On Kalina cars, the generator is three-phase and produces alternating current. There is no need to go into too much theory; an ordinary motorist only needs to know how to independently diagnose and repair the installation. This means installing the generator and voltage regulator directly. The fact is that at the output of the power windings the voltage jumps in the range of 10-30 V, and to power the entire on-board network you need 12 V. The first step is to rectify the voltage and then stabilize it.

Review of prices of generator manufacturers for the Lada Granta

| Manufacturer article number | Price, rub.) | Resource (thousand km) |

| KZATE 9402.3701-14 | From 4900 | 90 — 110 |

| BOSCH 21700-3701010-13 | From 5300 – 5500 | 90 — 110 |

*prices are current as of October 30, 2018.

Recommendations for choosing a converter

In order to ensure stable operation of the power supply system, replace the standard KZATE converter with a BOSCH one. Despite identical technical characteristics, the workmanship of the latter is better.

Also, the BOSCH generator better “transfers” loads in the network from activated equipment, optics, and heaters.

The service life of both KZATE and BOSCH is within 90 – 110 thousand km. mileage Moderate loads and average driving speeds will increase the service life by 10 - 15%.

Door pinout for first generation Kalina

In all versions of the first generation Lada Kalina, the cable routing is the same.

Driver's door

- Output to the rear harness.

- A bundle of wires for connecting the speaker.

- Locking device.

- Driver's door control switch pinout element.

- Voltage to switch harnesses.

- Connection of the harness line to the mounting unit.

- Same as 5.

- Same as 6.

- Window regulator.

For front passenger

- Exit to the stern beam.

- Output to the appropriate speaker.

- Door lock drive.

- Electric window lift key.

- Power window control unit terminal harness.

- To the switch key of the corresponding node.

- Gearbox of the above device.

Rear doors

On the rear doors, the terminals are similar for both sides. Only two terminals are used here, where the first serves to connect to the rear electrical harness. The second is designed to supply an impulse and power to lock the doors.

Typical Lada Kalina pinout intended for the rear wiring harness

- Output to the rear door harness behind the driver.

- Voltage and indication of the rear left optical element.

- Same as 1 for the opposite side.

- Terminal for handbrake output.

- Kalina instrument pinout line.

- Output to the driver's door.

- Same as 5.

- Car interior lighting lamps.

- To the left turn signal.

- Connecting the fuel pump.

- Reverse transmission lock switch.

- Continuation of the highway from the front passenger door.

- Line articulation to the rear right speaker.

- Illumination lamp for the interior of the cargo compartment.

- Auxiliary stop.

- Alarm control unit.

- Same as 13 for the opposite side.

- Rear right turn.

- Output to rear optics located on the left side of the car.

- Output to cargo compartment wiring elements.

- Heated rear windshield.

Instrument panel pinout Kalina first generation

The decoupling is considered the most complex element of a car's electrical circuit. Here there are outputs from all important elements and assemblies of the machine:

- 1-5 – outputs responsible for connecting the front beam indication;

- 2.8 – similar for the stern;

- 6,7,9,10 – continuation of lines to the mounting unit and fuse-links;

- 11 – control lines for side, head and interior lights;

- 12 – combination instrument panel;

- 13 – keys for adjusting the heater cooler positions;

- 14 – for powering the air supply box;

- 15 – factory anti-theft element – ignition unit;

- 16 – immobilizer switch;

- 17 – part of the Kalina instrument panel pinout, responsible for indicating and supplying current to the ECM;

- 18 – onboard cigarette lighter;

- 19 – emergency warning button;

- 20 – brake light button located on the pedal;

- 21 – indicator on the windshield wiper system;

- 22 – rear window heating switch;

- 23 – power supply unit for turn signals and low/far modes of head optics;

- 24 – wiper control lever;

- 25 – horn button;

- 26 – supply voltage to the light bulb in the glove compartment;

- 27 – similarly, for the on/off key;

- 28-29 – pinout for Kalina radio – standard position:

- 30 – voltage to the heater cooler motor;

- 31 – resistor network of the above element;

- 32 – main pinout of Kalina EUR;

- 33 – lighting of the ventilation channel and stove.

Front wiring harness pinout

- 1 – left head optics cable;

- 2-5 – connection chips to the dashboard;

- 6 – reverse gear activation locking element solenoid;

- 7 – key for activating the reverse gear lamp;

- 8 – voltage for starter;

- 9 – connector for connecting the line to the battery and starter;

- 10 – battery;

- 11 – electricity generator;

- 12 – the same as 1;

- 13 – relevant for hatchback, front window washer;

- 14 – washer motor;

- 15 – sensor for measuring temperature outside;

- 16 – powering the horn.

Actions when charging disappears

The generator on a Kalina with air conditioning has more power than on cars without an air conditioning system. The design and faults are the same. What to do if charging is lost? Don't panic and check immediately:

Voltage regulator. The easiest and most expensive way is to replace it with a known good one. But you can also apply voltage of 12 V and 15 V to check operation. Regardless of whether the regulator is mechanical or electrical, it will behave the same. In the first case, voltage will be supplied to the excitation winding, but in the second - not. Alternator slip rings and brushes. You can use a simple lamp probe to check the contacts. The length of the brushes must be more than 5 mm, otherwise they should be replaced. The integrity of the field winding can be checked with a tester. Moreover, there is no need to remove the generator, just crawl up to the slip rings and check the resistance between them

Please note that they should not short to ground. The condition of the stator winding and diode bridge can be assessed only after dismantling the generator.

Installation and repair features

Installation occurs in reverse order. If necessary, the generator is replaced or repaired. In some cases, repair will be impractical, since there are many unusable components, including stator and rotor windings. Restoration will be expensive; it will be much easier to completely replace the generator on Kalina. The cost of a new generator in stores is 4-5 thousand rubles. At "showdown" you can buy it 2-3 times cheaper.

Electrical equipment Lada Kalina

If the voltage regulator unit, capacitor and not a tight fit of the brushes are faulty, or if they are worn out, the vehicle's supply voltage deviates from the norm. In this case, it is necessary to check the above listed elements and, if necessary, replace them. In this article we will talk in more detail about diagnosing and replacing generator elements in a Lada Kalina car.

To remove the Lada Kalina voltage regulator you will need the following tool:

flat-blade screwdriver, 8mm and 10mm open-end wrenches and 7mm, 8mm and 24mm socket wrenches, hammer, soldering iron, universal meter (with DC voltmeter and megger)

Checking the functionality of the voltage regulator on the Lada Kalina generator

1. Move aside the rubber insulating boot of the positive terminal from the generator. 2. Start the engine and allow the engine to warm up so that the vehicle operates normally at idle speed. 3. Measure the voltage between the positive terminal and the body (negative terminal). The voltage should be 14.5-15.1 volts.

If there is a deviation from the specified range, the voltage regulator must be replaced. See also checking the Lada Kalina generator regulator in the section “Replacing the voltage regulator”

Checking the functionality of the Lada Kalina generator capacitor

The capacitor is usually checked with a specialized meggometer, since not all universal devices have a measurement of up to 10 MoM. The device is set precisely in the range of 1-10 MΩ. Before connecting to the capacitor, the device shows infinity. If connected to a working capacitor, it begins to charge and an electric charge accumulates on its plates - current flows and, accordingly, the resistance on the device drops. After charging it (saturating the capacitor plates), the resistance again becomes infinite.

Replacing the voltage regulator Lada Kalina

carried out as follows

1. Disconnect the negative cable from the battery. 2. Disconnect the excitation block from the generator.

3. Disconnect the positive terminal from the battery by unscrewing the nut.

4. Remove the factory seal from one of the screws holding the plastic casing and remove the screws. Remove the protective plastic cover. 5. Remove the two screws securing the regulator and remove the voltage regulator.

6. Check the ease of movement of the brushes. They must protrude at least 5 mm from the voltage regulator housing. 7. You can check the voltage regulator by connecting a 12 V lamp to its outputs and applying a voltage in the range of up to 12 volts to its inputs, while the lamp should light and the voltage is more than 12 V to 16 V.

If the voltage is too high, the lamp should go out. If this algorithm does not work, then the regulator must be replaced. Installation of the regulator is done in the reverse order.

Replacing the rectifier unit with a capacitor Lada Kalina

1. Using a soldering iron, unsolder the six leads and remove the 3 bolts.

2. Remove the rectifier unit from the generator. Installation of the rectifier unit is carried out in the reverse order

Checking diodes on the rectifier block Lada Kalina

1. Dodas are checked with a universal device. (6 diodes in total) Attach the black “negative” probe to the negative plate, and the positive “red” probe alternately to the three contact terminals of the diodes. The resistance should be 580-620 Ohms.

Attach the red “positive” probe to the negative plate, and the negative “black” probe alternately to the three contact terminals of the diodes. The resistance should be 580-620 Ohms.

Checking the windings of the Lada Kalina generator

1. Check the generator windings with a device. All windings should have approximately equal resistance, without significant deviations. Deviations indicate a break or short circuit.

How to replace the voltage regulator and check its serviceability on a VAZ 1117-VAZ 1119?

Checking the voltage regulator for serviceability:

1) At the beginning of the operation, you will need to find where the generator itself is located and after you find it, move your hand to the side with the rubber cover indicated by the red arrow, this cover covers the “B+” terminal; in simpler words, this is the positive terminal and it comes from the generator to this terminal (By the way, it is also indicated by a blue arrow) you will need to connect the positive wire of the voltmeter and after connecting it, throw another wire (Minus wire) coming from the same voltmeter to ground (The places where you need to connect the wire , indicated by a green arrow), after the operation has been completed, a DC voltmeter will show you the voltage in the vehicle’s on-board network.

2) After everything is connected, start the engine of the car and turn on the headlights, when the engine is started, let it run for a while (About 15 minutes) and after this time has passed, at medium speed engine, measure the voltage in the on-board network, which you should have in the range of 14.4-15.1 V.

Note! If this voltage is either more or less, then replace the voltage regulator with a new one!

3) Now, as for the capacitor, to check whether it works or not, you just need to use a megohmmeter to connect the leads that go from it to the contact of the capacitor; when connecting, your resistance should initially decrease and then become infinite (What kind of infinity do you have on the device? it’s very easy to understand, for this, without connecting anything, first look at the numbers that the megohmmeter shows, for example, if it shows 0, then this will be infinity), if this is what happened, then in this case the capacitor is fully operational and does not require replacement, otherwise, replace the capacitor with a new one.

Note! Capacitor - it is built into the voltage regulator itself, and as such it serves as a filter for current, thanks to it the voltage in the network is equalized; for example, it can pass high-frequency currents through itself well, but will delay low-frequency currents!

Types of generator faults

Due to the fact that any generator is an electromechanical device, there will be two types of faults - mechanical and electrical.

The first includes the destruction of fasteners, housing, malfunction of bearings, pressure springs, belt drive and other failures not related to the electrical part.

Electrical faults include winding breaks, diode bridge faults, brush burnout/wear, turn-to-turn short circuits, breakdowns, rotor beating, and relay-regulator faults.

Often, symptoms that indicate characteristics of a faulty generator can also appear as a result of completely different problems. As an example, poor contact in the fuse socket of the generator field winding circuit will indicate a generator malfunction. The same suspicion may arise due to burnt contacts in the ignition switch housing. Also, the constant lighting of the generator malfunction indicator lamp can be caused by a breakdown of the relay; the blinking of this switching lamp may indicate a generator malfunction.

The main signs of a malfunctioning autogenerator:

- When the engine is running, the battery discharge warning lamp flashes (or stays on continuously).

- Discharging or overcharging (boiling) of the battery.

- Dim car headlights, a rattling or quiet beep when the engine is running.

- Significant change in headlight brightness with increasing speed. This may be acceptable when increasing the speed (re-throttle) from idle, but the headlights, having lit up brightly, should not increase their brightness any further, remaining at the same intensity.

- Extraneous sounds (howling, squeaking) coming from the generator.

It is necessary to regularly monitor the tension and general condition of the drive belt. In case of cracks and delaminations, immediate replacement is necessary.

Reasons for failure of the relay regulator

The reasons for the failure of the voltage regulator may be:

- short circuit in the circuit, including interturn short circuit of the excitation winding;

- failure of the rectifier bridge (diode breakdown);

- reverse polarity or incorrect connection to the battery terminals;

- penetration of moisture into the housing of the regulator and/or generator (for example, when washing a car or driving in heavy rain);

- mechanical damage to the unit;

- natural wear and tear of the unit, including brushes;

- poor quality of the device being directly tested.

There are a number of simple methods for checking the regulator, regardless of whether the unit is removable or not.

About the belt? car generator actions

The generator operation of the Lada Kalina unit is based on the following principle: an alternating current is subsequently induced in the stator winding, and the current is transformed into direct current through a rectifier module located on the body of the unit. The generator cover is also equipped with an electronic voltage regulator and a brush holder. device The rotor receives torque from the crankshaft pulley. A poly V-belt appears as a transmission link.

Among the basic characteristics of the generator installation there are the following parameters:

- maximum generated current – 85-90 Amperes;

- operating range of onboard voltage – 14.4-15.1 Volts;

- rotation ratio of the rotor and motor – 1:2.4;

- right-hand direction of rotation.

The housing is held together by pins that tighten the covers onto the stator. In the mounting sockets of the indicated covers, bearings are present, due to which the ability of the rotor to rotate is ensured. The rear bearing is installed inside the cover with a minimum gap. The front element is endowed with the ability to slide along the surface of the shaft and is fixed. It has a rotor inside the front cover with a small one on the outside, and the pressure plate covers it with tension. part The rear of the device is protected by a plastic casing.

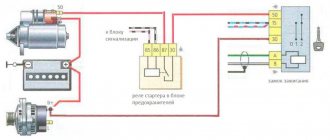

diagram to Let's move on to switching the generator with the on-board network. connections The scheme is very simple. After turning on the voltage regulator, the ignition voltage begins to supply power to the circuit through the battery discharge indicator lamps. When the motor starts, the excitation winding is supplied with power from three diodes mounted in the rectifier unit.

indicated Using a signal lamp, you can check the generator unit. If the device is working properly, the lamp lights up when the ignition is turned on. When the engine starts, it goes out. When such a phenomenon does not occur and the lamp continues to shine, the generator installation should be diagnosed for the presence of malfunctions. In some cases, replacement is required, and many are interested in whether to remove the generator?

Checking the rectifier and winding integrity

The rectifier unit is checked using an ohmmeter or a test lamp. In the latter case, it is necessary to apply a positive voltage through the lamp to the “B+” terminal of the generator, and a negative voltage to the housing. If the lamp lights up, this indicates a short circuit in the rectifier unit.

If the lamp lights up when the negative (“+” remains on the “B+” terminal) is transferred to one of the windings, one or more diodes are faulty. A breakdown of the negative diodes is indicated by a burning lamp when a “plus” is applied through it to the winding terminal, and a “minus” is applied to the generator housing. You can exclude a short circuit or break in the stator winding using the same test lamp. When the winding terminals are connected to a voltage source, the lamp should light up, but when the terminals of different windings are connected, it should not.

You can also check for a short circuit in the windings using an ohmmeter. If, when the probes touch the leads of one winding, it shows infinity, there is a break. Similar readings when touching the terminals of different windings indicate the absence of a short circuit between them. Thus, you need to check each of the three windings. If they are ok, you need to replace the diode bridge.

The malfunction may also consist of a break in the rotor windings. To check, it is necessary to close the slip rings on the rotor shaft using ohmmeter probes or a test lamp with a voltage source. If the lamp does not light and the ohmmeter shows infinity, there is a break.

The main elements of an automobile voltage generator are a voltage regulator, a diode bridge, a rotor and a stator. Checking them individually will allow you to understand the cause of the malfunction. If the windings break, it is advisable to replace the generator assembly; the rectifier unit and voltage regulator can be purchased separately.

Source

Checking the rectifier unit (diode bridge)

To perform this diagnostic, it is necessary to remove the diode bridge from the Kalina generator; this was described in more detail in previous articles in this section.

Then we connect the tester with the black wire to the negative plate of the block, and the red one in turn to the three contact terminals of the diodes. This way we check all the rectifiers in the block. The values on the device should be in the range from 400 to 800 Ohms. Personally, on my Kalina, during this test, all diodes showed a resistance within 535 Ohms. But the repair instructions from the Third Rome publishing house talk about numbers of 580-620 Ohms. I will say right away that when I rang two serviceable generators, the values specified in the manual were not achieved, although there were no problems with charging, so I personally doubt the accuracy of the data in this instruction.

Then we carry out the same operation, only swapping the contact wires of the multimeter. In this case, the device, with working diodes, will show infinity, that is, its readings will not change:

How to remove the generator on the LADA Granta

The “Grants” generator has to be removed for various reasons: for repair, maintenance, modification of the unit. You can do this without the help of others if you know how to remove the generator on the Grant. Depending on the modification of the car (8 or 16 valve engine, presence of air conditioning), the procedure for dismantling the generator has its own characteristics, so it is worth considering each option separately.

How to remove a generator on an 8-valve Grant without air conditioning

The following will be useful for work:

Before removing the generator on a Grant without an air conditioner, you should disconnect the ground from the battery by removing the negative terminal. The procedure is as follows:

- unscrew the 2 rear bolts securing the motor protection;

- unscrew the 4 front motor protection bolts;

- remove the engine protection (mudguard) from the car;

- disconnect the wiring block from the generator;

- remove the protective cap of the nut holding the power wire;

- unscrew the nut and disconnect the generator power cable;

- unscrew the top nut securing the “Grant” generator;

- press out the generator with a mounting spatula and remove the upper mounting bolt;

- unscrew the lower bolt securing the generator;

- move the generator away from the engine with a mounting blade and remove the lower mounting bolt;

- move the generator towards the right mudguard;

- remove the generator belt from the unit pulley;

- pull out the generator;

- Remove the alternator belt from the crankshaft pulley.

To put the LADA “Grant” generator in place, you need to perform the steps in reverse order.

Important: when installing the generator belt, make sure that the pulley grooves and the groove tracks on the belt match

How to change the generator on a 16-valve Grant

The generator mount on the 16-valve Granta variation is distinguished by the presence of a belt tensioning mechanism. Therefore, the procedure for replacing the generator on this model is slightly different. To work, you will need socket wrenches 8, 10 and 13. As when dismantling the generator from the 8-valve Granta, before starting work you need to remove the ground terminal from the battery to eliminate the possibility of a short circuit.

We remove the Lada Kalina generator and change the armature contact rings.

https://youtube.com/watch?v=gVC1DyDADBk

How to remove a 16kL generator. Kalina. If you have any questions, you can ask them in the VKontakte group -…

After this, you need to remove the engine protection by unscrewing the 4 front and two rear bolts securing it to the body parts. The 16-valve “Granta” generator is removed as follows:

- disconnect the block from terminal “D” on the generator;

- remove the rubber cap covering the “B+” terminal of the generator;

- Using a 10mm wrench, unscrew the nut holding the wire tip;

- loosen the tension bar nut using a 13mm wrench;

- by rotating the tensioner adjusting bolt counterclockwise, loosen the tension on the Grant generator belt (a 10mm socket wrench is required);

- move the generator towards the engine and remove the belt from the pulleys;

- Unscrew and remove the adjusting bolt of the belt tension mechanism from the generator mounting bracket;

- remove the tension bar;

- unscrew the lower nut securing the “Grant” generator;

- remove the spacer bushing and remove the lower mounting bolt;

- remove the tension bar;

- pull out the LADA Granta generator.

To install the generator, you need to do the above in reverse order.

Important: after installing the 16-valve LADA “Grant” generator, it is necessary to adjust the belt tension

How to remove a generator on a Grant with air conditioning

The LADA Granta air conditioner is driven by a generator belt, which complicates the operation. You must first move the air conditioner to the side, and then proceed to remove the generator. To work you will need:

First, as usual, you will have to disconnect the ground from the battery. Removing the generator on a Grant with air conditioning is done as follows:

- treat the bolts holding the engine mounts and bracket with WD-40;

- dismantle the protection by unscrewing the fastening bolts;

- when the WD-40 product takes effect, unscrew the bracket nut;

- place a jack under the right front part of the car;

- loosen the bolts holding the front right wheel;

- raise the jack, hanging the wheel;

- remove the wheel from the car;

- unscrew the tension roller;

- unscrew the bolts securing the pillow;

- carefully lower the car, hanging it (the cushion will move towards the engine, opening access to the belt and generator).

Next, it remains to remove the generator using one of the methods described above.

The procedure for installing the generator is the reverse of the procedure for dismantling. After installing the generator, you need to screw on the cushion, install the engine protection and wheel, and attach the ground terminal to the battery.

Lada Kalina dashboard diagram

1,2,3,4 — blocks of the instrument panel wiring harness to the blocks of the rear wiring harness;

5,6 — blocks of the instrument panel wiring harness to the blocks of the front wiring harness; 7 — block of the instrument panel wiring harness to the block of the wiring harness 8 — block of the instrument panel wiring harness to the block of the front wiring harness; 9 — lighting control module; 10 — ignition switch; 11 — on-board computer mode switch; 12 — windshield wiper switch; 13 — sound signal switch; 14 — light signaling switch; 15 — instrument cluster; 16 — evaporator temperature sensor; 17 — interior air temperature sensor; 18 — air conditioner switch; 19 — controller of the automatic climate control system; 20 — heater damper gearmotor; 21 — rear window heating switch; 22 — alarm switch; 23 — brake signal switch; 24 — cigarette lighter; 25 — electric amplifier control unit; 26,27 — blocks of the instrument panel wiring harness to the radio; 28 — backlight lamp for the heater control panel; 29 — illuminator; 30 — mounting block: 31 — heater electric motor switch; 32 — heater electric motor; 33 — additional resistance of the heater electric motor; 34 — lampshade lighting of the glove box; 35 — glove box lighting switch; 36 — control unit of the APS-6 automobile anti-theft system; 37 — driver airbag module; 38 — passenger airbag module; 39.40 — blocks of the instrument panel wiring harness to the blocks of the ignition system wiring harness. KZ - additional starter relay; K4 - additional relay; K5 - relay-interrupter for direction indicators and hazard warning lights; K6 - windshield wiper relay; K7 - headlight high beam relay; K8 - sound signal relay; K9 - relay for turning on fog lights; K10 — relay for turning on the heated rear window; K11 — electric seat heating relay; K12 - air conditioning compressor clutch activation relay;

Instrument panel wiring harness - 11186-3724030-20.

generator viburnum

Post by sea » January 28, 2014, 12:00

Post by puh » Jan 28, 2014 01:46 pm

Post by Parodist » Jan 29, 2014, 02:52 p.m.

Post by Sasha-Irpen » 30 Jan 2014, 06:38

Post by puh » 30 Jan 2014, 08:53

Post by Sasha-Irpen » 30 Jan 2014, 10:23

Honestly, it’s a pity to waste time explaining basic truths, but since I seem to have chewed everything out in great detail (especially since such information is not secret and is on the Internet), I’ll explain it again, but more slowly. (For those in the tank).

There are generally accepted digital symbols in electrical circuits. 1). The direct “+” of the battery is usually designated as “30” and, most often, purple (red) wires are used for this bus. For example, on the generator, near the power bolt you can see the designation “30”. If you have noticed, when the ignition is turned off, on some sensors with an oscillator with an input voltage of 1 mOhm, you can see a voltage of several volts. BUT, can we say that they have a “30” tire? 2). The voltage appearing after the ignition switch is usually designated “15”. (Options 15/1, 15/2 are possible). On a VAZ this is a wire, usually blue (possibly with a black stripe). On the contact group of the ignition switch you can see both 30 and 15 and even 50. (“50” is the starter retractor). In my understanding, bus “15” is a voltage of approx. 12 volts, which appears after turning on the ignition and is capable of powering a load of several amperes. 3). On the decimal generator, near the 6.3 mm plug, it says D+, or “61”. So 61 is a bus for excitation of the generator; on a VAZ it is connected with a brown wire with a white stripe and has nothing in common with bus 15, since it has its own name - 61. If, with the ignition on, measure the voltage on this plug, its value will be from 1 to 3 volts. This is another confirmation that this is not a “15” tire. If you try to connect a load to this wire (even a light bulb from the dimensions), then this light bulb will not light up, and the maximum that can be achieved is that the light bulb on the instrument panel with the battery drawn will light up. 4). I hope that there is no need to talk about tires “31”, “49”, “56”, “58”, etc.? Dear, it seems that you have small gaps in your knowledge, so it’s better to learn the materiel.

On Kalina cars, the generator is three-phase and produces alternating current. There is no need to go into too much theory; an ordinary motorist only needs to know how to independently diagnose and repair the installation. This means installing the generator and voltage regulator directly. The fact is that at the output of the power windings the voltage jumps in the range of 10-30 V, and to power the entire on-board network you need 12 V. The first step is to rectify the voltage and then stabilize it.

Classification of generator faults

Since a car generator is an electromechanical device, its main faults are divided into two categories - electrical and mechanical. Electrical faults include breakdowns of the diode bridge, interturn short circuits, damage to the windings, breakdowns of the relay regulator, burnout of brushes and their wear, as well as breakdowns.

But mechanical malfunctions include damage to fasteners, problems with bearings, destruction of the generator housing, disruption of the correct operation of the belt drive and other malfunctions that have no connection with the electrical “stuffing” of the generator.

Very often, signs indicating a generator breakdown are caused by completely different problems that appeared earlier. For example, a generator malfunction may be the result of burnt contacts located in the ignition switch housing. Sometimes the light indicating that the generator is not working is lit due to a broken relay.

Typical signs of a faulty generator in a car:

- The battery is being overcharged or discharged.

- When the engine is running, the battery discharge light is on or flashing.

- Significant increase in headlight brightness with increasing speed. This can happen during revving after idling, but the brightness of the headlights cannot increase constantly.

- The sound signal is too weak, the headlights are not bright enough when the engine is running.

- The presence of specific sounds that the generator makes.

Experts recommend periodically checking the tension of the generator drive belt and monitoring its condition. If the slightest defects, such as cracks, appear, the belt must be replaced.

Video “Repairing GU at home”

Visual instructions for repairing a power unit with your own hands are presented in the video below using the example of a Ford Transit car (the author of the video is Ramanych).

The electrical equipment of a car fails quite often, so auto repair shops usually classify such malfunctions into a separate category. In most cases, the problem lies in the breakdown of energy sources or failure of current consumers. The sources are batteries and generators, and the consumers are headlights, ignition, air conditioning, etc.

If the battery or alternator is not working, you will not be able to use the vehicle normally. As a rule, the car cannot move at all. If one of the electrical energy sources in the car fails, expect problems with the other.

A simple example: destruction of the battery will increase the charging current of the generator. In the end, everything will end in the breakdown of the diode bridge.

Another option: if the voltage regulator supplied by the generator fails, the charging current very often increases. This, in turn, causes the battery to be recharged regularly, which leads to rapid battery destruction.

Replacing generator brushes for Lada Kalina sedan (VAZ Kalina)

If the voltage regulator unit, capacitor and not a tight fit of the brushes are faulty, or if they are worn out, the vehicle's supply voltage deviates from the norm. In this case, it is necessary to check the above listed elements and, if necessary, replace them. In this article we will talk in more detail about diagnosing and replacing generator elements in a Lada Kalina car.

To remove the Lada Kalina voltage regulator you will need the following tool:

flat-blade screwdriver, 8mm and 10mm open-end wrenches and 7mm, 8mm and 24mm socket wrenches, hammer, soldering iron, universal meter (with DC voltmeter and megger)

Checking the functionality of the voltage regulator on the Lada Kalina generator

1. Move aside the rubber insulating cover of the positive terminal from the generator.2. Start the engine and allow the engine to warm up so that the vehicle operates normally at idle speed.3. Measure the voltage between the positive terminal and the body (negative terminal). The voltage should be 14.5-15.1 volts.

If there is a deviation from the specified range, the voltage regulator must be replaced. See also checking the Lada Kalina generator regulator in the section “Replacing the voltage regulator”

Checking the functionality of the Lada Kalina generator capacitor

The capacitor is usually checked with a specialized meggometer, since not all universal devices have a measurement of up to 10 MoM. The device is set precisely in the range of 1-10 MΩ. Before connecting to the capacitor, the device shows infinity. If connected to a working capacitor, it begins to charge and an electric charge accumulates on its plates - current flows and, accordingly, the resistance on the device drops. After charging it (saturating the capacitor plates), the resistance again becomes infinite.

Replacing the voltage regulator Lada Kalina

carried out as follows

1. Disconnect the negative cable from the battery.2. Disconnect the excitation block from the generator.

3. Disconnect the positive terminal from the battery by unscrewing the nut.

4. Remove the factory seal from one of the screws holding the plastic casing and remove the screws. Remove the protective plastic cover.5. Remove the two screws securing the regulator and remove the voltage regulator.

6. Check the ease of movement of the brushes. They must protrude at least 5 mm from the voltage regulator housing.7. You can check the voltage regulator by connecting a 12 V lamp to its outputs and applying a voltage in the range of up to 12 volts to its inputs, while the lamp should light and the voltage is more than 12 V to 16 V.

If the voltage is too high, the lamp should go out. If this algorithm does not work, then the regulator must be replaced. Installation of the regulator is done in the reverse order.

Replacing the rectifier unit with a capacitor Lada Kalina

1. Using a soldering iron, unsolder the six leads and remove the 3 bolts.

2. Remove the rectifier unit from the generator. Installation of the rectifier unit is carried out in the reverse order

Checking diodes on the rectifier block Lada Kalina

1. Dodas are checked with a universal device. (6 diodes in total) Connect the black “negative” probe to the negative plate, and the positive “red” probe alternately to the three contact terminals of the diodes. The resistance should be 580-620 Ohms.

Attach the red “positive” probe to the negative plate, and the negative “black” probe alternately to the three contact terminals of the diodes. The resistance should be 580-620 Ohms.

Checking the windings of the Lada Kalina generator

1. Check the generator windings with a device. All windings should have approximately equal resistance, without significant deviations. Deviations indicate a break or short circuit.

Any electrical equipment fails sooner or later. Thus, the most common generator malfunction on the Lada Kalina remains the regulator relay. Replacing this element is not difficult, but requires certain knowledge and skills.

Video on replacing the voltage regulator relay on a Lada Kalina:

This video story tells about replacing the generator regulator relay on a Lada Kalina, the nuances of installation and configuration.

Checking the serviceability of the voltage regulator with brushes

To do this, you need to connect a 12 Volt light bulb to the two ends of the brushes, and apply 12 Volt voltage to the regulator contacts. If this device is working properly, the light should light up. When the voltage supplied to the regulator increases to 15-16 V, the light should go out.

In case of detected malfunctions in various devices, we replace them. More details about this are written in previous articles from the “Generator” section.

Welcome! Voltage regulator - it is installed on the generator and is directly connected to it, thanks to it, the entire current that the generator gives out changes and flows more evenly, for example, the more you turn the engine of a car (increase the speed, that is), the generator will work stronger and much more give out current, all this happens because the generator is connected to the engine (namely, it is connected to the crankshaft), but the voltage in the on-board network will also change from this (The more current the generator gives, the stronger this current increases in the entire on-board network car), therefore, when the speed increases, the light will constantly burn stronger, and when it decreases, it will dim because the current strength will decrease, so no matter what happened, a voltage regulator was invented, thanks to which the current strength in the on-board network always remains the same, but it changes when you turn on additional devices that need more current, that is, for example, you turn on the high beam headlights of a car and the current supply increases through the regulator so that there is enough power for these headlights, in addition, the current supply flowing through The regulator is constant and does not jump higher or lower, so the headlights work in the same mode and do not shine either stronger or weaker.

Note! In order to change or check the voltage regulator, you will need: Two different types of screwdrivers, as well as two wrenches that will be “12” in size, and you will also need a DC voltmeter thanks to which you can clearly determine what voltage you have in your on-board network and whether it is jumping, and among electrical appliances, a megohm meter is also useful, thanks to which you can check the regulator’s capacitor for serviceability, thanks to which the current strength remains constant when supplied to the on-board network!

Summary:

Where is the voltage regulator located? It is located on the generator itself, as was already said a little earlier, a plus wire and a wire block are also suitable for it, so that the regulator does not become dirty; for this purpose it is also closed with a plastic cover, in more detail the pin that comes out of the regulator you can look at photo which is located below, in this photo you can just see the same plastic cover that closes the regulator, and in the other photo (Small) you can see that the cover has already been removed and only one pin sticks out, which comes from the regulator (This pin is on both indicated by a red arrow in the pictures).

How to remove the generator on the LADA Granta

The “Grants” generator has to be removed for various reasons: for repair, maintenance, modification of the unit. You can do this yourself if you know how to remove the generator on the Grant. Depending on the modification of the car (8 or 16 valve engine, presence of air conditioning), the procedure for dismantling the generator has its own characteristics, so it is worth considering each option separately.

How to remove a generator on an 8-valve Grant without air conditioning

To work you will need:

- socket wrenches for 8, 10 and 13;

- mounting blade.

Before removing the generator on a Grant without air conditioning, you should disconnect the ground from the battery by removing the negative terminal. The procedure is as follows:

- unscrew the 2 rear engine protection mounting bolts;

- unscrew the 4 front engine protection bolts;

- remove the engine protection (mudguard) from the car;

- disconnect the wiring block from the generator;

- remove the protective cap of the nut holding the power wire;

- unscrew the nut and disconnect the generator power cable;

- unscrew the top nut securing the “Grant” generator;

- press out the generator with a mounting spatula and remove the upper mounting bolt;

- unscrew the lower bolt securing the generator;

- move the generator away from the engine with a mounting blade and remove the lower mounting bolt;

- move the generator towards the right mudguard;

- remove the generator belt from the unit pulley;

- pull out the generator;

- Remove the alternator belt from the crankshaft pulley.

To put the LADA “Grant” generator in place, you need to perform the steps in reverse order.

Important: when installing the generator belt, make sure that the pulley grooves and the groove tracks on the belt match

How to change the generator on a 16-valve Grant

The generator mount on the 16-valve Granta variation is distinguished by the presence of a belt tensioning mechanism. Therefore, the procedure for replacing the generator on this model is slightly different. To work, you will need socket wrenches 8, 10 and 13. As when dismantling the generator from the 8-valve Granta, before starting work you need to remove the ground terminal from the battery to eliminate the possibility of a short circuit.

After this, you need to remove the engine protection by unscrewing the 4 front and two rear bolts securing it to the body parts. The 16-valve “Granta” generator is removed as follows:

- disconnect the block from terminal “D” on the generator;

- remove the rubber cap covering the “B+” terminal of the generator;

- Using a 10mm wrench, unscrew the nut holding the wire tip;

- loosen the tension bar nut using a 13mm wrench;

- by rotating the tensioner adjusting bolt counterclockwise, loosen the tension on the Grant generator belt (a 10mm socket wrench is required);

- move the generator towards the engine and remove the belt from the pulleys;

- Unscrew and remove the adjusting bolt of the belt tension mechanism from the generator mounting bracket;

- remove the tension bar;

- unscrew the lower nut securing the “Grant” generator;

- remove the spacer bushing and remove the lower mounting bolt;

- remove the tension bar;

- pull out the LADA Granta generator.

To install the generator, you need to do the above in reverse order.

Important: after installing the 16-valve LADA “Grant” generator, it is necessary to adjust the belt tension

How to remove a generator on a Grant with air conditioning

The LADA Granta air conditioner is driven by a generator belt, which complicates the operation. You must first move the air conditioner to the side, and then proceed to remove the generator. To work you will need:

- socket wrenches for 8, 10, 13 and 18;

- wheel wrench;

- jack;

- WD-40 product.

First, as usual, you will have to disconnect the ground from the battery. Removing the generator on a Grant with air conditioning is done as follows:

- treat the bolts holding the engine mounts and bracket with WD-40;

- dismantle the protection by unscrewing the fastening bolts;

- when the WD-40 product takes effect, unscrew the bracket nut;

- place a jack under the right front part of the car;

- loosen the bolts holding the front right wheel;

- raise the jack, hanging the wheel;

- remove the wheel from the car;

- unscrew the tension roller;

- unscrew the bolts securing the pillow;

- carefully lower the car, hanging it (the cushion will move towards the engine, opening access to the belt and generator).

Next, it remains to remove the generator using one of the methods described above.

The procedure for installing the generator is the reverse of the procedure for dismantling. After installing the generator, you need to screw on the cushion, install the engine protection and wheel, and attach the ground terminal to the battery.

Disassembling the device

To disassemble the generator, you need to perform several simple manipulations:

- Remove the drive pulley. Try not to lose the key.

- Unscrew the nuts from the back cover that secure all parts of the structure.

- Remove the voltage regulator. At the same time, evaluate the condition of the brush assembly.

- Disconnect all parts of the generator.

After this, you can begin to carry out repairs.

Bearings often fail, especially the one located in the front cover. The reason for this is excessive belt tension. To make a replacement, you need to unscrew four screws and press the bearing out of its seat. Instead, install a new bearing. To increase reliability, change both rollers at once.

The generator must always be in good working order

Any modern car is equipped with electrical equipment that is absolutely necessary for the vehicle:

- without a starter it is impossible to start the engine;

- a car cannot be driven without lighting at night;

- The heater motor creates heat in the cabin;

- The wiper motor clears the windshield of rain and snow;

- FM radio makes it possible for the driver not to get bored on the road.

But all these devices cannot work without electricity, so the car must have a power source.

The current from which all consumers in the car are powered is produced by the generator, and the performance of the entire electrical circuit of the vehicle depends on its condition.

Therefore, the generator must always be in good working order, and if any breakdowns occur with it, they must be eliminated in a short time.

Common battery problems

As a rule, motorists encounter the following battery malfunctions :

- damage to the plates (chemical or mechanical);

- short circuit of the battery plates or electrodes;

- damage to the battery case, due to which the battery banks lose their seal;

- chemical oxidation of the terminals at the battery terminal.

In most cases, battery malfunctions occur for the following reasons:

- Incorrect use of the battery.

- End of battery life.

- Manufacturing defects.

It's time to move directly to the car's alternator. Generator breakdowns are much more common, which is caused by the more complex design of this element. And it can be much more difficult to detect problems.

Specialists often deal with the following generator malfunctions:

- voltage regulator failure;

- damage to the diode bridge (aka rectifier);

- wear of current collecting brushes;

- defects in the charging circuit wires;

- damage or operational wear of the pulley;

- wear of slip rings or commutator;

- short circuit of individual turns on the stator winding;

- bearing failure.

Every self-respecting car enthusiast should understand what causes generator malfunctions most often and how they can be dealt with. It is also necessary not to forget that timely prevention helps to avoid serious problems. Towards the end of the article, we will look at some tips that will help you learn how to test the generator yourself. But let's first learn about the internal structure of the node.

There are DC and AC generators. Nowadays, passenger cars are equipped with AC devices with an integrated rectifier, which is also called a diode bridge. It is this part that ensures the conversion of alternating current into direct current, which is necessary for the functioning of electrical devices in the car. In most cases, the diode bridge is located in the housing or cover of the generator. Typically, it is built into one of these parts.

The electrical equipment of a modern car can only operate within a given voltage range. Very often, a voltage from 13.8 to 14.7 Volts is considered working. Since the generator is connected to the engine crankshaft using a special belt, its operation directly depends on the speed of the vehicle and the current engine speed.