Despite the fact that in their meaning such concepts as the order of operation of the engine cylinders and their numbering are different. However, there is still a certain relationship between them. And every motorist should know the numbering of the cylinders. This gives him the opportunity to calmly operate in the order of their operation to carry out work on adjusting the thermal clearance of the valves and correctly connecting the wires to the spark plugs. Moreover, regardless of the operating manual, as well as the order of operation of the cylinders, the first serial number is always the master cylinder. There is always a candle in it.

How cylinders are installed in engines

There are many types of internal combustion engines - these include outdated engines with one or two cylinders, classic in-line options with four and six cylinders.

Larger structures had V-shaped blocks - these structures could contain eight or more combustion chambers.

Engine stroke operation

To ensure an even load on the crankshaft, each piston has a certain amount of torque. This sequence is referred to as the order of operation of the engine cylinders. Different versions of power units have their own order, which depends on how many cylinders and their tacticity.

Sequential liners are spaced apart for best performance. The number of cylinders in an internal combustion engine is affected by their location.

Row arrangement

In this system, the cylinders are placed in one row. This configuration uses 2, 3, 4, five or 6-cylinder engines.

Internal combustion engines with two and three cylinders are installed on new cars quite rarely, despite the fact that the demand for them is gradually increasing.

If we talk about in-line “four”, then these blocks are installed in most engines for passenger cars - the volumes of these engines start from 1 liter, and the largest in-line internal combustion engine is 2.4 liters. and more.

What about now?

Contrary to popular belief, 8-cylinder engines are installed not only in luxury foreign cars, but also in ordinary tractors, trucks and construction equipment. As with weaker engines, the most balanced type is the in-line engine type. In other words, when all the cylinders are located in a row. They were used to equip the most expensive cars for a long time. This design was especially appreciated in America. However, the record holders here are the Germans, who highly value the balance and reliability of the in-line engine.

But even they, over time, had to switch to V-twin engines. The reason is simple and banal - the eight-cylinder Python simply did not fit in the standard engine compartment of modern cars.

In two rows

How to make a huge in-line internal combustion engine smaller?

- The engine can be "divided" in half, placing the two parts next to each other and having the pistons turn one crankshaft. This structure resembles the letter “V”.

- Here the combustion chambers are placed in two rows at an angle. This arrangement is quite common among manufacturers and is inferior only to the in-line “four”.

8 combustion chambers in this configuration are placed 4 in 2 rows. This is the most compact assembly for large-sized motors. If we talk about structures with 12 cylinders, the only difference is their number.

Definition

Cylinder firing order is the sequence in which the cylinders fire alternately. Otherwise, we can call it a sequence of alternating expansion cycles. Factors influencing it: the number of cylinders, the nature of their arrangement, the design of the engine (in particular, the camshaft and crankshaft), as well as the interval between flashes. To be more precise, it is influenced by the location of the cylinders, crank journals and camshaft cams. The smooth operation of the engine, it is worth noting, depends, among other factors, on the sequence of strokes.

With offset

The developers have found an alternative to make a powerful and at the same time small power mechanism for middle-class passenger cars. The offset design is a V-block with 6 cylinders.

They are located opposite each other diagonally. 6 cylinders tilted at fifteen degrees form a rather narrow and short structure.

Five-cylinder

These are units with 5 cylinders standing in a row. The relative displacement of the crankpins is 72 degrees. There are both two- and four-stroke samples; for the first (2 strokes), the standard order of optimal operation of the cylinder block for these engines is the activation sequence 1–2–4–3–5. This ensures uniform combustion of the fuel. These motors are widely used in marine technology.

On passenger cars, engineers report a different order for the operation of the “pots” of 5-cylinder typical engines - the 1-2-4-5-3 system.

Cylinder block:

Opposite type

It's no secret that on a V-like block the angle of inclination of the 2 parts is ninety or sixty degrees. If it is one hundred and eighty degrees, then it is a boxer engine.

Here the cylinders are placed opposite each other, in a horizontal order. The crankshaft in these devices is common, placed in the center, and the pistons move away from it.

Theory of internal combustion engine operation

The general principle of operation of engines running on gasoline or diesel fuel is known, perhaps, to everyone - fuel, burning in the cylinders, creates gas pressure that pushes the pistons, and then the force is converted into torque going to the wheels.

In order for the engine to operate evenly, fuel combustion does not occur in all cylinders at the same time, but in a certain order. The following are responsible for its compliance:

- gas distribution mechanism design;

- the angles between the cranks of the car crankshaft;

- cylinder arrangement - V-shaped or in-line;

- device of the ignition system for gasoline cars, and fuel injection pump for diesel cars.

Motors W

These power plants combine 2 rows of combustion chambers with a VR arrangement. In each row, the cylinders are tilted at an angle of fifteen degrees.

Both rows are installed at an angle of seventy-two degrees. If we are talking about a device with eight cylinders, the block consists of 2 V-like blocks located at a slope of seventy-two degrees.

How to find out engine size: determine the working volume of the internal combustion engine

As you know, engine displacement is directly associated with power and speed for many car enthusiasts. In practice, this often happens, because if we are talking about passenger cars, and not about special equipment, then the larger the engine volume, the faster, more powerful and more dynamic the vehicle turns out to be.

Note that the only exception to this unspoken rule can be considered units with a mechanical compressor or turbocharging, where the displacement may be relatively small, but the power of such an engine is quite high compared to atmospheric counterparts.

Drivers also know that generally accepted designations are 1.5, 1.8, 2.0, 3.5, etc. may differ slightly from the actual volume of the internal combustion engine. For example, a 1.5 liter engine may physically have 1497 cubic centimeters, but a 4.4 engine actually has as much as 4499 cubic centimeters of volume.

For this reason, some owners have a desire to find out the real volume of the power unit. This may be necessary to calculate some taxes on vehicle maintenance, etc. Next, we will try to answer the question of how to determine engine size.

Tactfulness of the motor

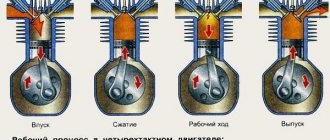

The operating principle of the cylinders consists of the following stages:

- Intake - the piston moves to the bottom dead limit, at the same time the combustion chamber is filled with air-fuel composition through the intake valve. The exhaust valve is closed.

- Compression - both valves are closed, the piston moves to the top dead limit, squeezing the fuel. The temperature in the chamber increases several times due to pressure and the pressure in the engine cylinder increases. For vehicles with a high octane rating, high octane fuel must be filled.

- The working stroke is when the valve is closed, and the liquid from the spark plug ignites. Under pressure in the cylinder of the unit when fuel is burned, the piston moves to the bottom, causing the crankshaft to rotate. For high productivity, it is necessary that the liquid is consumed in full before the piston reaches BDC. To ensure this process, the ignition timing is used. In new cars, the setting is performed by a built-in electronic unit. Older machines are equipped with a mechanical regulator.

- Exhaust - the working stroke ends with the evaporation of exhaust gases from the cylinders of the structure. At this stage, a significant process is taking place - cooling the system cylinders. It is performed with the intake and exhaust valves open at the same time. After the piston moves to TDC, the intake starts again.

Repair of car components

The cylinder block structure consists of parts that operate in aggressive conditions, and therefore are often subject to breakage and wear.

Restoring an engine cylinder block consists of the following operations:

| Power stroke | Fuel and air intake | Compression of the air-fuel mixture | |||

| Second | 180-360 | Fuel and air intake | Release | ||

| Compression of the air-fuel mixture | Working stroke | ||||

| Third | 360-540 | Compression of the air-fuel mixture | Fuel and air intake | Working stroke | Release |

| Fourth | 540-720 | Working stroke | Compression of the air-fuel mixture | Release | |

| Fuel and air intake | |||||

| No. of works | Operations Performed | Technical equipment. | |||

| 1 | Grinding the surface of the crankshaft bearing stop | Vertical milling machine | |||

| 2 | Replacing worn camshaft bushings | Press-fitting device | |||

| 3 | Repairing threaded holes | Drilled equipment, set of drills, lantern, die | |||

| 4 | Pressing out the fastening pins | Special press | |||

| 5 | Boring, repair of engine CPG cover. Adjustment by plane, installation by holes | Vertical milling machine | |||

| 6 | Processing the body for sleeves and boring for thrust edges | Vertical boring machine | |||

| 7 | Boring of main bearing seats | Horizontal boring machine | |||

| 8 | Gas-thermal spraying on treated bearing seats | Special technological equipment | |||

| 9 | Double-circuit boring of the body | Honing machine | |||

| 10 | Washing the engine and cleaning the oil channels | Equipment for jet washing of parts. | |||

| 11 | Painting the block | Spray gun. Compressor. |

Repair of the engine cylinder block ends with a control inspection on the test plate. Using a feeler gauge and indicator devices, the installation rigidity and alignment of the mounting components in the engine cylinder block are checked. After the engine cylinder body has been restored, a leak test is carried out.

Cylinder head assembly

Repair of the engine cylinder head is performed for the following reasons:

- broken drive shaft belt;

- cylinder head deformation due to overheating;

- duration of service lines;

- incorrect assembly after repair of the unit cylinder block.

Defects of engine cylinder head parts

You can restore defects using the following steps:

- grinding valves;

- the cylinder head is polished;

- gaskets and belts are being replaced;

- Bushings and valve seats are bored.

Post-repair control

After troubleshooting, the cylinder head is painted and the pressure in the cylinder is checked.

Numbering of cylinders of motors of various types

Such information is needed mainly for those who repair internal combustion engines of foreign cars. Typically, all front-wheel drive cars have a perpendicularly mounted motor.

In this situation, the cylinders of the structure are counted from one of the parts, and the main first cylinder is located from the passenger part.

- For V-shaped designs with multiple cylinders, the main cylinder is placed in the row closest to the passenger compartment on the driver's side. Then odd-numbered cylinders are placed, and multiple cylinders are placed from the radiator.

- In American buildings there are 2 variations of cylinder installation. Four or six-row American engines may have one main cylinder from the radiator, while the rest are counted towards the passenger compartment.

- Another variation with the opposite numbering, in this situation the main cylinder is the one located next to the passenger compartment.

Designers from France have also developed 2 ways to count the cylinders of the system. This is either a reading from the gearbox, or from the right side of the transmission, in V-like structures.

Therefore, given the huge amount of information, which is not always unambiguous, it is very important to read the instructions of the engine manufacturer - the vehicle. It would be a good idea to ask for help with this question from the community of car owners specifically for your car.

Tell me where to get the cylinder numbers from?

Where is the countdown from? From the gearbox or from the generator? I read somewhere that Renault is not like everyone else.

And one more thing: the universal on-board computer (inserted into the round air duct) from the ATS connector gives misfires in the 3rd cylinder. How is he counting down? Where?

Error 0300 and 0304? The exact decoding will be - frequent misfires - frequent misfires in the 4th cylinder. And this somewhat expands the search, because the cause can be either a spark or gasoline. If there is no ignition for a long time, the brains will turn off the cylinder injector, i.e. supply of gasoline so as not to kill the catalyst. The engine revs clearly. After the restart, it will turn on the injector, but if there are any gaps, it will turn it off again.

But I would start by moving the spark plug and ignition coil from the good cylinder to the 4th one and see if the error moves to another cylinder. If not, then the reason is in the fuel supply, compression, valves.

Threat. But I haven’t figured out where the brains get the information from)), perhaps through the knock sensor. PS.2. Yes, on old Renaults the 1st was from the clutch flywheel. It’s unlikely that the paddling pools allowed Muscovites to change technological maps and then adjust all the diagnostics and brains to the opposite side. )

RE: “ Three. But I haven’t figured out where the brains get the information from)), perhaps through the knock sensor.

By decelerating the flywheel, with DPKV. And which cylinder out of pairs of cylinders (1-4 or 2-3) - according to the DPRV.

I would like a link to technical literature.

And I set it to 4 pulses from the knock sensor per revolution according to the knee sensor, and the DPRV is already calculating the cylinder.

Threat. There are many reasons for uneven XX, but there is no omission error. Why?

Source