In our article, we will look at the design and operating principle of an automatic transmission, list the main types of automatic transmissions, get acquainted with the operating modes, and analyze the advantages and disadvantages of automatic transmissions.

What is automatic transmission

An automatic transmission (AT) is a transmission that independently determines the most appropriate gear ratio depending on the current speed limit. The automatic transmission, without driver intervention, selects and switches the desired gear ratio, adapts to the speed set by the driver, and ensures a smooth start and smooth ride of the vehicle. The automatic transmission removes the lion's share of the load from the driver while driving compared to a classic manual transmission.

Since there are now different options for automatic transmissions (robots and CVTs), to avoid confusion, automatic transmissions are also called: classic automatic, hydraulic automatic, hydromechanical transmission, planetary automatic.

How to distinguish a robot from an automatic or CVT

The fact is that manufacturers strive to simplify as much as possible the entire process of interaction between the driver and the gearbox. For this reason, for example, a robot may have the same selector and modes (PRND) as a CVT or automatic transmission.

As for the driving sensations (provided that the transmission and the car itself are in full working order), you can pay attention to the following:

- in the case of a “classic” automatic machine and preselective robots in mode D, a slight push may be felt;

- on the variator the moment of switching is not felt;

- a single-disc robot can shift relatively smoothly at low speeds in quiet mode, but during dynamic driving the box begins to push harder.

We also recommend reading the article about what an automatic transmission selector is. From this article you will learn about the different types of automatic transmission selectors, as well as what features and differences in the implementation of the automatic transmission selector can be found on different types of automatic transmissions.

For this reason, it is recommended to study the vehicle manual separately to determine exactly what type of transmission is installed on a particular model. In general, pay attention to the following instructions:

- AT - often means hydromechanical automatic;

- CVT - variable speed transmission;

- AMT - robotic gearbox with one clutch;

You can also visit specialized auto forums, study technical literature separately, etc.

The history of the automatic transmission

The idea of creating an automatic transmission belongs to the German engineer Hermann Fettinger, who developed the first torque converter in 1902, and at first such a transmission was used only for the construction of ships.

The first car equipped with a planetary automatic transmission was the American Ford T. After the release of this car, the most active role in the development of automatic transmissions was played by General Motors, which managed to release a semi-automatic transmission in the mid-1930s. The same GM created the first completely automatic transmission in 1940

Automatic transmission device

An automatic transmission has a complex structure and the mechanism itself, through which gear shifting is ensured, is complex. The essence of this process comes down to turning the clutches and brakes on and off using the pressure of the working fluid.

There are several types of automatic transmissions that have some differences in design, but their basic elements are the same.

- Hydraulic transformer (torque converter)

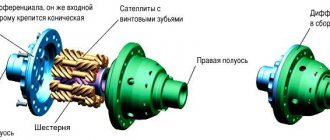

. It is a metal body that is filled with a special working ATF fluid (oil). Its main task is to transmit rotation from the engine to the gearbox. In fact, this is an analogue of the clutch in a manual transmission. Consists of pump, turbine and reactor wheels, locking clutch and freewheel. The wheels have blades with holes for the circulation of working fluid. A freewheel is needed so that the reactor wheel can rotate in the opposite direction. The lock-up clutch allows you to lock the torque converter under certain vehicle operating conditions. - Planetary mechanism.

This is a gearbox that changes speeds as a result of changing the gear ratio on the gears. Consists of: planetary gears (sun gear, satellites, ring gear, carrier), shafts, drums with friction clutches, overrunning clutch and band brake. Blocking one of the elements of the planetary gear leads to the transmission of rotation and a change in torque. The planetary gear set can be locked by a band brake, an overrunning clutch and friction clutches. The planetary gear acts as a block of gears in a mechanical box. - Hydraulic system

. Consists of an oil pump, filter, pushers, hydraulic distributor. The working fluid creates working pressure in the box and protects internal elements from overheating and corrosion.

- Electronic control unit.

Collects incoming information from pedals, ABS and ESP systems, sensors, automatic transmission knob and other systems, processes it. Then it generates signals that are sent to the valve body actuator valves. The control unit regulates the operation of the friction clutches and directs the flow of working fluid to one or another clutch, which leads to a speed change. That is, the control unit is literally the “brain” of the automatic transmission; it controls the gearbox. A breakdown of the control unit leads to the machine switching to emergency mode.

What is a manual transmission (MT)

The manual transmission has a very simple operating principle. The driver uses a lever to engage certain gears, which helps the car shift into the desired gear. A clutch mechanism is used to disconnect the gearbox from the engine.

Manual cars have been produced for more than a hundred years. During its existence, the device was brought to perfection. A modern manual transmission has many advantages. It is considered a reliable, economical and affordable device. However, its main disadvantage is the need for manual gear shifting.

So, the main advantages of the device include the following:

- Simplicity of design, relatively cheap repair and maintenance.

- High resource of use.

- Fuel economy. The device also provides good acceleration dynamics.

- High efficiency.

- Possibility to tow a car without using a tow truck.

- Good speed of increasing car engine speed. In this case, the driver can independently choose his driving style by changing gears.

- Light weight.

- Ability to start the engine if the ignition and battery fail.

At the same time, a manual transmission also has disadvantages:

- Difficulty of use. Beginners can damage the clutch or unit components.

- Engine overload due to incorrect gear selection. This also applies to inexperienced drivers who may not switch to the right gear in a timely manner. As a result, the engine will operate at high speeds.

- Increased gear shift interval.

- Driver fatigue due to the need to constantly change gears in city mode.

Comparison of automatic transmission with manual transmission

In the modern world, “mechanics” are slowly but surely losing ground to their more progressive counterpart - automatic transmission. Automatic transmissions provide smoother and more economical engine operation and smoother running of the machine.

The driver is not required to constantly monitor the speed and engine speed in order to engage the desired gear in time. The automatic will do everything for him, which is especially convenient when driving around the city, and extremely convenient if you are in a traffic jam.

The driver does not need to devote the lion's share of his attention to driving the car. Although there are drivers who like a manual transmission, which allows them to enjoy the continuous physical process of driving the car and complete control of the ride.

Pros and cons of automatic transmission

An automatic transmission has its advantages and disadvantages, which you need to know before buying a car with an automatic transmission or switching from a manual transmission to an automatic transmission.

Pros of automatic transmission

- Simplicity and ease of control, as there is no need to manually switch speeds. The driver only controls the steering wheel and presses the gas and brake.

- The third pedal, the clutch, is missing.

- It's easier to get moving in a car with an automatic transmission.

- Smooth gear shifting and high efficiency.

- High reliability of modern automatic transmissions.

- Inability to “burn out” the clutch and no need to periodically replace the clutch.

Disadvantages of automatic transmission

- Manual transmissions are more economical than automatic transmissions. A car with an automatic transmission consumes about 10-15% more fuel. Although the gradual improvement of machines leads to a decrease in this indicator.

- Automatic transmissions are much more expensive than manual transmissions to maintain and repair. If the machine breaks down and needs to be completely replaced, it will cost a significant amount (up to a third of the cost of a used car).

- The impossibility of rapid acceleration and a sharp increase in speed, which is especially felt when overtaking at a limited distance or in dense oncoming traffic, that is, when you need to overtake very quickly. This problem is partially solved by turning on the sports mode.

- The automatic limits the individual driving experience, unlike manual cars where the driver has complete control over the ride.

- Inability to push start the car.

- The machine can quickly fail if used incorrectly.

- An automatic car has towing limitations, and these are things you need to know before towing another car or trailer.

What is the difference between manual and automatic?

When choosing a specific type of gearbox, it is important to understand their differences. It is worth considering the purposes for which the car is purchased:

- for driving in the city;

- to overcome forest impassability and drifts;

- for transportation of goods.

Expert opinion

Karnaukh Ekaterina Vladimirovna

Graduated from the National University of Shipbuilding, majoring in Enterprise Economics

It is also worth taking into account driving experience. It is easier for beginners to use an automatic transmission, while a manual transmission is also suitable for experienced drivers.

To make the right choice, you should take into account the following parameters:

- Price. A car with an automatic transmission will cost about 50 thousand rubles more than a manual one. In addition, automatic transmission is considered more expensive to repair and maintain. Another negative point is considered to be higher fuel consumption.

- Maintenance and repair. Both boxes require an oil change. This substance acts as a lubricant and removes excess heat. This helps to avoid wear of rubbing elements. In addition, the oil forms a film on the metal surface, which provides protection against corrosion.

- Efficiency and acceleration. Thanks to manual control in the mechanics, the driver can accelerate the engine to the red marks on the tachometer. At the same time, it is possible to make maximum use of engine power and torque. Thus, mechanics are characterized by higher efficiency and dynamics.

- Reliability. Structurally, the mechanics seem more reliable. It has no hydraulics or electronics that can fail. In addition, the manual transmission can withstand loads in the form of towing or slipping. At the same time, the electronic control of the machine allows you to eliminate the human factor and control the condition of the device.

- Service life. This parameter depends on design features, operating conditions and timely maintenance. Some automatic machines of the eighties and nineties could go 500 thousand kilometers without repair. Modern six- and eight-speed units require repair after 150 thousand kilometers. The service life of the mechanics reaches 250-300 thousand kilometers.

- Winter driving. In winter, the automatic transmission takes longer to warm up. This is due to the large volume of liquid. When slipping on ice, the device is heavily loaded. This increases the wear rate of oil and parts. A manual car starts faster. At the same time, the mechanics are not afraid of slipping on ice or snow.

- Comfort. An automatic transmission is considered more convenient for the driver. Even a beginner will be able to get going and climb the hill without sliding down. Operating a manual transmission requires high concentration and skill.

- Engine and clutch life. The ability of mechanics to spin the engine to the limit reduces the life of the power unit. The automatic transmission is equipped with electronics. This allows you to keep engine speed under control and prevent overheating.

- Car behavior on the road. An automatic car has a smoother movement. The car climbs hills easily and does not stall. At the same time, fans of mechanics believe that this type of box allows you to better feel the road and the car.

Types of automatic transmission

There are now three types of automatic gearboxes:

- classic automatic transmission

. When they say automatic transmission, they mean this particular type of gearbox, and in this article we are talking about this type. They are installed on most modern cars and trucks, although the other two types are gradually increasing their presence in the car market. - Robot

(robotic gearbox). It is one of the automatic transmission options. Its main feature is the presence of a clutch, which ensures quick gear changes without loss of engine power. The robot has input and output shafts, which are combined using gears, which leads to speed switching; they are controlled by a synchronizer. The robotic gearbox is usually controlled by a special electronic control unit, but can also be controlled by the driver. - The variator

does not have fixed gears, so speed shifting is very smooth. The speed mode is switched using cone-shaped pulleys at the input and output of the box. The belt connection ensures the movement of the nodes. The planetary gear is responsible for reversing. The CVT has the highest efficiency of all automatic transmissions.

What does a gearbox do?

The gearbox is one of the most important components of a car. In many ways, the impression of owning a car depends on it. The presence of jerks during acceleration and high fuel consumption spoil the lives of many motorists. At one time, problems with DSG and Powershift gearboxes significantly spoiled the reputation of the Volkswagen and Ford brands. And for many motorists, a robotic gearbox is an evil that is best avoided. In fact, each type of gearbox has its own pros and cons. The main thing is to understand for what purpose you are purchasing a car. Then everything will fall into place.

Operating principle of automatic transmission

When the engine starts, the automatic transmission is activated by turning on the oil pump, which creates operating pressure inside the transmission. After this, the hydraulic transformer is started, which spins up to the speed of the crankshaft.

When you press the gas pedal and switch the automatic control knob, oil rushes to the turbine, which begins to rotate. The operation of the automatic transmission radiator prevents overheating of the transmission oil. The control unit collects all incoming information from the degree of pressure on the gas pedal and various vehicle sensors, processes it and sends a signal to the hydraulic unit, where, by moving the clutches and brakes, the gear ratio is changed, the most optimal in the given specific conditions.

The oil that fills the internal cavity of the automatic transmission is essential for its efficient operation. You need to monitor the oil level so that it is not too much or too little. The operating oil pressure is 2.5-4.5 bar.

The operating temperature of the oil is 80ºC, so before starting to drive the car should be warmed up a little, which is especially important in winter to avoid damage to the plastic elements of the box.

Oil cooling most often occurs due to a liquid radiator, less often - an air radiator. An unfilled automatic transmission and without a torque converter weighs on average about 70-80 kg. After refueling, its total weight can reach 110 kg.

Robotic box

Relatively recently, automakers have been introducing a new type of transmission - a robotic gearbox. Structurally, it is a manual transmission, and the controls are like an automatic transmission. Such a tandem is obtained by installing an electronic actuator in a conventional manual gearbox, which controls not only gear shifting, but also the operation of the clutch. For a long time, this type of transmission was the main competitor of automatic transmissions, but most of the shortcomings, which engineers exclude to this day, caused a lot of discontent among car owners.

So, the “robot” in its classic design has an electronic actuator unit, as well as an actuator, which turns the clutch on and off for you.

In the early 2000s, VAG released an experimental version of the DSG robotic gearbox. The designation “DSG” stands for Direkt Schalt Getriebe. 2003 was the year of mass introduction of DSG on Volkswagen cars, but its design differs in many ways from the understanding of the classic “robot”.