Yaromir Romanov/ Znak.com The applicant challenged the provisions of paragraph 2 of part 1 of Article 446 of the Civil Procedure Code (CCP) of the Russian Federation and paragraph 3 of Article 21325 of the Federal Law “On Insolvency (Bankruptcy)”.

In 1999, Ivan Revkov lent money to a friend, who did not repay the loan. He went to court for recovery, but enforcement proceedings did not produce results. Over the years of waiting, the amount of debt was indexed and increased to 4 million rubles. In the meantime, the debtor purchased an apartment with an area of more than 110 square meters. m. and declared herself bankrupt. Revkov insisted on the sale of this property, purchased after the initiation of enforcement proceedings.

The courts, however, denied him on the basis of Article 446 of the Code of Civil Procedure of the Russian Federation, which prohibits foreclosure on the only home of the debtor and his family members.

However, as the Constitutional Court considered, “executive immunity in relation to the only home of a debtor-citizen, although justified, cannot be unconditional and requires legislative adjustments.” The contested norm of the Code of Civil Procedure of the Russian Federation will no longer be the basis for a complete ban on the seizure of debtors’ housing if the court considers it unjustified to apply this executive immunity, including in cases of bankruptcy of citizens.

It is still up to the legislature to determine exemptions, but until these decisions are made, refusal to apply executive immunity is possible subject to a number of conditions. In particular, the debtor cannot be left without a home, and the area should not be less than

Source

Synchronizers or clutch?

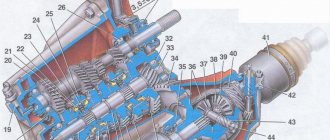

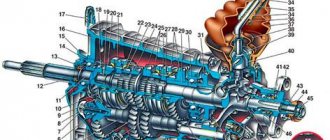

In the design of a manual transmission, synchronizers are necessary to equalize the rotation speed of the input shaft and the selectable gear mounted on the secondary shaft.

The hub is rigidly connected to the gearbox output shaft, while the helical gear of each gear rotates freely on the shaft. When changing gears, the sliding clutch moves, locking together a pair of hub and helical gear corresponding to the desired gear. Since the speed of rotation of the hub and gear will be different when moving to a higher/lower stage, synchronizers are needed for smooth and silent shifting.

In the design of a synchronized manual transmission, the clutch, when moving, presses the locking ring against the synchronizer cone. Due to the high friction force between the cone and ring, the speed of the output shaft and the helical gear are equalized. The sliding clutch then seamlessly engages the gear with the output shaft hub.

If the synchronizer malfunctions, due to different rotation speeds of the input shaft and gear on the secondary shaft, rigid engagement occurs, accompanied by a characteristic roar/crunch.

You can distinguish a synchronizer malfunction from a clutch failure by the frequency of sounds. If the problem is in the release drive or the clutch basket itself, then the gearbox crunches with every shift. In the case of burnt or worn synchronizers, the sound appears when changing to a specific gear. For example, on front-wheel drive VAZ cars, due to a design flaw in the domestic manual transmission, a characteristic roar most often occurs when switching from 1st to 2nd gear.

After disengaging the gear, release and then depress the clutch again before engaging the next gear. If after double squeezing the gears shift softer, the problem is clearly in the synchronizer.

Gear shift knob, or what is the design of the system?

A feature of all manual gearboxes is the need to manually operate the lever. We can assume that it is precisely this that performs the most important function in determining the speed limit of your movement. This means that without it, driving a vehicle becomes simply impossible. The principle of operation of the lever is quite simple: by tilting it in the longitudinal and transverse directions, you set it to a position that corresponds to a certain speed.

The gear shift lever handle is connected to the synchronizer via a fork, the position of which transmits information about the number of the selected speed. The synchronizer sets the gears of the gearbox so that the generated engine power allows the car to move at a given speed. When the position of the lever corresponds to neutral gear, it is held in place by springs. The gear shift pattern is often depicted on the head of the lever.

The gearbox is stuck, what to do?

Each car consists of many systems and mechanisms. During operation, there are frequent cases of failure of one or another system or mechanism.

Every breakdown does not bring anything good, but one of the most unpleasant is such a thing as a jammed gearbox.

This malfunction happens to all cars, both front- and rear-wheel drive.

There are several types of gearbox jams. The first is a complete jamming of the gearbox, in which the drive wheels are blocked. There are cases when the box jams when any gear is engaged. Moreover, turning off this transmission is impossible.

How can the gear shift lever be positioned?

The location of the gearbox levers can be either floor-mounted or steering column mounted. And despite the fact that the latter is considered more convenient to use, nevertheless, in most cases, car manufacturers prefer the first option. This is due to some disadvantages of the steering column arrangement, including: low speed and clarity, the likelihood of incomplete gear engagement, the rods wear out much faster, sometimes they can jam, as well as “knocking out” the gear.

But in both cases, the design of the gear shift lever remains the same. The only differences can be in length, and if previously it could reach even 30 cm, today manufacturers strive to make it as small as possible, eliminating too much travel of the gear lever. Therefore, with a floor arrangement, nothing will change significantly in the design, but there will be noticeably fewer breakdowns.

Full jam

If the transmission is stuck on the road, there are several ways to deliver the car to the repair site. In the first case, when the gearbox is jammed along with the drive wheels, you can turn to the services of a tow truck.

Owners of rear-wheel drive cars can also have their car towed, but to do this they need to unlock the drive wheels. This can be done quite simply.

You just need to lift the rear of the car and unscrew the bolts securing the propeller shaft from the rear axle, thereby disconnecting the axle from the jammed gearbox.

It is important that after disconnecting the driveshaft, securely fix it in a suspended state.

Owners of front-wheel drive cars are less fortunate in this regard; they will not be able to unlock the drive wheels. A car can only be delivered by partially or completely loading the car onto a tow truck.

Hydraulic and power regulator levers

Three distributor spool switch handles 27,28,29 are located on the right side of the control panel near the tractor windshield. Each lever has four positions. The levers are constantly in a neutral position, in which the working fluid supplied by the pump to the spools is passed into the drain cavity, and the working cavities of the hydraulic cylinders are locked by the spool and are in a fixed position. Moving the lever up corresponds to the “Lift” command - the spool opens the flow of oil into the cavities of the hydraulic cylinders for lifting. The first lower position corresponds to the “Lower” command. The second extreme position corresponds to the “Floating” hydraulic operating mode. The far right lever 29 of the standard distributor controls the hydraulic cylinder of the rear linkage, two free ones are intended for connecting additional equipment mounted with the tractor. On tractors equipped with a hydraulic increaser of the grip weight of the GSV , its control handle was located in addition to the three hydraulic distributor levers.

On the right side of the seat, on the same panel with the manual fuel supply handle, there is a position lock for the handle 43 of the power regulator and a lever for the regulator itself 45 . The rearmost position of the power regulator lever is “raising the implement” when lifting, hold the handle with your hand. After lifting, the handle is released - it moves and is fixed in the “transport neutral” position. The intermediate position forward from the “transport neutral” is the “regulatory zone”. The extreme forward position is “forced lowering”. After lowering is completed, the handle automatically positions itself at the beginning of the control zone. The flywheel of the position regulator switching valve 52 is located under the driver’s seat and has three positions: the right position – “position control”; left – “power regulation”; medium – “off”. Handwheel 53 adjusts the correction speed of the power regulator. At the base of the driver's seat, closer to the right side, there is a leash 40 for controlling the fixation of the hitch in the transport position.

Box jamming in gear

If the gearbox is jammed while any gear is engaged, then there are two options for getting out of this situation.

You can try to fix the problem right on the road or continue driving in gear to the repair site.

The fact is that there are cases when, when the gear is abruptly engaged, the lever can jump out of the groove of the slider and in this case it is impossible to return the slider to its original position with the lever.

In rear-wheel drive cars, since the gearbox is located directly in the passenger compartment tunnel, it is possible to remove the lever and make sure whether the cause of the malfunction is the lever jumping out of the slider groove.

Moreover, with the lever removed, it is possible to return the slider to its original position using a powerful screwdriver.

For front-wheel drive cars, everything is somewhat more complicated, since the force from the lever to the sliders is transmitted through a rod system.

In these cars, when jamming in one of the gears, first of all you need to check the fastening of the rods. It is quite possible that the fastening between the rods has become loose and the force applied to return the slider to its original position is not transmitted by the rods.

In any case, if the gearbox is stuck in gear, you should check the gear shift mechanism. Very often this is where the problem lies.

If the mechanism is in order, it means that the problem is inside the gearbox, and it will not be possible to restore the operation of the gearbox in the field. To do this, the car will need to be delivered to a service station or garage.

What to do if the car is stuck

If your car is stuck, you shouldn’t panic and press hard on the gas pedal. You should get out of it and assess the situation. The scheme of further actions is determined by the specific situation and location of the incident.

Car stuck in mud:

- use shovels to remove dirt film, clearing is carried out in front of or behind the machine;

- a forceful technique in the form of pushing is suitable if there is a passenger;

- rocking is used if there are no available means; It is assumed that the gear is engaged, smooth pressure on the gas, periodic engagement and disengagement of the clutch; when the car swings strongly, you should try to get out of the trap;

- a jack is a reliable assistant that is installed on solid ground or a special support; When lifting the wheels, they place branches and stones under them, which creates conditions for driving off.

The car got stuck in the snow:

- rocking is the most effective method in this situation; for front-wheel drive models, turning the steering wheel to exit is performed when the forward gear is engaged, and for rear-wheel drive models, use the rear and handbrake;

- sand, salt, glass cleaner - substances that corrode the ice under the wheels, making it easier to drive out.

The car cannot drive out of the sand:

- it is recommended to reduce the pressure in the wheels, increasing the area of contact with the base, attempts to release are carried out without sudden movements, it is important to avoid slipping;

- pneumatic cushion - the car is left on the handbrake, the space under the bottom is cleared, the cushion is installed, the hose is attached to the exhaust pipe; the body is raised, allowing you to place branches and stones under the wheels for driving off.

When thinking about how to pull a car out alone, it is worth remembering that if attempts do not yield results, you will need the help of a towing service or passing cars.

Reasons for complete jamming

There are not so many reasons for a complete jamming of the gearbox. One of these reasons is the destruction of the teeth of a gear. Broken tooth fragments can become meshed with the teeth of other gears, which in turn makes the gears unable to rotate.

It is also possible that one of the internal bolts of the box may rupture or spontaneously unscrew. In this case, the bolt gets between the gears and blocks them.

To check whether the cause of jamming is the destruction that occurred inside the box, simply drain the oil from the box crankcase and check it. The fact is that if any element of the box is destroyed, a large amount of metal shavings will get into the oil.

Transmission controls

In addition to the speed shift levers and the clutch release pedal, additional transmission controls include:

- 41 engagement handle for MTZ 82, which is located on the right side of the seat

- In the case of the steering control with HPS, for short-term forced locking of the rear axle differential, a lock 5

- In the configuration of the tractor with power steering, to control the locking of the rear axle, there is a handle for switching 3 in automatic operating mode, installed on the tractor control panel

The auto-locking handle has two locking positions: the extreme position is “locking off”; middle position - “automatic locking mode is on.” The extreme clockwise position "forced locking" when released is released under the action of a spring.

If the tractor is equipped with a speed reducer, the engagement rod is brought out to the cabin field on the left side, in the same place where the engagement rod is routed in the case of installing a side PTO gearbox.

How to remove the gear knob?

I searched and found nothing but the answer that it cannot be removed!

How to remove it? I want to cover it with leather. The steering wheel has already been retightened, but its original one.

Removing the automatic transmission handle

on page 3, message 66

Removing the manual transmission handle

on the first page below

Last edited by Alexan; 12/23/2015 at 19:10.

z18XER AT Station Wagon (AH) CHIP tuning done 07/26/2016 returned STOCK!

Well then, another answer: “it’s not removable!” I was puzzled by this myself! My handle became worn and stretched, and cracks appeared around the top cap! I looked at it both in the program and at the showdown (I was thinking about buying a used one, upholstering it and installing it right away)! Can't be removed. Comes with the rod (link) and the entire mechanism!

Yes, I also heard somewhere that it was written there.

Well, in general, I read at some Opel club that a girl’s manual transmission knob fell off in order to get to the service center, her husband beat it with his fist, and then the dealer’s car service center could not remove it. I decided to try it. Everything is filmed! This is the technology. We remove the “stick” itself from the wings. To do this, look at the very bottom of the “stick”, under the upper leather cover. Down there the “stick” is held in a ball joint. It is below the ball with the slide. Two latches are visible on the right and left. They need to be pressed out and the lower ball joint can be pulled up, along with the “stick”. Don't be alarmed. It crawls through the curtain. In your hands you have a “stick” with a knob with a reverse stop and half a connection with the slide. Now we remove the knob. We clamp the free section of the “stick” in a vice. It turns out to clamp the handles near the knob. We insert two plates into a small gap between the yews and the knob. I took two files and pulled the knob together like a lever. It sits tightly, just on the notch at the end of the “stick”. Now a shiny ring with a leather case attached. The white ring under the case is simply snapped onto the knob along with the shiny one. And a cover is sandwiched between them. It is better to pull it (the cover) out of this clamp with force. Then carefully use a small screwdriver to pry the white ring down. Actually, I did the opposite. He pulled the cover off the car, pulled off the ring, trimmed the cover along the seam and removed it through the knob. And only then, having freaked out this morning, he began to tear the handle. But I guessed that there were two latches down there. I snapped them off. I took the whole thing off and then removed the knob of the handle!

All. Thanks to all. If my experience is useful to anyone, I will be glad.

Controls for individual tractor components

To activate the tractor compressor, a flywheel with an arrow is placed on its body. When an arrow is indicated on the flywheel, “forward” corresponds to the off position, “backward” to the on position. Switching on is carried out with the engine turned off or at minimum diesel speed.

The hydraulic pump of the hydraulic system is turned on by a lever located on the right side of the tractor in the upper part of the housing of the intermediate part of the transmission. The position of the leash up corresponds to the on position, down - to the off position.

The engine radiator shutter is controlled by handle 4 , located in the cockpit on the control panel on the left side.

On the left side of the tractor, with the starting engine installed, there is a handle for engaging the bendex clutch for engagement with the diesel flywheel. For convenience, this lever can be pulled out into the driver's cabin.