; 23 – rod protective ring; 24 – nut of the strut body; 25 – compression buffer support; 26 – rod; 27 – spring cup; 28 – rotary lever; 29 – rod limit sleeve; 30 – rack body; 31 – cylinder;

32 – drain tube

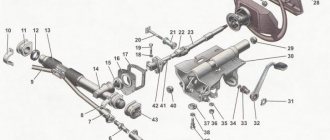

Front suspension assembly

1 – telescopic stand; 2 – nut; 3 – eccentric bolt; 4 – nut; 5 – steering knuckle; 6 – front wheel drive shaft; 7 – protective cover of the hinge; 8 – external shaft joint; 9 – lower lever; 10 – ball joint; 11 – decorative disk (cap) of the wheel; 12 – hub; 13 – brake disc; 14 – protective casing; 15 – rotary lever; 16 – lower support cup; 17 – suspension spring; 18 – protective cover of the telescopic stand; 19 – compression stroke buffer; 20 – upper support cup; 21 – upper support bearing; 22 – upper support of the rack;

A – control size

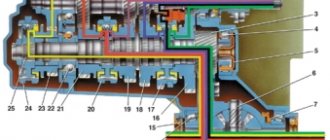

Steering knuckle and front wheel hub parts

1 – steering knuckle; 2 – outer mud ring; 3 – hub bearing; 4 – wheel hub; 5 – thrust washer; 6 – nut; 7 – retaining rings;

8 – internal dirt ring

https://youtube.com/watch?v=jhfbQtpuceg

Figure 1 shows part of the front suspension. It is based on a telescopic hydraulic shock absorber strut 1, the lower part of which is connected to the steering knuckle 5 with two bolts. The upper bolt 3, passing through the oval hole of the strut bracket, has an eccentric collar and a washer. Turning the top bolt changes the camber of the front wheel.

The following elements are installed on the telescopic rack: - coiled coil spring 17, - polyurethane foam buffer 19 compression stroke, - upper support 22 of the rack assembly,

— bearing 21.

The upper support is secured with three self-locking nuts to the body mudguard strut. Due to its elasticity, the support ensures the rack swings during suspension movements and dampens high-frequency vibrations.

Telescopic stand.

A hydraulic recoil stroke buffer is installed in the upper part of the cylinder, consisting of a plunger 15 and a spring 16. It limits the movement of the rod during the recoil stroke. The lower part of the steering knuckle 5 (see figure “Front suspension assembly”) is connected by a ball joint 10 to the lower suspension arm 9.

Braking and traction forces are perceived by longitudinal braces, which are connected through rubber-metal hinges to the lower arms and to the front supports of the front suspension cross member.

At the junction of the brace with the lever and the front support, adjusting washers are installed, which change the angle of the longitudinal inclination of the steering axis.

Important

In the steering knuckle (see figure “Steering knuckle and details of the front wheel hub”) a double-row angular contact bearing of a closed type is attached, on the inner rings of which the hub 4 of the wheels is mounted with interference. The bearing is tightened with nut 6 on the shank of the outer wheel drive joint housing and is not adjustable.

All front and rear wheel hub nuts are the same and have right-hand threads. The anti-roll bar is a bar, the knees of which are connected to the lower suspension arms through struts with rubber and rubber-metal hinges.

The middle (torsion) part of the rod is attached to the body with brackets through rubber pads.

We will replace

— Overhaul of the engine - overhaul of the removed engine - removal and installation - oil in the hydraulic booster - oil in the engine VAZ 2110-2111-2112, Lada Priora, Largus - engine valves - brake piston ring pads - gearbox mechanical repair - steering knuckle assembly - sump - engine crankcase - Spark wheel bearing - exhaust pipe Alexander Kalyuzhin, 2022. - cylinder head gaskets VAZ 2110-2111-2112, Lada Priora, Largus - valve cover gaskets - rear or front springs - radiator VAZ 2110-2111-2112, Lada Priora, Largus - camshaft - steering rack mechanism - steering tip left or right - steering rod right or left - lower front suspension arm right or left - rear hub - starter VAZ 2110-2111-2112, Lada Priora, Largus - front hub with knuckle and brake disc assembly - clutch - fuel pump - fuel filter - ball joint VAZ 2110-2111-2112, Lada Priora, Largus - ball joint with rivets - Daewoo internal CV joint - CV joint, Spark external - CV joint, external boot - cabin filter, oil Alexander Kalyuzhin, 2022.

Extraneous knocks in the suspension

Often, a knocking sound from the front suspension of a VAZ 2110 appears when the ball joint fails

Please note that the knocking noise may disappear at high speeds, but appears when driving at low speeds. It is also issued at the moment when someone gets into or exits the car. In the event that a knock in the front suspension appears precisely because the ball joint fails, the repair will cost you about 300 rubles

In the event that a knock in the front suspension appears precisely because the ball joint fails, the repair will cost you about 300 rubles.

This is how much the hinge and boot cost

Please note that it is best to fill a small amount of lubricant under the boot, for example, Litol-24 or CV joint. This can slightly extend the service life of the hinge. Of course, no suspension can work without a lever system that gives the car stability.

Of course, no suspension can work without a lever system that gives the car stability.

The lower arm of the front suspension, attached to the wheel hub using a ball joint, is considered, perhaps, the main element of the design

Please note that the lever is attached to the body using rubber-metal silent blocks. In the event that the two sides of the car work independently of each other, without communication, the body will go wrong. Regardless of what levers are used, there will be no stability when the car moves during cornering or other maneuvers.

It is for this reason that stabilizers are located between the left and right wheels. With their help, synchronous operation of all suspension elements on both sides occurs

Regardless of what levers are used, there will be no stability when the car moves during cornering or other maneuvers. It is for this reason that stabilizers are located between the left and right wheels. With their help, all suspension elements on both sides operate synchronously.

The front suspension of the VAZ 2110 also consists of one very important unit, with the help of which the shock absorber rod is movably attached to the body

Please note that in dozens, as well as in any front-wheel drive cars, the rack has the functions of a mechanism that turns the wheels

In other words, it should rotate without problems. The support bearing is very simple in design, no different from any other mechanism with a detailed operating diagram. But the front suspension of the dozens will not be able to work normally without this element

When carrying out repairs, you must pay attention to the condition of the support bearing.

If it fails, a knock or other extraneous sounds appear. It is quite possible that the bearing may simply jam. In this case, turning the steering wheel will be impossible. Replace the support bearing, as well as all other suspension elements, according to the repair and maintenance plan for the VAZ 2110 vehicle.

The tips from the steering rack are connected to the shock absorber strut. Approximately in the middle of the rod there are adjusting nuts, which are necessary for adjusting the toe angles of the wheels. The camber is adjusted using two bolts that secure the hub to the shock absorber strut.

The front suspension of the VAZ 2110 is very simple and contains a small number of elements. You can do the repairs yourself very simply, and you don’t need a large number of special tools

But pay attention - this type of suspension is very effective in city mode. If you need to drive in off-road conditions, it is better to look at rear-wheel drive cars or all-wheel drive

How to upgrade wipers

In most cases, the windshield cleaning area will be improved. In principle, there is nothing complicated here. But first you can change the wipers if they do not cope with their function

It is worth drawing your attention to the fact that from the driver's side the visibility should be 100%, especially on the left. Dirt appears right on the left pillar side, which the wipers cannot cope with.

One of the outputs is to adjust the position of the device. In our case, it is necessary to slightly raise the driver's wiper, that is, change its initial position. But not everyone will like this method, and the result is not 100%, since some of the dirt still remains. In this case, a slightly different modification to the VAZ-2110 wipers will be required.

Sometimes the cause is a windshield that does not allow the glass to be cleaned evenly. In this case, for a more noticeable result, you need to bend the frill leash. You can direct the hook under the brush; near it we need to bend the leash a little. There's already a factory bend there that we need to make a little bigger. In addition, you need to bend the end of the wiper spoiler slightly upward. This is done so that it does not catch the brush. After this, it is advisable to check if everything worked out for you. That, perhaps, is all that needs to be done on the VAZ-2110. Modifications to the wipers, of course, are different, but they are done quite quickly and simply, so you will succeed

Now let’s move on to something no less important – the car’s heater, which warms us up in the cold. There is a lot you can do here, but let's talk about the most important thing.

View gallery

CV joints

Most often, a faulty CV joint manifests itself as a distinct crunching sound when the steering wheel is turned in any direction when driving hard. When this symptom is observed in a car, it makes sense to drive the car into a pit and check it.

In order to check the CV joint yourself, you first need to perform a visual inspection; if the boots are torn, there is a high probability that the CV joint is faulty, since the dirt that will fly under it will act as an abrasive and will accelerate wear several times.

Next, check for play. To do this, grab the drive and pull it clockwise and counterclockwise; if you feel play, it means the CV joint is faulty.

The above is not all that is included in the diagnosis. These procedures will only help determine the general condition of the main suspension components. For a more in-depth analysis of the wear of a particular element, equipment that is only available at a service station may be required.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at