Errors Lada 2110

Many VAZ 2110 car owners, especially those who have no accumulated experience in driving and repairing the “tens”, fall into a slight panic if “CHECK” suddenly lights up on a seemingly serviceable car, and the on-board computer begins to generate an error.

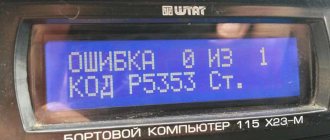

They are usually expressed using the letter P and a numeric four-digit code. Naturally, error codes for the VAZ 2110 are not difficult to find in special tables in order to understand in which system the cause should be looked for. However, the decoding is often very vague, and it is not clear what to do next?

OBD 2 error codes

VAZ error codes

Error codes for Mikas 10.3/11 controllers

- 1 Electronics

- 2 Crankshaft and camshaft

- 3 Electrical equipment

- 4 Idling

- 5 Throttle valve

- 6 Oxygen sensor

How to Troubleshoot or Reset Trouble Code P0505

Some suggested steps to troubleshoot and fix error code P0505:

- Read all data and stored error codes using an OBD-II scanner.

- Clear the codes and check if the P0505 code appears again.

- Observe the engine's operation at idle speed, with the gear engaged and disengaged. To check whether the engine idle speed corresponds to the values specified in the manufacturer's technical documentation.

- Check the engine for vacuum leaks.

- Inspect the throttle body for carbon buildup. And also on the body and inlet of the idle air bypass control valve.

- Disconnect and check the idle air control valve.

- Check if the idle air control valve passages are clogged.

Electronics

Let's look at some especially annoying error codes, which, as if they don’t affect the speed, but constantly remind you that something may be wrong with the VAZ 2110. These include:

- error 1621, warning the driver that the RAM is disabled, that is, code 1621 indicates that the controller is not working, which means that errors are not read, you remain in the dark about what is happening with the systems of your car. Most often, when drivers see the numbers 1621, they ignore them, reset the RAM error (remove the terminal from the battery for a couple of minutes, then put it back on) and drive on. But, after turning off the car and starting it again, they see the same ill-fated code 1621. You can try to carefully inspect the twist near the ECU (to ground), and perhaps additionally solder the factory crimp. However, often even contacting specialists does not help; code 1621 remains on until the RAM memory is changed;

- Sometimes it happens that the injector light comes on. This is especially observed in winter, and when the engine warms up well, the light goes out. Although this is not so scary, it is somewhat unnerving, and the light bulb breaks down if it burns for a long time. It’s better to contact a service center where they can update the firmware, then the light bulb will stop bothering you.

Crankshaft and camshaft

- code 0335 indicates a malfunction of the crankshaft position sensor. Therefore, when you see 0335 on the computer, you need to check whether the signal is coming from this sensor. If you find that the signal is weak, you can help by changing the air flow if it is excessive (above the maximum). After this, error 0335 should disappear;

- When you see error 0340, you know that the camshaft position sensor is most likely faulty. Although in fact, even if 0340 is displayed, the camshaft itself may be in good condition, the car is working as usual. But when the numbers 0340 do not disappear while the engine is running, this unit should be carefully inspected.

Crankshaft position sensor

Electrical equipment

Malfunctions of the electrical equipment of the VAZ 2110 should be responded to as quickly as possible. By the way, this can be signaled by code 1602, although its decoding sounds like a loss of on-board power supply voltage in the RAM.

Sometimes it is enough to reset error 1602, and it will not appear again. Some people call these numbers “good”; 1602 may appear after the battery is disconnected, due to a voltage surge when starting the engine (for example, in cold weather). However, if 1602 “pops up” constantly, you need to look for a network break.

First, try to clean the battery terminals and secure them well. Did not help? Check the circuit, starting from the “+” of the battery, be sure to check the fuse, fuse link.

And also inspect the mass of the ECU, TPS. There are cases when code 1602 appears due to the fact that the security alarm blocks the controller circuit, and it issues this as an error every time. You should contact the installer of your alarm system.

Idling

Code 0505 indicates a malfunction of the idle air control. Moreover, 0505 is most often “issued” when the engine is started with the gas pedal pressed. This often affects drivers who switched from a carburetor VAZ 2110 to an injection one.

However, 0505 also occurs if the ignition module, spark plugs are faulty, there are broken wires, or the engine speed is not the one set by the XX regulator.

If you notice popping noises in the muffler, this may also indicate displacement of the crankshaft ring gear. Code 0505 can be displayed either alone or with 0300 (missing cylinders).

How to check errors on a VAZ 2115

To read car dashboard codes yourself, follow a simple sequence of steps.

- Insert the ignition key into the hole, but do not turn it.

- Press and hold the odometer button.

- Turn the key to position 1 and release the odometer button.

- Now all the arrows on the tidy will make 1 revolution and drop into place.

- You need to press the odometer button twice with an interval of 4-5 seconds.

- In the menu that opens, you can view existing faults.

Throttle valve

The on-board computer issues two unpleasant errors - 0122 and 0123 when there is a problem with the throttle sensor. Moreover, 0122 will be displayed if the signal level of this sensor is low, and 0123 will be displayed if the signal level is high.

Both one and the other, naturally, are not good. Especially if the on-board computer readings are accompanied by increased idle speeds, jerks at low speeds and dips. In this case, replacing the sensor does not always help.

If codes 0122, 0123 are issued, be sure to check the signal and power wires for breaks, and also pay attention to whether there is any leakage through the injector rings. Remember: the main enemies of DPZD are engine washing and also the manufacturing plant, since there are a lot of defects here.

Technical description and interpretation of error P0505

OBD II Trouble Code P0505 is defined as “Idle Air Control System Malfunction.” Set when the powertrain control module (PCM) is unable to maintain or control engine idle speed.

In most cases, the PCM will attempt to make adjustments to various systems such as fuel timing, ignition timing, injection pulse timing, and others. Trying to maintain a given idle speed. However, when this limit is reached, the PCM will set code P0505 and turn on the warning light.

Idle speed in gasoline engines is adjusted and controlled by the idle air control valve, which is usually located on the throttle body. The valve is driven by a stepper motor, which receives commands from the PCM based on information received from various sensors located on the engine.

For example, if the engine is started in sub-zero temperatures, the PCM commands the valve to allow less air to enter the engine. This allows you to enrich the fuel-air mixture and creates conditions for regulating idle speed in cold weather.

As the engine warms up and combustion becomes easier and more complete. The PCM commands the idle air control valve to increase the amount of air entering the engine in response to changing conditions.

If the load on the engine changes, for example, when some electrical consumers are turned on or off. The PCM adapts the signal voltage to the idle air control valve. To ensure that the idle speed remains stable and at the RPM specified by the manufacturer.

[textbox note that the idle air control valve is closed by the PCM when the throttle valve is opened. This is done in order to prevent excess air from entering the engine.

Oxygen sensor

For some reason, it is quite difficult to find code 0525 in the decoding tables, but this is simply an error in the oxygen sensor, otherwise called a lambda probe. And if you see 0525 on the display again, it means that not everything is in order with the oxygen content in the exhaust.

This sensor is not installed on all VAZ models; it sends a signal to the engine regarding how much oxygen should be in the fuel system. That this sensor does not cope with its duties is evidenced by:

- increased fuel consumption;

- unstable work at XX;

- loss of power, lack of "response".

In principle, the lambda probe should be changed after about 60 thousand mileage, but this can happen earlier, especially considering the quality of our gasoline. Therefore, it may display 0525, warning that it is time to replace the oxygen sensor.

- Author: Veniamin

Error P0123 - what it means, symptoms, causes, diagnosis, solution

Trouble code P0123 indicates a problem with the throttle/pedal position sensor. When the engine control module (ECM) detects that the rated output voltage of the throttle position sensor exceeds the manufacturer's specification, it generates trouble code P0123.

The throttle position sensor (TPS) is another name for a potentiometer. It is located on the throttle body while the pedal position sensor is connected to the accelerator pedal.

The throttle position sensor monitors the movement of the accelerator pedal and determines how much power the engine requires. Code P0123 is triggered when the TPS voltage value is outside the specified range.

Decoding error codes of the VAZ electronic control unit

- P0030-Oxygen sensor heater before the converter, control circuit open

- P0031-Oxygen sensor heater before the converter, control circuit short to ground

- P0032-Oxygen sensor heater before the converter, control circuit shorted to board. net

- P0036-Oxygen sensor heater after the converter, control circuit open

- P0037-Oxygen sensor heater after the converter, control circuit short to ground

- P0038-Oxygen sensor heater after the converter, control circuit shorted to board. net

- P0102-Mass Air Flow Sensor Circuit Low Signal

- P0103-Mass air flow sensor circuit, high signal level

- P0112-Air temperature sensor circuit low signal

- P0113-Air temperature sensor circuit, high signal level

- P0116-Coolant temperature sensor circuit, signal out of acceptable range

- P0117-Coolant temperature sensor circuit low signal

- P0118-Coolant temperature sensor circuit, high signal level

- P0122 - Throttle Position Sensor Circuit Low Signal

- P0123 - Throttle Position Sensor Circuit High Signal

- P0130-Oxygen sensor before the converter is faulty

- P0131-Oxygen sensor circuit to converter, low output level

- P0132-Oxygen sensor circuit to converter, high output level

- P0133-Oxygen sensor circuit to the converter, slow response to changes in mixture composition

- P0134 - The oxygen sensor circuit to the converter is inactive

- P0136-Oxygen sensor after the converter is faulty

- P0137 - Oxygen sensor circuit after the converter, low signal level

- P0138-Oxygen sensor circuit after the converter, high signal level

- P0140 - The oxygen sensor circuit after the converter is inactive

- P0141-Oxygen sensor after the converter, heater is faulty

- P0171 - Fuel supply system too lean

- P0172 - Fuel system too rich

- P0201-Injector cylinder 1, control circuit open

- P0202-Injector cylinder 2, control circuit open

- P0203-Injector cylinder 3, control circuit open

- P0204-Injector cylinder 4, control circuit open

- P0217-Engine temperature is higher than permissible

- P0230-Fuel pump relay circuit malfunction

- P0261-Injector cylinder 1, control circuit short to ground

- P0263-Injector driver fault 1

- P0264-Injector cylinder 2, control circuit short to ground

- P0266-Injector driver fault 2

- P0267-Injector cylinder 3, control circuit short to ground

- P0269-Injector 3 driver malfunction

- P0270-Injector cylinder 4, control circuit short to ground

- P0262-Injector cylinder 1, control circuit short to on-board network

- P0265-Injector cylinder 2, control circuit shorted to on-board network

- P0268-Injector cylinder 3, control circuit short to on-board network

- P0271-Injector cylinder 4, control circuit short to on-board network

- P0272-Injector 4 driver malfunction

- P0300 - Random/multiple misfires detected

- P0301-Cylinder 1, misfire detected

- P0302-Cylinder 2, misfire detected

- P0303-Cylinder 3, misfire detected

- P0304-Cylinder 4, misfire detected

- P0326-Knock sensor circuit, signal output out of acceptable range

- P0327 - Knock sensor circuit low signal

- P0328 - Knock sensor circuit, high signal level

- P0335 - Crankshaft position sensor circuit is faulty

- P0336-Crankshaft position sensor circuit, signal out of acceptable range

- P0337 - Crankshaft position sensor, short to ground

- P0338-Crankshaft position sensor, open circuit

- P0340 - Camshaft Position Sensor Malfunction

- P0342-Phase sensor circuit, low signal level

- P0343-Phase sensor circuit, high signal level

- P0346-Phase sensor circuit, signal out of acceptable range

- P0351-Ignition coil of cylinder 1 (1-4), control circuit open

- P0352-Ignition coil of cylinder 2 (2-3), control circuit open

- P0353-Ignition coil of cylinder 3, control circuit open

- P0354-Ignition coil of cylinder 4, control circuit open

- P0363-Misfire detected, fuel supply to idle cylinders is turned off

- P0422 - Neutralizer efficiency below threshold

- P0441-Gasoline vapor recovery system, incorrect air flow through the canister purge valve

- P0444-Canister purge valve, control circuit open

- P0445-Canister purge valve, control circuit short to ground or on-board network

- P0480-Fan relay, control circuit open

- P0481-Cooling fan 2 circuit malfunction

- P0500-Vehicle speed sensor is faulty

- P0506-Idle system, low engine speed

- P0507-Idle system, high engine speed

- P0511-Idle speed control, control circuit faulty

- P0560-On-board network voltage is below the system operability threshold

- P0562-On-board voltage, low level

- P0563-On-board voltage, high level

- P0601-Engine management system controller, ROM checksum error

- P0615-Additional starter relay, control circuit open

- P0616-Additional starter relay, control circuit short to ground

- P0617-Additional starter relay, control circuit shorted to on-board network

- P0627-Fuel pump relay, control circuit open

- P0628-Fuel pump relay, control circuit short to ground

- P0629-Fuel pump relay, control circuit shorted to on-board network

- P0645-A/C compressor clutch relay, control circuit open

- P0646-A/C compressor clutch relay, control circuit short to ground

- P0647-A/C compressor clutch relay, control circuit shorted to board. net

- P0650-Malfunction indicator lamp, control circuit faulty

- P0654-Instrument cluster tachometer, control circuit faulty

- P0685-Main relay, control circuit open

- P0686-Main relay, control circuit short to ground

- P0687-Main relay, control circuit shorted to on-board network

- P0691-Fan relay, control circuit short to ground

- P0692-Fan relay, control circuit shorted to on-board network

- P1102 - Oxygen Sensor Heater Resistance Low

- P1115 - Oxygen sensor heating circuit faulty

- P1123 - Rich mixture at idle

- P1124 - Lean mixture in idle mode

- P1127 - Rich mixture at Partial Load

- P1128-Lean mixture in Partial Load mode

- P1135 - Oxygen sensor heater circuit 1 open, short circuit

- P1136 - Rich mixture in Light Load mode

- P1137 - Lean mixture in Light Load mode

- P1140 - Measured load differs from calculation

- P1141 - Oxygen sensor 1 heater malfunction after converter

- P1171-Low level CO potentiometer

- P1172-High level CO potentiometer

- P1301-Cylinder 1, misfire detected, critical for the converter

How to diagnose error code P0123?

Connect your car charger

Before searching for the cause of the P0123 code, be sure to connect the car charger.

During diagnostics, the ignition will be turned on and this can lead to rapid depletion of the battery charge. To avoid this situation, it is recommended to install a car charger before testing.

Use an OBD2 scanner

OBD2 scanner is a must-have tool for scanning trouble codes. An on-board diagnostic system is included in every vehicle manufactured after 1996.

The OBD2 scanner has the ability to read and clear error codes, as well as receive real-time data and record this information.

Alternatively, you can use a digital multimeter, which is cheaper but lacks the functionality that an OBD2 scanner has.

Check the TPS wiring

Before replacing the sensor or performing any other procedure, it is recommended that you check the wiring harness that leads to the throttle position sensor. Inspect the wiring and note any signs of damage or corrosion.

Inspect the throttle body

Visually inspect the throttle body and see if it is dirty. If it's really dirty, use throttle body (carburetor) cleaner, which can be easily found at any auto store. After cleaning the throttle body, reset the error and see if it occurs again.

Check the ground

Using a multimeter, check the voltage at ground. Connect the red lead of the multimeter to the positive terminal of the battery and the black lead to ground. If the reading is close to the battery voltage, then the grounding is good. If not, it could be a power issue.

Sensor check

If you didn’t find anything during a visual inspection of the TPS, it’s time to check the voltage on it. Set your multimeter to test voltage and look at the wiring diagram to see what each wire means.

Insert the black probe into the signal wire pin of the connector and the other pin into ground. Slowly open the throttle valve and watch the reading. The voltage should increase when the throttle is opened.

At wide open throttle, the ideal reading is 4.5 volts. In the closed position, the reading should be 0.45 Volts.

Cleaning the sensor and connector

Before you think about replacing the sensor, it is recommended that you clean and repair it first, as a dirty sensor will send incorrect data to the ECU. To do this, you should have the following tools ready:

- Carburetor cleaner.

- Clean cloth.

- Screwdriver.

- Gloves.

Step 1: Let the engine run for a while

Start the car and let the engine idle for a few minutes. This will heat up the engine and some of the dirt will loosen on its own.

Step 2: Open the hood and locate the sensor

Once the engine is warm, open the hood of the car and locate the throttle position sensor. You may have to remove the engine cover to do this.

Step 3: Disconnect the connector

Disconnect all wiring and connections leading to the TPS. Next, unscrew the nuts and bolts securing the sensor and carefully remove it.

Step 4: Clean the sensor and connector

Clean the sensor with cleaner. Clean around the sensor thoroughly until all dirt is removed.

Step 5: Drying the Sensor

After cleaning the sensor, use a dry cloth and rub gently to remove any remaining liquid. Then plug the sensor into place, close the hood, and you're done.

Error p1621 VAZ 2110

VAZ 21093 error P1621, brain Jan 5.1.1, car won’t start, no other errors

Check the power supply to the computer under load. Well, in current ones. battery voltage and engine speed when cranked by the starter.

I’ll believe you, thank you, I still have an idea about the masses on the ECU, tell me where are the points for attaching them to the body

I don’t remember exactly, but the mass on the engine is in the DPRV area

if only these 2 points then everything is ok with the mass

and also in the 2nd and 3rd cylinders the spark plugs are black, everything was replaced with new ones and MZ AND WIRES AND CANDLES, the car was started last week with difficulty with a rope, and then once with the key, no immo, the engine was overhauled but even before the repair the car was barely running , smoked, spat oil, then one day it simply stalled, when opening the piston, they dangled in the cylinders and the connecting rod in one of the cylinders was bent, engine 2111 without a camshaft sensor

and as it turned out right now, the ecu was flashed before me, but I don’t remember the firmware number, tell the guru, maybe the reason is in the ecu process itself

You need to check the timing marks and compression. There is a spark from the MZ for breakdown, especially in cylinders 2 and 3. Let the engine after repair. And everything is new but needs to be checked. How's the starter turning?

and as it turned out right now, the ecu was flashed before me, but I don’t remember the firmware number, tell the guru, maybe the reason is in the ecu process itself

Yes of course it can. If everything else is in order, then you can try to reflash the ecu.

the starter turns well, it is new, Bulgarian, the generator is the same, by the way, during the cold run-in the compr was about 9, I didn’t measure it after starting, I threw up the MZ from the working machine, the same picture, the valves were also adjusted before assembling the engine, the spark plugs were tested on a stand 21 kW at 14 atm, The spark plugs in all cylinders are wet when cranking, there is a spark on all of them

something similar to what I observed on a Fiat Punto once with p1621, so there I saw the charging time of the coils, and on 2 and 3 the same time was less than 1-4, then they changed the ecu to a new one

look at the drive disc, it may have turned. And it’s easy to check - you set the top point of the piston to 1c. and count the number of teeth from the knee sensor to missing 2 teeth, there should be at least 20 teeth

maybe he was metal

So, during assembly, the crankshaft bolt could have been loosely tightened, which would have turned the drive disk on the sprocket key. check all marks.

no with marks and other things, everything is hockey

So why haven't you started it yet?

yes, as if there is other work, until it reaches the pelvis

It didn’t even come up for two days, and I gave the ecu back for firmware, maybe it will help, I don’t know

if there are problems with the power supply to the computer, check the integrity of the piece of wire directly on the + battery. a black wire about 20cm long is a kind of fuse, a wire with distributed resistance. can be replaced with ordinary copper stranded wire.

It could be easier! The skipping of teeth on the pulley should start from the timing belt (on the right side of the belt)

Guess what? The ECU will arrive after the firmware, then we’ll see. Still, it’s an interesting error related to the controller’s RAM. The firmware may not help, though. everything happened.

Let's continue the story with ECU 5.1.1 January, today I spent a couple of hours on this car, the marks and masses of the ECU were checked, all pins were ringed on the ECU block, poor contact of terminal 15 in the ECU connector was detected. everything is fixed, now everything is as it was at the factory, after lunch they brought the ecu with the firmware, installed the same picture, the programmer said that the ecu was not flashed properly, since it was flashed on the table, and when removed + the ecu firmware crashes, they said that he had received a bug, he ordered it today new ecu is exactly the same January 5 1 1- 1411020-71

, can anyone tell me if it is possible to install a Bosch 1.5.4-1411020-70 ecu

, the pins are the same, in theory they should be interchangeable

. Don’t go to him again.

Message from Sanych : Should you have checked the exhaust for clogging before flashing it?

Don't go to him anymore.

there was a cat on the car from the factory, they threw it out 2 years ago, and they tried to start it without a muffler, the result is the same, as for flashing the ECU, I won’t say anything about the specialist, maybe he messed up, but that’s not the point, those who are mistaken It’s doing something, I’m waiting for a new ecu, but maybe I can try to change the old one myself?

One more question along the way, the car does not have a lambda, but there is a wire going to the computer, as I understand it, from a variable resistor, to adjust the CO, WHERE IS THIS REGULATOR? In another VAZ 2109 from 1999 it stood on the engine panel, in a VAZ 2110 at the driver’s feet in the cabin, but in this car I didn’t find it at all, I just didn’t want to mess with the harness to go along the wires.

quarrel confused the car from 2004 and there was no cata there, there are just a lot of such cars and they got mixed up

let me know if it started what was the problem

Is there gasoline in the oil?

it is also possible 1411020-72 they work with the same wiring harness. simultaneous injection. The ECU of these series is equipped with a virtual correction system whose readings can only be changed through a scanner. Lambda is missing. US standards 83.

Well, if you 100% checked the marks on the pulley, the crankshaft sensor, the spark is normal and does not differ on all cylinders, did you remove the air flow sensor at startup? You can, of course, try and throw in another block. In your case, it’s something that ends at 70,71 or 72 bosh, January or vs. but I don’t think that an eprom error can be the reason for the engine not starting, and how the unit is flashed and when you remove the power the firmware crashes, which also gave an eprom error to the scanner and connected to the scanner.

Hello everyone, sorry for not writing for a long time, I’ll raise a topic, I started the car, I didn’t change the ecu, a car just arrived with the same ecu and I just took and inserted my “dead brain” into the donor’s car, and it worked quite well, so I decided to hack wiring, and got to the point where I discovered that the shielded wire going to the DPKV was all broken, brought an oscil and everything immediately became clear, replaced the wire with a new one and the car came to life, but I don’t understand why the DPKV break error was not recorded? But nevertheless, I’m glad that everything ended so simply, without unnecessary hassle, many thanks to everyone who wrote back

As they said wiring

I wish I had connected the oscil sooner and not created unnecessary posts. Hanter came up with an interesting idea, having checked everything, blame everything on the DPKV.

Error P1602 on VAZ 2110 engines: reasons, how to fix

Errors in the engine control system on VAZ cars equipped with injection engines of the tenth family (and this is almost the entire model range, starting with the VAZ 2110, Kalina, Priora...) are not as rare as we would like. Among them there are error codes that require immediate elimination and identification of causes, and there are those that appear from time to time. Among them, one of the leaders was error P1602. What the error code means, what it means and how to fix it, we’ll figure it out together.

Error P1602: what does it mean, decoding

The appearance of error code p1602 when scanning with a diagnostic device or during self-diagnosis using an on-board computer is a fairly common problem. Despite the fact that in the absence of other symptoms of malfunctions, you can use the car without problems, the message itself with error code P1602 begins to irritate. Especially when this has not been happening for the first month. Theoretically, error code 1602 stands for a message from the ECU about an interruption in the on-board network voltage. In practice, this means that in some place there is no contact on the terminals, plugs, connectors.

The message may also mean that one or more electrical devices on the on-board network may not have contact with ground, temporarily or permanently. Naturally, if the battery is not in full contact with the vehicle’s ground , we will not see any message, since the electrical equipment will simply die without signs of life. True, this happens extremely rarely, but it doesn’t hurt to remember it. As well as temporary problems with charging the battery , which can be associated both with the battery itself and with the charging relay, generator or their contacts.

Error Diagnosis Methods

In 2022, errors on the VAZ 2110 on-board computer can be identified in two ways.

- Self-diagnosis. The method is feasible thanks to a special option in the on-board computer. The principle is that the system shows faults in the main circuits and mechanisms. The advantage is that there is no need for additional equipment or special programs - everything that is needed is already “hardwired” into the on-board computer. The disadvantages include the low accuracy of the readings.

- With the help of auxiliary equipment. This type of procedure is characterized by high accuracy of the read data. Thanks to a third-party analyzer, you can find out exactly where the breakdown occurred, which simplifies the repair process. An obvious disadvantage is the need to connect a computer with a special program. Such equipment is present only in specialized service stations.

Self-diagnosis VAZ 2110: error codes

To enable self-diagnosis mode, the driver or technician will need to perform a certain sequence of actions.

- Turn off the engine ignition.

- Press the daily mileage reset button and, without releasing it, turn on the ignition. In this case, all digital cells should light up on the display.

- Click on any module control button twice.

- The device will display the error number.

If everything is done correctly, one of the following symbols will light up on the device:

- 2 – critical excess of the rated voltage of the on-board network, a short circuit of the main line or loaded components is possible;

- 3 – a similar error on the instrument panel of the VAZ 2110 indicates that the gasoline level sensor is damaged or there are problems in the sensor’s power supply; to check, you can replace the part with a new one and ring the circuit;

- 4 - error 4 VAZ 2110 indicates that the antifreeze temperature sensor is broken or its wiring is broken, the problem is resolved in the same way;

- 5 – the thermometer designed to measure the temperature outside is faulty;

- 6 – the engine is very overheated, you need to stop and wait for it to cool down, and there should be a sound signal (add antifreeze/water into the radiator);

- 7 – the lubricant pressure in the crankcase compartment of the engine is below the established norm, the losses must be urgently replenished;

- 8 – error 8 VAZ 2110, interpretation shows that the brake system is damaged, possibly a drop in the fluid level in the expansion tank or severe wear of the pads;

- 9 – the battery is completely discharged, the element needs to be charged or replaced with a new module;

- E – software failure of the on-board computer firmware; complete diagnostics with a scanner and qualified repairs in a workshop will help here.

Also, error 14 VAZ 2110 or another two-digit number will indicate the presence of two problems. Usually, with such a picture, the ciphers are summed up. For example, error 10 VAZ 2110 may indicate problems in circuits No. 4 and 6.

How to reset errors on a VAZ 2110

Typically, the procedure is carried out after repairing the unit for which the fault code is responsible. In this case, the symbol does not disappear - it must be forcibly reset. This is done quite simply. The user is required to enter the service mode (hold down the daily mileage button), then double-click on any control. After completing the manipulations, a code will appear on the display. To eliminate this, the daily mileage button is pressed for 3-4 seconds and the system is reset. The machine exits the dialog box automatically after 30 seconds of inactivity.

What to do when error P1602 appears: DIY diagnostics

It is clear that with such an error code it is necessary to look for poor contact in the engine control system circuits. True, the direction of the search is not entirely clear and it depends on the symptoms. Therefore, we can only assume what can happen to the electrical system of a VAZ injection engine with error P1602, based on reviews from owners and personal experience:

- No contact at the negative terminal battery It's easy to check. We remove the terminal, assess its condition, if necessary, clean the terminal and terminal, and lubricate it with a special conductive lubricant with an anti-oxidative effect.

- Lack of contact at the negative wire of the battery at the point of connection to the body . We unscrew the wire from the body, carefully clean the terminal and the attachment point, install the terminal in place, carefully screwing it into place with clean fasteners.

- No contact on electronic control unit board . Here the situation is more complicated, since for diagnostics you need to have at least basic knowledge in the field of electronic systems and circuitry.

First, we inspect the ECU contacts, if necessary, clean them, as well as the terminals on the block. After this, you can open the block and visually inspect the board. If there is a loose solder on the board, solder it with a low-power soldering iron, being careful not to overheat the elements. In some cases, warming up the board with a hairdryer helps, but this is a temporary measure. - No contact on the generator . The contact may be damaged either on the power wire or on the signal wire. In both cases, the generator may not charge the battery.

Alternatively, you can remove the generator and check (clean) the contact of its housing with the cylinder block. In some cases this works. - In some cases, periodically power supply to the electronic control unit is lost engine. In these cases, either the fuse may be to blame (depending on the VAZ model, it may have different designations). We check the fuse, as well as the contacts of the mounting block.

Practice shows that these main reasons are the reason for the occurrence of error code P1602 on VAZ cars with an injection engine.