April 30, 2021 Lada.Online 22 660 13

We have written about the howl and hum of VAZ gearboxes (manual and AMT) more than once. The reason is gear vibrations. The problem can be radically solved only by updating the factory equipment, which is not planned in the near future. Is it possible to reduce increased gearbox noise using transmission oil additives?

We have identified three of the most popular gear oil additives. Here's what LADA car owners write about them.

Description of transmission

Below we will consider the most important indicators that affect the operation of the car:

- the gear ratio for the VAZ 21807 shows figures of 3.94, for the French analogue this figure is slightly lower - 3.87;

- with this transmission, the Lada Vesta accelerates to one hundred in 10.2 seconds, which is a second faster than the JH3 - 11.2;

- the maximum speed for the VAZ 21807 is 188 km/h, for the JH3 the figure is 178;

- The fuel consumption of Lada Vesta with a domestic gearbox is 7.5 liters, the French gearbox consumes 7 liters.

Manual transmission

The most important thing the engineers worked on was modifying the transmission tooth profile. They took an example from European models, where the noise of the gearbox should merge during downshifts with the roar of the engine. Lada Vesta designers applied new developments, improving the entire system and adjusting its balance.

What is the moral of this fable?

One gets the feeling that among all the shortcomings of Vesta, the main one is the low level of production culture (in simple terms, the crookedness of the hands of those who assemble it). And also the need to forcefully kick official dealers so that they do their job.

Timing roller. It seems like a cheap part, but if adjusted incorrectly it can become a source of much bigger problems. An overtightened belt wears out faster, and the load on the shaft bearings and their wear also increases. Regular replacement of the belt on Vesta is provided every 180 thousand kilometers. What will tightened belt turn into after such a mileage?

During a conversation with the master, he casually said that they had another Vesta in service and was waiting for an engine replacement. The reason is a jammed timing belt tension roller, which results in a belt break and the valves meeting the pistons. Mileage - 30 thousand kilometers. Draw your own conclusions.

Problems with manual transmission VAZ 21807

Knowing about the shortcomings and errors of the transmission on the basis of which the 21807 was designed, buyers are subconsciously wary of investing money in a car with such a transmission. Statistics show that almost half of consumers want to buy a Lada Vesta with a French gearbox.

The howl may be mistakenly attributed to the VAZ 21807. If the manual transmission hums in neutral gear when the speed decreases from 3000 rpm, the reason may well be a defect in the muffler vibration compensator.

Driver's method - through transmission

If the reverse gear on your Lada Vesta is engaged with problems, crunching, not the first time, and there is no time to wait a few seconds, then there is another way.

Surely many drivers paid attention to the following fact. If you decide to park, drive up to an obstacle in 1st gear, squeeze the clutch, brake

If you immediately engage 5th gear, this will happen without problems. This is the principle of “through transmission”.

I'll explain in more detail. The car is parked, the engine is running, the gear knob is in neutral. We need to backtrack. Everything can be done according to the instructions. If you don’t have time to wait, then squeeze the clutch and engage not reverse, but 3rd gear. After it, immediately engage reverse gear. Then there will be no crunching or problems.

New gearbox 21807 in Lada Vesta - owner reviews

My car has a VAZ manual transmission. As long as you're happy with the work, manufacturers don't lie. You have to wait for something to break in order to identify errors or hope for the best and the absence of a breakdown. The howl of the box was not noticed, and I also did not hear any hum or extra noise. There are no sudden jerks when changing gears, reverse speed does not cause headaches. I don’t notice much difference compared to foreign manual transmissions.

People are doing the right thing by not completely trusting their compatriots. Lada Vesta is almost a foreign car anyway. When you hear that a reliable French box is being replaced with something of their own that is not particularly trustworthy, interest in the product disappears. Consumption increased by half a liter. This is a lot for a long journey. Acceleration to one hundred and maximum speed are, after all, not the most important things for the reliability and durability of the box.

My Vesta with a VAZ manual transmission began to hum after 500 km. This upset me very much, because at first I didn’t feel any problems, but now I have to contact a repair center. At first I heard a rattling noise, which went away after the engine warmed up. It's very annoying when the box buzzes. Unpleasant howls are heard in three gears. I hope the technicians will fix everything and this problem will no longer arise on my Lada Vesta.

As a rule, when buying a new car, those who are primarily concerned about reliability opt for models equipped with a manual transmission. And this is not surprising, because in general the “handle” is more reliable compared to an automatic machine.

The same applies to potential buyers of LADA Vesta. Many people prefer the “handle”, not only for the reason stated, but also because the Russian sedan does not have a classic automatic transmission. There is only a robotic transmission - AMT - however, this option, although it has certain advantages, still does not suit everyone.

Driver's method - through transmission

If the reverse gear on your Lada Vesta is engaged with problems, crunching, not the first time, and there is no time to wait a few seconds, then there is another way.

Surely many drivers paid attention to the following fact. If you decide to park, drive up to an obstacle in 1st gear, squeeze the clutch, brake

If you immediately engage 5th gear, this will happen without problems. This is the principle of “through transmission”.

I'll explain in more detail. The car is parked, the engine is running, the gear knob is in neutral. We need to backtrack. Everything can be done according to the instructions. If you don’t have time to wait, then squeeze the clutch and engage not reverse, but 3rd gear. After it, immediately engage reverse gear. Then there will be no crunching or problems.

Problem

However, as experience in operating the model has shown, the manual transmission is also not without some drawbacks. Sometimes owners begin to clearly hear extraneous sounds, similar to crackling and clicking noises in the manual transmission of the Lada Vesta. Moreover, for some they appeared on completely new cars that had not driven even 15,000 km.

In most cases, noises are heard while driving in third gear, however, over time, the situation worsens and a similar sound, only even more pronounced, begins to appear in fourth gear. But only in cases when the accelerator pedal is released.

This is clearly demonstrated in a video made by one of the members of the DRIVE2 community, known there under the nickname Zheka700.

The fact that this is a crackling and clicking sound in the manual transmission of the Lada Vesta is also confirmed by the fact that it is enough to press the lever handle a little and the sound disappears. This means that the problem is directly in the transmission, and not in the lining.

Which boxes howl?

The noise problem appeared after Auto VAZ introduced a manual transmission of its own production with a cable drive. These boxes pleased us with clearer gear shifting, but disappointed us with a rather loud howl, especially in 2nd and 3rd gears. The transmission that has this problem is manual transmission 2181.

Box 2181 is an improved previous model 2180. Instead of rigid rods, it is driven by a cable drive. Thanks to the reduction in the bevel of the synchronizer teeth, the gears began to engage more clearly. In 1-2 gears, conventional synchronizers were replaced with multi-cone synchronizers.

New Lada: Do-it-yourself adjustment of Lada Granta headlights: instructions

The plant received a large number of complaints from car owners, so in 2022 the manufacturer modernized the transmission. As AvtoVAZ assures, the updated version has become 25% quieter, but it is still far from ideal.

AvtoVAZ reaction

It is worth noting that not all sedans are susceptible to this problem, but only the first batch cars.

In September 2016, the issue was resolved - all Vestas began to be equipped with new manual transmission cables. So the Russian automobile concern acted quite quickly.

As for the instructions, if such a defect exists, AvtoVAZ recommends contacting the dealership and having the cables replaced.

However, not all owners are ready to do this. The fact is that such a procedure is quite lengthy, since to replace it it is necessary to dismantle the entire dashboard, then remove the steering column, including the electric power steering, and also the heater. Also, such a replacement involves draining antifreeze and freon.

Naturally, this is quite a long time and not every Vesta owner is ready to give the sedan for service for such a long period of time.

If such a situation arises, but you want to do without replacing the cables, and the car is under warranty, it is strongly recommended that you make an appointment for diagnostics at a dealership. And in order to narrow down the search and help those who decide to fix the defect themselves, we will give recommendations on where to look first.

How to eliminate the howling of a VAZ box

The first thing you can do is contact the service center and request that the noise be eliminated as part of the warranty repair. This process is long, painstaking, requires patience and does not always end in victory. In most cases, the manufacturer claims that the sound during transmission operation is normal and the vehicle is not subject to warranty repair. But if the sound is very loud or the buyer is very persistent, the manufacturer suggests replacing the box. But, judging by the reviews of drivers who managed to replace the manual transmission under warranty, this does not always solve the problem. The fact is that a howling box is a manufacturing feature, not a defect, so whether it’s worth replacing it with exactly the same one is up to you to decide.

Modification of the clutch cable

Sometimes the noise is due to vibration transfer between the fork and the clutch cable. This problem can be solved with a simple modification that does not require financial investment. You need to remove the clutch cable from the fork, replace the standard rubber insert with a washer made of softer rubber, which dampens vibration well. The element is glued to a plastic part, which serves as a stop for the cable.

This method does not help everyone and will not allow you to achieve ideal silence, but it makes the unpleasant sound much quieter. In any case, it won't hurt to try to implement this simple modification.

Dismantling

Before you begin work on eliminating crackling and clicking noises in the manual transmission of the Lada Vesta, you will need to remove the central tunnel. It consists of 2 sections - front and rear, with the rear being noticeably smaller.

To remove the rear section, you need to arm yourself with a ratchet with a Torx 20 bit (asterisk), use it to unscrew the 2 mounting screws, and then remove the plug. The trim itself is carefully pulled out - to do this you will need to remove the handbrake from it.

As for the front part, the tunnel is covered with plastic shields on both sides. They are secured with screws (1 per side), which need to be unscrewed and the plastic removed.

The screws need to be unscrewed

Then, carefully prying up the frame with a knife or screwdriver, the cover of the manual transmission lever is removed, after which the plug is disconnected and the lining is removed.

In the end, all that remains is to unscrew the 4 mounting screws and remove the remaining cladding.

Everything is clearly shown in the plot.

Why might there be interruptions when engaging first gear?

The reasons for the breakdown of this unit worry many Kalina owners, since the failure of certain gearbox elements, due to which the gears are poorly engaged, can already be called a “disease”. And this disease, one way or another, is associated with a certain defect in the production and assembly of serial models of this car at the plant, which, unfortunately, was never eliminated by AvtoVAZ engineers.

In fact, there may be quite a few direct reasons why the first speed does not engage well, as a result of which even experienced specialists will not be able to immediately calculate the breakdown. What can we say about ordinary car enthusiasts?

Work in the salon

Retainer

It is the plastic clamp, to which the drive cable is connected on one side, while the transmission lever is attached on the other, that is one of the possible reasons.

To get rid of sounds, it is recommended to place elastic material under the cable. This will cause the cable entering the clamp to rest against the lining. As a rule, simple electrical tape is used.

To do this, the tape is first glued in half (with the adhesive side inward), after which the cable is pulled out a little and the tape is installed. The cable is put back and it will push the tape into the lock itself.

It is recommended to carry out similar modifications for both clamps.

Ties and lining

The cables themselves are attached using plastic brackets, and a slight play is visible, which can also become a source of background noise.

Causes of gearbox failure

The complex mechanism constantly works under load and under extreme conditions. Constant vibration, rising temperatures, dust and dirt. If one or more speeds fail to turn on, you should check:

- cable tension and integrity;

- fastening the scenes;

- wear on the clutch disc;

- petals on a basket;

- bearing integrity;

- plug condition.

Clutch

When the clutch discs wear out, the pedal moves up and its position becomes higher than the others. In this case, when turned on, a crunching sound may be heard and the lever does not move, as if it is resting against an obstacle. You should not force the assembly, as this can lead to more serious damage - the gears will fly.

You can check by removing the rubber plug. The destroyed disc leaves fibers that look like tangled strands of hair. If such a phenomenon occurs, then a new clutch disc should be installed.

Due to constant loads, the cable stretches and must be periodically adjusted and tightened. In this case, the VAZ 21093 does not engage the first and second gears, and the rear may also fail. To fix the breakdown, you need to drive into the pit and tighten the cable. If it is worn out, replace it immediately. You can do this yourself.

A similar breakdown can also manifest itself in the failure of the gears to engage while the engine is running. Sliding along the splines is limited and fixation does not occur.

Basket

The reason for difficult shifting of individual gears, especially if there is a crackling sound that gradually fades during movement, may be the destruction of the spacer ring in the basket

Notice that there are drops of oil on the outside. Then remove the basket and check the O-ring and disc blades

Pay attention when purchasing new parts, because on some models the disk is missing and then you have to install pins and secure it yourself.

Engine compartment

Near the manual transmission

If modifications in the interior do not produce results, it is recommended to look for the reason under the hood.

To begin with, you can better secure the cable directly in front of the transmission using plastic clamps.

Screed in front of manual transmission

Near the engine shield

The fourth option for independently eliminating crackling and clicking noises in a Lada Vesta manual transmission also involves the use of plastic clamps, but they must be placed not near the place of fixation, but as far as possible from it.

Screed near the engine shield

In this case, you just need to tighten the cables together with a clamp.

What changed?

The logical question would be, what has changed in contrast to the old 2180 box? Has it become quieter? Has the howling gone?

AvtoVAZ, with the help of foreign partners, did a great job in refining the box. What was done: The production complex was equipped with other equipment in order to create a main gear and a second gear with a different gear tooth structure. The work was carried out in such a way that when braking the engine, when shifting gears down, the hum of the box was not so pronounced and coincided with the hum of the engine. In addition, the gear selection mechanism has also undergone minor modifications: now the gearbox shifts have become much clearer.

Couplers and spring

In this case, there is no need to go into the engine compartment. This troubleshooting option was proposed by another member of the DRIVE2 community named Roman, who is known there under the nickname Roy04.

First, he dismantled the lining of the central tunnel to gain access to the mechanisms. After examination, it was determined that the sounds were coming from 3 points.

Further, after a test drive with the tunnel removed, it turned out that this was not the cause, but only its consequence. It's all about the design of the Lada Vesta transmission. Due to the design features, when driving at speed III, vibration occurs in the gearshift mechanism, which is directly on the transmission (under the hood). And from behind the scenes the cable vibrates and moves longitudinally.

There are no devices for damping these vibrations, but you can make your own “counterweight”, from scrap materials. To do this, you can use plastic clamps and a spring, for example, from a figure eight carburetor.

With the help of clamps, the rigidity of the components that make sounds is increased, and the spring guarantees tension on the manual transmission handle itself.

As a rule, after such modifications, crackling and clicking noises in the manual transmission of the Lada Vesta disappear.

In mid-2016, AvtoVAZ officially abandoned the use of manual transmissions from the French manufacturer Renault. The reason is the high cost of the “product” and the lack of a base for maintenance.

If domestic gearboxes cost 20–25 thousand rubles, then imported ones reached 45–50 thousand. Obviously, such a rise in price automatically increased the cost of the car as a whole. Perhaps because of this factor, many car enthusiasts preferred a model with a classic automatic or robotic option.

However, there are those who claim that the quality of production of domestic new mechanics (21087) is inadequate. They are ready to pay an additional 30,000 rubles for the French version. Let's compare the Renault JH3 (JR5) manual transmission and the VAZ 21087 manual transmission.

Let's look at the instructions for identifying AMT faults

The check procedure is described in the book on operation, repair and maintenance of the Lada Vesta car:

1. We make sure that the AMT control system is working, to do this, turn on the ignition. Then, pressing the brake pedal, move the selector lever in turn to all positions, and the corresponding symbols should be displayed on the instrument panel. After that, return the selector lever to position N (“neutral”).

2. Start the engine. If you hear a whining sound , the clutch release bearing is likely worn out. A similar sound may be caused by worn transmission bearings.

3. Keeping the brake pedal pressed, we switch the selector in turn to all positions, while making sure that the gear shift mechanism is working. Turning on should be easy, without crackling or crunching.

- If the whining sound intensifies , the clutch release bearing is worn out. If the sound disappears, then the gearbox bearings are worn out.

- If you hear a cracking sound and the car jerks , it means that the clutch is not disengaging completely. The cause may be a malfunction of the gear shift mechanism, wear or loss of elasticity of the clutch diaphragm spring, as well as a malfunction of the electric clutch release drive. To check the gear shift mechanism and the electric clutch release drive, it is necessary to check the fault codes stored in the transmission control unit, so this work should be performed at a specialized service station with the necessary equipment.

4. Set the selector lever to position N (“neutral”). We lower the brake pedal, but the car should not start moving.

We also recommend that you read

5. Check the operation of the Lada Xray gearbox in motion. To do this, turn on mode A (forward movement in automatic mode) and slowly press the gas pedal. In this case, the clutch should engage smoothly. We move first with acceleration and then with deceleration, making sure that the clutch is engaged smoothly, that gear shifts smoothly (both up and down), and that there is no crunching, knocking or other extraneous sounds from the gearbox.

6. Turn on M mode and repeat the test, shifting gears manually. To do this, move the selector lever first towards the “+” symbol and then “─”. The box should work smoothly, changing gears in the selected direction.

7. Stop the car and move the selector lever to position R. After releasing the brake pedal, the car should start moving backwards.

- Jerking and rattling when the clutch is engaged can be caused by oiling or warping of the clutch discs or destruction of the torsional vibration damper.

- Untimely gear shifting , or engaging a gear that does not correspond to the driving speed, is caused by a malfunction of the transmission control unit.

- Jerks and delays when changing gears while the car is moving, or shifting into gears with an impact may indicate a malfunction of the gear shift mechanism or the electric clutch release drive. Troubleshooting such problems requires reading fault codes stored in the transmission control unit, so such work should be performed at a specialized service station with the necessary equipment. In addition, when replacing a faulty electric drive mechanism, it is necessary to configure the transmission control system. Otherwise, correct operation will not be possible.

Specifications

| Name | Renault JH3 (JR5) | Manual transmission - 21087 |

| type of drive | Wire rope | |

| Number of speeds | 5 | |

| Main couple | 3,9 | |

| Gear ratio | 3,87 | 3,94 |

| Acceleration to “hundreds” | 11,2 | 10,2 |

| Maximum speed (km/h) | 175 | 188 |

| Fuel consumption (l/100 km) | 6,9 | 7,5 |

| Gear ratios for each gear | 3,636; 1,950; 1,357; 0,941; 0,784 | 3,727; 2,048; 1,393; 1,029; 0,795 |

Installing a shorter main pair increased the dynamics of acceleration, taking one second from the French “brand”. Adjusting the gear ratios for each gear made the transitions to higher gears smoother, without jerking, and dynamic.

Is it worth flashing

This is an individual decision for each driver.

You need to understand the consequences of this procedure. The dealer will see this firmware, and it is unknown how he will react to it. It is a fact that the car drives better. The new mode is more correct for engine operation. There are no unnecessary jerks or slips, it just switches smoothly. If the car is under warranty, then you should know the consequences if a warranty claim occurs. I don’t recommend flashing if the clutch is about to be replaced. Firmware 3.0 will only ruin it, but there will be no harm to the new clutch. Also, before changing the program, negotiate with the technician on shore so that you can come and roll back to the stock firmware while you contact the dealer.

In addition, do not forget to adapt the gearbox every 10 thousand km. This is setting the correct positions of the actuator.

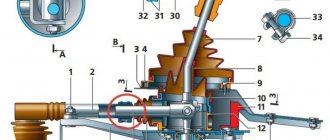

Design and diagram of manual transmission on Lada Vesta

with engine capacity

1.6 / 106 hp., 1.8 / 122 hp.

| Name | Data |

| Type | Mechanics |

| Factory index (article) | 21087 |

| Drive unit | Front |

| Engine capacity | 1,8 |

| Torque | 170 Nm |

| Default oil type | ZIC GFT 75W-85 |

| Oil volume | 2,2 |

| Lubricant replacement | Every 75,000 km |

| Filter update | Likewise |

| Average service life before major overhaul | 180000 km |

Checkpoint operation diagram

To find out the transmission type of your car, look at the VIN code:

- GFL11: mechanics;

- GFL12 - AMT box;

- GFL13 ─ mechanics from Renault.

Why did you abandon the French box?

Previously, Vesta was equipped with a manual transmission with index jh3 and jr5. Undoubtedly, they were better than the VAZ mechanics of that time, but they still had jambs with hum and gear shifts. But the most important factor in refusing French units was the cost: French mechanics are almost 2 times more expensive than domestic ones. The situation is the same with the Nissan engine; they will not install it on Vesta, they will leave the 129 and 179 engines. In addition, box 21807 is capable of withstanding the torque of a 1.8 motor. (In general, the VAZ gearbox holds torque well; as an example, you can use motorsports athletes who install a standard gearbox on turbo VAZs).

“Pros” and “cons” in comparison with an automatic machine (robot)

| Advantages | Flaws |

| Acceleration dynamics have become better, the car picks up speed faster | Increased fuel consumption in the combined cycle |

| The car is 30 - 35 thousand cheaper when purchased with a manual transmission | Crunching, creaking when driving at low speeds |

| Long service life | |

| Cheapness of spare parts and components | |

| The car is more expensive on the secondary market compared to the robotic version |

Lada Granta Liftback Odyssey › Logbook › How to get rid of manual transmission howling

An intriguing name?) So, I already described how on Saturday I changed the transmission oil to synthetic ZIC GF TOP, plus on Sunday I installed additional door seals RGI-135 and RKI-19. Yesterday I traveled, walked a little more than two hundred km, along the highway and around the city. I share my impressions.

As I thought, the miracle did not happen. The box continues to howl, but it still works with a softer noise and is quieter. I drove backwards out of the yard and even “lost” the engine noise, as if the car had stalled. In neutral, it also seemed to rumble somehow softer, I don’t know.

When driving at high speed, the wind continues to whistle somewhere right behind your head))) I was very unpleasantly surprised. What's whistling there? What gap? It's like the window isn't fully closed. This was upsetting at first. But when I was driving home with a passenger, I suddenly noticed that it had become more comfortable to talk, I could hear my interlocutor better, I didn’t have to speak louder for him to hear me. You don’t need to turn up the volume of the radio much at speed to drown out the noise... That is, the cabin has become really quieter. Zero good!) Well, in cold weather it should be warmer in the cabin due to the fact that it has become more airtight. We need to think at our leisure how and where else to compact =)

Back to the main point. To the howl of the box. Having realized that this problem could not be overcome with oil, I began to observe at what moments this sharp, irritating sound appeared. And this is what I noticed. With this car, I quickly realized that the engine pulls well and higher gears can be stuck in early. That is, I slowed down in front of an unregulated intersection, for example, quickly turned my head to see that there was no one there, stuck the third one in and accelerated (that’s where it howls)). Or, for example, he slowed down to move over the rails more smoothly, then a third and forward, howling again. Well, similar situations when the third gear is stuck at low speeds, when there are few revolutions. At this moment this nightingale song begins around 2000 rpm. I guess anyone whose gearbox howls in third gear has the same driving style as I do)) I checked, if you are not too lazy and first turn on second speed, accelerate closer to 3000 rpm, and then switch to third, then there is no howling. Yes, when accelerating in second and third, a more serious roar of the engine appears from faster acceleration (personally, I’m quite happy with it), but the box doesn’t squeal. In order to drive like this, you need to change your driving style a little, to more accurately feel your speed, when it is better to go to second and when to third. Otherwise, it may be that when you turn on the second car, the nose may nod off, if the speed still turns out to be high, you need to hold the throttle more in such cases when you release the clutch. In short, practice is needed. But I have no idea how to get rid of the howling noise when braking the engine. You can, of course, not use engine braking at all, but that’s only in the summer; in the winter, it’s a hell of a thing.

More about Shumka. I sat in the cabin, leafed through a VAZ magazine and read a funny thing. They write something like this. Like the owners of non-luxury Grant cars do the sound insulation on their cars themselves. But the manufacturer believes that it is not necessary to sizing the car, but to eliminate the sources of these noises. Holy shit, what do they mean by that? Should I change the gearbox to an automatic?) How else should I eliminate noise sources?)

PS: An hour after I wrote this, I drove around the city. Once again I tested my theory with gear shifting... It's all bullshit))) In city mode it's impossible to drive like this (in the sense of taking the second gear all the time to accelerate at 3000 rpm), it's too fast. You have to switch frequently, slow down, etc. and so on. In general, this is not a solution at all. It still howls, not on the third, but on the second...

Malfunctions and ways to eliminate them

| Malfunctions | Troubleshooting Methods |

| Transmission howl at 2000 – 3000 rpm | Insulation lining for gearbox control cables |

| Knock at idle | Replacing the pressure bearing |

| Critical wear of gears and teeth | Replacement with new ones, cannot be restored |

| Oil leaks from seals are less common. | Replacement of sealing seals with new ones. Overhaul of gearbox |

Brief features of the robot (AMT)

Robot on the Lada Vesta The robotic transmission on the Lada Vesta is domestically produced and widely used, but is created on the basis of foreign components and the extensive experience of French and Japanese colleagues.

The advantage of AMT is as follows: actuators from Germany are mounted inside the robotic gearbox, the clutch is from the French company Valeo; The robot box is equipped with a system for compensating for wear of parts and clutch failure; AMT has less weight than an automatic transmission (automatic transmission), therefore it reduces the cost of gasoline and oil; the Lada Vesta robot system eliminates unauthorized switching; it is possible to use a lever to change gears; built-in option for resetting stages; you can move away without pre-warming; the robot can operate with a low battery and skid for a long time when entering snowy or sandy terrain; repair and operation costs little money; Cars are towed without any visible disruptions.

AMT gradually replaced the automatic from the entire Lada model range, as it operates smoothly and relatively quietly. The developers say that such a transmission can last about ten years. A manual gearbox cannot boast such durability due to the fact that it has many components, while an AMT is easy to create.

Immediately after the release of the robotic transmission, rumors appeared about big problems in its operation. There have been complaints that the lever needs to be put in neutral after every braking. They said that the box was setting the gear incorrectly. These misunderstandings were rejected by the headquarters of the Russian manufacturer and did not find sufficient evidence in widespread consumption.

Service life - from the factory and actual

The manufacturer in the operating instructions indicates an average interval of 180,000 km before major repairs. In fact, the mechanics last up to 200,000 km, provided that the manufacturer’s recommendations for care and maintenance are followed.

At the stage of using mechanics, breakdowns associated with depressurization of the system, oil leakage, and wear of the pressure bearing are most often recorded. Malfunctions are insignificant, not critical, and can be eliminated in a few hours of work by technicians at a service station.

Conclusion

The manual transmission under the factory code 21087 is a real technological breakthrough of domestic engineers. The transmission turned out to be not only more powerful, but also faster. At the same time, fuel consumption increased by 0.5 liters.

“Mechanics” has its advantages and disadvantages compared to the robotic version. Therefore, before purchasing, carefully analyze the technical characteristics of each type of gearbox.

From personal experience I will say the following:

- The mechanics are most adapted for active use on rough terrain.

- The robotic version, “automatic”, is mainly used for high-speed modes.

Is there any point in changing transmission lubricant?

Technical documentation confirms that there is no need for frequent oil changes for Lada Vesta. The plant actually fills in high-quality oil designed for the entire service life of the car. And yet, there are certain regulations established by the manufacturer. The regulations are quite long and amount to 75 thousand km or 60 months of vehicle operation. This procedure is not included in the list of warranty work.

Many experienced motorists are convinced that factory lubricant is of dubious quality.

This is allegedly confirmed by reviews from experienced owners who, when draining the factory oil, paid attention to its strange appearance. It turns out that the waste material looked like such oil would hardly benefit the gearbox in case of long-term operation

At the same time, it must be recognized that this is an unofficial opinion that is advisory in nature. Many people prefer to change the oil at their discretion. There are often cases when, after independently changing to new oil, owners noticed improvements in the operation of the transmission. The noise and vibrations that owners of Lada Vesta with factory lubrication often complain about disappeared from the gearbox.

Thus, we can conclude that it makes sense to change the factory oil only if the owner of the Lada Vesta notices unclear gear shifting, as well as hum and vibration in the gearbox. The oil change process (draining and filling) usually takes 30-40 minutes.

Reviews

| № | Positive |

| 1. | Dmitry , 33 years old (drive2.ru): they can’t say anything bad about the mechanics, the gearbox works properly. The car is only a year old, I regularly undergo maintenance, I don’t drive, I drive carefully. |

| 2. | Vyacheslav Petrovich , 47 years old (prom.ua): in a year and a half I drove about 20,000 km, mileage is above average. Impressions of the new mechanics are only positive. There is something to compare with; before this there was the Lada Granta. Grantmakers understand what I'm talking about. |

| 3. | Alexander Alekseevich , 43 years old (drom.ru): after buying the car, I changed the transmission oil for the first time at the 7000 km mark. I didn’t wait for 75,000 km, as the manufacturer recommends. The waste was of a natural color, metal shavings were present, but their quantity was insignificant. I did the same. |

| 4. | Alexey Petrovich , 48 years old (rozetka.ua): I’ve heard numerous negative reviews about the mechanics, I can’t confirm. I believe that the technical condition and performance of the unit depends on the driver. I don’t have any problems with this, I take care of my equipment. |

| 5. | Semyon Vyacheslavovich , 40 years old (Auto.ru): This is the second year since I bought and actively use a Lada Vesta on the mechanics. The review is positive, there are no comments about the work. |

| 6. | Vasily Timofeevich , 43 years old (Auto.Mail.Ru): for a year and a half of using a car with mechanics, he once made an unscheduled visit to a service station for diagnostics. I was at fault for the hum in the manual transmission, but it was the suspension. I hope that the device reaches the 180,000 km specified by the manufacturer. |

| 7. | Dmitry Gennadievich , 41 years old (drive2.ru): I like the mechanics more than the robot, I drove the AMT for three months, I can compare. Both robot and automatic are not adapted for domestic roads. The units do not last long, so it is better to buy a manual transmission. |

| 8. | Sergey , 35 years old (drive2.ru): on the mechanics, as soon as I pressed the pedal, I pressed it. And overtaking, and maneuverability, without kickdowns, delays in switching. Choice: definitely mechanics. |

| Negative | |

| 9. | Dmitry Semenovich , 52 years old (prom.ua): no matter how hard we tried, a miracle did not work. We decided to save several tens of thousands, but for the wrong reasons. It would be better to make the plastic cheaper than to install a Russian gearbox instead of a French one. Knocking and noise in the manual transmission was detected at 40,000 km. With such a low mileage there are such significant defects. |

| 10. | Gennady , 46 years old (Bibika.ru): after 30,000 km, cases of clutch slipping, delays when changing to higher gears, and howling of the gearbox became more frequent. You need to go to a workshop and order diagnostics. Couldn’t it have been done better from the start? |

| 11. | Boris , 38 years old (drive2.ru): at 25,000 km a gearbox whine appeared on a Lada Vesta. The officials said that the pressure bearing needs to be changed, but this is not certain. The final diagnosis will be announced after a comprehensive diagnosis. |

| 12. | Sergey Gennadievich , 45 years old (Avtodispatcher.ru): a knock in the gearbox was detected already at 31,000 km. Initially the fault was with the suspension, but after diagnostics the technician assured me otherwise. |

What to do

There are several options for solving problems:

- It is possible to adjust the clutch sufficiently. This applies to cars with a decent mileage, or with a new clutch replaced.

- There really are problems with the checkpoint. Specialist intervention is needed. If the Lada Vesta is under warranty, then you should contact an official dealer to solve this problem.

- The driver is doing something wrong. This applies to novice drivers with little experience.

If you carefully study the car manual and do everything according to it, then to engage reverse gear you need to:

- Stop the car.

- Press the clutch pedal.

- Pause for at least 3 seconds.

- Move the shift lever to the right until it stops.

- Move it backwards in the direction of travel of the car.

If you fail to turn it on, you do not need to pull the lever or turn it on with great force. Return it to its original position, release the clutch, squeeze it again and repeat. The manual also says to press the clutch pedal all the way down. You can release it only after reverse gear is fully engaged.

If you feel that the switching on has not occurred completely, there is no need to release the pedal. Repeat the steps again. Otherwise, when driving backwards with the speed not fully engaged, the gearbox may break down.

Shift cables

Removing the gearshift cables

1. Place the car on the work station, brake with the parking brake, turn off the ignition, open the hood and disconnect the ground wire terminal from the battery (spanner 10).

2. Disconnect the pipes of the intake resonator 1 from the air intake and the air filter housing, unscrew the two fastening bolts and remove the resonator (replaceable head 10, knob).

Intake resonator:

- intake resonator;

- air filter pipe;

- air intake pipe

3. Press down the buttons 2 of the cable end clamps and disconnect the ends of the shift cable 4 and gear selection cable 5 from the gearshift mechanism 6 levers.

Removing the shift cables:

- cable sheath fastening clamp;

- button for securing the cable end;

- bracket for fastening gearbox control drive cables;

- gear shift cable;

- gear selection cable;

- gear shift mechanism

4. Move the clamps 1 for fastening the cable sheaths in the direction indicated by the arrow and remove the cable sheaths from the fastening bracket 3.

5. Remove the front floor tunnel lining and the instrument panel module (see Chapter 19 “Body”).

6. Press down the buttons 4 of the cable end clamps and disconnect the ends 5 of the shift cable and the gear selection cable from the drive levers 3 for controlling the gear shift mechanism.

Removing the shift cables:

- cable sheath fastening clamp;

- fastening nut;

- gear shift control drive;

- button for securing the cable end;

- cable end

7. Move the clamps 1 for fastening the cable sheaths in the direction indicated by the arrow, remove the cable sheaths from the grooves of the drive housing 3 for controlling the gear shift mechanism.

The problems get worse and it becomes impossible to drive

I planned to solve all the problems with the box before the May holidays, so that I could go to Riga without hassle. It didn't work out.

The already painful nine-hour wait in traffic jams at the border was aggravated by the fact that every start of the heated car was accompanied by the most disgusting shaking. We were really afraid of getting stuck at the border at night with a broken box.

By nine thousand kilometers, manipulating the gas at start stopped helping. As a result of this, the car was guaranteed to twitch when starting from a standstill. Moreover, the jerking appeared when driving in reverse. And they were so strong that before parking I had to take the girls out of the car so that they would not hear the obscene language with which I was commenting on what was happening.

Starting uphill or with the wheels turned completely out also caused strong vibrations. In general, it was impossible to operate the car.

Variable speed drive

The fourth transmission option available for the Lada Vesta is the Jatko JF015E CVT. It works with a 1.6-liter Nissan H4M engine producing 113 hp. With.

The engine is assembled in Togliatti, and the variator is supplied assembled from Japan. The CVT has been used since 2010 and is installed in many Renault Nissan Alliance models with small-volume engines up to 1.8 liters.

The CVT transmission is the most technically complex compared to other options. Therefore, it will be significantly more expensive in maintenance, repairs and components. The unit is combined. It uses a torque converter, which serves as a buffer for dynamic loads, a variator and a two-stage planetary gearbox.

What's good and bad about a CVT transmission?

The first is the level of comfort. Of all the options available for Vesta, the CVT will be the best offer in terms of comfort. Gear shifting occurs very smoothly, without jerking, almost imperceptibly. Provides a high level of acoustic comfort in the car interior. There is no noise and hum that a conventional manual transmission gives.

Driving through traffic jams in a metropolis in a Lada Vesta with a CVT is much more pleasant and comfortable than in a Vesta with other types of transmission. For a familiar perception of gear shifting, a 6-speed simulation function is provided.

The second advantage of the variator is that, unlike a classic automatic transmission, due to its design, compact body, and low weight, it provides the vehicle with fuel efficiency at the level of manual transmissions. This is why CVTs have always been loved and appreciated. As AvtoVAZ representatives stated, the choice of a CVT rather than an automatic was due precisely to this factor.

On average, consumption on a Vesta with a CVT is 7.5-8 liters per 100 km in the combined cycle. For comparison, the lighter Granta with a classic 4-speed automatic transmission from the same Jatko company consumes all 12 liters in the combined cycle. The difference is significant and obvious. Automatic machines are already really outdated and are good only because they can hold a lot of torque. But they are inferior to the CVT in terms of efficiency and environmental friendliness.

How long will the variator last?

The more often you change the oil, the longer the variator will last. It is the replacement of lubricant that allows you to remove metal shavings and friction dust, which inevitably forms during operation. All problems and breakdowns come from it.

When changing the oil, you need to change the coarse and fine filters, as well as clean the magnets. The procedure will cost approximately 20 thousand rubles. It is recommended to do it every 50 thousand km.

NS2 is not suitable for winter, as it thickens more, so the valve body fails faster. I believe that the CVT transmission is aimed at a specific target audience. That is, the CVT is better suited for drivers who love comfort and adhere to a calm, measured driving style.

There is no need to be afraid of the CVT. It has a long service life, subject to the rules and operating conditions, and can last for more than 200 thousand km.