Before examining the question of which clutch is better for the VAZ 2114, you should first talk about the general principles of operation of this mechanism. The clutch, which is the subject of our conversation, operates on the friction principle (unlike a number of clutches on other machines that use hydraulics in their operation).

Clutch VAZ 2114

Its main design and operating features can be expressed as follows:

- a dry single-disc clutch is used;

- a pressure spring is involved in the process of disengaging the clutch;

- the driven disk has a built-in vibration damper;

- The cable-type drive has no gaps between the bearing and the petals of the diaphragm spring.

As for the sizes, the Samara model has a clutch with a clutch diameter of 19 cm, and Samara 2 - 20 cm. In addition, later types of clutches have special dampers that make it possible to suppress uneven loads when rotating the crankshaft not only at idle, but also under load .

When purchasing a clutch in a store, the first thing you should do is carefully examine the box (take into account the quality of the fonts, paint, and its material) - this will help you protect yourself from buying a fake at the very first stage of your choice.

Removing the clutch

1.Hang it in front of the car, preferably higher on jacks on both sides.

- Unscrew and remove both front wheels and place them under the car for your safety.

- Remove the battery and air filter (required)

- Disconnect the clutch cable from the gearbox and remove it from the bracket (two 17 mm wrenches)

- Unscrew the bolts securing the ball joints to the steering knuckles (17 mm wrench);

- Loosen the rear mounting of the left trailing arm (24 mm socket);

- Unscrew the bolts securing the left extension bracket (17 mm head) and rotate the lever 90 degrees downwards;

- Disconnect the ground from the gearbox (if it is attached to it, use a 13 mm wrench);

- Unscrew the lower flywheel protection cover (10 mm wrench);

- Unscrew the left power unit support (two 17 mm keys);

- Unscrew the rear support of the power unit from the body (17 mm wrench) and the gear shift drive clamp (two 13 mm wrenches), remove the gear shift drive

- Unscrew three bolts and one nut securing the gearbox to the engine;

- Carefully, tilt the power unit, remove the gearbox from the engine and leave it hanging on the drives;

- Very carefully, using an 8 mm socket with sharp edges, unscrew the clutch basket;

Starko

The second Turkish manufacturer of parts for domestic cars is “Starko” on our list; Kraft is less common.

It is difficult to find original Starko packaging, which already indicates a high probability of purchasing a low-quality fake. First, let's list the advantages:

- Good combination of price and quality;

- Smooth gear shifting.

The disadvantages include the following:

- In traffic jams, vibrations are observed when starting to move;

- A small number of reviews and opinions of drivers.

The price of a standard set is no different from competitors - 3000-3500 rubles.

Clutch replacement

Replace the release bearing.

Replace the clutch driven disc (or better yet the entire clutch assembly), not bad manufacturers of Lada spare parts Valio, Sachs. Using a special mandrel for centering (photo No. 9) the clutch disc;

Don’t forget to lubricate the clutch fork (photo No. 3), many of you have probably noticed that the clutch pedal has become tight, this is due to the fact that the lubricant dries out and the fork may burst and then you will have to do the whole procedure again.

Now let's put everything together in reverse order.

After replacing the clutch, take your time to check that everything is in place and that everything is as it should be. Check the adjustment of the clutch drive; this is the full travel of the clutch pedal (all the way to the mat), which should be 120–130 mm. As the clutch disc lining wears, the pedal rises and its full travel increases. The maximum permissible stroke is 160 mm.

To adjust the clutch drive, place a regular ruler (photo No. 6) next to the clutch pedal platform, resting it perpendicular to the floor mat. Use a ruler to determine the distance from the mat to the surface of the rubber pad of the pedal pad. If it is more than 160 mm, adjust the clutch drive (photo No. 7). Press the clutch pedal several times until it touches the floor mat and check the distance from the pedal pad to the floor mat again.

If necessary, adjust the full pedal stroke with the adjusting nut and tighten the lock nut (photo No. 7). Don’t forget about the clutch cable, put the cable back, my pedal rested against the dashboard due to the tension, and we begin to adjust the mount (photo No. 8) and it’s ready.

When using this method of replacing the clutch, you can:

- do not drain the oil from the gearbox;

- do not remove the starter (but it’s better to remove it anyway, it’s more convenient and easier);

- do not pull the CV joints out of the gearbox;

- Do not unscrew the speedometer cable.

Clutch kit PILENGA SPORT /ceramics/ VAZ 2108-21099, 2113-2115, 1117-1119 8V /Lada-Kalina/

APPLICABILITY: VAZ 2108, 2109, 21099, VAZ 2113, 2114, 2115, VAZ 1117, 1118, 1119 (Lada Kalina with 8 valve engine).

The damper clutch reduces the shock loads on the transmission that occur when the clutch pedal is suddenly released.

Includes: pressure plate, driven disk and release bearing.

Speaking about PILENGA , one cannot fail to mention clutch kits with metal-ceramic driven discs for front-wheel drive VAZs. Two types of clutches are produced: SKR 4004 XR (for VAZ 2108-21099, 2113-2115, Kalina 8V) with a maximum transmitted torque of up to 21 kgm and SKR 4005 XR (VAZ 2110-2112, Priora, Kalina 16V) with a maximum torque of up to 30 kgm. These clutches have been available since 2003 and over 600 sets have been sold in that time. Consumer reviews are the most favorable. Metal-ceramic clutch kits were installed by the teams “AGA Racing”, “ELBERT RALLY”, “ZIL Motorsport”, “Tuning Club”, “VISTA Racing”, “CSKA MVO” on cars taking part in rallies, circuit competitions and cross-country racing, as well as and in 400 meter races. We draw the attention of buyers to the fact that metal-ceramic clutches do not provide comfort when starting the car; their purpose is to instantly (without slipping) transmit torque from the engine to the transmission for a quick start.

On sale you can find clutch discs for VAZs with metal-ceramic linings. However, installing a metal-ceramic driven disk with a conventional standard clutch basket is fraught with rapid wear of both the flywheel and the basket pressure plate. Therefore, PILENGA only supplies clutch kits. The clutch pressure plate is made of special cast iron, the springs are also made according to special requirements, in order to protect the flywheel as much as possible from slipping. The release bearing has a higher thermal performance than that used in production clutch kits.

founded in 1947 in the Italian city of Comun Nuovo, Bergamo. Pilenga ironworks produced plates for household irons. The crisis in the early 60s forced the company to consider other alternatives, and Pilenga began to develop a specialized workshop responsible for giving the finished shape of the brake disc. In the first years of its existence, Pilenga produced only castings for the needs of automobile factories. Pilenga production program consists of 35% of final products (brake discs and drums), and 65% of finished products (brake cylinder bodies, clutch pressure plates, pad frames, various gears, pins, rods, racks, etc.) for several dozen European manufacturers of spare parts.

Currently, Pilenga is the largest manufacturer of brake discs and drums for assembly lines of car factories in Europe and the USA (Chrysler and Harley Davidson). After a change in management, in 2000 Pilenga began supplying products to the aftermarket under its own name. Deliveries to Russia began only at the end of 2001.

The range of products produced under the Pilenga brand:

* brake and clutch master and slave cylinders * ball joints and steering ends * clutch kits * steering racks * wheel bearings * gearbox bearings * CV joints and drive assemblies * disc and drum brake pads * VAZ engine parts

All Pilenga fully comply with the quality standards adopted in the EU. Orders for Russian cars are made on the same equipment and using the same technology as orders from buyers from EU countries. Pilenga products manage to achieve competitive prices on the Russian market due to large sales volumes.

The company has its own research and development center, which is engaged in the development of formulations for alloys of non-ferrous and ferrous metals for the entire range of products. Much attention is paid to improving machining technology and control methods at all stages of production. In metallurgical production there is a computer system for controlling metal welding, which makes it possible to eliminate the slightest deviations from the given recipe. All products are manufactured on modern equipment using the latest advances in the field of metal production and processing. Modern 3D design technologies allow the brake disc development process to be carried out incredibly quickly, calculating the weight and dimensions that form the basis of the foundry phase of production. The number of items in the company's catalog is constantly growing, which is a consequence of the company's rapid adaptation to market requirements.

Pilenga produces about 200 types of clutch pressure plates. Over the past few years Pilenga has undergone many changes: the machining department has acquired a significant role and become an integral part of the foundry, quality control has become incredibly strict...

Just recently, Pilenga received an order to produce several hundred wheels for a Daewoo car, a very rare car in Italy for which the company had never produced wheels before.

Over 80% of the company's turnover is provided by exports. 90% of brake discs produced go abroad, on par with Germany, which occupies a leading position in this area. As for unprocessed cast iron billets, which account for 22-23% of turnover, the company has several foreign buyers.

Required spare parts

Depending on the type of repair, you may need:

- disk (article - 2109-1601-085);

- rivet (article - 2108-1601-295);

- bolt (article - 2108-1601-207);

- overlay (article: 2109-1601-138-04, 2109-1601-138-03, 2109-1601-138-01 or 2109-1601-138);

- driven disk (article - 2109-1601-130);

- pressure bearing (article: 2109-1601-182 or 1111-1601-182);

- coupling assembly (article - 2110-1601-180);

- spring (article - 2108-1601-188).

Tools you will need for your work

To perform the work you may need the following tools:

- two jacks;

- hub key;

- metal brush;

- a set of open-end and ring wrenches;

- set of heads;

- installation guide and other tools that every driver has.

For an experienced technician, replacing a VAZ 2113, 2114 or 2115 clutch with your own hands takes about 4 hours. A beginner will have to tinker longer. But the expenditure of effort and time will be fully justified, since in a car service center the price for replacing a VAZ 2113, 2114 or 2115 clutch is from 3 thousand rubles as of 12/01/2018. U

Order of Operations

There are two ways to change this node: regular and simplified. The second one is more accessible for self-repair - replacing the VAZ 2114 clutch without removing the box. The procedure for performing the work in the usual way is as follows:

- It is better to put the car in a pit, but if there is none, then you need to lift it with jacks.

- We remove the front wheels and de-energize the car by disconnecting the minus terminal from the battery.

- Now you need to disconnect the speedometer cable from the gearbox, remove the clutch cable, and turn off the gear drive.

- From the gearbox side, the motor support is dismantled, and the flywheel is removed.

- The flywheel should be examined for chips, cracks and other defects.

- The oil should be drained from the gearbox; you can take advantage of the situation and change the working fluid.

- The internal CV joints are removed from the gearbox, unscrew the fastenings and remove the gearbox.

- Now you can remove the bearing.

- Be sure to clean the shaft from working fluids, dirt and dust.

Installation of a bearing with a coupling on the input shaft. - We attach the basket to the flywheel.

- Subsequent operations are performed in the reverse order of the above.

Watch the DIY VAZ 2114 clutch replacement in the video:

Buying a unit is a rather complicated question, since it is sold both in parts and as an assembly. The manufacturer provides article numbers for each, since he lists them as different parts. He believes that these are completely different details. You can use analogues in your work. So, many VAZ owners prefer to purchase the SACHS collection (3000-951-211), but its cost is 3 times higher. Tuning analogues are offered by Brembo and ATI, the average price is about 10 thousand rubles.

Replacing the clutch cable of VAZ 2113, 2114 and 2115

Another repair and restoration operation to restore the clutch’s functionality can be done with your own hands - replacing the cable. It is less labor intensive. Replacing the VAZ 2114 clutch cable is carried out in the following order:

Driving style and clutch: choosing a set

Still haven't figured out what to buy to replace the coupling? Let's look at one more aspect - driving style, because each of us prefers to move in a manner unique to him. Conventionally, we divide the number of driving styles by four. Based on reviews and operational experience, we will try to create sets of companies that would correspond to a particular driving style. Thus, we will try to answer the question, which clutch is best installed on the VAZ 2114 and why.

Changing the clutch on a VAZ-2114 with your own hands: tips + video

Every owner of a VAZ-2114 car may encounter a problem when the car’s clutch fails. Previously, this unit was replaced individually depending on the breakdown. So, the main parts of wear were: the disk and the release bearing. But, modern car production has led to the fact that the clutch assembly changes. The article will give practical recommendations for replacing and selecting this part.

Hola

Under the Hola brand name, it is easy to find relatively inexpensive Dutch-made spare parts specifically for domestic cars, including 4-wheelers.

The kit with a releaser, basket and disc from Hola stands out from other manufacturers with the following list of advantages:

- Good combination of price and quality;

- Does not burn out and does not slip during sudden starts;

- The bearing does not make unnecessary noise;

- There are practically no fakes.

As for the shortcomings, “Hola” “distinguished itself” in the following points:

- Judging by reviews from owners of cars with the Hola kit, pedal vibrations occur when changing gears;

- The pedal stiffness is higher than that of analogues.

Due to the good price-quality ratio, a set of parts from this Dutch manufacturer is in demand. The cost in some online stores today is 2800-3000 rubles.

Clutch device

Before considering all the issues related to replacing the VAZ-2114 clutch, it is worth considering the design and structure of this unit. This is necessary in order to understand the principle of operation and the sequence of actions aimed at replacing a part.

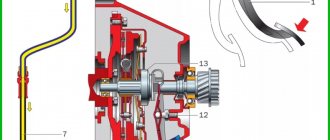

So, let's look at the car clutch device:

1 – cable sheath; 2 – lower tip of the cable sheath; 3 – cable fastening bracket; 4 – cable protective cover; 5 – lower cable tip; 6 – adjusting nut; 7 – lock nut; 8 – cable lead; 9 – clutch release fork; 10 – clutch casing; 11 – bolt securing the clutch to the flywheel; 12 – drive disk; 13 – flywheel; 14 – driven disk; 15 – gearbox input shaft; 16 – lower cover of the clutch housing; 17 – clutch housing; 18 – pressure spring; 19 – clutch release bearing (release bearing); 20 – bearing coupling flange; 21 – bearing coupling sleeve; 22 – seal; 23 – upper tip of the cable sheath; 24 – upper cable tip; 25 – clutch pedal bracket; 26 – clutch pedal spring; 27 – clutch pedal; 28 – thrust plate

Also, it’s worth schematically looking at the principle of operation of the clutch:

The process of replacing the clutch on a VAZ-2114

Once the operating principle of the clutch is understood, you can begin to consider replacing the part. But, before you move directly to action, you will have to collect everything you need. So, what do you need to carry out the replacement: a set of keys, rags, new parts. Well, everything is assembled, and you can move on to the step-by-step instructions for replacing the unit:

- Place the car on a flat surface. Of course, the best option is a hole or overpass, but in their absence, we will make do with an ordinary jack.

- Both front wheels will have to be removed.

Practice: which clutch is better to buy for a VAZ 2114 car and how to determine it?

When evaluating a friction clutch and its components, the experience of friends and acquaintances who have purchased them at least once is very useful. For example, a novice car enthusiast who decides to independently replace the clutch on a VAZ 2110 will certainly be helped by the recommendations of experienced motorists.

As practice shows, when purchasing a clutch kit, the owner is mainly concerned about the issue of fakes and defects. Therefore, let’s look at some interesting points separately.

Package

What do we immediately pay attention to when making any purchase? That's right, on the packaging. The same pattern applies here. The box itself and its quality are not evidence of a fake, but still two points should be paid attention to:

- No self-respecting manufacturer will package their products in a flimsy box with crooked text and errors.

- If the letters on the package are erased by the touch of a finger, then feel free to put it back and leave this store.

If we like the box, then we move on.

Clutch disc

Thinking about the question of which clutch is best to buy for a VAZ 2114, we slowly take the disc out of the box. We evaluate the geometry of the product; the disc must be smooth, without any teeth, chips or other defects.

We inspect the damper springs - from a good manufacturer they are always painted with clear varnish or some color. The craftsmen point out that they have not yet encountered original clutches that are unpainted. By the way, many companies themselves recommend this method of identifying counterfeits.

Release bearing

If the kit includes a plastic bearing, you can put the box aside or then replace it with a standard VAZ metal bearing. During active driving, the plastic part begins to “howl” and then crumbles. Attempts to solve the problem by “immersing” the bearing in lubricant solve the problem only for a short time.

Basket

If even one petal protrudes, the car will twitch and the pedal will constantly vibrate. Any deviations are unacceptable; if there are any, we immediately refuse the purchase.