Many owners of cars with an automatic transmission know what an automatic transmission selector is. Drivers who have driven a manual gearbox all their lives do not know what it is. For those who do not know what a selector is, let us explain. This is the same lever for shifting gears, but it only moves up and down. The purpose of the automatic transmission selector is to enable you to choose directions of movement or enable the desired function on the automatic transmission.

Signs of automatic transmission malfunction in the valve body

- The box only works well in cold/hot conditions. Solenoid contamination.

- The car cannot move, the reverse works. It's a valve problem.

- Transmissions are not activated. The solenoid is broken.

- Only reverse and first gear work. The valve is stuck.

- Slipping as you move uphill. Solenoid or valve body channels.

- Shocks and jerks during transmission operation. Such breakdowns can cause contamination of the valve body and broken wiring.

- The car stalls when changing to the next gear if you don't accelerate. The valve stuck, breakdowns occurred in the mechanical part of the automatic transmission.

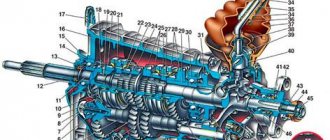

"Iron". Planetary gear, hubs and calipers. As the box and sealing elements wear, vibrations increase. Multiply this by oil starvation and you get completely non-ideal conditions for contacting metal parts. They begin to wear out, crumble, and burst. Failures in the “iron” part of the machine are typical for older machines; they rarely occur on new ones.

Planetary gear automatic transmission

Disassembling the mechanism

In order to repair the automatic transmission selector, it is necessary to disassemble it after dismantling. To do this, it is recommended to adhere to the following sequence:

- Unscrew all screws connecting the housing;

- Effortlessly separate the body into halves;

If the tracks are destroyed, it is better to replace the contact group with a new one. During disassembly, avoid getting debris and abrasive objects inside the selector. If necessary, it is recommended to put marks to facilitate subsequent assembly.

Starting a car with automatic transmission

5 convenient gear shift knobs from aliexpress

So, how to start a car with an automatic transmission? First of all, you need to start it with P or N, they turn on when you press a special button.

Better, since “Neutral” is more related to the service system, thereby separating the engine and gearbox. To start moving, you should switch to “Drive” without releasing the brake to release the lock.

Do I need to warm up my car before driving?

There is no point in warming up a car with an automatic transmission if the temperature outside is not below zero and there is no frost. When starting the engine, wait a few minutes for the oil to circulate. If the car is installed in “Parking” and turned off, then, in principle, it already runs through the oil.

It is recommended that in severe frost and the box is not heated, do not use powerful pumps to avoid damage.

How to drive with automatic transmission

How to drive an automatic car correctly for beginners and what features you might encounter?

Here's how to start an automatic car:

- Press the brake pedal.

- Remove the lever from “P”.

- Set Drive or other auxiliary gear.

- Release the gas pedal.

The car will start moving spontaneously, without pressing the gas pedal. Brake automatically The box is operated using a motor and special buttons.

Driving a car with an automatic transmission in traffic jams and traffic lights

You need to understand how automatic transmissions work. In congestion conditions, or when there is heavy traffic on the road, the engine should not be running, so turn on “Neutral”.

In neutral, the engine does not work, but the vehicle can travel about 5 km. The mode saves fuel and protects the car from repairs. At traffic lights the situation is the same, but you can use additional lanes, for example - 2, two lanes will help you move on automatically. smoothly.

Stopping on a hill using automatic transmission

- Release the brake smoothly, adjusting the speed of descent.

- You climb the climb.

- You slow down.

- Set the lever to Neutral and the engine stops running.

- Turn on Parking, ensuring safe parking of vehicles, blocking traffic.

- Take your foot off the brake and within a few seconds the car will be in the correct position.

"S" mode

Many have S installed and it denotes dynamic use. That is, an additional system where vehicles can be accelerated to a certain speed, it quickly starts and accelerates, and overtakes. Another name for it is sports.

It depends on the car model and its class; the more powerful the car, the better “Sport” works. With such a system, a large load is placed on the engine, body and the tires themselves.

Mode "E"

There are other designations for automatic. gearbox, for example, the E icon indicates an economical trip. Provides smooth, easy and quiet driving speed, thereby saving gasoline or diesel even in the cold season.

It's icy outside, and the economical dir. allows you to feel safe on the road.

Descent to automatic transmission

There are descents: sharp and protracted, but the instructions are the same for each. It is not recommended to descend using the brake pedal depressed; you can only slow down.

The operating principle is usual:

- the lever is set to “Drive”;

- the gas pedal is pressed;

- don't forget to put the handbrake down.

They use transmissions such as r. 1, r. 2. But the car does not always drive slowly on them.

How to overtake in a car with automatic transmission

Overtaking is a serious matter, you should take such a step more decisively, confidently and consciously. The box has additional modes for performing this maneuver. With them, the car drives quickly, picking up speed and confidently overtaking the nearest car.

There are certain rules under which overtaking is not allowed, but if you feel confident, then use “Sport” and quickly overtake. Please note that fuel consumption is maximum.

How to tow a car with an automatic transmission

To begin, move the lever to “Neutral”, carefully watch the car in front of you on the cable. Do not jerk the steering wheel and remember to stop every 30 minutes - this is a rule about the safety of the gearbox so that a breakdown does not occur.

The engine does not work, so no oil gets in.

How to stop moving correctly

To start moving, press the brake pedal and stop the car, then set “Parking”, which blocks movement.

Pull the handbrake on the car and release the brake, turning off the engine.

How to brake with an engine

The machine has its own nuances. They usually slow down on a slope or where you constantly have to hold the brake pedal. When braking, switch to manual, that is, r. 2 or 3.

Auto parts for foreign cars, auto repair

The whole assembly is fastened with 4 bolts, we use a key or, more conveniently, a head on it. Two cable rods go to it, the left one is on latches, the central one is a cable on a bolt, the same head, the rod braid is fixed on the body of the selector itself and is pulled up. First, remove the rods before putting the car on the handbrake.

how to disassemble the Toyota automatic transmission selector From all electrical connectors, we snap off the contacts and wiring attached to the unit body. Next, we clean the fixed contacts. We clean the cover. We lubricate the fixed contacts and the cover with cyatim lubricant, just without fanaticism, and assemble the mechanism.

Before you disassemble the contact group, you need to find the pinout of the contacts for your car, since the Toyota Crown has several connector options. Checking the gearbox's response to lever positions is only possible from inside the car. When disassembling the unit, it is necessary to check the functionality of the backlight bulbs, as they often fail.

Automatic transmission selector: repair basics

The lubricant used in the contact group has a short lifespan, so it is recommended to replace it every time the unit is disassembled. Otherwise, abrasion of the contact lamellas will occur at an accelerated rate.

Citroen C5 has contacts that are poorly resistant to corrosion, so most unit malfunctions are associated with oxidation deposits. It is recommended to clean contacts using acetone.

When choosing a lubricant, you should check for the presence of corrosion inhibitors and high dielectric properties. If a selector malfunction is detected, further operation of the car can lead to serious problems with the automatic transmission. To eliminate it, use gasoline, kerosene, WD or solvent.

It is necessary to clean with a brush, without resorting to excessive pressure that can bend the contact bars. It is recommended to use silicone lubricants as a replacement. Litol, solid oil and similar consistent materials should not be used. Moisture and small debris quickly accumulate in them.

Problems when paying with bank cards

ZIL-130 car gearbox: shift diagram

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at [email protected]

What does the PWR button on a car mean?

PWR - The program is configured to maximize the use of engine power, so upshifts occur in the area of maximum engine speed, at which the engine develops maximum power. In this case, the car accelerates with significantly greater acceleration.

Interesting materials:

How to understand 1 2 soda? How to understand 4-dimensional space? How to understand the actual residential address? How to understand Budget Accounting? How to understand that the battery is faulty? How to understand that the watch has become magnetized? How do you know if this is an artistic style? How do you understand that this is a story? How do you know if microsporia is going away? How can you tell if a newborn is cold or hot?

Troubleshooting manual transmission yourself

Types of automatic transmissions

You should immediately clarify: repairing a manual transmission yourself is a rather serious and responsible task - so if you are not confident in your abilities and are afraid of aggravating the situation, it is better to get to the nearest service center. Moreover, all work (except, perhaps, changing the oil - which we have already described above) requires special skills and equipment

For this reason, we will not describe how to fix the problem, but will simply provide a list of them - so that you know when to pay attention to the condition of the car

There are not too many main problems that actually arise more often than others:

- noise while driving and when changing speed;

- oil leakage (traces of oil remain under the car);

- difficulty changing gears;

- gear slipping to neutral speed;

- inability to switch to any gear (or all gears).

Under no circumstances should these problems be ignored (and the last point cannot be ignored at all - the car simply cannot be used).

The reasons for the occurrence of the above (and indeed any) problems with manual transmission are as follows:

- use of low-quality gearbox oil (or oil of unsuitable quality);

- use of low-quality spare parts installed during repairs;

- wear (or depletion) of spare parts;

- improper operation of the gearbox;

- use of incorrect gearbox operating modes.

What is automatic transmission and the history of its creation

Automatic transmission selector An automatic transmission, or automatic transmission, is a transmission that allows the selection of the optimal gear ratio in accordance with driving conditions without driver intervention. This ensures a good smooth ride of the car, as well as driving comfort for the driver.

Currently, there are several types of automatic transmission:

In this article, all attention will be paid to the classic slot machine.

History of invention

The basis of the automatic transmission is a planetary gearbox and a torque converter, first invented exclusively for the needs of shipbuilding in 1902 by the German engineer Hermann Fittenger. Then, in 1904, the Startevent brothers from Boston presented their version of an automatic transmission, which had two gearboxes and resembled a slightly modified mechanics.

First production GM Hydramatic automatic transmission

A car equipped with a planetary gearbox first saw the light of day under the Ford T brand. The essence of the box was smooth gear shifting using two pedals. The first included upshifts and downshifts, and the second included reverse gears.

The baton was taken up by General Motors, which released a semi-automatic transmission in the mid-1930s. The clutch was still present in the car, and the planetary mechanism was controlled by hydraulics.

Around the same time, Chrysler refined the design of the gearbox with a fluid coupling, and instead of a two-stage gearbox, overdrive was used - an overdrive gear with a gear ratio of less than one.

The world's first fully automatic transmission was created in 1940 by the same company, General Motors. The automatic transmission was a combination of a fluid coupling with a four-speed planetary gearbox with automatic hydraulic control.

Today, six-, seven-, eight- and nine-speed automatic transmissions are already known, the manufacturers of which are both automakers (KIA, Hyundai, BMW, VAG) and specialized companies (ZF, Aisin, Jatco).

Pros and cons of automatic transmission

Like any transmission, automatic transmission has both pros and cons. Let's present them in the form of a table.

| Pros of automatic transmission | Disadvantages of automatic transmission |

| 1. Smooth and automatic gear shifting, creating comfort for the driver. | 1. Complexity of the design. |

| 2. No need to periodically replace the clutch. | 2. High cost of the box itself. |

| 3. Good dynamics due to the ability to manually change speeds. | 3. High cost of its maintenance. |

| 4. The automatic transmission can adapt to the driver’s driving style (adapt). | 4. Lower efficiency and increased fuel consumption compared to mechanics. |

How to get going automatically

Getting started with an automatic is much easier than with a manual. There is no clutch pedal, which means there are no difficulties that novice drivers experience with this control. However, starting to drive a car with an automatic transmission has its own characteristics, which it is advisable to know about. You can drive without these problems, but it can no longer be called proper operation.

Algorithm:

- Make sure N or P mode is on.

- Start the engine.

- Press the brake pedal.

- Turn on D mode.

- Remove the car from the handbrake.

- Release the brake pedal.

- Smoothly press the accelerator pedal.

The car will start moving

Before pressing on the gas when starting off, pay attention to the characteristic push. It indicates that the machine is “ready” to drive.

The backward movement is performed in the same way. Only the selector is switched to R mode. When parking or in other situations where driving forward and backward is used alternately, you only need to switch modes when the car is stationary, and not while driving. Unlike driving a cold automatic, rushing in this case can actually shorten the life of the transmission. This is already a proven fact.

Varieties

There are several varieties, mainly selectors differ in the location and shape of the handle.

The boxes also differ in the method of protection against accidental mode switching.

When the lever is in the drive position, it is very important that the parking or reverse mode is not activated. This may lead to damage to the automatic transmission.

Some levers require either recessing or lifting to switch modes. In fact, the method works. While driving, when the lever is in the driving position, if it is accidentally touched, another mode will not turn on, and the automatic transmission will not be damaged.

There is another system of protection against accidental mode switching; this system allows you to change gear only after pressing the brake pedal.

Features of the location of the automatic transmission selector

Convenient placement of the device under the steering column allows you to change gears without interference. Thanks to this interior design, there is an additional opportunity to use a solid seat in front, where a third passenger can fit. Similar designs were widely used in American-made cars at the end of the last century.

Push-button selectors were actively used in cars equipped with high-slung seats. In the fifties, such selectors were very popular and were installed in automatic machines of minibuses, minivans, jeeps and other models of that time. The main manufacturers of cars with push-button selector for automatic transmissions at that time were such well-known companies as Chrysler, Honda and some Japanese brands.

Modern vehicles manufactured in Europe and Japan are most often equipped with floor-mounted automatic gearshift levers. Here, the selectors are located in the middle of the cabin between the driver's seat and the front passenger seat.

Automatic transmission device

A classic machine consists of four main components:

- Hydraulic transformer - replaces the clutch, converts and transmits torque to the wheels. Consists of a centrifugal pump, a bladed turbine and a reactor, providing smooth and precise changes in torque. The pump is connected to the crankshaft, and the turbine is connected to the gearbox shaft. Energy transformation is carried out due to fluid flows and the pressure generated by them. The torque converter changes rotation speed and torque in a small interval, so a planetary unit (box) is added to it.

- The planetary gearbox consists of a central gear (sun gear), satellites, a crown gear and a planetary carrier. Shifts gears by blocking some gears and unlocking others.

- The brake band, rear and front friction discs provide direct gear engagement.

- The control system consists of a gear pump, an oil sump, a hydraulic unit and an electronic control unit (ECU). The hydraulic unit consists of channels with solenoids (valves) and plungers that perform monitoring and control functions. The ECU carries out control using information from sensors that collect various indicators.

A robotic gearbox is a more advanced version of a manual gearbox with highly productive control systems.

In a variator, the transformation of the gear ratio is carried out by a mechanism consisting of drive and driven pulleys, through which a V-belt passes.

Range D (Drive) is the main mode for moving forward.

This mode performs automatic sequential gear shifting (in this mode, all gears are usually involved except for upshifts). This mode is recommended under normal driving conditions. Range 3 (Number 3 on some types of automatic transmission) - the first three gears are engaged while driving. This mode is active, it is great for city driving, and turns off when the ignition is turned off. Especially at high operating speeds of the automatic transmission, it will not be possible to save fuel; this mode does not allow the torque converter clutch to be repeatedly locked and unlocked in rough city driving conditions (no more than 80 km/h), and is also partially blocked when switching to higher gears. Most suitable for driving when frequent stops are inevitable and for driving on roads with ups and downs. Engine braking is possible in this mode. Range 2 (Number 2 on automatic transmission) - in this mode, driving is only allowed in second and first gear. Most suitable for use on winding mountain roads. Switching to fourth and third gear is prohibited. Range 1 (L or Low) - low gear. In this mode, driving is only allowed in first gear. The traction capabilities of the engine in this range are realized to the maximum, since the torque transmitted to the wheels only in first gear is maximum. Engine braking is especially effective in this mode. Driving on steep descents and ascents must be done in first gear.

Overdrive (O/D)

Some automatic transmissions have a mode in which automatic upshifting is possible. The O/D (Overdrive) button is used to activate this automatic transmission mode. Its recessed position when the Drive mode is on allows you to switch to a higher gear. If you release this button, switching to the last gear will again become impossible. The O/D OFF indicator indicates the status of the control system. If the indicator is on, then using the Overdrive mode is impossible, but otherwise there is such a possibility.

It is recommended to use overdrive mainly on the highway for more economical and measured movement. Interestingly, some four-speed automatic transmissions (for example, (Toyota)aisin 241e) can disable 4th gear with gear ratio 1, which is not an overdrive!

One of the differences between an automatic transmission and a manual transmission is the inability to perform engine braking in each mode. In overrunning clutches, in modes that do not allow engine braking, the transmission slips and the car coasts. And when driver position 1 is selected, engine braking is applied in first gear. In the first gear in position D, such braking is impossible.

Special cases of functions in the electronic transmission control system EGS

Remembering a change in direction of movement

The driver wants to move the selector lever from position “D” to position “R” or from position “R” to position “D”.

- When driving speed is below 5 km/h:

The electronic transmission system (EGS) implements the driver's intentions.

- At driving speeds between 5 and 10 km/h:

The electronic transmission control system includes the selector lever position “N”. The engaged position display changes to the selector lever position “D” or “R” specified by the driver. The value set by the driver is stored in memory. If within 1 second the speed drops below 5 km/h, the control unit implements the driver’s intention, that is, it turns on the “D” or “R” position. If the speed does not drop, then the “N” position remains on and the “N” indication appears on the indicator.

- At driving speeds above 10 km/h:

The electronic transmission control system includes the selector lever position “N”.

Memorizing the transmission lock in parking

The driver wants to engage the “P” position (transmission lock in parking)

- At driving speeds below 2 km/h:

The electronic transmission control system includes the selector lever position “P”.

- At driving speeds between 2 and 5 km/h:

The current position of the selector lever does not change; the value set by the driver is stored in memory. If the vehicle speed drops below 2 km/h within 1 second, the electronic transmission control switches the selector lever to “P”.

- At driving speeds above 5 km/h:

The driver's intention is ignored. The current position of the selector lever does not change. The display shows the automatic diagnostic system message “Transmission position “P” only when parked.”

“N” position holding period

When driving at a speed below 2 km/h and the engine is off:

When the selector lever position “N” is engaged, a 30-minute period of holding the “N” position begins. The function indicator remains illuminated and the selector lever position “N” is illuminated in the shift diagram.

At the end of the “N” position holding period, the display begins to flash. After 10 seconds, the Electronic Gearbox Control (EGS) switches the selector lever to “P”.

If the selector lever is moved during the holding period, a new 30-minute holding period begins.

We reserve the right to make typographical errors, semantic errors and technical changes.

Automatic transmission gear selector: types, disassembly and repair

Almost every modern automobile manufacturer has cars with automatic transmissions installed on them, in which the driver changes gears through the automatic transmission selector. The automatic transmission is easy to operate, especially for novice drivers, designed for city driving with its daily traffic jams and frequent braking and acceleration.

Thanks to the automatic gearbox, an independent change in the gear ratio in the transmission is provided, without the direct participation of the driver, depending on the current driving conditions.

Automatic transmission selector, what is it?

If we describe what an automatic transmission selector is, then it is an element for controlling the operating modes of an automatic transmission; in the standard version it is a lever with a button. By moving the lever, you can select the vehicle's driving mode (park, neutral, reverse and forward)

Features of the location of the automatic transmission selector

The location of the gearbox selector paddle is typical for cars manufactured in the USA before the 90s. This allowed two more passengers to sit in front, due to the one-piece long seat, and fit compactly into the interior of the steering column area.

Design and principle of operation of a hydromechanical gearbox

The push-button switch option is found on Land Rover, Honda and Chrysler vehicles from the mid-20th century, a characteristic feature of minivans and high-riding cars.

The floor option is the most popular and familiar in Europe.

Selector protection against accidental movement

The gear selector is protected by several mechanisms, but can also fail:

- When mounted on the floor, the lever has a lock button, only when pressed will the lever move.

- Switching modes will take place only after pressing the brake pedal.

- The method of “recessing the lever” down or moving it towards the driver before directly changing gears.

Removing the automatic transmission selector

Removing the selector from the car may vary depending on the make and model of the car; the gear shift device is much more complex than on a manual transmission.

We perform the following actions:

- Place the car on a smooth, level surface, set the handbrake and open the hood.

- To make it easier to get to the lever, remove the battery, battery mounting pad and air filter.

- Set the lever to neutral position.

- Disconnect the electrical connectors one at a time.

- Using a screwdriver, disconnect the cable and rod from each other.

- Using gentle rocking, remove the rod from the top of the rod. You need to be careful not to allow the gear position to change, and if you have any difficulties, use a screwdriver.

- Disconnect the sensor that controls gear engagement.

- After loosening the plastic clamps, remove the block from the casing by bending the antennae.

- Pull out the dipstick.

- Next, unscrew the fasteners connecting the selector housing.

- Slowly pull out the knot, without applying force, as there may be a risk of damage to the product.

Automatic transmission reset, calibration and adaptation

Conclusion

You should not delay repairing the selector; waiting will lead to further problems with the operation of the car. Malfunction and incorrect operation of the automatic transmission gear selector does not allow the driver to enjoy a confident and comfortable ride in the car, because gears are changed with additional effort.

Factors that accelerate the aging of the machine:

- changing transmission oil less frequently than within the time limits specified by the manufacturer;

- gearbox oil starvation;

- deformation of working surfaces between each other due to friction;

- overheating of parts and components;

- sticking of automatic transmission solenoids.

Try to take care of your automatic transmission, as repairing it at a service center will be expensive due to the complexity of the design.

Operating principle of automatic transmission

When the engine starts, the automatic transmission is activated by turning on the oil pump, which creates operating pressure inside the transmission. After this, the hydraulic transformer is started, which spins up to the speed of the crankshaft.

When you press the gas pedal and switch the automatic control knob, oil rushes to the turbine, which begins to rotate. The operation of the automatic transmission radiator prevents overheating of the transmission oil. The control unit collects all incoming information from the degree of pressure on the gas pedal and various vehicle sensors, processes it and sends a signal to the hydraulic unit, where, by moving the clutches and brakes, the gear ratio is changed, the most optimal in the given specific conditions.

The oil that fills the internal cavity of the automatic transmission is essential for its efficient operation. You need to monitor the oil level so that it is not too much or too little. The operating oil pressure is 2.5-4.5 bar.

The operating temperature of the oil is 80ºC, so before starting to drive the car should be warmed up a little, which is especially important in winter to avoid damage to the plastic elements of the box.

Oil cooling most often occurs due to a liquid radiator, less often - an air radiator. An unfilled automatic transmission and without a torque converter weighs on average about 70-80 kg. After refueling, its total weight can reach 110 kg.

How to shift gears on an automatic transmission

So, in our previous article we looked at how to engage reverse gear on a manual transmission, as well as how to correctly shift gears on a manual transmission. Now let's look at the automatic transmission.

First of all, there are several types of automatic transmissions: “classic” hydromechanical automatic transmission, CVT, and also robotic gearbox. It should be noted that although these types of “automatic machines” differ from each other structurally, they are functionally similar and have similar basic operating modes.

Among these main modes are:

- R- parking, parking;

- R - reverse gear;

- N-neutral;

- D - drive, forward movement;

- M - manual control mode;

Park mode allows you to start the engine, after which the engine idles (for example, during warm-up). It is also recommended to leave the car parked in this mode.

It is noteworthy that after turning on “P” the automatic transmission shaft locking is also activated. This blocking prevents the car from rolling and is an additional “insurance”.

Mode “R” is responsible for reverse gear and is activated only after the car has come to a complete stop. Ignoring this rule may cause serious damage to the gearbox.

The “N” mode, unlike the “P” mode, allows you to separate the transmission and the engine, and this mode does not have any additional locks (as in the case of “parking”).

However, unlike “mechanics” and some individual types of robotic gearboxes (for example, AMT), during a short stop with the internal combustion engine running, there is no need to switch to neutral. In fact, “neutral” on an automatic transmission is only needed for towing the car in the event of a breakdown (if the manufacturer has provided for such a possibility), and also as a service mode.

You can also turn on the “N” mode in a traffic jam, when the car has been standing for a long time (more than 10 minutes) and the engine is running, but you need to remember that in this case you need to additionally use the handbrake (parking brake) or hold the car with the brake pedal, otherwise the car may start rolling randomly.

Mode “D” allows you to move forward, gears change automatically. No additional action is required from the driver; all that remains is to press the gas to accelerate and the brake to slow down or come to a complete stop.

You can also highlight M - manual control mode (Tiptronic automatic transmission). The mode is not available on all automatic machines; if it is available, there are additional symbols: “+” (switching to an upshift), “-” (switching to a downshift). This mode is semi-automatic (the driver himself selects one gear or another, but the electronics may still not turn it on if the speed and conditions do not correspond to it).

The gear shift lever itself (automatic transmission selector) on different cars with an automatic transmission, regardless of the type, often simply moves along special grooves. Each slot corresponds to a separate mode (as a rule, there are symbols next to the slot; also, the selected modes on most cars are duplicated on the dashboard).

To turn on one or another automatic transmission mode, you need to insert the key into the ignition and press the brake pedal. Typically, pressing the brake pedal releases the lock, which is a “protection” against accidental movement of the selector.

In parallel, on the side of the selector handle on many types of automatic transmissions there is a special button, pressing which allows you to move the lever to one mode or another. In other words, pressing the brake pedal and holding the pedal allows you to unlock the shaft in the “parking” mode, while pressing the button on the lever makes it possible to further move the selector itself, including the desired modes.

Also, on many cars, starting the engine is only allowed in “P” or “N” mode when the brake is pressed. This solution can be considered a “protective” function that helps prevent unwanted vehicle movement and damage to the automatic transmission and internal combustion engine.

Let us also add that many automatic transmissions, in addition to the main ones, are equipped with a number of other additional modes. Such modes can have either separate slots for activation or can be activated using buttons. For example, you can select only the first gear (mode L1 or 1), inclusion in automatic mode no higher than the second gear (L2 or 2), OD (overdrive) mode, which disables the transition to upshifting fourth or fifth gear.

Also, automatic transmissions often have a “sport” mode (letter “S”), an economical “eco” mode (letter “E”), winter mode (letter “W” or a snowflake icon), etc.

Automatic transmission indicator for GAZ and other cars

Product catalog » SWAP - INSTALLATION OF JAPANESE MOTORS »

Indication of automatic transmission operating modes when swapping Japanese engines of the jz and uz series.

When installing a Japanese engine 1jz ge vvti, 2 jz ge vvti, 1 jz gte, 2 jz gte, 1 uz fe, 1 uz fe vvti on GAZ, UAZ, GAZelle and other cars, many technical problems arise that need to be solved for normal and convenient use of the car.

One of the problems that needs to be solved is the indication of automatic transmission operating modes.

Our automatic transmission selector display device is universal and fits into any standard dashboard due to its miniature size.

Orioncars 1st generation automatic transmission position indicator:

Thanks to the use of a connecting cable between the indicator and the controller, the indicator can be unfolded and twisted, thereby adjusting it to the installation location without much difficulty. This solution unifies the methods of installing the indicator, making it a very convenient and useful device when swapping a Japanese engine.

Often, when installing a Japanese engine in a Volga, GAZ 21, GAZ 24 and other cars, the question arises about indicating the operating modes of the automatic transmission. We offer a universal automatic transmission mode indicator for modifying the standard dashboard of these vehicles.

The indicator shows the main operating modes of the automatic transmission selector: P, R, N, D, 4, 3, 2, L, Z. The inputs of this indicator are + 12 volts for each contact of the corresponding mode. Pin Z is a wire that must be connected to the dimensions to implement the dimming mode in the dark - so that the indicator does not attract increased attention.

After all, the original purpose of this device is to indicate, not to distract attention.

The LED indicator is invisible when turned off and does not stand out from the overall appearance of the instrument panels. Thus, without disturbing the design of the dashboard and the aesthetics of the dashboard as a whole.

Orioncars automatic transmission position indicator for 2nd generation swap projects:

Available LED colors are green. We recommend using green color - as it is soft and does not attract attention when driving, which has a beneficial effect on the passive safety of the driver and passengers of a car with a Japanese engine. It’s so difficult to restrain yourself and not press the gas pedal when there are more than 200 hp under the hood!

Installing the device with us is a standard procedure when swapping Japanese engines 1jz ge vvti, 2 jz ge vvti, 1 jz gte, 2 jz gte, 1 uz fe vvti, 1 uz fe and other types of internal combustion engines.

Self-installation - you can easily install this indicator yourself, thanks to the miniaturization and ease of connection of this device. We have listed the main contacts just above on this page. You need to add only two contacts to them: this is 12 volt power “+” and “-“. Power is supplied when the ignition is turned on.

The cost of an automatic transmission indicator is 3,500 rubles.

When ordering an indicator, please indicate your full name and place of registration (residence).

Sending is carried out by the services of Ems, Ratek, Energy.

Support

Best regards, Orioncars.

Manual transmission diagnostics: how to find out the oil level?

One of the most important tasks that every driver must periodically perform is checking the oil level in the manual transmission.

It is necessary to check it if you suddenly notice oil stains appearing under the car. Usually it is performed by service specialists during a technical inspection or various repair work - this is quite enough

But still, extra precaution won’t hurt - if you check the level periodically, nothing bad will happen

The verification process may differ in different car models, but the essence is the same for almost all. We will consider the procedure using the example of an excerpt from the instructions for the Opel Vectra B:

- The vehicle is installed on a flat surface (after all, when tilted, there is no way to accurately determine the level) above the inspection hole.

- Turn off the engine and start checking no earlier than 5 minutes after stopping.

- Locate and unscrew the gearbox oil level plug. It is located behind the drive shaft.

- The oil should be level with the bottom edge of the hole - under the plug that you removed.

- If necessary - if there is noticeably less oil - it must be added. To do this, unscrew the breather located in the upper part of the gearbox housing and add oil through the hole until it begins to flow out.

- Wipe off excess with a rag and replace the plugs.

Mechanical transmission repair - approximate prices

Since manual transmission repairs will almost always have to be done at a service center, we will provide a list of current prices for your reference. Let us immediately note that for each model the cost of work may differ, and differ significantly. Therefore, we will give average amounts.

- manual transmission oil change: from 300 rubles (excluding the price of the oil itself);

- manual transmission diagnostics: from 800 rubles;

- manual transmission overhaul and required repairs: from 5,000 rubles (excluding the price of the required parts).

Start from a tug

There are also recommendations on how to start a car with an automatic transmission from a tow. Of course, you won’t be able to “push” the machine, but if you accelerate it to a certain speed, you’ll still be able to start it:

- Set the lever to the “N” position and turn on the ignition. If the weather is cold, press the gas before driving;

- After starting to move, you need to accelerate the car to 30 km/h (winter) or 50 km/h (summer);

- Move like this for about 2 minutes;

- Turn the lever to position 2, after the engine starts to rotate, press the gas;

- Once the engine starts, move the lever to “N”;

Bottom line

When taking control of a car with an automatic transmission, it is worth taking into account the individual characteristics of the car. If you're coming from a manual, the first thing to learn is to keep your left foot off the pedals and not pull the lever while driving. Otherwise, driving such a car is often much easier to master than mechanics, and the focus in a driving situation is on the road situation, and not on the clutch pedal. If you are a beginner, then it will be much easier for you to master the machine. Driving an automatic is more fun for people who don't have much driving experience. Be careful on the roads and have a good trip!

Our post today will be devoted to such a pressing topic as the automatic transmission, the meaning of the letters, it is especially relevant for those who are changing from a manual transmission to an automatic transmission. Such a driver sees the speed lever with completely unfamiliar values and numbers. And the first feeling he will have is that nothing is clear, the native mechanics are closer to the heart and understandable. But in fact, everything is very simple, literally after a week of driving an automatic transmission, the newly-minted “automatic driver”, so to speak, will, without any difficulty, set the car’s speed control knob to the position he needs, without even thinking about it.

Here, for example, are ordinary photos of some types of automatic transmissions in automobile gearboxes. For many mechanical enthusiasts, these symbols do not mean anything, but only confuse them more and distance them from the automatic transmission.

Therefore, let's try to dispel the fog of doubt and ignorance by explaining the meaning of each symbol on the automatic transmission:

- R – translated in English as Parking, parking or parking. The car is switched to this mode only after a complete stop. If you are standing on a hill, it is recommended to first put the car on the handbrake and only then move the lever to the Parking position, after which you can leave the car and go about your business

- R - literally Reverse, back, back - that is, normal reverse gear, engage it when there is a need to drive in reverse

- N - translated as Neutral, that is, neutral, neutral speed, it is mainly used for towing a car, usually when standing in a traffic jam, it is recommended to hold the brake pedal without moving the car to the neutral position - since this is not a manual transmission, but nevertheless, many automatic transmission owners when parking, especially in traffic jams, move the lever to position N, because you must admit that keeping your foot on the pedal for 20-30 minutes is not at all comfortable

- D or A - you can find both of these designations Drive or Automate, which is essentially the same thing, that is, you switch to this position when you need to drive, squeeze the brake, put the speed lever in position D or A and simply press the gas pedal, smoothly releasing the pedal brakes and all movement has begun, now there is no need to switch the handle, just regulate the speed of your movement by pressing the gas pedal in your car with your foot

- L or B (l, 1, 1L) - some types of automatic transmissions are equipped with additional functions (Low or Bottom) which can literally be translated as slow or first gear. Typically used on ice, very steep descents or uphills, or for engine braking.

- B or simply Block often means differential locking, usually on jeeps or all-wheel drive cars, in which cases it is better to read the manual for your car model

- 2 or 2L, 3 or D3, 4 or D4 - means limiting the speed switching by the gearbox, that is, set it to 2 - it means the box will not shift above the second gear, no matter how hard you press on the gas, set it to mode 3 - the box will not shift above the third gear no matter what you do with the accelerator pedal, it’s the same with 4 - shifting will not occur above the fourth speed, for example, you have 6 gears in the box, you set it to mode 4 - which means the car itself will shift from 1st to 4th gear, the car in 5th and 6 will no longer switch

Pulling out the selector

I decided to highlight this separately because I spent more than 3.5 hours on this matter due to the complexity and inaccessibility of the mounting location.

The first difficulty: the ill-fated 10mm bolt behind the engine on the automatic transmission holding the tab holding the wiring harness. Accessible, with difficulty, on the right side. I spent about 5 minutes on it, no more, it’s inconvenient, but possible. This bolt has been described several times in the forum.

The second difficulty: (I have not seen this anywhere in the descriptions of this work in the forums.) Two cable bundles are tied with a plastic tie, 10 cm deeper than the bolt with the tab is installed. You wouldn’t wish this place on your enemy; there’s simply no place there. It took more than 3 hours to try to cut with a knife and scissors/snack with wire cutters/tear with a knife/saw with a hacksaw blade, my hands were torn to pieces. In the end, she was cut with a knife, but only because she was exhausted by everything else.

Difficulty three: Despite the descriptions in the forums that the length of the freed cable is enough to place the selector on the engine, this turned out not to be the case. A separate harness for the selector is combined with another harness somewhere under the distributor. The cable is long enough to pull the selector to the ERG valve area

In the photo there is ________________ screed (add all imaginable epithets, take your soul away, take revenge for my torment)

Remove the selector by pressing the connector latch with your fingers and inserting a screwdriver between the selector body and the connector. In the photos: Selector from the outside and inside. Selector connector with some kind of beige grease. Who can say why? Is it necessary to save it?

I was exhausted with this damn screed, it got sharply cold, it started raining and windy, so I grabbed everything and brought it home, so that, after resting, I could do the rest in warmth and comfort and put it in its place tomorrow.

To be continued.

By the way, on older versions of this switch there is no connector, the wires grow directly from it

Washed the block, blunt, ferry and brush

Using a screwdriver with a good bit, suitable, unscrew 5 screws and disconnect the block.

Outwardly, everything is not so scary, the lubricant in non-working places is even pure yellow, but it has lost its viscosity

The cause of the malfunction is that one of the moving contacts on the “foot” (the far one) “sticks”. It is clear that he does not return to the same level as his neighbor. And it “sticks” because the lubricant has turned into sticky resin

The block of fixed contacts (rear wall) in the niches between the contacts is also filled with a dense substance that is difficult to remove with a screwdriver.

The reason is most likely that the contact points still heat up and the lubricant loses its properties. Well, of course, I’m old; no one has climbed into this block in my 13 years. There is no particular dirt in it, only signs of wear, but I don’t really swim in mine or in mud, and it doesn’t seem like anyone has bathed me before either.

Everything is washed thoroughly, old grease where it is not washed off is picked out. Lubricated with lithol (from -40 to +120), a little, but carefully, checking mobility. Where the rubber band is added, a little sealant is added to the cavity under it. Everything is assembled and screwed together.

I'll put it back tomorrow.

Great report, great photos. Really worthy of a FAQ.

I’ll add on my own behalf: - on my Escudo TD01W 1993. the tubes did not interfere at all with removing the selector. — I don’t remember fussing with the screed, there are two options - either with a cap. When repairing the automatic transmission, this tie was not installed, or I somehow pulled it into the engine compartment and cut it with side cutters or snapped it open. — I don’t have a connector on the selector itself, the wires go straight from it, the harness goes along the top of the automatic transmission through the same clamp and tie and goes under the intake manifold. There are 2 large connectors that are very poorly separated - idiotic design, as a result, when pulling them apart, the connector even had to be broken a little on the outside (the skirt), and I was not the first to do this - at the end. During automatic transmission repairs they have already been pulled apart. It’s very inconvenient, the Japanese should be shot for this arrangement of connectors. — lithol is probably too thick a lubricant, especially for winter. - in addition to wear and sticking of the sliding contacts, there may be another malfunction - “recession” of the fixed contacts inside the plastic so that the moving contact no longer reaches the moving ones. Accordingly, after repair and assembly, but before installation on the machine, it is highly recommended to test the functionality of the contacts - so as not to remove it from the machine again later.

How to clean the selector yourself

Before surrendering to the mercy of service station mechanics, you can inspect the unit in a garage.

Dismantling:

- Before removing the selector, be sure to mark with paint the location of the parts in relation to the box block and the moving part of the selector.

- We remove the battery tray, the air filter housing and, if equipped, the cruise control vacuum pump (unscrew the 8″ bolt and remove the mustache from the groove).

- We snap the gearshift cable off the washer and axle, then remove it, but it is better to do this together with the rod.

- Without any effort, unscrew and remove the 13″ nut from the shaft splines. You will have to shake it a little and pry it (but very carefully).

- Since there are many connection wires, you can clean the selector without completely disconnecting them, that is, on the spot. Remove the connector with the main harness (unscrew two 12″ bolts). You can remove the other two by completely disconnecting the selector, but you need to take into account the condition of the wires and the ability to get to the connector (one of them is connected under the box).

- Remove the wire casing (it is held on by two screws), slightly prying it up with a screwdriver.

- We disassemble the selector itself - unscrew the 4 screws. Let's reveal it.

- The main thing is not to lose 3 contact crackers and 3 springs (one of them is double).

- We wash off the old grease with gasoline. It is good to clean the selector contacts with kerosene and WD40. If the dirt cannot be washed off, you can use fine polishing sandpaper and an ink eraser.

- Apply silicone grease.

- We put everything back together in reverse order, not forgetting to match the marks.

After this procedure, the selector should work normally again.

[FAQ] Cleaning the automatic transmission contact selector (the rear light does not light up, the beeper does not squeak)

Symptoms: It has gotten colder and when the automatic transmission is engaged in reverse, the reverse lights do not light up and the reverse alarm (beeper) does not work.

Diagnosis: Contamination and aging of the lubricant in the automatic transmission contact selector. In the manual it is called the “engine start prohibition switch”. Located on the automatic transmission on the right along the direction.

Forecast: Failure of other contacts, loss of power supply, ext, up to breaking of the claw with contacts (info from our forum)

Indication: Removing the contact selector, disassembling, cleaning, replacing lubricant, assembling with sealant, installation

To remove selector 0 we need: 1. Unscrew the lock nut 1 by 10 mm from the cable rod from the automatic transmission handle 2. Unscrew the nut securing the lever by 12 mm and remove the bushing under it. 3. Remove the lever. 4. Unscrew the 22mm nut screwed onto the selector collet 5. Remove the shaped washer 6. Remove the rubber washer 7. Unscrew the bolt securing the selector to the automatic transmission housing by 10mm 8. Unscrew the automatic transmission cooling tube by 14mm as it does not allow the contact selector to be removed.

We disassemble the lever following steps 1,2,3,7

To pull the selector off the rod, perform steps 4, 5, 6. And then screw the 22mm nut onto the collet again, but not all the way. Clinging it with a large screwdriver and resting the screwdriver on the front driveshaft, we move (by gentle tapping) the selector from its home place. It will not come off because it will rest against the automatic transmission cooling pipe.

So that the unscrewed tube can be moved slightly, unscrew the tube fastening in front along the direction of the tubes

All disassembly before this was done without unscrewing the tubes just so as not to get smeared with dextron drips, but still everything in it drained about 1 liter. We send the removed selector to the top of the box, now there will be some fiddling with it under the hood.

What's the result?

As you can see, the automatic transmission selector is an important element in the design of an automatic transmission. In this case, we are talking not only about hydromechanical automatic transmissions, but also about CVT variators, single-disc AMT robots and preselective robotic gearboxes with two DSG type clutches.

In any case, not only the comfort of operating the car, but also the overall safety of the driver, passengers and other road users depends on the correct operation of this device.

In practice, there have been cases when the inability to engage one or another automatic transmission mode due to a malfunction of the selector caused serious damage to the automatic transmission itself or accidents due to the fault of the driver of a faulty vehicle.

Finally, we note that in order to restore the functionality of this device, it is optimal to immediately contact specialized automatic transmission repair services, since in this case they usually have not only the necessary diagnostic equipment, but also the necessary spare parts.

As a result, repair of the automatic transmission selector can be completed in the shortest possible time, while the owner, as part of the service, also receives a general idea of the condition of the automatic transmission after in-depth professional diagnostics.

Optional equipment

The main auxiliary device of the automatic transmission is the automatic transmission selector position sensor. It is needed to display the engaged gear on the dashboard.

Like all car devices, this sensor tends to break. Breakdowns often occur due to the fact that there is no protective casing for this device. Because of this, dust, debris, and sometimes water gets into the sensor, as a result of which it cannot read readings from the selector.

Because the sensor cannot indicate the lever position, the automatic transmission may go into limp mode. Such a sensor cannot be repaired; in any case, it will have to be replaced. In order to replace the sensor, you must first buy it. You can purchase the sensor you need online or at your local automotive store. You can replace it yourself or at a car service center.

In order to correctly replace the sensor that is responsible for determining the gear engaged, you need to read the instructions in detail on how to do this for your car.