01/24/2022 20,692 Transmission

Author: Victor

In any car, the gearbox is one of the main units. And if we are talking about KamAZ, then it is also a complex device. This material will help you understand the design features, as well as how to change gears on a KamAZ and what not to do.

[Hide]

Content

User manual

- Controls, cab equipment and instrumentation

- Vehicle operation

- Operating a vehicle in cold weather

Maintenance

- General Maintenance Information

- List of vehicle maintenance operations

- Maintenance of vehicle systems, components and assemblies

Engine

- Power unit

- Removing and installing the engine

- Engine repair

- Engine lubrication system

- Cooling system

- Supply system

- Air intake and exhaust system

- Possible engine malfunctions and ways to eliminate them

Clutch

- Hydraulic clutch

- Clutch

- Possible clutch malfunctions and ways to eliminate them

Transmission

- Removing and installing the gearbox

- Gearbox repair

- Dimensions and permissible wear of gearbox parts

- Possible gearbox malfunctions and ways to eliminate them

Transfer case and power take-off

Cardan transmission

- Cardan transmission

- Repair of cardan shafts

Drive axles

- Drive axles

- Removing and installing the front axle

- Removing and installing the intermediate bridge

- Removing and installing the rear axle

- Removing and installing the front axle gearbox

- Removing and installing the intermediate axle gearbox

- Removing and installing the rear axle gearbox

- Repair of drive axles

- Dimensions and permissible wear of drive axle parts

- Possible malfunctions of drive axles and ways to eliminate them

Front axle, wheels and tires

- Front axle, wheels and tires

- Removing and installing the front axle of the car

- Repair of front axle components

- Spare wheel

- Removing the front wheels

- Removing the wheels of the intermediate and rear axles

- Wheel disassembly and tire installation

- Possible malfunctions of wheels and front axle and ways to eliminate them

Suspension

- Suspension

- Removing and installing the front spring

- Removing and installing rear spring

- Suspension repair

Steering

- Removing and installing the steering mechanism

- Disassembling and checking the steering mechanism

- Removing and installing the power steering pump

- Steering mechanism repair

- Possible malfunctions of the steering system and ways to eliminate them

Brake system

- Brake system

- Brake equipment repair

- Possible malfunctions of the pneumatic drive of brake mechanisms and ways to eliminate them

Frame and fifth wheel

- Frame and fifth wheel

- Frame repair

- Towbar repair

- Fifth wheel coupling repair

- Winch repair

- Possible frame malfunctions and ways to eliminate them

Cabin

- Cabin

- Anti-corrosion treatment

- Removing the cabin

- Removing the front cab supports

- Removing and installing doors

- Removing the hatch cover of the inner door panel

- Removing the door lock

- Removing the window regulator

- Removing the roll-down door glass

- Adjusting and removing the rotary window

- Removing and installing windshields and rear windows

- Installing the Roof Vent Cover

- Removing and installing heater components

- Removing and installing seats

- Removing and installing cabin upholstery

- Removing the instrument panel

- Front fender repair

- Installing seat belts

- Possible malfunctions of the cab raising and lowering system and spare wheel and how to eliminate them

- Possible malfunctions of windshield wipers and door locks and how to eliminate them

Platform

- Tractor vehicle platform

- KamAZ-55111 dump truck platform

- KamAZ-55102 dump truck platform

Electrical equipment

- Electrical equipment

- Functional electrical diagrams

- Generator

- Starter

- Accumulator battery

- Cold starting system

- Preheater

- Lighting system

- Instrumentation

- Sound alarm system

- Switching equipment

- Electrical wires, fuses

Applications

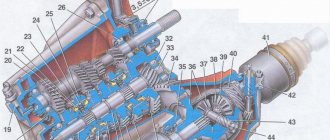

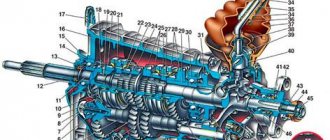

Kamaz gearbox device

Gearshift rocker: purpose, device, adjustment of the gearbox rocker

For KAMAZ vehicles, two types of gearboxes are produced:

- Model 14 - 5-speed;

- Model 15 - 10-speed.

The 14th model is for single vehicles, the 15th is for a road train.

The 15th model of the KAMAZ gearbox, in which 10 gear shift speeds are the same five-speed gearbox of the 14th model plus a gear divider. The design of the rear axle gearbox of a passenger car differs from the design of the divider gearbox. The design of the gearbox-divider together with the gearbox of model 14 creates 10 forward speeds and 2 reverse speeds.

Pros of boxes with a divider:

- The switching frequency becomes lower. You have to switch less often.

- The thrust of the internal combustion engine of the car increases.

- Ease of control increases.

Since KAMAZ vehicles are classified by purpose, that is, for transporting heavy loads, for such models the automobile plant made 14 modernized models out of the box, which is called KPP 152.

What improvements have been made to the old 5-speed gearbox:

- Synchronizers have become more reinforced.

- A new gear mount was added to the design.

- To avoid the 4th and 5th speeds slipping out, which happens with conventional KAMAZ gearboxes, 4 degrees were added to the system to thin the teeth.

- The gearbox splines have also become more reinforced.

- The control scheme has been improved.

- The spline mount has been removed.

- The height of the teeth has been increased.

The divider receives the load from the pneumatic system and is controlled by it. In new KamAZ vehicles the design is more complex, so it is advisable to repair the gearbox and divider in specialized service stations.

This is interesting: The main breakdowns of KamAZ gearboxes and how to repair them yourself - we explain the question

ZF gearbox repair

Before starting repairs, it is necessary to carry out diagnostics. To do this, you need to set the error code, correlate it with the type of malfunction and its possible cause. In some cases, you can fix the problem yourself, but since the gearbox is a complex device, it is better to entrust the repair to professionals.

In order to repair the transmission, you must first disassemble the gearbox:

- Remove the gear shift assembly: unscrew the M8 screws from the shift housing, remove the housing and seals, remove the thrust plate and spring

- Remove the bearing mounting flange: loosen the mounting screws, remove the flanges and seals

- Disassembling the shafts and rods: unscrew the plugs with the seal, remove the springs and pins from the crankcase, remove the screws around the perimeter of the crankcase. Loosen the locknut on the PTO flange. Pull out the needle bearings and the central control shaft. Remove the output shaft and gear shift forks.

In the process, you can reassemble parts, replace seals, strengthen connections, and replace worn screws. It is also necessary to remove any oil residue.

Based on the fault code, you can find out repair recommendations, for example, if there is a short circuit in the clutch pressure regulator, then you need to check all cables and connections; if a cable is pinched somewhere or there is a break, then this section needs to be changed.

In addition to electronics, transmission malfunctions very often occur, in particular, the synchronizer breaks down. In such cases it must be changed.

Rules for shifting gearboxes in different conditions

Gearbox device

Knowing how to start and how to continue moving is not enough for the correct operation of the KAMAZ transmission. To avoid problems with the unit when using the gearbox, you must follow the rules. Errors made during operation can lead to serious malfunctions.

On the rise

How to change gears on a KamAZ when driving uphill

Driving a domestic truck when lifting must be done at increased speed. To switch from first to second speed, the driver needs to depress the clutch twice. Consider the fact that you must simultaneously press the gas pedal and the fuel pedal. These actions are important as they help stabilize the overall performance of the crankshaft. To avoid problems with the operation of the unit, you do not need to reduce the engine speed to less than two thousand when climbing. This will cause the car engine to turn off. Also, such driving increases the operating temperature of the power unit, and this can cause its breakdown.

When driving a car using this principle, you can achieve maximum directional stability. Thanks to the principle of dividing the transmission circuit into two modes, easier engine operation is achieved. Moreover, regardless of whether the car is loaded or not.

On the descent

If you are driving downhill, you do not need to turn off the engine. When the engine is turned off, the steering wheel will lock. And this will lead to an emergency on the road. When driving downhill, do not turn off the auxiliary braking, and also depress the clutch pedal all the way. Newer versions of trucks use improved transmissions, which has allowed engineers to reduce the load on the main gearbox parts. Therefore, when driving in critical conditions and on descents, the car’s engine will not wear out.

KamAZ vehicles use a double-boost braking system. That is, in addition to braking by the power unit, there is an additional engine stopping system. If you are driving downhill with active auxiliary braking, then you cannot disengage the clutch and change gears.

Schemes of the main and transfer cases on KamAZ

Icy areas

Driving a truck on icy areas should be done with the greatest reserve of speed and travel. When braking, use the active brake assist system. If emergency braking occurs, the driver must stop the trailer wheels. If you do not take this point into account, you will end up in a skid. It is recommended to slow down with the power unit only in exceptional cases. Because this leads to accelerated engine wear, but the braking distance is significantly reduced. When braking, do not allow the wheels to slip. To avoid this, you need to turn off the reduced speed in time, this will lead to a drop in crankshaft speed.

Skid

When skidding, follow the main rule - do not squeeze the clutch, otherwise this will worsen the situation. During the production of cars, engineers introduced a scheme due to which the car can drive with the greatest power reserve. Thanks to this, you can achieve course stabilization while driving on any road. If a skid occurs while driving, the steering wheel of the car must be turned in its direction. That is, if the car skids to the left, then the steering wheel also turns to the left.

If the truck begins to slip, then you need to stop moving as quickly as possible and immediately disable the differential axle. You can see the switch to turn it off on the dashboard. When the differential axle is disengaged, a corresponding indicator will appear on the instrument panel. After this, the start of movement is carried out at increased speed, from second gear. When you drive through a hard-to-reach section of the road, do not forget to engage the differential (video shot and published by Vladimir Nikonov).

Loading …

What you need to know about the transmission

The machine transmission consists of the following parts and components:

- power point;

- gear box;

- block for engaging reverse gear;

- three-shaft crankcase;

- unit protective cover.

The type and design of the gearbox directly depends on the truck model. At the moment, most cars are equipped with a five-speed manual transmission. The transmission can have a gearbox with 10 gears. 5-speed gearboxes are mainly used on KamAZ trucks, which are operated as individual trucks. 10-speed ones are relevant for huge road trains transporting impressive loads.

KamAZ models on which these two types of boxes are installed:

- 55111;

- 43118;

- 4308;

- 5490;

- 5511;

- 53229;

- 53212;

- 53205;

- 53114;

- 65115 and many others.

The ten-speed gearbox has increased power. It was developed specifically for vehicles that are operated in difficult conditions, for example, on unsuitable ground for driving, mountainous terrain, and transporting large and massive loads.

The main design feature of this box is the appearance of a gearbox that allows operation in two modes, specifically low and high. It has an improved synchronizer. The power of the transmission has increased significantly due to the mode divider. It is necessary to reduce the load on the engine, which has a positive effect on its performance and efficiency.

When driving in light mode, the divider lever must be in the lowered position. If you intend to drive with a load, it must be placed in a raised state.

Regardless of the type of gear engaged - both low and high speed, the use of the clutch system is mandatory. The driver operates it using the appropriate pedal in the cabin.

Gearbox control

Repair of the gearshift mechanism of the Niva Chevrolet

Shift gears in the gearbox using the gear lever located to the right of the driver's seat. Change gears with the clutch disengaged. Press the clutch pedal all the way. Engage and shift gears at minimum idle speed. Start driving only from first gear (to avoid premature clutch failure). To quickly accelerate the vehicle on good roads and in difficult conditions, it is recommended to use all gears sequentially according to gear shift patterns. In cars with a cable drive to control the gear shift mechanism, a gearbox with a servo shift is used. The servo shift is used to facilitate gear shifting; air is supplied to it from the car's pneumatic system.

Attention! Do not change gears until the operating pressure in the pneumatic drive is reached (from 6.5 to 8.0 kgf/cm 2 ) to avoid cable breakage due to the servo shift not developing the required force. If the gearbox has a divider, a gear divider control switch is mounted in the gearshift lever handle (see

rice. Gear shift lever). The switch can be used to select the highest “B” or lowest “H” gear in the divider. It is recommended to use the entire range of low and high gears. To switch from a higher gear to a lower one, and vice versa (without shifting the lever), you need to move the gear divider control switch to the desired position, and then press and release the clutch pedal after a short (1 second) delay - the gear will engage automatically. To simultaneously shift the lever and engage a higher or lower gear, set the divider control switch to the “B” or “H” position, press the clutch pedal and shift the lever

If there is a divider in the gearbox, a gear divider control switch is mounted in the gear shift lever handle (see Fig. Gear shift lever). The switch can be used to select the highest “B” or lowest “H” gear in the divider. It is recommended to use the entire range of low and high gears. To switch from a higher gear to a lower one, and vice versa (without shifting the lever), you need to move the gear divider control switch to the desired position, and then press and release the clutch pedal after a short (1 second) delay - the gear will engage automatically. To simultaneously shift the lever and engage a higher or lower gear, set the divider control switch to the “B” or “H” position, press the clutch pedal and shift the lever.

Gear shift lever

For gearboxes of models 144, 154, shift gears according to the diagrams (see Fig. Gear shift diagram in a model 144 gearbox and Gear shift diagram in a model 154 gearbox).

Shift diagram for a 144 transmission

Shift diagram for a 154 transmission

For the ZF 9S1310 model gearbox, shift gears according to the diagram (see Fig. Gear shift diagram in the ZF 9S1310 model gearbox):

- 1-2-3-4-lower gears (lowest range of multiplier);

- 5-6-7-8-high gears (highest range of range).

When slowing down, change gears only sequentially: 8-7-6-5-4-3-2-1. Always keep the gear engaged when driving.

Gear shift diagram in the gearbox model ZF 9S1310

Low gear “C” is intended for starting in difficult road conditions and for maneuvering.

Attention! For gearboxes it is strictly prohibited:

- switch from the highest range of the multiplier to the lower range of the multiplier at a speed of more than 30 km/h (for ZF gearboxes);

- move with the gear shift lever in neutral position;

- engage reverse gear (R) when the vehicle is not completely stopped and when the clutch plate is rotating.

Gear shifting in the multiplier occurs automatically: the highest gear is engaged when the gearbox control lever moves from the fourth to the fifth position, the lowest gear is engaged when switching from fifth to fourth. When the lever is moved through the “◊” position, the valve is activated, providing automatic switching of the range multiplier. When the low range is turned on in the range multiplier, the warning lamp lights up on the instrument panel

Description of the boxes used

The gear shift pattern directly depends on the type of transmission installed on the KamAZ vehicle. Most of the machines used use a box with five forward speeds and one reverse; this is a model with index 14. The mechanism is relevant if there is no need to tow a trailer, or the cargo being transported weighs less than 10 tons.

Equipment used for transporting large loads, or participating in road trains, uses a transmission marked 15. In this case, you need to know how to drive a KamAZ dump truck, since the gearbox includes a gearbox. This is the same 14 transmission with five forward and one reverse gears. The divider, if necessary, includes lower speed ranges, as a result, the car has twice as many gears.

The gearbox used is index 16, with eight mechanical speeds. A four-stage gearbox and a low gear are provided. ZF gearboxes are also installed, which are equipped with nine gears and an auxiliary reduction stage.

Regardless of the transmission model, the gearbox is of a mechanical type, control is carried out using the clutch pedal. The switching takes place in stages, taking into account the lower and higher modes. The lever on the rocker handle is responsible for switching modes. When creating, it was taken into account that KamAZ is a heavy vehicle, which when loaded requires a reduction in force. Conversely, if you drive with an empty body, this will not lead to overheating and fuel consumption.

Gearbox and transfer case control

Gears in the gearbox

shift using the gear shift lever located to the right of the driver's seat.

Shift the lever with the clutch disengaged.

Press the clutch pedal sharply and fully. Change gears at minimum idle speed.

Start driving only from first gear (to avoid premature clutch failure).

To quickly accelerate a KamAZ vehicle on good roads and in difficult conditions, it is recommended to use all gears sequentially according to gear shift patterns.

For gearboxes

models 142, 144, 152, 154: Shift gears according to the diagram (see Fig. Gear shift diagram I).

It is recommended to use the entire range of low and high gears.

To switch from the highest “B” gear to the lowest “H” and vice versa (without shifting the lever), it is necessary to move the gear divider control switch to the desired position (see Fig. Gear shift diagram I) (on a car with a gearbox of models 142, 144 without there is no divider), and then press and release the clutch pedal after a short (1s) delay - the gear will engage automatically.

To simultaneously shift the lever and engage a higher or lower gear, set the divider control switch to the “B” or “H” position, press the clutch pedal and shift the lever.

Gear shift pattern I

For the model 152 gearbox with the possibility of using a power take-off box on the top hatch and on the flywheel housing, change gears according to the diagram (see Fig. Gear shift diagram II).

Gear shift pattern II

For gearboxes of models ZF - 9S109 and ZF - 9S1310, shift gears according to the diagram (see Fig. Gear shift diagram in the gearbox of models ZF-9S109 and ZF-9S1310):

- 1-2-3-4-lower gears (lowest range of multiplier);

- 5-6-7-8-high gears (highest range of range).

When slowing down, change gears only sequentially: 8-7-6-5-4-3-2-1.

Always keep the gear engaged when driving.

Attention! For gearboxes it is strictly prohibited:

- switch from the highest range of the multiplier to the lower range of the multiplier at a speed of more than 30 km/h (for gearboxes of ZF models);

- move with the gear shift lever in neutral position;

- engage reverse gear when the vehicle is not completely stopped and when the clutch disc is rotating.

Gear shifting in the multiplier occurs automatically: the highest gear is engaged when the gearbox control lever moves from the fourth to the fifth position, the lowest gear is engaged when switching from fifth to fourth.

Gear shift diagram in the gearbox of models ZF-9S109hZF-9S1310 C - low gear

When the low range is turned on in the demul tiplicator, the control light (orange) lights up on the instrument panel.

When the lever is moved through the “◊” position, the valve is activated, providing automatic switching of the range multiplier. When the range shifter is switched, the gear shift lever rod of the main box is blocked, and a force is felt on the lever, after which it is recommended to wait 1-1.5 s to ensure the gear shift in the range shifter.

The transmissions of the ZF-9S109 and ZF-9S1310 models have a low “C” gear, which is designed for starting in difficult road conditions and for maneuvering.

Transfer case

it is controlled by two pneumatic valves, the handles of which are located on an additional panel under the instrument panel.

The gear shift valve handle has three fixed positions, each of which corresponds to a transfer case gear.

- N - neutral (front, intermediate and rear axles are disabled);

- I - first (downshift) gear is engaged. At the same time, the downshift indicator lamp (color red) lights up;

- II - the second (overdrive) gear is engaged.

When driving on roads, use second gear. Engage first gear when driving along difficult sections of the road, as well as when parking the car for long periods.

You can change gears only after the car has come to a complete stop.

Engaging neutral in the transfer case while the engine is running and the gear in the gearbox is engaged is prohibited.

The valve handle for controlling the locking of the center differential of the transfer case has two fixed positions:

- blocking enabled;

- blocking is disabled.

Design and principle of operation

Let's consider the location and design of the KamAZ vehicle gearbox. KamAZ trucks are equipped with manual transmissions. They have 5 speeds. The gearbox is switched by pressing the clutch pedals and moving the gearshift lever to the desired position. Since the car is heavy, it is necessary to transfer the gearbox from one gear to another in several stages.

The principle of operation of the KamAZ gearbox is as follows: with a diesel engine it works either in high mode B or in low mode H. They were created to reduce the load on the engine of a heavy vehicle when it is full, and at the same time not force it to work too actively without load.

The design of a KamAZ gearbox with a divider is simple, but it differs depending on the model of the gearbox. Let's look at the KamAZ gearbox diagram, which is found on diesel vehicles. When driving on a flat road, you need to change gears without a clutch. The design of the KamAZ transfer case can be represented by the following formula: 1B - 2B - 3B - 4H - 4B - 5H - 5B.

Switching speeds is carried out as follows:

- First, switch the gearbox operating mode from high to low using a lever.

- Then release the clutch.

- The lever is set to the desired gear, without jumping over them, but turning everything on in order.

There are gearboxes with automatic mode switching.

How does the divider work on KamAZ?

The gearbox divider or multiplier is an additionally installed overdrive, which converts a 5-speed gearbox into a 10-speed gearbox.

The principle of its operation is as follows. The multiplier reduces the ranges between the main gears, tightening the number of gear ratios of the box and expanding them by 20-25 percent.

This modification allows you to improve such vehicle characteristics as:

- fuel efficiency;

- acceleration speed;

- traction force;

- controllability.

The mechanism is located in front of the gearbox, or slightly to the right of it, since the main unit does not experience heavy loads and does not require structural modifications. This allows you to repair and adjust the divider yourself if a malfunction occurs.

Location and order of gear shifting on KamAZ

Most cars from the Kama plant are equipped with manual gearboxes with 5 steps (with or without a divider). Gear shifting is carried out by moving the gearbox rocker with the clutch pedal pressed. But gears on trucks should not be engaged directly, but in stages. Theoretically, this reduces the load on the engine when driving with a full load, and when working with an empty body, it saves fuel.

The usual operating modes of the KamAZ gearbox are increased “B” or decreased “H”. In cars equipped with a gearbox with a multiplier, switching from mode “B” to mode “H” is carried out by lowering a special single divider lever.

It is important to know how to engage a higher gear when driving a KamAZ with a full load: experienced drivers recommend engaging the first 4 gears in the heavy secondary “H” mode, and then transferring the 4th speed to the “B” mode, switching to the 5th lower gear, and then go to “B”. The shift order may vary depending on the specific gearbox model.

Hill climb control

Driving up a slope is accompanied by the gearbox switching to a lower mode (H). This makes the transmission work harder and overcome obstacles more easily.

- When lifting heavy equipment, shifting from first to second gear is carried out using the double clutch method;

- To ensure the operation of the power plant, depress the gas pedal to prevent an interruption in the fuel supply;

- The crankshaft speed readings do not fall below 2000 min-1, otherwise the power plant will overheat and stop working.

KamAZ, control on an icy road:

Choosing the correct gear shift mode is an aspect of the normal operation of the car, on which the performance of the power plant, as well as the components and mechanisms of the unit, depends.

Start of movement and maneuverability

The Kamaz power take-off is a complex mechanism that should be closely monitored during operation. It will be difficult for you to shift if even a small part has failed, and it can also lead to more serious damage to your vehicle. The Kamaz gearbox diagram will be extremely clear to anyone who understands this area, but it may no longer be possible to cope with the problem alone, due to the significant size of the vehicle.

Checkpoint diagram

It is imperative to start from the lowest gear.

Shift gears only with the clutch released, this is exactly what the Kamaz model 5320 gearbox requires. The transfer case can easily withstand loads, so you should not be afraid for its condition when moving correctly; its tense state is a normal operating mode.

Repair of the Kamaz gearbox is not required if you follow all the instructions in the work. Shift into second gear only when the number on the speedometer is at least 7000 rpm. Remember that removing a Kamaz gearbox is a very complex and costly process, so it is better to initially ensure proper control of the transfer case. It is worth noting that you can then safely switch speeds in the usual mode, reaching about three to four thousand revolutions.

Kamaz power take-offs are not very fond of sharp maneuvers. This, of course, is primarily due to the size and weight of the equipment. For more convenient movement, gears are changed by double pressing.

This gear shift scheme is designed to organize engine operation as efficiently as possible, save fuel and protect internal mechanisms.

This action may cause the steering wheel to lock and thereby severely limit the driver's ability. For your safety, you can use the additional braking device that is available in the car; it helps to brake not only the engine, but also the gearbox.

Instructions

Now we suggest you find out how to start and in what sequence to correctly engage the gears on a KAMAZ gearbox. There are certain features in this process, and the procedure for changing gears differs from passenger cars.

Start of movement

You need to know how to change gears on a KamAZ. The start of movement on KamAZ should be done at a reduced speed

Please note that when driving away, the gear shift is carried out with the clutch disengaged. In KAMAZ gearboxes, the switching scheme is carried out in several stages, this is due to the peculiarities of increasing and decreasing speeds

How to turn on the speeds on KamAZ:

- The truck can drive quickly on different types of roads, but at the first stage, in accordance with the diagram, it is recommended to start driving in gear 1B.

- After this, 2V transmission is switched on.

- At the final stage of starting from a standstill, speed 3B is switched on.

In accordance with this traffic pattern, the vehicle starts at a reduced speed. That is, the shift lever on the box does not need to be touched until fourth gear. To start moving, you need to increase the crankshaft speed to about seven thousand revolutions (the author of the video lesson on how to switch gears on a KamAZ truck is Nikita Vagin).

Switching speeds

Now we’ll tell you how the gearbox on a KamAZ is switched when the car starts moving. When the car accelerates, the gear shift order on KamAZ is as follows - 4N-4V-5N. To activate the second speed, the crankshaft speed must increase to three thousand revolutions according to the tachometer. Please note that the operation of the crankshaft plays a major role. By changing gears correctly, you can achieve savings in fuel consumption. In this case, the most economical operation of the motor without downtime will be achieved.

Reverse

As for reverse, according to the diagram, to activate it, you need to set the switch to the lower left position. Activating reverse gear is not allowed while driving. To engage reverse, stop the vehicle completely and then perform the maneuver.

How to use a divider on a Kamaz

It is necessary to skillfully combine the divider gears with the gearbox gears.

Acquiring the skills to correctly select gearboxes and dividers can significantly reduce fuel consumption, increase the average speed, create a more economical mode for engine operation, and increase the service life of the clutch, brakes, cardan transmission and drive axles. Gear shifting in the divider is carried out by moving the control valve switch installed in the head of the gear shift lever.

To change gears in the divider, the control valve switch should be moved to the upper or lower position, which corresponds to the highest or lowest gear. Press the clutch pedal all the way and hold it until the gear is fully engaged in the divider (approximately 0.6...0.8 s). When the clutch pedal is pressed all the way, the divider activation valve opens and the divider automatically switches to the selected gear. After this, smoothly release the clutch pedal.

Promotional offers based on your interests:

The control valve switch can be moved to the selected gear position in advance. After this, at the right moment, it is enough to depress the clutch pedal all the way.

When starting the car from a place, the gears in the divider are selected depending on the road conditions and vehicle load.

To accelerate the car to a speed of 10...11 m/s (30...40 km/h) (i.e. to third or fourth gear), it is enough to change the gear in the main box without changing the gear in the divider. To accelerate from third or fourth gear, it is advisable to use both gears of the divider. To do this, when accelerating in difficult road conditions, the following switching sequence is recommended: 1Н—2Н—ЗН—4Н—4В—5Н—5В, when accelerating a car on a paved road—IB—2В—ЗВ—4Н— -5Н-5В.

If during acceleration it is necessary to simultaneously change gears in the main box and the divider, then you should move the switch of the divider control valve to position H, depress the clutch pedal all the way and engage the next higher gear in the gearbox, then smoothly release the clutch pedal.

If the car is moving with the low gear of the divider engaged, and the road resistance has increased and it is necessary to simultaneously change gears in the gearbox and the divider, you should move the divider control valve switch to position B, depress the clutch pedal all the way and engage the next lower gear in the gearbox, then smoothly release the clutch pedal.

KAMAZ 4310 gearbox weight

Installation of KamAZ gearbox

How to install a synchronous divider KAMAZ

A Kamaz with a manipulator can replace several pieces of equipment.

https://youtube.com/watch?v=Zth5mrzZ6GE

Kamaz 4310 pulls Kraz out of the ditch. Russian military trucks

https://youtube.com/watch?v=oDLI8bB01Ps

Everyday life of a manipulator 2

PALFINGER-30002K (analogous to ANT-22-2) - 7200 kg loader crane, on KAMAZ-6522 chassis

https://youtube.com/watch?v=4tGoHyIyD7k

test drive LAZ 699R Tourist

neat Japanese. transporting an excavator through narrow Japanese streets.

https://youtube.com/watch?v=wvsOavM3s3o

New Kamaz 5490

https://youtube.com/watch?v=ya6syVZ_CRE

The piston came to Kamaz, repaired, replaced the piston.

- KAMAZ windshield wiper motor pinout

- Sludge sucker for 507am KAMAZ 65115

- How much oil to pour into KAMAZ 5511 axles

- Gross weight of KAMAZ 65117

- KAMAZ hydraulic cylinder retarder device

- Military jeep based on KAMAZ

- KAMAZ receiver pressure sensor

- KAMAZ gearbox width

- KAMAZ mounted spare parts

- KAMAZ Glonass in the tank

- How to check the winding of a KAMAZ generator

- KAMAZ 4310 hub repair

- KAMAZ 53102 video

- KAMAZ low quality tires

- Alteration of brakes on KAMAZ

Home » Hits » KAMAZ 4310 gearbox weight

kamaz136.ru

What operating errors can lead to gearbox failure?

KamAZ 6520 and 5460 vehicles use 16S151ZF-ECOSPLIT transmissions. The machine comes with a manual for operating such gearboxes. In practice, they often fail precisely because of improper operation. Therefore, the car owner needs to carefully study the instructions in order to comply with the requirements and avoid mistakes.

Let's look at the main mistakes that car owners make when operating the gearbox:

- When the driver changes gear, the clutch pedal must be depressed all the way. If you do not fully depress the clutch, this will result in accelerated wear of the transmission synchronizers.

- One of the main requirements is that it is prohibited to switch from higher gears to lower gears. That is, switch from 5, 6, 7 or 8 speeds to 1, 2, 3 and 4 if the vehicle speed is more than 30 km/h. Such an error will quickly lead to failure of the range synchronizer.

- If it is necessary to switch from high speed to low speed, this must be done sequentially. You cannot jump over a gear, as this will also cause destruction of the transmission synchronizers. If you need to switch to a higher speed, then such a switch is allowed.

- You cannot completely grasp the gearbox lever when switching from one speed range to another. The switching process should be carried out with an open palm.

- If it is necessary to move from neutral position I to position II, you need to use a light blow with an open palm; the clutch does not engage. This is how the range switch switches.

- When driving at neutral speed, you cannot move the selector to the right or left to search for neutral. The KAMAZ gearbox has fasteners that fix the gearbox selector in the neutral position. Moreover, they keep it between the third and fourth speeds in the lower range, and also between the fifth and sixth speeds in the higher range.

- You cannot coast downhill. The transmission oil pump rotates from the movement of the input shaft of the box. When the car is coasting, the engine is idling and the oil pump is at reduced speed. Because of this, the pressure generated by the pump will be insufficient for optimal lubrication of the bearing elements. And if there is not enough lubricant, the bearings will quickly overheat.

- It is not allowed to tow a vehicle with the driveshaft connected from the gearbox to the drive axle or transfer transmission. This refers to all-wheel drive vehicles. If this rule is not followed, the gearbox oil pump may fail due to lack of lubrication.

- When starting the engine by towing, only use high speed ranges.

- Before leaving the KamAZ in the parking lot, you need to set the gearbox selector to the left neutral position.

- Let's talk separately about the reverse gear. Its activation is possible when the car comes to a complete stop and the idle speed drops to a minimum. This is allowed 10 seconds after the clutch is disengaged.

Malfunctions and repairs

Transmission repair consists of disassembling the unit, diagnosing, repairing or replacing worn elements. After the mechanism is restored, the unit is reassembled and the system is tested in operation. You can contact a service center, but it is better to repair the transfer case yourself.

How to check the oil level

The oil level in the box is checked as follows. Unscrew the crankcase plug. When checking, you must install the crankcase indicator into the hole until it stops. The oil from the crankcase of a ten-speed manual transmission is drained through 3 holes. Of these, 2 holes are located in the lower part of the gearbox housing, and the third is located in the divider. The five-speed gearbox housing is drained through 2 holes.

Change of oil

To change the oil, you need to wash the gearbox housing with engine oil. Clean the magnetic plugs from metal particles and fill in oil to the top line of the indicator. The oil level is measured after 5 minutes. When the car is moving, the gearbox should operate without hesitation, speeds should be switched freely and locked firmly. Loud noise may indicate worn shaft bearings, insufficient oil level, or poor quality lubricant in the crankcase.

How to remove the box

Removing the gearbox is carried out as follows:

- You need to remove the driveshaft. To do this, unscrew the 4 fastening nuts.

- The PSU is being removed.

- Dismantle the starter mountings.

- Disconnect the tube that goes to the reduction gear.

- Remove the gear shift lever.

- Place a jack between the flywheel and the engine pan, and dismantle the engine through a wooden stand.

- Unscrew the rear yoke nuts and remove it.

- Dismantle the spacer rod.

- Unscrew the exhaust system bracket fastening bolts.

- Connect the hoist to the bolts and tighten it.

- Unscrew the fastening nuts to the side engine mounts.

- Unscrew the bolts that secure the gearbox to the internal combustion engine.

- Raise the hoist and move the gearbox away from the engine to the output of the transmission input shaft.

- Pull out the gearbox.

How to adjust

Now you need to adjust the gearbox and troubleshoot components and parts. If they fail, replace them with new ones. Spline connections must not have defects or chips. Gear bearings should be replaced after first inspecting the place where they are installed to see if there is any wear or areas pressed through by the rollers.

The shaft bearings are replaced because, as a result of breakage and metal shavings getting into the oil, the rolling areas of the bearings were damaged, which could cause gearbox failure. Inspect the gears, detect damage and wear of gear teeth. The conical synchronizer races must not be deformed or worn. The guide shafts should not be loose. There should be no damage to the splines.

How to assemble correctly

The gearbox is assembled in the reverse order. The intermediate shaft is installed in the gearbox housing. Mount the bearings - front roller and rear spherical. Tighten the support washer. Fix it with a nut and close the rear cover of the spherical bearing mount. Install gaskets. The shaft should rotate easily, there should be no jamming of the part when moving.

Repair diagram for KamAZ-5320 gearbox with divider

To repair the KAMAZ-152 gearbox with a divider, it must be disassembled. Analysis includes the following steps:

- To disassemble the box, you will first need to dismantle the air switch and unscrew the fasteners;

- remove the gearbox shift shaft and fork;

- the next step will be to dismantle the fork and release shaft, as well as the synchronizer;

- Next, you need to open the rear bearing cover by unscrewing the screws that first fix it;

- dismantle the bearing and shaft;

- also, to open access to the gearbox multiplier, you will need to remove the support roller washer, metal cup and driven shaft bearing;

- using a rubber (not metal) hammer or a wooden block, you must carefully remove the bearing from the multiplier housing, being careful not to crush the part;

- next you need to remove the coupling and oil injection nuts using the appropriate wrenches;

- The last stage of disassembling the unit is to dismantle the roller bearing, bushing, and gearbox drive gear.

Next, you should inspect all the parts and replace worn ones, and then assemble the device, following the above instructions in reverse order.

Switching rules under different conditions

Gear changes depend on the various conditions in which the vehicle is moving. These rules should be followed so that during the use of the gearbox it does not fail.

Climb

During an ascent, you must switch the gearbox to mode H, as a result of which the transmission will begin to operate at increased voltage.

The following rules must be followed:

- When switching from 1st to 2nd gear when ascending a KamAZ truck, you must use the method of depressing the clutch pedal twice.

- In order for the crankshaft to work correctly when changing gears, you need to use the fuel pedal; it also needs to be pressed periodically. At the same time, you can overcome any steepest climb.

- The shaft speed when lifting must be more than 2000 rpm. Otherwise, the engine may shut down, which may cause an accident while driving on the road.

- During the climb, switch to the desired mode, this will facilitate the operation of the engine and all components of the machine.

Descent

Some drivers turn off the engine when descending a mountain to save gas. This should not be allowed at KamAZ.

KamAZ braking occurs not only as a result of stopping the engine, but also by activating the auxiliary braking system. When a heavy vehicle is going downhill and the driver applies the auxiliary brakes, the clutch should not be depressed and the driver should not shift from one gear to another.

Icy areas

You need to drive a truck on icy areas with maximum speed and range. When braking, you must use the engine stop assist system. If emergency braking is required, the operator must stop the trailer wheels. If you do not take this rule into account, you may end up in a skid.

It is possible to slow down the internal combustion engine only as an exception, as this can lead to its wear. When braking, the wheels should not slip. To avoid this, you need to turn off the reduced speed, which will help reduce the rotation of the crankshaft.

Skid

When skidding, do not disengage the clutch. When the truck skids, you need to turn the steering wheel in the direction of the skid. If the KamAZ skids, you need to take your foot off the gas pedal and press the differential. This must be done using the regulator located on the panel. As a result, the indicator on the panel will turn on. You need to start the move from the second high gear. After overcoming the skid, the differential should be unlocked.

Switching Features

If a KamAZ vehicle is driving down a mountain, use high gear. The transition from 1st to 2nd speed occurs by pressing the clutch foot lever twice. The maneuver is accompanied by the addition of gas in order to smooth out the crankshaft speed. If the car goes up, the shaft speed should be 2000 min-1 or higher. Failure to follow this advice will lead to overheating, as well as to stopping and failure of the motor.

The KamAZ transmission is distinguished by its quality, reliability and directional stability during operation. Dividing the box into two modes is used to make the engine easier to move under different vehicle loads. When starting on a loaded vehicle, an increased speed is used, bringing the shaft rotation to 2600 min-1.

Shifting gears on KamAZ (ZF):

Gearbox adjustment

Adjustment of the remote drive for controlling the gear shift mechanism in transmissions of models 142, 152 is carried out with the gear shift lever in neutral position in the following order: Set screw and lock nut: 1 - lock nut, 2 - set screw Adjustment of the drive: 1 - lock nut, 2 - set screw, 3-bolt, 4 - adjusting flange, 5 - coupling bolt, 6 - rod, 7 - rod Gear ratios L - low gear in the divider, S - highest gear in the divider, R - reverse gear, C - low gear Clutch drive: 1 - dust fuse, 2 - cover, 3 - stem stop, 4 - stop (flag) of the valve stem.

Check the stroke of the gear divider lever with compressed air in the brake pneumatic drive.

For measurement: Divider mechanism: 1 - inspection hatch cover, 2, 5 - set screw, 3, 4 - lock nut.

Specifications

The KamAZ gearbox with a divider includes the following elements:

- a crankcase in which the drive, driven and intermediate shafts assembled with gears are mounted;

- bearings;

- synchronizers,

- reverse gear block,

- top cover of the box,

- gear shift mechanism.

The gearbox of KamAZ vehicles can be five- or ten-speed. The gearbox divider has high and low gears and, in combination with the main gearbox, allows for 10 forward gears and 2 reverse gears. The divider system improves the traction qualities of the machine, makes it easier to control, and reduces the frequency of shifting gears with a lever. Transmission ratios are available in the operating instructions for the device.

The 141 KamAZ gearbox has a reversing light switch. To prevent the simultaneous activation of 2 gears, there is a ball-type lock in the cover, and a spring-finger fuse is used to prevent accidental engagement of reverse gear. The gearbox with divider weighs 320 kg. The cuffs are located in the shaft covers. They protect the gearbox from clogging and prevent oil leakage. Insufficient oil volume in the gearbox leads to its damage. When you first fill the gearbox there should be 9 liters of oil, when changing the fluid - 8 liters.

Technical characteristics of the KamAZ-141 gearbox: Carter:

- The diameter of the bearing bore is 150 mm.

- The diameter of the hole in the gear block axis is 32 mm.

Main shaft:

- The diameter of the front bearing journal is 24 mm.

- Rear bearing - 59 mm.

The secondary shaft has the following diameters for the parts:

- Fourth gear gear bushings - 63 mm.

- Roller bearings - 80 mm.

- Reverse gear bushings - 70 mm.

- The outer diameter of the sleeve is 72 mm.

Intermediate shaft:

- The diameter of the front bearing journal is 65 mm, the rear one is 49 mm.

- The diameter of the rear bearing cup is 119 mm.

- The diameter of the intermediate shaft is 65 mm.

- The inner diameter of the gear is 65 mm.

The weight of the gearbox with divider is 320 kg.