Make or buy

Let's start with the main thing. Namely, from the idea of modernization. The gearshift lever is usually located inside the case, and the top handle itself, which the driver grabs when changing gears, can be plastic, silicone, leather, etc.

The leather option is usually found on more expensive models. And in Soviet or old domestic cars, glass knobs with flowers, roses and other once-fashionable handle decor options are not so rare. Now some people appreciate rare solutions, trying to decorate the interior of their own car with something similar. Making a complete lever attachment from glass, plastic or silicone is quite problematic. It's much easier to buy it. But you can sew the cover yourself if you have certain skills and desire.

How to remove the gear shift lever?

Sometimes car owners are faced with the problem of removing the gear shift lever. This procedure must be carried out when replacing the silent blocks of the lever or extension, as well as when replacing the lever itself. The extension is removed to replace the silent blocks on it or to completely disassemble the front suspension. Since these repair procedures are not very difficult, you can remove the lever yourself rather than contact a service station for help.

Advice: it is advisable to carry out the work in the presence of an inspection hole or a lift.

Material selection

All work begins with the selection of material. Nobody forbids you to take some kind of rubber, fabric or any other option. But here the issue of practicality and operational stability should be taken into account.

It is optimal to choose one of the following materials.

- Leather. If we take practicality, quality, aesthetics and price-quality ratio, then leather cases are objectively the best. Only leather should be purchased specifically for cars, and not for haberdashery or furniture. These are materials that are completely different in quality and characteristics. Automotive leather has a polymer coating that additionally protects against mechanical damage, ultraviolet radiation, chemicals, oil, gasoline, etc. When selecting parameters, it is also worth choosing perforated leather without large pores;

- Eco leather. Fashionable and popular material based on polyurethane. Do not confuse with leatherette, which uses PVC. The latter does not breathe and has worse performance characteristics than eco-leather. Practical, inexpensive and easy to use. Although the skin is still a little inferior;

- Alcantara. A relatively new material that is very pleasant to the touch, does not fade, does not freeze, unlike leather, and does not crack. Don't be put off by the fact that Alcantara is thin. In fact, it is durable and wear-resistant. May cost slightly more than genuine leather. Plus, Alcantara is easier to work with and can be processed better.

Regardless of what you choose, each material is perfectly suited to the task at hand.

It doesn’t matter what kind of car you are going to sew a leather, eco-leather or Alcantara cover on.

Recommendations for covering

First of all, you need to remove the handle from the main long gearshift lever. It is the handle that we will tighten. If you wish, you can also replace the cover of the lever itself, which hides the metal pipe in the tunnel. But more on that another time.

The task is to obtain blanks. Here is an option:

- wrap the handle with cling film;

- or just use a plastic bag;

- wrap tape (stationery or masking tape) on top, but most importantly tightly;

- Use a marker to apply future markings on the tape;

- Use a sharp knife to cut the wound tape;

- you will receive something like a blank or papier-mâché;

- remove, level on the table;

- Apply the completed patterns to the purchased material for reupholstery;

- cut according to the pattern, but make leather blanks literally 2-3 mm smaller, otherwise the cover will hang;

- step back 5 mm from the edge of the leather and go through it with a sewing machine (stitch);

- return the pattern to the gearshift knob, treating the reverse side with glue;

- when the glue fixes the handle, you can start sewing together the pieces of leather;

- insert good quality threads into the stitches of the seams and tighten them tightly;

- if leather was used, wet the material after stitching is completed;

- Replace the gear diagram, if there was one.

But there is another option. It is suitable for those who like the old case's shape and seam placement, but the product is simply worn out. To do this, carefully remove the old trim from the gearshift knob.

It will be used as a template for a new case. Cut out blanks from the new material in the shape of the old cover, and sew them together in the same way. The convenience of this option is that you do not need to measure anything, make markings, etc.

IMPORTANT! The cover should be sewn from the wrong side so that the seams are not on the outside. Then the comfort of gripping the gearbox will deteriorate significantly.

I think we can end here. If you have personal experience with gearshift knob trim, be sure to write in the comments, share your secrets and highlight the important points of the procedure.

Thanks to everyone who reads us! Subscribe, ask your questions and invite your friends to join us!

( 1 ratings, average: 5.00 out of 5)

Did you like the article?

Subscribe to updates and receive articles by email!

We guarantee: no spam, only new articles once a week!

Also check out

- Remove the plastic bushings and wash off any remaining grease from the metal bushing.

- Using a ruler, set aside 1-3 millimeters from the edge of the sleeve and draw a line.

- Wrap the sleeve along the drawn line with electrical tape, grind off the excess (you can use a grinder, emery, or a powerful file).

- Reinstall the bushing and reassemble in reverse order. Apply lubricant to the required areas.

Results:

- The rattling of the handle at idle has disappeared.

- During acceleration and high speed there is no extraneous sound or vibration.

- The lever stroke became tighter.

The time spent was no more than 20 minutes, and the result is immediately noticeable.

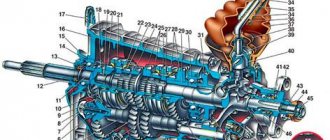

How to change the gear knob on a VAZ 2114

Replacement of the gearshift knob is required only in case of mechanical damage. More often you have to remove and install it to replace a loose cardan or repair a broken lever bushing. The sequence of actions for dismantling the lever is as follows:

- remove the handle cover to open access to the handle mount;

- remove the hatch of the decorative plastic tunnel;

- unscrew the fastening screws;

- remove the plastic tunnel;

- unscrew the lever axle nut;

- remove the axle;

- remove the lever.

To install the lever in place, you need to do the following:

- insert the lever into its original place;

- apply lubricant to the lever axis or to the inner surface of the bushing;

- insert the lever shaft and tighten the nut;

- install a decorative tunnel;

- tighten the screws securing the tunnel;

- install a decorative hatch;

- put the cover on the VAZ 2114 gearbox handle and secure it.

Why change the cover on the gearshift lever?

The reasons for replacement are not only aesthetic. Due to a torn or damaged cover, dirt and dust get onto the backstage parts, which subsequently leads to the appearance of creaks and backlashes. And loosening of the speed switch drive leads to breakage of the plastic parts under the cover. The boot itself can be made of artificial leather or leather, but in any case, over time it will lose its presentation and properties. You can change a worn cover on the gear lever either at a service station or on your own, following certain instructions.

For cheaper models made of leatherette, wear occurs after an average of 50,000 km, for leather - from 150,000 km.

How to eliminate the rattling of the VAZ 2114 gearbox handle

Often, the VAZ 2114 gear knob resonates with the operation of the engine and makes an unpleasant rattling sound due to the following problems with the bushing:

- wear of plastic bushing inserts;

- discrepancy between the length of the sleeve and the dimensions of the fork.

In the first case, you will have to change the plastic inserts or the bushing assembly. In the second, you will have to bring the dimensions into line. To do this you will need a file, electrical tape and a vice. Often the manufacturer installs a bushing, which with its edges touches the traction fork (stage) and knocks on it when it vibrates. To get rid of noise, you need to do the following:

- unscrew the bushing fastening;

- remove the bushing;

- clean (wash with kerosene) the bushing from any remaining lubricant;

- make preliminary markings by drawing a line 1-3 millimeters from the edge of the sleeve;

- wrap the sleeve with electrical tape along the marking line, leaving the edge open;

- Clamp the bushing in a vice and use a file to file off the edge protruding from the electrical tape.

After such an operation, all that remains is to put on the plastic inserts and put the gearshift knob in place. The edges of the bushing will no longer touch the metal fork and the VAZ 2114 gear knob will stop rattling.

Eliminating rattling

Some people don’t even realize that eliminating the rattling of the gearbox lever in a VAZ 2110 is a completely feasible task, and does not even require special skills. Replacing the VAZ 2110 generator bearing and its. Release the shift knob from the cover in the cabin; Gearbox VAZ 2110. Can be replaced. Of course, you will have to tinker a little, but then being in the car will become much more pleasant. We also remember: what helps one car may not be useful for another car. Therefore, we experiment.