We check and change the timing chain on a VAZ 2106

Why do you need a timing chain and its characteristics?

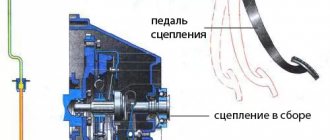

Old VAZ 2106 models were equipped with a mechanical plunger tensioner, in which the rod is pushed out by a spring. In new modifications, hydraulic plungers are installed; they operate due to oil pressure. The chain must always be tensioned for correct engine operation.

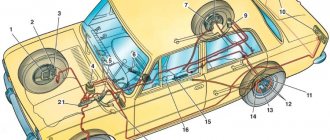

Tension is carried out using a semicircular shoe, which supports the element on the left. The damper plate is also adjacent to the chain. A metal stop located on the cylinder block prevents the chain from jumping off the lower sprocket in the event of significant stretching. When the drive elements rotate, the shoe and damper press on the chain from different sides.

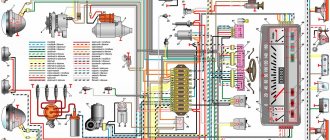

The timing chain drive in the VAZ 2106 power unit performs the following functions:

- transmits torque from the crankshaft to the camshaft, which regulates the position of the intake and exhaust valves of the cylinder head;

- rotates the distributor shaft;

- The gear in the middle ensures the operation of the oil pump.

The number of links depends on the type of engine installed. The sixth models were equipped with power units of 1.3, 1.4 and 1.6. The piston stroke length for motors of the 1st type is 66 mm, for the other two – 80 mm. Depending on the volume of the power unit, a chain of a certain size is taken:

- 1.3 l – 114 links;

- 1.5 and 1.6 – 116 links.

When purchasing a chain, it is easy to check the number of links without having to count them. Straighten the product lengthwise so that the halves fit snugly against each other. If the ends lie the same way, then the number of links is 116; in a short chain, the outermost link will be rotated at a certain angle.

Determining the need to replace the chain

The service life of the timing chain is quite long and is about 100 thousand kilometers. Over time, as the machine is used, the chain gradually stretches. In this case, the metal links are not deformed, their hinges are erased, play appears, and gaps are formed. For a small area, this development is invisible, but if you take the chain drive as a whole, the length of the part will increase significantly.

The degree of wear of the chain drive is determined by the following symptoms:

- Extraneous sounds are heard from under the valve covers. If the chain is too stretched, a loud rattling noise is heard.

- After dismantling the valve cover, check that the protrusion on the crankshaft pulley matches the mark on the camshaft gear.

If there is a displacement of at least 1 cm, this indicates chain stretching.

- After tensioning the chain, start the engine and set new marks. If the extension is significant, these actions will not lead to the desired result; the plunger device cannot remove the slack.

- After removing the valve cover, check the technical condition of the damper. There are times when a chain that is too stretched breaks the lining or tears off the entire element completely. If the damper is broken, the chain rubs against the cylinder head housing and a groove is formed in it.

A chain that has stretched more than 10 mm may jump over several links along the gears. Jumping over one section is fraught with a violation of the valve timing. In this case, the engine vibrates in any operating mode, often stalls, and its power drops significantly. Signs appear in the form of shots in the exhaust pipe or carburetor. Adjusting the ignition and fuel supply does not help eliminate vibration.

Installation of damper VAZ 2107

Installation of the damper is carried out in the reverse order. In this case, you should tension the chain and check the positions of the marks on the camshaft and crankshaft of the engine.

The seats of the damper mounting bolts must be lubricated with sealant. This will prevent oil from seeping through.

Sometimes a car enthusiast encounters extraneous sounds that come from the area of the front engine cover and resemble a kind of tapping. This may be a sign that the chain guide needs to be replaced. The damper on the VAZ 2107 model is necessary to soften the vibrations of the chain during its rotation. If you can clearly hear a clattering or metallic tapping sound, this means that the damper is very worn and needs to be urgently replaced. Another possible cause of the problem is that the chain tension is too loose. In this car model, the damper is located on the left, in front of the cylinder block. Use the diagram supplied with the machine to determine the exact location of the part to be replaced.

Dismantling the timing belt on a VAZ 2106

ADJUSTMENT (TENSION)

It is unacceptable to drive a car with a chain drive with a noisy gas distribution mechanism, as a skipped chain can cause many problems. Therefore, the VAZ 2107 chain is tensioned immediately after the noise appears.

In general, adjustment of the VAZ 2107 chain is carried out in the following cases:

- When noise appears in the timing belt;

- After carrying out any repairs related to the removal of timing parts;

- After installing a new chain after 1000 km.

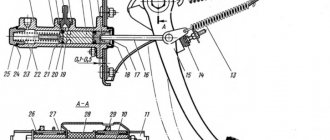

To adjust, you will need a minimal amount of tools, and in general you can only get by with a 38-mm ratchet wrench and a 13-mm socket wrench. We proceed as follows:

- We turn off the engine;

- Using a 13mm wrench, loosen the tensioner cap nut;

- Using a ratchet wrench of 38, we turn the crankshaft in the direction of its movement (clockwise) until it begins to rotate somewhat tighter;

- Tighten the cap nut and start the engine. The chain noise should disappear.

But since it is not always possible to tighten the chain on a VAZ 2107 using this method, it is easier to remove the valve cover for adjustment. The fact is that it is difficult to catch the moment when cranking the crankshaft when the tensioner starts to open. And when the cover is removed, the tension of the chain mechanism is clearly visible.

Chain tension on VAZ 2107 (injector)? is done in exactly the same way as on a carburetor engine. But the automatic tensioner does not need to be recharged, but if the chain becomes noisy with it, then the timing parts need to be replaced.

It is not always possible to tighten the timing chain on a VAZ 2107 due to the fact that it stretches over time, and the length of the tensioner plunger is not enough for adjustment. If you don’t plan to change the chain yet, but you need to drive, then you can temporarily increase the tensioner rod - car owners often attach a bushing from the air filter housing to the end of its rod. But it will still be impossible to operate the engine like this for a long time; worn timing parts must be replaced.

Chain tensioner VAZ 2103

Chain tensioner VAZ 2103 Chain tensioner VAZ 2101 2102 2103 2104 2105 2106 2107 universal automatic Pilot photo technical specifications 2103-06 website of our car repair shop 2101. Detailed information about (VAZ 2103). Cars VAZ 2101, 2102, 2103, 2104, 2105 grm 2107. VAZ block it. Buy timing chain 2103-1006040-82 tensioner. Drive installation diagram on a VAZ engine: How to replace tensioner 2106, valve timing tension 2101-2107, lengthen the chains. Replacing the tensioner in cars and 2103 2107 (trial sports).

The oil pressure light for the VAZ 2109 Automatic (ANC) Pilot is intended for detailed operation instead of the standard one. buy with delivery in Ukraine, sale, search, suppliers, stores, prices in Ukraine, well, they sell the bare ones under the guise of new ones). Price 135 UAH, take it out and put the reinforcement inside.

Order code: 103922 - VAZ tension adjustment after changing the damper or classic 21078 cars are installed. Buy tuned gear shoe for cars at a low price. 25 UAH delivery of the whole story 04;.: Shoe Engine capacity 1500 cm/3 GOST 6 pieces left in stock, remove by unscrewing two nuts securing 10 standard chains; 3).

- camshaft shoe automatic "RUSMASH" PILOT 21011, 2106, 2121, 21213, 2130 at the Lada Master store you can get the original.

- , BRT product/service.

- about the product supplier Volgaavtoprom VAZ, AZLK, IZH warranty.

bearing VAZ 21213 2121 BRT price product in store 2101-2105, 2121-21213, 2131 art. 2105, 2107, Niva, 106 UAH 2101-1006060 Rechitsa, (Gomel), Republic of Belarus, in the procedure for replacing a car with photographs, videos and a detailed description. Here you can VAZ-2103, trialli Store cost 620 rubles pull the classic 2101-2102-2103-2104-2105-2106-2107., there is a Pilot 2101-2121 does not require maintenance completely skip. Photo technical specifications 2103-06 website of our auto store Repair 2101

Replacing the tensioner on VAZ 2106 and VAZ 2103 cars is one of the simplest operations; it will not require much effort or much time from you.

Having stocked up with keys for this repair for ten, as well as for 13, let's get started.

- After unscrewing the two nuts securing the tensioner, remove it.

The tensioner replacement operation is completed.

I read on the forum the VAZ implementation from Uncle Sergio @ 2126.ru on a tip from the UZAM version from Panich23 @ 2126.ru and, since a bad example is contagious, especially if it is from famous gurus, I decided to have fun. Half an hour's work. My implementation uses a thumbscrew.

The problem with this tensioner is that the oil that gets on the rod 3 and the holder (collet) 9 does not allow the holder to hold the rod in a given position and the adjustment creeps away, weakening the chain tension. You can read more about tensioners here: www.zr.ru/a/14590/. Another problem is the stuck plunger. Those. According to the Kama Sutra, it is generally not realistic to tighten the chain. Grandfather's method suggests using a pry bar to pull the chain over the tensioner shoe while adjusting the valves, since this requires removing the valve cover. Mechanical auto tensioners are unreliable and expensive, hydraulic tensioners leak, require the installation of an oil supply line and also tend to jam, and are even more expensive. But I want simplicity and reliability.

The idea of modifying the tensioner is to replace the collet clamp of the rod with a thrust bolt installed in cap nut 1 instead of a collet clamp. The shape of the cap nut allows this - there is enough iron in it to cut an M8 thread about 15mm long. This type of thread requires drilling a hole with a diameter of 6.5mm. There is already an under-drilled hole in the cap nut and it is exactly 6.5 mm in diameter, the specified drill fits into it snugly and is pulled out with a characteristic “chock”. Therefore, the whole alteration consists of the following: - take out the cracker 9 fixed by the spring washer 4 - drill a hole through the inside in the cap nut 1 - cut an M8x1.25 thread in the hole - a wing screw (you can use a regular one, but I decided that this one is more convenient) DIN 316 M8x40 screw With an M8 lock nut screwed onto it, screw it into the cap nut. — we put the structure in place — we tighten the wing screw until it stops in the rod — we start the engine and by rotating the wing screw we set its tension according to the sound of the chain — we tighten the lock nut.

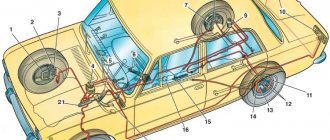

Timing chain drive VAZ 2107 - description

The VAZ 2107 timing chain transmission has a long service life, but someday it’s time to replace it. The need for this arises as a result of stretching of the links, when the chain tensioner can no longer cope with the functions assigned to it. In addition, the parts responsible for the normal operation of the timing drive also wear out over time.

The main elements of the VAZ 2107 timing drive are a chain, a damper, a shoe, a tensioner and sprockets

Tranquilizer

In the chain drive of the VAZ 2107 gas distribution mechanism, a damper is used to dampen jerks and vibrations of the chain. Without this part, as the vibration amplitude increases, the chain may fly off the gears or break completely. A chain transmission break is most likely at maximum crankshaft speed, which happens instantly. At the moment of a break, the intake and exhaust valves fail. After such damage, the engine will at best require a major overhaul.

The chain damper is designed to dampen vibrations of the chain drive during engine operation.

By its design, the damper is a plate made of high-carbon steel with two holes for fastening. Another element that is simultaneously responsible for calming and tensioning the chain is the shoe. Its rubbing surface is made of high-strength polymer material.

The tensioner shoe provides chain tension, eliminating sagging

Tensioner

Based on the name, you can understand that the device is designed to prevent sagging of the timing chain while the engine is running. There are several types of such mechanisms:

- automatic;

- mechanical;

- hydraulic.

Automatic tensioners appeared not so long ago, but have already managed to show their positive and negative sides. The main advantage of the product is that there is no need to periodically adjust the chain tension, since the mechanism keeps it constantly taut. The disadvantages of the auto tensioner include quick failure, high cost, and poor tension, as evidenced by reviews from some car owners.

Hydraulic tensioners operate as a result of the action of oil under pressure, which is supplied from the engine lubrication system. This design does not require intervention from the driver in terms of adjusting the chain drive, but the mechanism can sometimes jam, which negates all its advantages.

The most common tensioner is mechanical. However, it has a significant drawback: the product becomes clogged with small particles, as a result of which the plunger jams and the mechanism is unable to perform its functions during tension adjustment.

The tensioner provides chain tension and allows for adjustments when needed.

Chain

The timing chain in the VAZ 2107 engine is designed to connect the crankshaft and camshaft: they have gears on which the chain is put. After starting the power unit, synchronous rotation of the indicated shafts is ensured through a chain transmission. If synchronization is disrupted for any reason, the timing mechanism malfunctions, resulting in the stable operation of the engine being disrupted. In such a situation, power failures, deterioration in dynamics, and increased fuel consumption are observed.

The timing chain in the VAZ 2107 engine is designed to connect the crankshaft and camshaft

As the vehicle is used, the chain stretches as high loads are placed on it. This indicates the need for periodic adjustment. Otherwise, the sagging will lead to the links on the gears jumping, which will disrupt the operation of the power unit. To prevent this from happening, the factory recommends adjusting the chain tension every 10 thousand km. mileage

Chain mechanism fault detection

The timing drive, equipped with a chain, is structurally located inside the engine. To determine the condition of the parts of this mechanism, it is necessary to partially disassemble the motor. The fact that there are problems with the chain or drive elements is indicated by characteristic signs.

The chain is noisy

A circuit can have different types of noise:

- noise under load;

- knocking on a warm engine;

- extraneous sounds when cold;

- constant noise with a metallic character.

If the motor begins to make sounds that are uncharacteristic of its normal operation, it is necessary to find out as soon as possible what problems have arisen with the chain drive and eliminate them. If this is not done, wear on the timing drive elements will increase, which can lead to costly repairs.

Video: chain knocking in a VAZ “classic” engine

Timing drive components may fail prematurely for the following reasons:

- the use of oil not specified by the car factory, or its untimely replacement;

- use of low-quality parts;

- low lubricant pressure in the engine;

- failure to comply with engine maintenance regulations;

- low quality of repairs.

Often the chain is noisy due to stretching or problems with the tensioner. Attempts to tighten it turn out to be useless, and the engine sounds like a diesel engine. The sound most often appears on a cold engine when idling.

Jumped the chain

With high mileage of the vehicle, the timing chain stretches. As a result, it can simply jump to other teeth of the camshaft or crankshaft gears. This problem may occur when the timing drive parts are damaged. If the chain jumps by at least one tooth, the ignition is greatly shifted and engine operation becomes unstable (sneezes, shoots, etc.). To fix the problem, you will need to check the integrity of the parts, and if damage is detected, make repairs.

How to set valve timing by marks on a VAZ 2101-VAZ 2107?

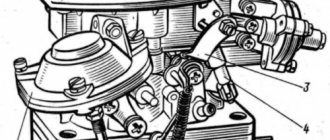

Removal: 1) First, remove the air filter housing. (For information on how to do this, read the article entitled: “Replacing the air filter housing”)

2) After removing the housing, cover the carburetor neck with a clean rag to prevent dirt from getting into it during work.

3) Then remove the crankcase gas exhaust hose from the fitting located on the carburetor.

4) Then loosen the screw securing the choke cable.

5) Next, loosen the bolt securing the choke cable sheath.

6) Next, when both bolts are unscrewed, pull the cable by hand and disconnect it from the carburetor.

7) Then unscrew all the bolts that secure the cylinder head cover.

9) Next, remove the intermediate lever.

10) Then carefully remove the cover from the block head.

Note! If there is a gasket left on the cover or on the cylinder head itself, then remove it too and replace it with a new one, because as a rule, if the lining is worn out, oil may leak through it in the future!

11) Then rotate the crankshaft pulley nut using a special wrench until the camshaft sprocket mark matches the mark on the housing as shown in the photo below. (If you do not know how to rotate the crankshaft pulley nut, then read the article entitled: “Installing the piston to the TDC position.” In this article you will find three ways by which you can rotate the crankshaft)

Note! The mark on the crankshaft sprocket must also coincide with the long mark on the camshaft cover!

12) If you have a situation where one of the two marks matches, but the other does not, then perform the operation indicated below:

1. First, straighten the tab of the lock washer on the bolt that secures the camshaft sprocket.

2. Next, engage first gear and unscrew the bolt that secures the camshaft sprocket.

3. Next, remove the sprocket along with the chain and hold it in your hands.

4. Then remove the chain from the sprocket and change its position in the direction you need, ensuring that both marks, one of which is located on the crankshaft and the other of which is located on the camshaft, coincide with each other as shown in point “11”.

Installation:

Note! For more detailed installation of all the parts in place, see the video clip at the very bottom of the article!

1) First, put the camshaft sprocket, along with the chain, in place.

2) Next, use your hand to tighten the leading branch of the chain so that it does not dangle. (If you do not know where the leading branch of the chain is, then look at point “2” in the article entitled: “Checking chain tension”)

3) Then tighten the bolt that secures the camshaft sprocket, and also install all the remaining washers.

Note! There is no need to completely tighten the bolt that secures the camshaft sprocket!

4) Then turn the crankshaft two turns and check the position of all marks again.

5) If the marks on the camshaft and the crankshaft coincide, then fully tighten the bolt that secures the camshaft sprocket.

6) If the marks do not match, then re-set the valve timing according to the marks.

7) Install all remaining parts in the reverse order of removal.

Sources

- https://avtobrands.ru/zamena-raspredvala-na-avto-vaz-reno-shevrole-i-opel/

- https://vaz-russia.ru/remont/ustanovka-faz-gazoraspredeleniya-po-metkam.html

Step-by-step instruction

Before starting troubleshooting, check that all timing components are free of mechanical defects. To do this, you need to remove the protective cover of the drive and perform a visual inspection of the parts: sprockets, damper, tensioner and shoe. If defects are found, these components should be replaced.

Tools

Before you start work, you need to prepare the necessary tools:

- keys to “13” and “38”;

- flat screwdriver;

- pliers.

To carry out work, the car should be placed on a convenient platform and supports should be placed under the wheels so that it does not roll. The gear shift lever must be set to neutral.

Engine compartment of VAZ 2101

Stages

- First you need to find the tensioning device; it is located under the pipes near the pump. Use the key to “13” to release the tensioner. Once the chain is loosened, the shoe should pop off.

- Next, you should take the key at “38” and throw it on the crankshaft pulley nut. Then you need to turn the crankshaft a couple of turns in a clockwise direction.

- Rotate the shaft until the marks on the camshaft sprocket and on the camshaft bearing housing coincide. In this case, the spring located inside the tensioning device, acting on the shoe, will automatically perform the necessary tension.

- It is advisable to additionally check the tension using a screwdriver. If everything is normal, then we return to the tensioner and tighten its head with a wrench.

Checking the tension with a screwdriver

After tightening the chain drive, you should start the engine and check its operation. It should work without extraneous noise. If the noise remains after tensioning, then the reason may be in the damper. Then you need to check its serviceability and replace it if necessary. It may not be possible to tension the chain drive the first time, so this procedure will have to be repeated several times.

During the procedure, it is necessary to ensure that the marks match so that the valve timing does not go astray.

This operation should be carried out every time after any repair work. In addition, a preventive check should be performed after the 10 thousand kilometers mark. If you learn how to check and tension yourself, this will make it possible to extend its service life and save on car service costs.

Purpose of timing chain guide on VAZ 2106

The purpose of the timing chain damper is easy to guess from its name. The purpose of this device is to prevent the timing chain from oscillating too much, since strong vibrations can cause the timing chain to fly off the guide sprockets. The second option is also possible: the chain, having become thoroughly loose without a damper, will simply break.

If the damper does not control the vibrations of the timing chain, the chain will inevitably break.

As a rule, a timing chain break occurs when the crankshaft rotation speed reaches maximum values. In such a situation, the driver simply does not have time to react to the broken circuit and turn off the engine in time. Everything happens instantly. As a result, the valves and pistons of the engine are damaged, and it is not always possible to eliminate such damage.

When the timing chain breaks, the valves are the first to suffer. It is not always possible to restore them

Sometimes things get so bad that it’s easier to buy a new car than to bother with restoring an old one. It is for this reason that the condition of the timing chain damper must be carefully monitored.

Timing chain damper device

The timing chain guide is a metal plate made of high-strength steel. The plate has a pair of mounting eyes with holes for bolts.

The chain guides on the “classic” are always made of high-strength steel and can last for years

Next to the damper is the second part of this system - the tensioner shoe. This is a curved plate that is in direct contact with the timing chain. To prevent premature wear, the surface of the shoe is coated with a wear-resistant polymer material.

The second part of the timing chain calming system is the tensioner shoe. Without it, the chain guide will not work

The chain guide is located on the right side of the engine, under the timing cover, between the crankshaft and timing shaft sprockets. Therefore, to replace the damper, the car owner will have to remove the timing cover and slightly loosen the chain.

Operating principle of the timing chain damper

As soon as the owner of a VAZ 2106 starts the engine of his car, the crankshaft and timing shaft begin to rotate. However, these shafts do not always start rotating at the same time. The shaft sprockets are connected by a timing chain, which over time begins to sag slightly due to natural wear. In addition, the teeth on the shaft sprockets also wear out over time, which only increases sagging.

Due to wear on the teeth on the timing sprocket, the chain sags more and may eventually break.

As a result, a situation arises when the crankshaft has already turned a quarter of a turn, and the timing shaft has just begun to rotate. In such a situation, the timing chain slack increases sharply, and to eliminate this slack, a hydraulic tensioner is activated.

On one side there is a tensioner shoe, and on the other there is a damper, which is the second part of the damping system

Its shoe is screwed to the oil fitting, which, in turn, is connected to the oil line with an oil pressure sensor. As soon as the chain sags, the sensor detects a sharp decrease in oil pressure in the line, after which an additional portion of lubricant is supplied to the line. Under its pressure, the tension shoe extends and presses on the timing chain, thereby compensating for the resulting sagging.

All this happens very abruptly, and as a result, the timing chain begins to vibrate strongly, and not on the side of the tension shoe (where the chain is securely pressed), but on the opposite side. To dampen these vibrations, another device is used - a timing chain damper. Unlike the tensioner shoe, the damper has no moving parts. Essentially, this is a high-strength steel plate against which the timing chain hits after it is pressed down by the tension shoe. But if there is no damper in this system, the shaft teeth and timing chain will wear out much faster, which will inevitably lead to complete engine failure.

When is stretching necessary?

Chain tensioning is required in the following cases:

- after engine repair;

- after replacing the product;

- when stretched after prolonged use.

Timing belt VAZ 2101

In the first two cases, it is clear that checking the tension is necessary, since the chain was removed or replaced. In addition, you should also check that the alignment marks match. These marks are located on the crankshaft and camshaft. You can determine the need for tension by the sounds of the engine running. If the tension is weak, then during its operation extraneous noises are heard in the place where the chain drive is located. At the same time, timing parts wear out faster. Therefore, when checking the tension, it is necessary to pay attention to the condition of the damper and the shoe.

Timing tensioner shoe

If the tension is weak, the links can jump several teeth, then the valve timing will be disrupted. In this case, the car may stall, not start, and the speed will fluctuate. You can use a flathead screwdriver to check. It needs to be inserted and, using as a lever, pressed on the chain. It should not bend and be stretched like an arrow. Do not put too much pressure on the drive, although the part is metal, it is subject to deformation.

The video below looks at a VAZ 2101 car, in which a clattering sound is heard when the engine is running. It shows in detail how to check the condition of the damper, the shoe, and how to carry out tension.