The problem of constant undercharging of the battery is familiar to every city dweller. Sooner or later it results in the inability to start the engine, and this usually happens at the most inopportune moment. It is not always necessary to blame the battery itself - quite often the generator is not working properly, and battery discharge is only a consequence of this. Today we will tell you how to determine that the generator is the culprit of a dead battery, why this happens, and how it can be fixed.

Signs of a generator malfunction

Modern passenger cars are literally crammed with electronics; there are several dozen sensors alone, and over time the situation only gets worse. Automakers try to increase the power of the generator according to the needs of the on-board network, but this is not always possible, and therefore, if problems arise with the battery, it cannot be ruled out that it is simply not charged when the engine is running.

How can you understand that the generator does not charge the battery, or that it is not able to cover the loss of battery charge when starting the engine?

There are several signs indicating that the culprit of undercharging is the generator unit:

- light indication in the form of a lit battery symbol;

- insufficiently bright headlights;

- extraneous noise heard from the generator;

- interruptions in battery operation.

The combination of any two of these signs should alert you.

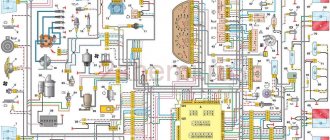

Note that all malfunctions associated with the operation of the unit responsible for powering the vehicle are divided into mechanical and electrical. The first include loosening of fasteners, wear of bearings and brushes, breakage of pressure springs, loosening of the drive belt tension, etc. There are also many electrical reasons - problems with wiring (breaks, short circuits), windings, burnout of the diode bridge, breakdowns, etc. .

An extreme case is a complete failure of the generator, which will simply immobilize your car. But this is not always a death sentence. In many cases the problem is fixable, although in some cases it will cost money, time and effort.

Replacing a generator is generally required only when the breakdown is quite serious, and the cost of repair, if possible, is not much cheaper than a new device.

How to determine that the network voltage is insufficient?

The easiest way is to get information from the on-board computer. Most often, even inexpensive computers have a function for measuring this parameter. Most devices have a built-in alarm function for problems with the on-board electrical network. For example, if the voltage drops below 12V, a certain signal is triggered and a message is displayed with various content options. The following problems may also occur during the process:

- a decrease in the activity of the instrument panel lighting, as well as various light blocks, including dimensions, brake lights, turn signals, low and high beams, they dim;

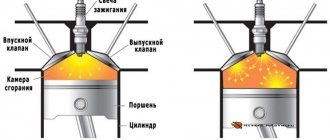

- at idle speed the car begins to choke and even stalls, this is due to a lack of voltage, a fatal drop in the entire system occurs, fuel is not supplied;

- the radio tape recorder fails, it can simply turn off and then turn on itself if its connection is configured correctly, this happens when there is a power surge in the lower zones;

- when you turn on the interior blower fan or air conditioner, there is a noticeable effect on the engine, the speed drops, there is an effect on the quality of lighting by the optics;

- Voltage fluctuations are noticeable during warm-up and during normal idling of the engine, this can be seen from the flickering of lights and uneven engine operation, floating speed.

These are the kind of troubles that can make you think about problems in the electrical network. These are only visible problems, but in reality this trouble has a much wider range of influence. The reliability of the fuel pump, the normal functioning of the on-board computer and the absence of errors with it depend on the quality of the voltage in the network. Let's figure out exactly which components can lead to such troubles in your car.

How to check the operation of the generator yourself

The generator-battery pair is the most important part of the car, without which it cannot function. Some people see the main battery in this connection, but in reality the main burden of supplying the on-board network lies with the generator, and it is its malfunctions that are responsible for the unstable operation of the electronics and undercharging of the battery.

In principle, you can check how well a generator set copes with its tasks on any sufficiently powerful consumer, but the easiest way to do this is on a battery. This will reveal the fact that the generator is not charging the battery, but to further determine the reasons, other studies and tests will be required, which we will discuss later.

The first stage of diagnostics consists of a visual inspection of the node responsible for generating electricity, and if no unusual facts are noticed, you can begin measuring voltage and current. You can check whether the generator is charging the battery with a multimeter. Twice a year you should check the tension of the drive belt, which tends to stretch. And due to the weakening of the belt, the torque is not transmitted to the generator shaft in full, and its performance decreases.

Every year you should check the quality of the fasteners, the operation of the relay regulator and the diode bridge; periodically it is necessary to carry out preventive maintenance in relation to the battery - clean the terminals, measure the level/density of the electrolyte.

Below we'll show you how to check your battery's charge using a readily available meter or load plug.

Reasons for battery discharge, why the car does not produce full voltage

Having turned the ignition key, the car enthusiast expects to hear the cheerful sound of the starter. If the battery is discharged, the starter does not have enough energy - the car will not start. Reasons for discharge:

- The battery itself. Low electrolyte level, sulfation of plates, short circuit, long standing without recharging. The battery needs to be charged and tested with a load plug.

- Constant passive discharge. There is a consumer in the car that consumes energy even when the ignition is turned off. This is most often an incorrectly installed radio, alarm system, or poorly repaired factory parts - fans, lights. Wiring that is frayed at bends can also drain the battery.

- The battery is undercharged when driving. This happens with frequent short trips or with a faulty generator.

What kind of charging should go to the battery from the generator?

The current required for the normal operation of all electrical equipment and charging the battery is individual for each model and is calculated with a margin so that the car owner has the opportunity to connect additional equipment.

The power spread is quite high - 50-amp generators are installed in compact city cars, and 200-amp generators are installed in respectable cars and SUVs.

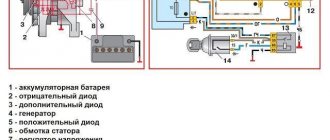

In any case, the relay-regulator ensures that the voltage transmitted from the generator to the battery is no more than 14 V - charging in this mode will protect the electrolyte from overheating (and in the summer it is very hot in the engine compartment - in the area around the engine at 100 degrees), at which The liquid boils, decomposing into oxygen and hydrogen.

The main problem is that the generator will charge a heavily discharged battery at a stable voltage with an increased current. For batteries that have lost most of their charge, this is fraught with big troubles, even complete failure. However, recently, expensive configurations of prestigious models have been equipped with functions that allow you to control the amount of battery charging current.

From the above, you need to understand: how many amperes the vehicle generator should supply to the battery depends on the state of charge of the battery. Under normal circumstances, this is approximately 1 A, and as the voltage in the battery increases, this value decreases to 0.5 A. Yes, this is not enough. It can be argued that generator charging of a battery is never complete, this is true. That is why it is recommended to charge once every six months using a charger.

As for the maximum current, its value is usually indicated on the generator label. If it or a component of the generator assembly is faulty, the battery will charge at reduced voltage and will be continually undercharged. Before checking the alternator voltage on the battery with a multimeter, you should make sure that other devices that consume electricity are working normally - this can narrow down further troubleshooting.

Premise search method

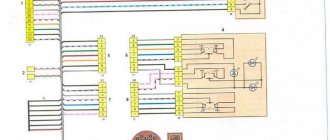

We looked at typical faults. But it is important to find the main reason. If the car has a standard configuration and there are no abnormal energy consumers, then you can begin to diagnose the generator specifically. If there are additional users, it is better to disable them. With all this, you need to turn it off at the physical level, from the on-board network.

Then all users connect and determine the leakage using a multimeter in the same way. If it is large, then the cause must be found not in the generator or battery, but in one of the devices in the on-board network. If no leakage currents are found at rest, then most likely the VAZ generator is not charging. We have already seen the prerequisites.

Causes of undercharging of the battery by the generator and ways to eliminate them

Since the generator and the electrical circuit responsible for charging the battery consist of many components, there may be several reasons for the battery to be undercharged. Let's describe the most common of them.

Generator overload

One of the main reasons why the generator does not provide sufficient charging to the battery is that it is simply overloaded. In the standard configuration, this situation usually does not arise, but if you connect gadgets hungry for electricity (smartphone, recorder, navigator, more powerful headlights, etc.) to the on-board network, then the situation may change for the worse.

Installing a more powerful battery (for example, a 70-amp instead of a 55-60 A battery) will also lead to the fact that it will experience a constant deficit of charge current.

So, before increasing the load on the on-board network, do not be lazy, find out the power of the generator and the total current consumption of all consumers - this will protect you from rash actions.

Poor or loose contact

This problem occurs when the slip rings and brushes are heavily soiled. Weakening of the contact can also occur due to a decrease in pressure on the brushes from the weakened spring. Finally, the brushes may simply jam. All these troubles can cause an increase in excitation resistance. The problem can be eliminated by timely cleaning of contaminated elements; if there are oxides on the rings, they are removed with sandpaper.

Breaks in the winding

Another reason why the generator does not charge the battery is the presence of a break in the excitation winding. Such a malfunction is easily diagnosed - just put your hand on the case - in such cases it gets very hot. To clarify the diagnosis, the end of the winding is connected to the generator terminal instead of a brush, and then the current is measured with a multimeter through the battery. If the readings are zero, there is a break. To search for the problematic winding, battery wires are connected to each coil in turn and the measurements are repeated. If the break is external, you can try to fix it with a soldering iron. Otherwise, the entire coil is replaced.

Generator short circuit

Unlike a break, a short circuit in any section of the winding will lead to the inoperability of the entire device. Most often, a short circuit occurs at the junction of the slip rings with the winding. Test method: connect a 5-volt lamp to the rotor core and the slip ring; if there is a short circuit, the lamp will light up. The malfunction is eliminated by replacing the generator (or alternatively, replacing the winding).

If the insulation in the stator coils is partially destroyed, the generator will begin to get very hot, and the battery will be fully charged only at high speeds. The same symptoms will be observed when the stator is shorted to the device body. In such cases, the easiest way out is to replace the generator.

Mechanical breakdowns

If the battery is not charging, the reasons may be mechanical. Most often in such cases, the culprit is a loose alternator belt. This problem is easily diagnosed - when the drive belt is stretched, the pulley gets very hot. The problem is solved by replacing the belt.

You should also check the battery terminals - if they are oxidized, this is the reason for the undercharging. The reason may lie in poor contacts in the places where the wires are attached to the generator components, in their breakage, or chafing. Finally, it's worth checking to see if the fuse has blown (although it's recommended to start the diagnosis there rather than end it).

The diode bridge has failed

Since the generator generates alternating current, it needs to be converted to direct current before it is supplied to the on-board circuit. This task falls on the shoulders of the diode bridge, which acts as a rectifier. It is called a bridge because it consists of several diodes. If one of them becomes inoperative, the normal operation of the generator is disrupted. This is also a fairly common cause of undercharging of the battery due to AC leakage. A similar malfunction will be indicated by dimming of the vehicle's external and internal lighting lamps. Diagnosis of the problem is carried out by measuring the voltage and current parameters passing through the battery terminals.

The procedure algorithm is simple:

- start the power unit, let it warm up a little;

- apply the parking brake and shift the gearshift lever to neutral (or to parking mode if you have an automatic transmission);

- switch the multimeter to low amplitude AC voltage measurement mode;

- If the device shows a non-zero voltage, the diode bridge must be replaced.

Control of other elements of the charging system

To determine why the alternator is overcharging or not charging the battery at all, you may need a multimeter. Using the tester, you can measure the battery voltage in two modes. With the engine turned off, the charge parameter should be in the range of 12.5-12.7 volts, and with the engine running - 13.5-14 volts. If these indicators are lower when the internal combustion engine is switched on, this may indicate problems in the operation of the diode bridge or brush assembly. By the way, brushes can wear out, so they need to be changed periodically.

If the cause of overcharging or lack of charging is a relay, it can be eliminated by replacing or resoldering the diodes. If the diodes will be soldered, it is necessary to select devices that are closest in technical characteristics. Otherwise they may overheat.