Gasoline prices continue to increase. This fact encourages more and more vehicle owners to switch to alternative fuels. Electric cars have a number of advantages. However, even talking about large cities, the number of charging stations for electric vehicles is minimal. The operation of private electric transport is complicated. Gas remains the optimal replacement for gasoline. Installing gas equipment will provide significant savings to the family budget with regular use of vehicles.

Naturally, for correct operation, fine tuning of the HBO and subsequent attention to technical nuances are necessary. If the speed on gas drops, there may be several reasons. Below we describe the most common approaches to eliminating the described problem.

Problem - floating idle speed when running on gas

A common problem is unstable operation of the internal combustion engine on gas at idle speed. What malfunctions do HBO have in such cases? Let's try to understand this issue.

There can be two reasons when the speed on gas fluctuates: either it “does not burn,” that is, the lean fuel mixture does not ignite well; or interruptions in spark. With the second case, everything is simple, because the circle of culprits is not so wide - a switch, armored wires or spark plugs. But in the case of a lean mixture, the search may take longer.

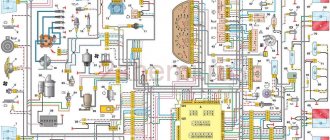

Mandatory electrical wiring check

We recommend starting with checking the electrical communications of the car. The presence of bare electrical wires, corroding contacts and terminals is not allowed. If there is no external damage, the integrity of the wiring is checked using special equipment.

If no problems are found in the electrical wiring, you can proceed directly to searching for the causes of the malfunction in gas equipment:

- filters;

- gearbox;

- nozzles;

- controller.

We recommend paying attention to the injectors. It is quite possible that the HBO was installed on the car incorrectly. Namely, if the injectors are located at a distance from the cut into the intake manifold, not all of the fuel mixture can enter the combustion chamber.

This is what causes “jumping” engine speeds. There is no confident acceleration dynamics or stable operation of the power plant.

Gas injectors

If it is not possible to connect to the computer, then you can pinch the hoses leading from each injector to the insert in turn, and thus detect the malfunction. You should also check whether an impulse is received from the ECU to the injectors, turning them off alternately. Possible problems and malfunctions:

- Natural wear and tear of the GF or its contamination with foreign inclusions in the fuel;

- Initially injectors that do not match the specific engine;

- No impulse is received (or is received intermittently) from the ECU;

- Air leakage, which depletes the air-fuel mixture on the way to the insertion or at the insertion point into the manifold;

- Air leakage through a leaky manifold gasket - this defect is also common.

In the first two cases, the injectors are replaced as non-conforming or repaired (cleaned, calibrated). Deposits of 5 microns reduce the performance of the GF by 20%, which affects engine operation. To avoid problems in the future, you should carefully choose a gas filling station and change the fine filter more often.

Gas speed fluctuates - causes and ways to eliminate them

Problem - floating idle speed when running on gas

A common problem is unstable operation of the internal combustion engine on gas at idle speed. What malfunctions do HBO have in such cases? Let's try to understand this issue.

There can be two reasons when the speed on gas fluctuates: either it “does not burn,” that is, the lean fuel mixture does not ignite well; or interruptions in spark. With the second case, everything is simple, because the circle of culprits is not so wide - a switch, armored wires or spark plugs. But in the case of a lean mixture, the search may take longer.

Methodology for finding problems on domestic carburetor systems

Before you start troubleshooting, you need to check that the carburetor is adjusted correctly. The manufacturer sets the settings for ideal operating conditions - the amount of oxygen in the atmosphere of flat terrain and gasoline that complies with GOST. And this is on a new car.

In reality, periodic adjustment of all 4-5 carburetor adjustment screws is required. At least two of them are responsible for stable idle operation. The adjustment is made with the engine running using a simple screwdriver.

The procedure is described in the owner's manual, and differs slightly depending on the carburetor model. The main condition for correct tuning is the absence of leaks, a clean air filter, and high-quality gasoline. The amount of oxygen in the air corresponds to daily use.

That is, if you live on a plain, there is no point in adjusting the carburetor while climbing a mountain serpentine to an altitude of 800 meters above sea level.

- Warm up the engine to a temperature of 90°C. If there is no thermometer, the degree of heating can be easily determined by the opening of the cooling system thermostat;

- We start the engine, give a small load - turn on the headlights and the climate system (without air conditioning). Each type of carburetor has its own idle speed, let’s take 750-800 rpm as a basis, as on Solex. The idle speed is controlled by the “quantity” and “quality” screws of the mixture. It will not be possible to establish normal speed with wine alone;

- The forced choke lever (choke) is closed;

- Using the “quality” screw, we adjust the speed to the maximum possible value. As a rule, the screw is fixed at the factory and closed with a plug. It needs to be removed;

- Next, using a standard (on the dashboard) or remote tachometer, set the speed to 900, turning only the “quantity” screw;

- Then use the “quality” screw to set the required value: 750-800 rpm.

Reducer-evaporator

Pay attention to the pressure when the speed increases sharply. A drop of more than 20% indicates either a leak, a faulty valve, or a narrowing of the gas passage channels. Traction disappears, the engine stalls when the gearshift lever is switched to neutral. The main reason is pollution. It can be solved by repairing the gearbox.

Tips and tricks

Let's look at how you can eliminate some of the malfunctions that lead to floating and speed jumps, and do it yourself.

- As mentioned above, the leakage of excess air can cause surges. To exclude or confirm the possibility of supplying such air, you need to check the tightness of the air supply system to the intake. You can remove the air hose and feed it air from a compressor or pump by placing the hose in a container of water. This method helps to identify cracks.

- As for the idle air control, you need to measure the resistance with a multimeter. If the resistance is between 40 and 80 ohms, this means that the device is not working.

- Also, as part of diagnostic procedures, in some cases it is necessary to clean the crankcase ventilation valve. The valve must be removed and washed with carburetor cleaning fluid or kerosene. This approach will remove deposits from the valve.

- As for the ECM sensors, in this case it is not advisable to try to repair such elements. For example, if the mass air flow sensor is faulty, it is better to immediately replace it with a new one.

- It is better to trust specialists to flush the throttle valve without proper experience, especially if such flushing is necessary with the removal of the valve. If we talk about the method of flushing the throttle without removing it, you can do the procedure yourself. The hoses are disconnected from the valve, then a cleaning aerosol is injected into the throttle.

Other possible reasons:

- Low level of coolant - lack of antifreeze can cause underheating of the gearbox, as a result - the liquefied gas does not partially turn into steam;

- If problems with idle speed coincide with a sharp change in weather, then additional idle adjustments on the gearbox may be required;

- With regular short runs, condensation may accumulate in the gearbox, interfering with the normal operation of the unit, so it would not hurt to check this fact.

More reasons

If all of the above has been checked, and the engine is still unstable on gas, you should check the coolant level. A low level of antifreeze may well cause underheating of the gas reducer, which in turn will affect the floating speed.

All electronic contacts associated with the operation of the gas equipment should be checked and cleaned; quite often, an oxidized contact can lead to floating speed.

Sometimes, as a result of power surges, the ECU settings are reset, in which case the entire system does not work correctly and is unstable. You should connect to the control unit and configure the system and calibrate the injectors.

Outdated ECU. It happens that in an effort to save money, technicians install an electronic monitor that is unable to properly monitor the operation of the injectors, resulting in incorrect or delayed processing of commands and, accordingly, malfunctions in the operation of the entire system.

Filters

Filters need to be replaced periodically. Typically the interval is 10 thousand km. However, as practice shows, sometimes it is because of a clogged filter that the speed fluctuates when the car is running on gas. This applies to both the coarse filter and the fine filter. In the first case, you will need to remove the filter for disassembly. Fine filters, as a rule, cannot be repaired and must be replaced.

Common causes of floating revolutions

So, we figured out the main symptoms. Now let's move on to the reasons. Let us immediately note that floating idle speed is often a problem with injection engines. The fact is that a complex ECM system is responsible for idling in this case.

This system assumes the presence of a controller, sensors and actuators. The control unit receives signals from sensors and transmits commands to actuators (for example, IAC), maintaining stable engine speeds at idle and other modes, regardless of the load on the internal combustion engine.

However, any failures that are associated with the supply of air, fuel, a violation of the composition of the working fuel-air mixture or its ignition, as well as various mechanical breakdowns will lead to floating speed.

- As a rule, in practice, the idle air regulator causes a lot of problems for drivers. In fact, this is a stepper motor that has a conical locking needle. When the throttle valve is closed, air bypasses the valve through a channel that is closed by the needle.

If malfunctions occur in the operation of the device, the ECU is not able to correctly “select” the mixture composition at idle, as a result, the speed floats.

- The mass air flow sensor also deserves special attention. During operation, the air flow sensor may become dirty or break down.

One way or another, the ECU does not receive correct data on air flow, which leads to disruption of mixture formation and jumps in engine speed.

- Often, a floating engine speed can be associated with severe contamination of the throttle valve itself or mechanical breakdowns of the throttle, damage, or deformation. The damper may jam and not close completely.

To prevent such complications, it is necessary to periodically clean the throttle from dirt, and on many cars, additional training of the throttle is required after cleaning.

- During diagnostics, you should also check the crankcase ventilation valves. Normally, crankcase gases are redirected to the intake, where they are mixed with air and fuel, after which they are burned in the cylinders.

- By the way, if you touch on carburetor engines, the speed on the carburetor floats, usually due to the settings and adjustments of this device being messed up. Also, one should not exclude the possibility of a breakdown of the carburetor solenoid valve or clogging of the idle jet.

Let’s also add that if the speed of a diesel engine fluctuates, this is often caused by rust on the fuel injection pump blades. Corrosion occurs due to the presence of water in diesel fuel.

4th generation HBO malfunctions

Often, when operating a vehicle on gas, owners do not pay due attention to the maintenance of the gas equipment system. And often the malfunctions of the 4th generation HBO, which are what we will discuss in today’s article, make themselves felt at the most inopportune moment.

The car simply refuses to run on gas, it loses power, the engine stalls, or fuel consumption increases significantly, why does this happen? Most often, experts identify two reasons why 4th generation gas equipment malfunctions occur:

- Maintenance of the gas equipment system was not carried out on time, or was not carried out at all. Remember! Filters on 4th generation gas equipment should be replaced once every 10,000 km, and with the quality of gas at our gas filling stations even more often!

- Wear of system parts over time, increased wear of components can also be influenced by poor quality gas, incorrectly configured ECU or incorrectly adjusted injectors.

How to clean and adjust rod gas injectors of the 4th generation of Valtek type LPG

Last updated April 2, 2022 at 11:57 am

When operating gas fueled vehicles, drivers often encounter incorrect operation or breakdowns of the gas equipment. The efficiency of this equipment largely depends on the serviceability of gas injectors. Their operation takes place under conditions of high temperatures and sometimes low-quality fuel.

Owners of gas-powered vehicles are advised to know how to repair, clean and adjust 4th generation LPG gas injectors with their own hands. This will help in some situations and save money.

Throttle position sensor malfunction.

The throttle position sensor has a direct connection with the idle air control sensor. I will tell you below how to find signs of a faulty throttle position sensor. What is a throttle position sensor and why is it needed? TPS monitors by what percentage the throttle valve opens. In fact, this is an ordinary variable resistor, you can compare it with the volume control on your grandmother's TV.

As a rule, it operates from 0 volts to 5 volts, because the change in voltage on it is monitored by the ECU processor. Almost all processors used in automotive ECUs are five-volt. Therefore, the throttle position sensor operates up to 5 volts, since the processor cannot measure voltage higher than its supply. Now let's look at the connection between the throttle position sensor and the idle air control. When we press on the gas pedal and the throttle position is not zero, the idle speed control is not activated, the ECU simply turns it off. In one of the articles I talked about why the ECU turns off the injector.

Now attention. As soon as we release the gas completely, the throttle valve closes, accordingly the throttle position sensor reads 0%. And then the ECU turns on the idle speed control so that the car does not stall. So until the position sensor reaches 0%. The ECU will not turn on the idle speed control feature. Now do you understand what the throttle position sensor has to do with the idle air control valve ?

If you have problems with idling, or the car jerks when revving, you should definitely check the operation of the throttle position sensor. As a rule, it comes with three wires, +5 volts, reference ground and control. How to check the throttle position sensor? To do this you will need a diagnostic program. By pressing and releasing the gas pedal, we can see in the diagnostic parameters a change in the percentage of the throttle position. A prerequisite is that when the pedal is released, the position sensor should read 0%. This manual does not apply to vehicles with electric throttle.

If the throttle position sensor shows at least 1%, the ECU will not turn on and will not supply power to the idle air control. As a result, the car will stall, the speed will jump and hang, and there will be no idle.

I have seen more than once when “auto electricians” pulled the throttle cable while trying to adjust the idle speed or tightened the locking bolt on the throttle assembly. The factory specially places seals on these units so that no one can twist them. But the playful hands of incompetent auto electricians constantly get in there. If an electrician performs such actions, this indicates that he does not understand anything about the operation of an injection car. Stay away from such masters! Also, the reason when the position sensor does not go to zero may be a poor reference ground going to the throttle position sensor.