Even experienced motorists treat the friction clutch with due respect, regularly inspecting and adjusting this unit. This fact is not surprising, because the comfort of driving a car fully depends on the quality functioning of the transmission.

to completely replace the clutch , but deciding which clutch is best to install on a VAZ 2110 is something he can do. The test results of specialists from the magazine “Behind the Wheel” will help you choose the right kit.

Which clutch kit to choose for Lada 2110?

Even experienced motorists treat the friction clutch with due respect, regularly inspecting and adjusting this unit.

This fact is not surprising, because the comfort of driving a car fully depends on the quality functioning of the transmission. to completely replace the clutch , but deciding which clutch is best to install on a VAZ 2110 is something he can do. The test results of specialists from the magazine “Behind the Wheel” will help you choose the right kit.

How to choose a clutch for a VAZ according to your driving style

When choosing a clutch, you need to take into account your driving style.

Calm driving style - low revs, smooth shifts, not harsh acceleration. Suitable kits from manufacturers:

- Luk - gears shift smoothly, no jerking.

- Valeo - soft clutch for a comfortable ride.

Most motorists drive at medium speeds, occasionally accelerating in traffic. The style is standard. Suitable mechanism from manufacturers:

- KraftTech - a coupling for comfortable movement.

- Sachs - a tighter device than previous options, suitable for many drivers.

- “VIS” is a domestically produced system, manufactured with high quality, and does not tolerate sudden movements.

With a dynamic driving style, sharp shifts and “throwing” of the clutch pedal are possible. The coupling experiences heavy loads, the following kits are suitable:

- Pilenga - recommended without metal ceramics. The clutch is hard, to avoid jerking you need to pick up high speeds and shift quickly.

- Sachs - suitable for many.

Some motorists prefer a sporty driving style when the mechanism is under stress. The same kits are suitable as for the dynamic style. The clutch will have to be changed more often.

Attention ! A sporty driving style is undesirable; frequent high speeds wear out many elements of the car.

When choosing a coupling, you need to take into account factors: cost, compatibility of the kit with the vehicle model, and operating features of the machine.

Among owners of VAZ cars, it is common to install the entire Sachs kit, except for the release bearing, which is replaced with a factory one.

Briefly about the torque transmission mechanism on the “ten”

Volumes have already been written about the technical side of domestic cars, so here we will consider only the very “tops” of the friction unit design. The classic “ten” is equipped with a single-disc dry clutch with a diaphragm-type pressure spring. The main parameters are as follows:

- Disc size 200x140 mm.

- Backlash-free cable drive.

- The casing is connected to the flywheel with six bolts.

When should the clutch or its components be replaced? It depends on the driving style and the quality of the assembly. Some can drive more than 100 thousand kilometers without repair, while others install a new part every 15-20 thousand. If the pedal travel increases, as well as ring wear on the pressure spring petals is more than 0.8 mm, it is worth thinking about replacing the clutch.

The presence of scoring, cracking and uneven wear on the driven disk is unacceptable. A distance of less than 0.2 mm from the top edge of the trim to the rivets also indicates the need to install a new element.

Anyone interested in the question of which clutch is best to install on a VAZ 2110 car should take one point into account. On the “ten” you can install a clutch from the Lada 2112; the disc there is the same size, but due to the reinforced pressure spring it is capable of transmitting higher torque values. In this case, when pressing the pedal, you will have to apply more force, and, quite possibly, change the clutch drive cable more often.

In conclusion of this brief review, we cannot fail to mention the advisability of a comprehensive clutch replacement. No, if you have a lot of time and a wealth of practical experience that allows you to disassemble and reassemble the unit several times a week, then please - today you can change the release bearing, and in a week - the driven one. The fact is that it is not known how long the remaining structural elements last after replacing one of them. Therefore, change the kit right away - it’s cheaper and more reliable.

Choosing a clutch for VAZ 2112

Good afternoon, comrades Vazovody!

The question arose: who praises which clutch? )) The price issue for all sets is almost the same (diameter 200mm): VIS 21120-1601000-00 LUK 620316600 KRAFTTECH W05200G Valeo and HOLA I don’t consider because of the price MENSAN, QML, AYWI PARTS - devilish names! They're just scary!

The factory one went through 110 thousand, was replaced with a Sachs rather as a preventive measure, the Sachs expired at 160 thousand, was replaced when the engine was overhauled, there was wear on the basket from the release lever, but there were no complaints about the work. Now it's factory again. Crafttech is on my father's 12, I don't like it, the release lever rattles, the pedal is too soft. Haven't ridden others

Thank you! unfortunately there is not enough money for it. It costs more than 3000 rubles. Looks like a factory VIS

The toad strangled me to buy Sachs, because it costs factory (there was a vis in the box of the fret)

Thank you! unfortunately there is not enough money for it. It costs more than 3000 rubles. Looks like a factory VIS

here one friend did this - he bought a VAZ car from a Priora (manufacturer Luk), everything separately, disc, basket, release lever, it came out to about 3 thousand. I can’t find the link from my tablet right now. Good luck with your purchase and installation.

So far 30 thousand, no complaints so far, the peal is a little heavier than the sachs, it feels like it grips more sharply

No way) when replacing the clutch, be sure to remove the clutch fork, inspect it for cracks and be sure to generously lubricate its bushings; it is better to buy a spare upper plastic one, because when removing it there is a high probability of breaking it. The fork itself broke, I had to throw off the box once again, an unpleasant phenomenon)

I bought the car from my stepfather, he drove it for 3 years before me and drove 30 thousand. After that, I drove another 15, then I decided to overhaul the body, and since I was removing the engine, I decided to change the clutch at the same time. I'm filming and studying. one employee comes up, he works part-time in the service in the evenings, looks at the disk and asks, why did I take a new one? That is, the clutch has driven exactly 45 thousand, and it is still unknown how much the previous owner has driven before, but it looks like new! LUK is clearly written on the disk, so my next clutch will also be LUK)))

If you don’t deliberately kill the clutch, then it will run on stock for a very long time, the main thing is that it was not originally made from g and sticks)

this is my first car)) at first it was very difficult for him)) so my choice is definitely LUK))

Source

Choosing which clutch is better to install on a VAZ 2110 car and why?

Any mechanic will tell you that with a properly tuned manual transmission, the components wear out almost evenly; this, so to speak, is an addition to the above. Most car repair shops that provide at least some kind of warranty refuse to replace the clutch piece by piece for fear of returns. Among the variety of kits, the editors of “Behind the Wheel” chose five manufacturers:

What indicators were compared?

To make it easier for our motorists to decide which clutch is best to install on their VAZ 2110, the publication’s specialists compared the following parameters:

- Compliance of the mass of the part with the requirements of technical documentation - the weight indicator of the unit has a significant impact on torsional vibrations, as well as inertial transmission loads. All presented samples meet the standards, with the heaviest being Pilenga, and the lightest being KraftTech. We can conclude that if the kits are interchangeable, there will be no significant changes.

- Clutch safety factor - characterizes the ability of the internal combustion engine to transmit torque, taking into account the wear of the linings. Pilenga and KraftTech formally comply with modern VAZ standards (2.1), but for cars of the tenth series any set from the five presented is suitable. Only the first two models are suitable for Lada 2112 engines.

- Pressure plate imbalance level - acceptable values are in the range of 0.10-0.25 Ncm. Tests showed a complete discrepancy between these numbers of the VIS set. Valeo has a deviation of 20-25 percent, the rest fully meets the requirements.

- The level of imbalance of the driven disk - the indicator for all models turned out to be within the normal range, only in the Pilenga it is on the verge of what is permitted. The same kit did not meet the standards for squeezing force.

- The distance from the edge of the petals to the friction plane is an indicator characterizing the entire assembly. Exceeding the norm significantly reduces the service life of the car part. Here again, Pilenga’s indicators are unimportant.

It's time to choose

This time, the specialists of the Za Rulem editorial board were unable to find an ideal answer to the question of which clutch is best to install on the VAZ 2110 sedan. Perhaps the best performance in the top five was demonstrated by KraftTech and Luk, although the latter kit has insufficient torque. Valeo occupied the rightful middle - the balancing failed a little. The final list, where quality indicators are arranged in descending order, looks like this:

- KraftTech – there is no marking on the factory release bearing, but the thrust bearing is designated as X2200C; driven disk – Y 3200A B0206. Main features: four damper springs, there are 18 petals on the diaphragm spring. The box bears the designation: 2110 W3200C B2240.

- Luk – the kit does not include a release bearing, its marking is: SKF 500 063820; the pressure plate is branded 2 D24 120 0252 10, and the driven disk is branded 320 030810. The latter has marks for precise orientation during installation. The driven disk has six springs, the basket has 18 petals. The side is last marked.

Test results of clutch kits for VAZ-2110

The clutch is one of those units that even seasoned specialists, as they say, respect. Replacing the clutch kit on the same VAZ “Ten” will most likely be beyond the capabilities of a beginner. The main question is, which one should you buy? Below are the test results of five “tenth” clutch kits.

Clutch for VAZ 2110. What did you measure?

Let's start with the most harmless parameter - mass. For all clutch kits, it turned out to be within the requirements of the technical documentation, and the lightest of them was “Krafttech”, and the heaviest was “Pilenga”. Let us recall that the mass of the clutch affects torsional vibrations and inertial loads in the transmission, but in our case we can say that there will be no visible changes when replacing one set with another.

With torque the situation is a little more complicated. Formally, only Krafttech and Pilenga met VAZ’s requirements: the required safety factor is 2.1. At the same time, the West has its own ideas about clutch operating conditions, and perhaps they do not need such reserves. In general, for VAZ 2112 engines it is better to use the mentioned brands, and for VAZ 2110 and 2111 - the rest.

Due to the imbalance of the pressure plate, “VAZINTERSERVIS” completely failed - triple the norm! Against this background, the performance of the same Valeo, which missed the mark by “only” 20 percent, looks quite acceptable. There are no complaints about the rest.

The imbalance of the driven disk turned out to be normal for everyone - except that Pilenga performed on the verge of a foul. It did not fit within the tolerance range for the clutch pressing force. Insufficient movement of the pressure plate at a given shutdown stroke was again noted at Pilengi, as well as at Krafttech. In terms of the distance from the ends of the petals to the friction surface, only “Pilenga” again “distinguished itself.” Let us recall that this value characterizes the assembly and is normalized for a specific car model. If the norm is exceeded, the resource of the driven disk is reduced.

Tips for choosing a clutch

If some clutch element fails after a significant mileage, there is no need to save money: it is better to replace both the release plate, the “basket”, and the driven disk at the same time. This is especially important when replacing one imported kit with another - the differences can be serious. The number of damper springs in the driven disk, in general, does not matter much - each manufacturer selects it himself. This makes it possible to implement the required angular rigidity in the product - as a rule, each company adheres to “its own belief.” As for the petals in the “basket”... well, let’s just say that the more of them, the more accurate the clutch works.

When replacing the clutch, in order to avoid warping of the “basket” casing, the mounting bolts are tightened gradually and one at a time. Before this, the mandrel used to center the driven disk is moved up and down and left and right - this facilitates accurate alignment of the driven disk.

Be careful not to confuse the orientation of the driven disk. If it doesn't have any identifying markings on it, look at it from the side. The side on which the damper springs protrude less from the level of the friction linings, as a rule, faces the flywheel. An error may cause the springs to catch on the flywheel bolts. By the way, do not allow the box to hang on the input shaft: this can cause deformation of the driven disk.

Clutch kits for VAZ 2110

Yes, it's time to choose. It was not possible to achieve the ideal, but Krafttech and, perhaps, LuK looked better than the others, although insufficient torque, of course, does not suit it... Valeo clearly occupies the middle of our top five: the balancing failed. For the rest, we will think that the copies we received were simply out of shape...

- The declared manufacturer is KRAFTTECH, the country is not specified. Marking: no bearing, driven disk Y 3200A B0206, pressure disk X2200C. Special features: no seal of approval. The driven disc has 4 damper springs. The diaphragm spring of the pressure plate (“basket”) has 18 petals. On the package of the kit there is a designation - 2110 W3200C B2240.

- The declared manufacturer is LuK (Lamellen und Kupplungsbau), Germany. Markings: bearing SKF 500 063820 (purchased separately), driven disk 320 030810, pressure disk 2 D24 120 0252 10. Special features: MT14 approval mark. The driven disk is marked for correct orientation during installation. The “basket” has 18 petals. The driven disk has 6 damper springs. The "basket" side is marked.

- The declared manufacturer is VALEO, the country is not specified. Marking: bearing VALEO SNR BB 126 18S50, driven disk missing, pressure disk missing. Special features: no seal of approval. The kit includes a mandrel for installation. The diaphragm spring of the pressure plate has 18 petals, the markings are erased. Marking on the package: 21102 - 21103 - 21108 - 2111 - 2112 826622.

- Stated, Russia. Marking: bearing missing, driven disc missing, pressure disc missing. Special features: seal of approval - AYA70. The pressure plate diaphragm spring has 12 lobes. The mounting plate for the linings is one-piece. The driven disk has 6 springs (4 large and 2 smaller). Marking only on the “basket” packaging - 2110-1601180.

- The declared manufacturer is PILENGA, the country is not specified. Marking: bearing missing, driven disc PILENGA, pressure disc missing. Special features: no marks of approval. On the package - SK-R-4005 2110. The pressure plate diaphragm spring has 18 petals, but there is no marking. The driven disk is equipped with 8 damper springs - 4 large, 4 small.

Expert comments on the measurement technique

VAZ-2110 cars can be equipped with two types of clutches, which differ in the stiffness of the pressure spring depending on the installed engine, or more precisely, on its torque. The first design is intended for cars with engines 2110 and 2111 with a torque of 115.7 N.m, the second - for 2112 (torque - 128.3 N.m). The maximum torque transmitted by the clutch must exceed the specified value by 2.1 times - this is the safety factor. Hence the numbers - 243.0 and 269.4 N.m.

The clutch squeezing force is measured by moving the ends of the pressure spring petals by 7.9-8.1 mm. The movement of the pressure plate is measured during the release stroke equal to 7.9-8.1 mm from the position determined by the distance of 8.26-8.34 mm between the “basket” and the flywheel. The thickness of the driven disk along the linings is measured under a compression load of 3400 N.

Recommendations for choosing a kit

A competent decision on the question of which clutch is best to install on a VAZ 2110 car is traditionally facilitated by the advice of experienced specialists. A few short but practical recommendations will come in handy, especially for novice motorists:

As already noted, it is better to replace the unit as a set. This is important if the machine already had an imported unit - the differences between the components can be significant.

- When replacing the coupling, tighten the mounting bolts one at a time to prevent warping of the basket casing. In this case, a centering mandrel should be used. After repair, you need to adjust the clutch in order to effectively use the power of the power unit.

- It is important not to confuse the position of the driven disk when installing it. If there are no marks on it, then just look at the disk from the side. The side where the damper springs protrude less is usually towards the flywheel. Incorrect installation threatens that during operation the springs will touch the flywheel bolts.

see also

Comments 24

If you like to sink, then the hatch or sax is good, vis is medium, Valeo and Kraft are now China, Pilenga, apparently, China has never heard anything either.

Put LUK is very good, I give it to clients, KRAFT - very good clutches (BUT there are only FAKES - because of this, DO NOT INSTALL) Valeo - also not a bad quality issue SACHS - the BEST choice and you will only take it as soon as possible.

At one time there was a VAZ 21099, it drove about 120 thousand km. I remember very well that I changed the clutch twice, both times I took Kraft...

Why does everyone criticize the craft... Normal clutch, we have been installing it on training vehicles for a long time. It runs about 50 thousand in not at all easy conditions, but we set the release gear to VISovsky.

It’s strange that everyone criticizes craft. I had the V8 for 1.5 years and it drove great.

valeo is very soft, onion is the complete opposite. both walk well. I went 40k on the bow and sold the car. Now almost 30 on Valeo.

I set the sax! 3 years no problems!

Valeo is the softest.

Sachs is the supplier of the VAG Luk cover - Renault Nissan Valeo is also of original quality, VIS is the type of supplier of the AvtoVAZ conveyor The choice is yours.

I had a VAZ 2110 - I drove 4 sets of clutches on it! As it turned out during the sale, the reason was not my driving skills, but a factory defect (the flywheel was installed incorrectly)! Found out when installing the latest kit. So that's what I mean. During this time, I rolled 2 CRAFT targets, 1 - LUK, and one was supposedly original (factory) 1. Craft - pleasant, soft, small resource, weak basket, very poor quality lately (only fakes). 2.Bow - crafting is softer, resource is the same as Crafting. 3. Original))) - rigid, more or less durable. My opinion is that if you want a soft clutch aspiring to a foreign car, take Kraft or its analogues; if you like to skid, I recommend the original one (I did just that - I drove about 30,000 km on it).

I will support! Just not craft! My father had the factory one installed on the shnivy and installed LUK, I liked it, the pedal became softer. two friends put it on: one on 2110, the other on Priora, both are happy! The one who was so fussy about 2110 before LUKom tried two more and didn’t like it, put LUK and started smiling!)))

Take Sachs assembled.

Sachs, Luk, Valeo, VIS just not craft

What can you say about the factory one?

Normal, a little tougher than the above. I would take Sachs or Luk

install the factory one. I drove 2 different ones myself. I changed it to my friends too. It's the factory one.

What kind of clutch and how many valves is better to install on a VAZ-2110

Having made sure that the car’s clutch is not functioning at the proper level, it is necessary to replace it as quickly as possible. The following signs may indicate that the mechanism is worn out:

- the clutch release pedal travel increases;

- self-adjustment only allows you to restore the operation of the pedal at the very top;

- Driving uphill is very problematic.

If the above symptoms are present, the clutch should be replaced as quickly as possible to prevent an emergency on the road. You can carry out this process yourself, if you take into account the advice and recommendations provided by experts. However, first of all, you need to determine which clutch is best installed on the VAZ-2110 model, so that in the future you do not have to replace the unit again.

Which clutch is better to install on VAZ 2110 and 2114? Choice matters

For those car owners who are going to repair the engine, it will be interesting to know which clutch is better to install on the VAZ 2110 and 2114. Interest in this can be caused by various reasons.

But in most cases it occurs when it fails too quickly. This can happen due to the installation of defective parts, heavy loads on the transmission, aggressive driving style and other circumstances. Which clutch is best to install on the VAZ 2110 and 2114 may also be of interest to owners because retail chains have a fairly large selection of such spare parts. Many drivers, especially those who are encountering such a problem for the first time, will be interested in this article. It will allow them to confidently navigate their choice, or control what the mechanics will install during repairs.

Why is it needed?

Without installing this mechanism on the car, the operation of the gearbox, the process of starting to move or stopping the car will be impossible. This unit serves as the main link for transmitting torque from the engine crankshaft to the drive wheels. The shaft rotates at a high number of revolutions, so direct access to the wheels is simply impossible. The connecting link between the engine shaft and the vehicle transmission is the clutch.

From its very name the principle of operation of this mechanism becomes clear. It is designed to connect and disconnect the motor with the drive wheels through the gearbox. With its help, there is a direct connection between the engine shaft and the wheels of the car; for this, it has several switching stages. The clutch mechanism provides just such an opportunity.

About clutch selection

Among the wide variety of such mechanisms, the most often paid attention to the kits of the following companies:

- KRAFTTECH

country of manufacture is not indicated on the packaging; - LuK

is made in Germany; - VALEO

also manufacturer unknown;

Let's look at the test results obtained. A weight check showed that all sets comply with GOST requirements for this mechanism. The spread of indicators is not very large, the smallest weight is found in the KRAFTTECH kit, and the greatest weight was found in products from PILENG. The mass indicator affects the rotational vibrations of the disks and possible inertial loads on the vehicle transmission. We can say with confidence that there will be no visible changes from installing various kits.

Checking the permissible torque showed results that were slightly worse than those required by the car manufacturer. Of the five samples that were tested, only two confirmed the declared characteristics. These are kits from KRAFTTECH

" and "

PILENGA

". They fully comply with the safety factor, the coefficient is 2.1. The conclusion of the experts is that for the “ten” you can use all the kits, and for more powerful engines only the specified ones.

The VAZINTERSERVICE kit did not pass the imbalance test; its value turned out to be more than three times higher than the nominal value. There are also complaints about the VALEO

“, but he is only about 20% above the norm. The remaining disks were within acceptable parameters. The testers did not have any unnecessary questions about them.

Checking the imbalance of the driven disks gave more encouraging results. Of the five tested kits, complaints appeared only about one, this product is from, the indicator was within the upper control indicator. There were questions about this kit regarding the force when squeezing it. It is also noted that there is insufficient travel of the pressure plates despite the fact that its setting value is set when turning off.

After checking the distance from the end of the petals to the friction surface with the release bearing, it turned out that the same “PILENGA” does not fit into the specified parameters. This value is standardized for each model specifically; it is one of the main characteristics of the assembled mechanism. If this norm is exceeded, you should expect accelerated wear of the driven disks.

If a problem is discovered with any part of the mechanism, experts advise changing the entire set, that is, the release bearing, the basket with the driven disk. This is explained by the fact that not in all cases complete interaction of all parts of the mechanism is possible if they are used from different sets.

In this short review, we tried to highlight the question of which clutch is best to install on the VAZ 2110 and 2114. Of course, it is impossible to get an absolutely complete answer, since it happens that world-famous brands sometimes fail, but you can navigate when choosing the right spare part you already can.

The main causes of clutch failure and how to eliminate them

First of all, you should understand that it is, of course, possible to completely replace the clutch yourself, but this work is quite labor-intensive and takes a lot of free time.

In some cases, simple repairs will help eliminate the cause of the malfunction, and if done correctly, taking into account the advice of professionals in their field, you can extend the machines for a long time.

But before starting repair work, you need to determine what reason led to the breakdown of the mechanism and choose an effective method to eliminate it.

Often the mechanism begins to malfunction and is pulled in different directions. To improve functionality, it is recommended to do the following:

- Check whether the drive is tensioned sufficiently and adjust it to the desired position.

- Make sure there is no deformation on the disc. If there is one, you will need to replace it with a new part.

- Check the operation of the hub; if it jams, you need to wash and lubricate it or replace it with a new element.

What to do when slipping and jerking

It also happens that the clutch does not engage completely; when activated, so-called slippage is observed. In this case, the cause of the malfunction may be:

- failed friction linings that need to be replaced immediately;

- the disk surface is filled with machine oil. To fix the problem, you will need to replace the engine and gearbox seals;

- malfunctions in the car drive. In this case, it is necessary to check the functionality of the entire drive and replace those components that are faulty.

If jerking is observed when the mechanism is activated, the following reasons may cause this problem:

- Automotive oil gets on the surface of the unit. How to eliminate the cause was described earlier.

- Disc deformation. In this case, you will need to replace the damaged element with a new one.

- Sticking when pressing the pedal. To fix the problem, you will need to find out exactly where the mechanism is jamming.

If the clutch completely disappears while driving, you must stop the car and contact a towing service for help. Under no circumstances should you continue driving as this may cause a serious accident on the road.

VAZ 2110 clutch device, repair and selection of the best

Let's look at what a clutch on a VAZ 2110 is, what role it plays in the car's control system, which system and from which manufacturer is best to choose. And also how to check the functionality and troubleshoot problems.

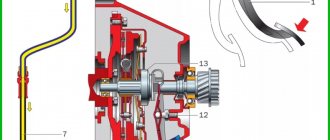

VAZ 2110 clutch diagram

Purpose

Actually, the clutch system is designed to smoothly transmit torque from the crankshaft to the gearbox.

Operating principle and components

The clutch is single-plate, with a central pressure spring. Drive – cable. The housing is attached to the flywheel and pressure plate. There is also a driven disk.

For dozens, the “native” clutch system is VIS, and although many reviews criticize it, there are also many who believe that there is no better VIS (VAZINTERSERVICE) for VAZ.

The main components are:

- casing;

- Pressure and driven disks;

- Carter with bottom cover. It also has support planes with which the crankcase is attached to the frame;

- Release bearing for disengaging the clutch;

- Flywheel;

- Power plug;

- The cable lead that goes directly to the clutch pedal (far left).

This, in brief, is the clutch device of the VAZ 2110.

Selecting an Alternative

As an independent study shows (based on online voting reviews), KRAFT-TECH is recognized as the best kit for the top ten, followed by LUK, then VALEO, SACHS. In fifth place was the Russian-made VIS (VAZINTERSERVIS) clutch - for those for whom the native one is better, clearer, and cheaper.

In addition, this system is easier to repair: having detected a malfunction, the VIS only needs to adjust the pedal, tighten the cable, and you can continue driving. And if you need to replace the entire assembly, it comes out much cheaper.

However, regardless of which set you have chosen for yourself: VIS or one of the European ones (we are not discussing China), or maybe a “prefabricated” one, you need to know how to identify faults and respond to them.

Troubleshooting and Correction

Let's talk about how to detect malfunctions based on special signs, as well as correct them.

1. If the clutch is leading, the following may be to blame:

- Insufficient pedal travel, possibly too tight. Adjusting the drive will help;

2. It slips, that is, it does not turn on. Possible reasons:

- The friction linings of the driven disc are burnt or worn. “Cure” by replacement;

- The surfaces of the flywheel and both disks are oily. These signs also indirectly indicate that it is time to change the engine and gearbox seals. You also need to check if there is any oil leakage through the bolts securing the flywheel. In this case, it is better to place them on sealant. And rinse the oily parts (white spirit is usually used);

- The drive jams. Check and replace what is damaged.

3. It works, but in jerks. This clutch operation can be caused by:

- Oil getting on surfaces, as mentioned above;

- Jamming in the drive. Trace the “chain”, troubleshoot;

- Deformations or damage in the pressure disk, requiring replacement of the casing along with the disk.

4. It makes a lot of noise when it turns on. Most likely, these are signs that the springs in the damper have broken. Replace the entire driven disk assembly.

5. It makes a lot of noise when it turns off. The first suspect is the release bearing. It can wear out, become damaged, and lose oil. Therefore, naturally, it is better to replace such a bearing.

6. During prolonged operation, the clutch may suddenly disengage. The reason most often is that the release bearing is stuck. It is located on the gearbox guide sleeve. A worn bearing must be replaced with a new one.

There are also other problems. For example, the clutch is very tight, or it disappears when overtaking. With such a problem, you can still slowly drive to the garage, but if the clutch is completely lost, you can’t go, you need to call a tow truck.

Let's look at how to properly dismantle it, repair it, and then reassemble it.

Dismantling

Most often you need to remove the gearbox, especially if you need a replacement rather than just an adjustment. It is not necessary to drain the oil from the box.

To determine whether the link is malfunctioning, it is recommended to read the following material: https://vazweb.ru/desyatka/transmissiya/kulisa.html

- Disconnect the battery;

- Remove the air filter;

- Disconnect the wiring harness;

- Raise the car, then loosen the clutch drive nut (on the right) and unscrew it completely on the left;

- Remove the suspension arm, ball joint;

- Remove the lower engine protection;

- Disconnect the transmission linkage;

- Remove the clutch housing and inspect it carefully. The main defects that the crankcase may have are cracks, wear of the threads or paws with which it is attached. New threads can be cut, cracks can be welded, thus returning the crankcase to working condition;

- After jacking up the engine, remove the gearbox, gaining full access to the clutch elements.

It is also possible to replace the clutch without completely removing the gearbox:

After repairs, you may notice that the clutch is too tight. But this is easy to fix without disassembling the entire system - from the interior side, by adjusting the pedal travel.

Which clutch is better to choose?

Many car owners know that the system can be either 16- or 8-valve, so quite often they are at a crossroads when choosing a mechanism, not knowing which clutch is best to install on their VAZ-2110. The answer to this question is quite simple. Of course, the best would be a 16-valve clutch, as it has the following advantages:

- increased power;

- economical fuel consumption;

- when operating, the 16-valve engine emits much less harmful substances into the atmosphere.

When choosing a mechanism, it is important to consider the manufacturer’s company. Of course, parts produced by a well-known brand, even if they are much more expensive, will last a long time, as they are distinguished by quality. A good unit can last more than 10 years.

What kind of clutch should be installed on a VAZ 2112?

This is my first 12th. before that it was a classic. In general, I took it not new, with a completely dead clutch, which could no longer be pressed at all, and immediately took it to the service center to change it. I had to change the flywheel at the same time, because... it already had deep grooves from the rivets of the old clutch disc.

On the advice of my father (he has 21099), I installed an imported clutch. I chose “MAPA” (the classic clutch from this company lasted 40,000 km without hemorrhoids). Moreover, I heard something about the need to install some kind of reinforced clutch on 16-valve 10s, since they are more powerful than 8-valve ones, but both in the store and in the service center they said that there was nothing about this They know and install the same clutches on both the 8th and 10th families. A new clutch in the store cost about 1,500 rubles. After about 3000 km. the car began to stall at the start (in first gear the revs picked up quickly, but when you pressed the gas “to the floor” it stopped accelerating normally) After some time, when driving in first gear, it began to smell like something was burning when you sharply pressed the gas pedal.

Is it possible to replace the clutch yourself?

You can replace the clutch on a VAZ-2110 yourself if you carry out the process step by step, taking into account the advice of specialists. Before replacing, you need to accurately determine the cause of the breakdown, because the progress of the work depends on this. If you just need to fix a problem, you don’t have to remove the box. Replacement takes place according to the following algorithm:

- the battery is disconnected from the power supply;

- the filter is removed;

- the wires are disconnected from the box;

- using a jack, the car is raised to the desired level;

- the right nut is slightly unscrewed using a wrench, and the left nut is completely removed;

- the ball joint and suspension arm are removed;

- the fixation of the lower power protection of the unit relaxes;

- The crankcase is removed and carefully inspected to identify faults. If they are detected (most often these are cracks), they are eliminated by welding, and if necessary, the surface of the thread is renewed;

- Using a jack, the entire box is removed to gain access to the clutch, which needs to be replaced or the fault repaired.

Upon completion of the repair work, all components are reassembled in the reverse order and the clutch replacement process can be considered complete. Finding out the reason for the breakdown of the clutch assembly or replacing it yourself is quite simple if the work is carried out step by step and taking into account the advice of professionals.

Choosing the best clutch for the VAZ-2110

Despite the fact that the clutch is just a consumable kit, we buy it for a long time. When you came to think about how to replace the clutch on a VAZ-2110, you should first think about which clutch is best to put on the top ten. And here even an experienced mechanic can hit the bar, since of the kits offered for sale, only a few are truly worthy of attention. Let’s get to know them better now.

VAZ clutch rating

Existing offers on the market can be divided into several groups. The best manufacturers and modifications of VAZ clutches are presented below.

7th place: STARCO

The ranking of the best market offers opens with a company that is a product that combines the developments of engineers from the USA and Turkey.

In principle, the company is represented on the Russian market as a Turkish brand, but technological developments have been collected from all over the world. Such a symbiosis ensures sufficient reliability, high quality indicators and reasonable cost, which attracts a large number of domestic motorists. Initially, the company was organized in 2005 as a result of the signing of an agreement between several brands located in Germany, Turkey and the USA. At the beginning of its work, the company produced a rather meager range of parts, which scared off buyers. As of 2022, the brand’s range has expanded to 7,000 items. Among other things, the brand has 2,000 models of clutch kits ready for installation.

The manufacturer is focused more on trucks. The choice of passenger modifications is scant, but you can buy a clutch at a VAZ.

- sufficiently strong clutch baskets can withstand inept operation;

- moderate cost;

- sufficient quality of packaging;

- The friction pads are protected against counterfeiting.

- The clutch disc wears out quickly;

- friction linings quickly become loose or fly off the rivets;

- damper springs of insufficient quality quickly sag or break;

- The release bearing begins to whistle almost immediately after installation.

6th place: AMD

The next representative of the ranking comes from Asia. The brand is organized by Japanese corporations to create consumables for their own cars. Thanks to a competent approach, the organization managed to achieve wide distribution of products far beyond the continent.

Clutch VAZ-2110

Despite the fact that the ten clutch is primitive, like a cart wheel, it must meet many parameters in order to flawlessly perform its functions - high-quality transmission and complete interruption of the transmission of torque from the engine to the gearbox.

In addition (and few people know this), two types of clutches :

- for cars with a carburetor or injection engine and a torque of 116 Nm ( 2110 and 2111 );

- for 1.6-liter engines with a torque of 128.3 Nm ( VAZ 2112 ).

Choosing a clutch - articles and brands

From the factory, our car was equipped with kits with factory part number 2110-1601180 on the basket.

VIS clutch kit for VAZ 2110-12: basket, disc, release bearing.

The driven disk must have part number 2110-1601130 . This kit is produced by the VAZInterService (VIS) plant, the external distinctive features are a diaphragm with 12 blades, one-piece smooth friction linings of the driven disk, the disk itself has 6 damper springs. The quality of the original kit is so-so. The high level of imbalance of the driven disk exceeds the permissible limit by almost twice. In addition, the VIS kit is quite heavy compared to its competitors.

This was also reflected in the preferences of the public - only 6-8% of users buy this kit for 2.8 - 3 thousand rubles.

Analogs

This is the most common choice of tens!

In addition to the Togliatti VIS plant, on the shelves you can find a lot of clutch kits from a variety of manufacturers, both domestic and foreign. Among the latter, a huge share is Chinese counterfeit. In principle, the list of the most popular manufacturers looks something like this:

- German clutch LuK (Lamellen und Kupplungsbau), driven disc 320 030810 , basket 2 D24 120 0252 10 .

- Their fellow countrymen, Sachs.

- Also the Germans FINWHALE and QML.

- Turkish companies Starco, Mapa, Kraft (article 2110 W3200C B2240 ).

- VALEO, France, article number 21102 - 21103 - 21108 - 2111 - 2112 826622.

- HOLA, Holland.

- MecArm and PILENGA from Italy.

- South Korean company FORTECH.

Domestic factories from Naberezhnye Chelny and Tyumen, as well as the local Nachalo brand, are also quite widely represented, but the quality of their clutches is difficult to compare with German, say, kits. And now a few words about how to choose a high-quality clutch on a VAZ-2110 without resorting to laboratory tests.

Rating of the TOP 8 best clutches for VAZ

Among the wide range of clutch kits, we can highlight the most popular and high-quality ones.

Valeo

The leader in the question of which clutch is best to install on a VAZ is the product from Valeo, which is valued among motorists for its reliability, quality, and service life.

The product is more expensive than competitors, which is explained by good performance. Average mileage is 120 thousand km. Often the mechanism remains operational up to 200,000 kilometers. The disk can withstand severe overheating without breaking.

The safety factor of the set is 6000 rpm. The device works normally at 9 thousand. This indicator is important for owners of modified models.

The average cost of a kit for a VAZ-2114 and other models is 7-8 thousand rubles.

Advantages and disadvantages

- high safety margin;

- withstands heavy loads;

- comfortable, soft movement;

- long service life.

- high price.

Attention! The Valeo clutch is popular, so there are fakes. You should select the coupling carefully.

Valeo clutch kit

Sachs

The clutch is designed so that the car starts moving earlier and there is less wear. The kits are manufactured with asbestos-free linings. The mechanism is maintenance-free and can withstand extreme loads. Suitable for a sporty driving style. The kit is designed perfectly. After installation, there is no grinding - the mechanism immediately functions properly.

You can only purchase a Sachs clutch from “officials”. The protection against counterfeiting is noted - the product has its own serial number, and there is a holographic tape on the packaging.

The average price of a kit for VAZ 2101-2107 is 5,000 rubles. For front-wheel drive cars of the Lada family with an engine of 8 or 16 valves - 4 thousand.

Advantages and disadvantages

- long service life;

- smooth torque transmission;

- no grinding required;

- high quality packaging.

- high price.

Sachs clutch kit

LUK

The manufacturer uses innovative technologies in manufacturing, which explains the soft switching and long service life (up to 120 thousand km). Reinforced friction clutch springs are used. The grinding period is minimal. The device is installed on classic AvtoVAZ models; narrow petals on the basket provide soft squeezing. Includes bearings with high-quality lubricant.

On some cars, the clutch is installed by the manufacturer.

The cost of the kit for all Lada models is 4,000 rubles.

Advantages and disadvantages

- high quality;

- soft squeeze;

- long service life;

- quick grinding.

- It’s easy to run into a fake.

LUK clutch kit

Hola

In 4th place in the ranking is the Hola clutch. The set is high quality, designed for high loads. On average, it travels 100 thousand km without breakdowns.

The organization imposes ISO standards on its products. Advantages: the device does not have a pressure ring and is protected from impacts.

Hola is often installed on the Chevrolet Niva model. After installing the clutch, the squeeze becomes soft, the shifting is smooth, and the torque is maximum.

The cost for the VAZ-2110 and other Lada models is on average 3,000 rubles.

Advantages and disadvantages

- high quality;

- anti-corrosion treatment;

- soft squeeze.

- takes a long time to grind in.

Attention! When purchasing a Hola kit, you need to be careful; defects are more common than with competitors.

Hola clutch kit

Fenox

Next on the list is a clutch from Fenox. Installed on some cars off the assembly line. If you have a small budget, you can give preference to this brand. The manufacturer guarantees improved heat dissipation due to copper fibers in the pads.

The bearing is of high quality and can withstand heavy loads. The mechanism functions properly at 12,000 rpm. Remains comfortable, the squeeze is soft.

The average cost is 3800 rubles.

Advantages and disadvantages

- low price;

- soft squeeze;

- fakes are rare.

- The clutch life is short compared to its competitors.

Fenox clutch kit

Kraft

The Kraft clutch is used by car owners who prefer a dynamic driving style. The model is able to withstand heavy loads. The manufacturer is responsible for the quality of products and packaging, which will not be damaged during improper transportation.

Kraft clutches can be purchased at many auto stores. There are few fakes due to the low cost of the original and the presence of individual markings on each product. The coupling is of high quality and meets the standards.

The cost of the kit for front-wheel drive Lada cars is 3,500 rubles. It is better to install the device on classic VAZ models, the mechanism is soft. For Zhiguli, the kit will cost 3,000 rubles.

Advantages and disadvantages

- reliable packaging;

- soft pedal pressure;

- guarantee;

- prevalence.

- slight vibration.

Kraft clutch kit

"VazInterService"

The quality of clutch kits from this company has improved and the range has expanded. A resource of 70 thousand km seems small. Taking into account the cost of the kit, the period of use is sufficient. The mechanism is suitable for a relaxed driving style; it is not designed for heavy loads.

The average cost for a VAZ car is 3,000 rubles.

Advantages and disadvantages

- the products were developed by AvtoVAZ specialists taking into account all the features of the models;

- little risk of running into a fake;

- nice price.

- relatively small resource, which is compensated by low cost.

Clutch kit "VazInterService"

STARCO

The brand took last place. Many innovative technologies are used in production, with an acceptable price/quality ratio. The kits are suitable for drivers with a relaxed driving style. With a dynamic driving style, breakdowns begin after 15 thousand km. The wheel bearing from this company is of poor quality and will have to be replaced.

Disadvantage - most spare parts under this brand are made for trucks, but clutches for VAZ cars can be selected.

The cost of the set is 3300 rubles.

Advantages and disadvantages

- price-quality ratio;

- withstands heavy loads;

- durable packaging;

- protection against counterfeiting.

- wears out quickly;

- damper springs become unusable after a short period of time;

- The bearing is of poor quality, you will have to look for an alternative.

STARCO clutch kit

Choosing a high-quality clutch for ten

For example, we have already decided on the brand. More precisely, with the price. Since the prices for all kits are different - from cheap domestic ones for 2500 rubles and ending with German clutches for 7-8 thousand.

However, no one is safe from counterfeiting, so we check each element of the kit visually upon purchase.

Driven clutch disc

The driven clutch disc from Valeo is a good combination of price and quality.

- First, we look at the surface of the friction linings - there should be no cracks or irregularities There can be no scuffing or roughness. Moreover, it is unacceptable for oil or other technical fluids to get on the friction clutch . It would seem that these are basic things, but manufacturers of counterfeit or very cheap spare parts are not able to comply with these conditions.

- Next we look at the splines. There should be no damage, scuffing is excluded.

- We pay special attention to the quality of the riveting. If you look closely, you can see that the shape is riveted. It is different for branded wheels and fake ones - the rivet should be uniform and not differ from rivet to rivet.

- We look at the damper springs, which should not have any play or displacement.

- In addition, pay attention to the markings - as a rule, they will be applied to the damper plate. It could be a hologram, a simple stamp or laser marking, but there must be something that says about the manufacturer.

Clutch basket

LUK clutch basket – German quality for a Russian car.

- Initially, we inspect the quality of the rivets and plates. All rivets must be identical, there should be no backlash. All rivets must be laid without distortions or displacements of the axes; there should be no cracks or chips on the heads.

- The basket body itself is made by stamping, so we look at its quality - there should absolutely be no nicks, cuts, chips or scratches. There should be no burrs in the holes.

- The pressure plate itself deserves special attention . It is cast from cast iron, after which the working surface is polished. It is the mirror of the pressure plate that will tell a lot about the manufacturer - cavities, scratches, microcracks, unevenness, and radial scratches are excluded. If there are no defects, then the disc is made of high-quality cast iron and processed in accordance with technology and high-quality equipment.

Choosing a VAZ clutch

The clutch of VAZ cars is the same as that of most other cars. Its design, at first glance, may seem complicated, but it is an elementary mechanism, and it looks like this: a driven disk is pressed to the engine flywheel, only five millimeters thick, but it is this disk that transmits all the power of the engine to the wheels of the car. A pressure disk hidden in the basket is attached to it.

No car can do without a clutch, and all because it is this part that provides your car with a smooth start and saves transmission parts from overloads. But still, the main task of the clutch remains the process of connecting and disconnecting the engine and gearbox.

The market is replete with offers for the sale of clutches for VAZ cars. Beware of fakes and buy auto parts only from branded auto stores that have proven themselves in the market. To prevent you from becoming a victim of a fake, we will tell you what features you should especially pay attention to when choosing a clutch.

VAZ-2101 clutch assembly SACHS

VAZ-2101 clutch assembly VALEO

VAZ-2108 clutch assembly VALEO

VAZ-2123 clutch assembly SACHS

VAZ-2123 clutch assembly VALEO

VAZ-2108 clutch assembly SACHS

Clutch VAZ-2190, Vesta, X-Ray (cable-actuated gearbox) assembled LUK

VAZ-1111 clutch assembly KRAFTTECH

VAZ-2110 clutch assembly VALEO

Clutch VAZ-2170,1118 1.6 16V assembled LUK

What should the clutch driven disc be like:

Friction linings are the most expensive part. It is by their condition that the quality of the driven disk can be determined. Manufacturers of cheap discs and counterfeits are not able to meet all the requirements for the manufacture of friction linings, so cracks, chips, irregularities and various roughnesses can be seen on their products, which should not be the case. The pads must not be oily or stained by other liquids.

You should pay attention to the overall quality of all riveting. The rivets must be identical to each other. Gaps with offsets at friction linings or damper plates are also not allowed. The splines inside the hub may have traces of oil, but they must not be damaged.

The damper plate must have a trademark in the form of a stamped corporate logo or hologram; there may also be laser markings or a manufacturer’s mark. This is protection against counterfeiting. Although not all manufacturers mark products in this way, it would be worth paying attention.

What should the clutch pressure plate be like:

On the pressure plate basket, you need to check the riveted connections, which, as on the driven disk, must be identical to each other. If they are done carefully, it means that the product was assembled in a factory, and not underground, not done in a garage.

The pressure plate housing must be made by stamping. The front surface of the pressure disk must exclude the presence of even the slightest microcracks or irregularities.

If the appearance of the discs matches those that we described above, then this means that you are looking at products made in accordance with all standards, using high-tech equipment.

Since there are numerous VAZ clutch manufacturers on the market, domestic and foreign, buyers are faced with the question of choice. What to choose - LUK, VALEO, KRAFT, SACHS, HOLA or other manufacturers? Locally produced VIS brand clutches are installed directly at the plant in Tolyatti.

New AVTOVAZ products are equipped with LUK and VALEO clutches.

The share of other clutch manufacturers, both domestic and foreign, in this market is small. But in the assortment of stores operating under the brand “Country of Spare Parts” you will also find other manufacturers. You need to choose a clutch based on your experience, since each car enthusiast will find more than one argument in favor of one or another manufacturer. I would like to introduce you to the most popular clutch models presented on this market and give you food for thought, and the choice is up to you.

Major clutch disc manufacturers

A subsidiary of AVTOVAZ. Founded in 1991. From the first day of operation, VIS became one of the main suppliers of spare parts for the AVTOVAZ conveyor belt. Auto parts produced at the enterprise are also supplied to other Russian enterprises associated with the automotive industry.

AVTOVAZ's own development is used on almost all models produced under the VAZ brand. You can hear very different reviews about the product. So, for example, someone is dissatisfied with the fact that the clutch has a short service life of 70 thousand km. At the same time, the product has a rather low cost, which is good news, plus, as practice shows, the VIS clutch of a newly purchased VAZ car will work flawlessly for at least the entire warranty period of the car.

VALEO

The French company VALEO has established itself as an excellent manufacturer of clutch parts around the world. The French also managed to gain a strong foothold in the market of Asian countries, including Korea in this list. Large Asian manufacturers have not ignored this company and the quality of the parts it produces. Automobile giants such as Kia, Daewoo, Hyundai, Ssang Young and many others install the VALEO clutch at the factory.

If you own a car of one of these brands, then rest assured that your car has a VALEO clutch.

The plant that produces this type of component has internationally recognized quality certificates:

- Rostest certificate,

- German TÜV certificate,

- ISO9001 certificate from the Korean Management Association,

- TS19949 and QS9000 certified by TÜV North America.

Since the VALEO company is recognized throughout the world, its customers include the French Peugeot and Renault, and the German Mercedes and Opel, as well as the Swedish concern Volvo, the Japanese Mazda and the American Ford.

Car enthusiasts characterize the VALEO clutch as soft and comfortable. The new kit can serve you and your car for about 150 thousand km. But the price of one of the leaders in this market is quite high.

The most famous manufacturer of automobile clutches in Germany. The company has been in the automotive component production market since 1965. LUK is a subsidiary of LuK-Aftermarket Service. The geography of the company has gone far beyond Germany: for example, eighteen industrial enterprises are located in Albion, France, Hungary, Asian countries (China, India, Korea), North (USA) and Latin America (Brazil, Mexico), and South America. Africa. More than ten percent of the total workforce (more than 9,500 people work for the company) are engaged in research and development activities.

The quality of LUK clutches is trusted by many famous brands: Mercedes Benz, BMW, Audi, VW, Opel, Renault, Citroen, Peugeot, Skoda, Saab, Volvo, Porsche, Jaguar, Land Rover, Chevrolet, Chrysler, Ford, Honda, Mitsubishi, Subaru, Mazda, Nissan, Toyota, Daewoo, Hyundai, Kia, VAZ, GAZ and many others.

The LUK clutch design uses a vibration damper for the driven and pressure plates. This clutch has the property of dampening vibration, thereby maximizing driving comfort. Russian motorists in most cases praise the LUK clutch. It combines the best ratio of price and quality, which is why such a clutch is most preferable for owners of VAZ cars.

KRAFT

The history of the company began more than 20 years ago in Germany. The company's factories are located in Europe and Asia. Certified centers in the production of auto components control the quality of manufactured products. In its production it uses only the latest technologies and equipment.

At the plant in Turkey, where clutches for VAZ cars are produced, new technologies are also in use. The price range of this clutch is lower than that of its European analogues, but at the same time higher than that of Russian manufacturers. Reviews from our car enthusiasts about this clutch vary. Some people praise the KRAFT clutch because it is not afraid of overheating even under severe conditions. The clutch has a soft release, but the release bearing can fail, the unsatisfactory design of which is sometimes complained about by VAZ owners.

SACHS

The German company SACHS has been producing clutch parts since 1930. It is known to Russian consumers as a manufacturer of high-quality automotive components. Thirty-nine businesses around the world. SACHS produces more than 150 million clutch sets per year. A small part of them is intended for the Russian automobile industry, but about 80% of all manufactured products remain in Europe. The SACHS clutch collects only positive reviews from car owners.

The SACHS clutch easily withstands increased loads and ensures smooth gear shifting. The clutch kit includes asbestos-free linings. However, SACHS has the disadvantage of high product cost.

Auto parts under the HOLA brand have been produced in the Netherlands since 2002. This is a young company, but thanks to the introduction of the highest quality requirements into its own production, it managed to gain a foothold in the automotive spare parts market and establish the production of components around the world.

The working life of the HOLA clutch is designed for a mileage of at least 100 thousand km. Many Russian car enthusiasts are not yet familiar with this brand. But those who bought this clutch praise it for its ease of pressing the pedal, because this does not affect the power unit, which transmits maximum torque.

FINWHALE

Another young German company that produces clutches for VAZ cars. The FINWHALE clutch performs equally well both cold and hot. In the production of clutch kits, a modified composition of friction linings is used, which has increased stability of the friction coefficient when temperature changes. The pressure plate is designed with vents to improve cooling and increase clutch life.

The manufacturer assures that the clutch will serve you for more than 100 thousand kilometers; these indicators have been tested in the best testing centers in Europe.