How can I get good ride quality?

To understand how to achieve good ride quality, you need to understand how a car's suspension works. When a wheel, for example, hits a bump, it should rise up. Ideally, the car’s suspension should “swallow” this obstacle without transmitting vibrations to the body.

However, in reality, the body will naturally receive some vibration transmitted through the springs and suspension arms. The magnitude of these “parasitic fluctuations” depends on several factors.

A spring - a coil spring, a spring, a torsion bar or an air tank - holds the car body at a given level. It also determines the compression rate of the suspension. As a rule, springs are characterized by two parameters: stiffness and load capacity.

Advantages

For the sake of this characteristic, many people overpay that much money for installing air suspension. But comfort is not the only advantage of this system. If we talk about commercial vehicles, installing air suspension allows you to increase the load capacity without harming the chassis. And the load itself, thanks to the pillows, will remain intact, since the springs dampen vibrations more rigidly.

The next plus is the high stability of the car on the road. Many. It allows you to eliminate rolls when cornering. This can also be done on a spring suspension by clamping the travel of the shock absorbers. However, driving comfort will remain in question.

Another plus is the ability to adjust the clearance. Usually this is a range of 10-15 centimeters. The driver will not have to cut or extend springs to achieve specific ride characteristics. All this changes in a matter of seconds, right from the salon.

History of creation

We won't dig deep. We only note that the installation of PTS on a mass-produced car was carried out by the French in 1655. This honor was awarded to the Citroen DS-19.

Each wheel was equipped with independent piston springs of a pneumatic operating principle with the possibility of adjustment. It’s interesting that the model in question still leaves the factory assembly line today with the original version of the springs.

In the States, air springs began to be installed in 1957: we are talking about mass production of passenger cars. The pioneer was the Cadillac Eldorado.

Subsequently, the Germans became interested in the new product. We used designs starting with the Mercedes-Benz 300 SE. This happened already in 1961. Further attempts at improvement did not bring the desired results and gradually diaphragm-type RKOs became history.

The USSR also studied this issue and tried to apply the design, so to speak, in practice. This affected freight transport and buses in the 50s. Large-scale meetings were held where new products were demonstrated. Over time, it was decided to introduce air springs based on RKO into mass production.

Buses with a new design have appeared on the roads of the post-Soviet space. These are equipment (buses) of LAZ (Lvov Automobile Plant) and trolleybuses ZiU (Uritsky Plant). In the late 50s and early 60s, the Izhevsk Automobile Plant produced the first Moskvich with a pneumatic suspension system.

Things didn't go any further than that. The fire of enthusiasts gradually died out. And only many years later it flared up again. The innovation has now affected passenger cars, where hose-type RKOs were installed. He aggregated with ESU.

Today you won’t surprise anyone with adjustable systems. Factories are mass producing these designs. The automobile giants of the USA, Japan, Europe and a number of other countries got down to business.

Features of car air suspension

Air suspension in its pure form exists only in theory. In practice, this is the name given to a fairly complex set of mechanisms and components of different types. In this suspension, only the elastic element itself remains pneumatic, which replaces classic springs, springs or torsion bars. Nevertheless, this allows air suspension to gain many advantages over other designs. The main thing is a smooth ride and the ability to adjust the vehicle's ground clearance.

General view of the Mercedes ml350 air suspension

The implementation of a pneumatic system is impossible without borrowing elements of other types of suspensions: MacPherson, multi-link suspension (Multilink), adaptive and hydropneumatic. Air suspension has a fairly high cost, so it is mainly used on premium-segment cars. Although several decades ago attempts were made to use it on mass models, such as the Citroen CX.

Air springs on a three-axle tractor

Air suspensions have become widespread in heavy vehicles and buses, since the load capacity, dimensions and application features of such equipment make it possible to fully realize all the advantages of pneumatics. Car suspensions of this type are complex in design and work, as a rule, with adjustable shock absorbers controlled by electronics. Such systems are called adaptive suspension.

How it works

The control unit collects information from sensors. If necessary, air is pumped into the air bags or released into the atmosphere. This is the general operating principle. The more complex the pneumatic system, the more subtleties there are in its operation.

When turning, the position of the body changes and it tilts. Position sensors detect this and transmit a signal to the control unit. It gives an impulse to the solenoid valves to open and increase the pressure in the air springs on the side that is tilted down. This minimizes body roll.

As the speed of the vehicle increases, in the case of adaptive air suspension, its stiffness changes. The air pressure in the air struts increases and the suspension becomes stiffer. This improves handling and directional stability, but reduces comfort.

Therefore, the driver is allowed to choose the suspension mode himself. If he wants more comfort, he selects the comfortable mode, some of the air is released from the elastic elements and they become soft. You need controllability, select the sport mode. More air is pumped into the air bags and they become stiff.

When going off-road, you can increase the vehicle's ground clearance. The driver presses a button, and the compressor pumps as much air into the pneumatic elements of the system as necessary to raise the car above the ground. By the way, this is one of the primary tasks set by the developers.

What is "pneumatics"

Of course, modern high-quality shock absorbers make driving a car with a classic suspension quite comfortable, but that’s probably all that can be said about the “classic”. No matter how elastic the springs and springs of such a suspension may be, the entire structure retains a high degree of rigidity. This means that the ground clearance (the distance between the bottom and the road surface) of a car equipped with a classic suspension remains unchanged.

This element was developed and put into operation to provide the driver with a greater degree of convenience and a high level of safety while driving.

Air suspension has become widespread on car trailers and truck-type equipment.

However, business-class passenger cars are also often equipped with “pneumatics” - this gives the model a special status and attracts the attention of those who value safety and convenience, while having the opportunity to purchase such a car.

Device

Most of the system elements are located under the bottom of the car within its frame. All of them are interconnected by air pipelines and electrical circuits.

Pneumatic elements

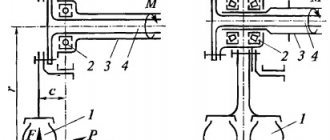

Air bags are cylindrical cylinders made of durable reinforced rubber. On the one hand, they are connected to the frame, and on the other, to the continuous rear axle of the car.

Each cylinder has a fitting to which an air line is connected through a valve. Depending on the load and the amount of pumped air, the height of the pneumatic element changes, which entails raising or lowering the body above the road.

At the same time, they serve as an elastic suspension element, that is, additional springs or springs are not provided.

The pads can be connected to each other when the equalizing valve is turned on.

Compressor

To pump air, a conventional piston or membrane type compressor, equipped with a receiver and filter, is used. The compressor is turned on and off via an electronic relay located in the control unit.

An additional dryer is installed between the compressor and the entire pneumatic system, which prevents the accumulation of moisture in the cylinders and lines. There is also an atmospheric valve for releasing excess air.

Receiver

The receiver acts as a compressed air accumulator, which allows you to reduce the load on the compressor and more quickly manage energy resources in the system.

So, for example, if it is necessary to quickly relieve pressure in the cylinders, the receiver valve opens and the air goes into it, only part of it can be released into the atmosphere.

In the same way, partial replenishment of cylinders occurs without unnecessary costs of compressor operating hours.

Control system

The control system includes a separate electronic air suspension control unit, a set of electric pneumatic valves, a manual body level switch and position sensors for the right and left sides.

Signals about vehicle speed and even the opening of body doors are also collected. The operating algorithms are programmed into the memory of the electronic unit processor and are quite complex. Up to the presence of undocumented functions.

The system allows for service adjustments, which mainly boil down to calibrating the position of the suspension sensors according to the method from the instructions. You can use a diagnostic scanner or a regular multimeter.

The sensors are quite simple; they are potentiometers driven by the rear suspension arms, adjustable in height.

Classic air suspension design

Air suspension diagram

Over the several decades during which air suspension was installed on production cars, it managed to prove its endurance, performance and, most importantly, practicality. Main elements of air suspension:

- pneumatic elastic elements;

- compressor;

- receiver;

- body position sensors;

- control system.

Pneumatic elements

Design of air suspension struts

Air springs, air spring, elastic element, they can be called differently. The essence does not change from this. The task of the pneumatic element is to effectively absorb the loads from road unevenness and maintain the vehicle's ground clearance at a given level. To do this, it needs to maintain a certain air pressure and maintain it in its volume. Structurally, the air spring can either be made together with a shock absorber, or installed separately. If this is a complex solution, then the shock absorber and air spring will be called an air strut. It is similar to MacPherson, but instead of a spring there is a rubber chamber filled with air. Some types of air bags have pressure limiting valves, and some have air accumulators, so as not to be so dependent on the pressure created by the next element of the system.

Compressor

Its task is to provide all air springs with air at a given pressure. This is not just a compressor, but a chain of elements that control the air supply and the overall pressure in the system; In addition, the compressor design must include a dryer to prevent moisture accumulation in the system.

Receiver

Audi A5 air suspension

A receiver is a reservoir that serves to accumulate compressed air and further maintain a given pressure in the system. This is an optional element, but its use is highly desirable, as it allows you to avoid forcing the compressor to pump air constantly. After the pressure in the receiver decreases to a certain limit, the electronics will give the command to the compressor to turn on.

Control system

An electronic control system monitors the pressure in the air cylinders and distributes it to each of them. For this purpose, limit and bypass valves are integrated into the air suspension system. Sensors monitor the operation of the pneumatic system, body position, vehicle speed, road surface quality, steering wheel angle and accelerator pedal position. Based on these indicators, the control system regulates the position of the car body and the degree of damping of the shock absorbers (in the case of adaptive suspension).

Principle of operation

The main task of the air suspension is to maintain a given level of body height above the road and effectively absorb all irregularities. The system can be controlled either manually or automatically. And here every year the manufacturer has more and more opportunities. The data received from the sensors is transmitted to the control system, and it already issues commands to the actuators: pump up and increase the pressure, or relieve pressure from the front or rear circuit (or both at once) and press the car body to the asphalt at the minimum permissible distance at high speed. Each air suspension has its own settings and purpose, which depend, first of all, on the type of car.

I want to build my own harness from scratch

No problem! Creating a good air suspension is no different from developing a traditional design. Even simpler. With spring, spring or torsion bar suspension, you should have an “estimate” of what the ground clearance (as well as ride quality) will ultimately be.

Everyone has their own favorite combination - using Malibu springs with one coil cut off or an S10 spring with a separated leaf. It will all work somehow. But let's look at why the design works and how to improve its performance.

Let's say your buddy is building a 48 Ford with a Camaro front subframe and S10 rear springs. He'll ride great! You want to do the same for yourself. Only you have a convertible with a big engine. As a result, it will “sit” too low and drive disgustingly. Now you will have to look for some other springs and leaf springs for the car.

With air suspension, the issue is resolved by simply increasing the air pressure to compensate for the increased weight in the front of the car and less in the rear. An added benefit: once you've seated three friends in the back, all you need to do is pump in a small amount of air to compensate for the drop and restore ride quality.

I need specific information

There are several things that you should definitely consider when creating your own suspension (including air suspension):

- Body height. The vehicle must have sufficient body height to handle the road imperfections that may occur in your area. In this case, the minimum height should not be lower than 114 mm, since the operation of a normal suspension also requires a compression margin of about 76 mm and a rebound margin of about 50 mm. After determining the height, you need to look for a place to install the air cylinders - vertically, to their full length. It is very important! If you have 230mm long air springs and you are trying to fit them into 175mm, the best ride quality will be achieved at a level that is at least 50mm higher than the maximum possible. Even if you lower the cylinders to the desired 175 mm, the ride quality will still suffer. Any competent supplier of air springs will be able to give information on their exact dimensions, both fully inflated and deflated.

- Ground clearance. Many customers want to “lay” the car body as low as possible. Do not do that! You should have at least 25mm of clearance with the air springs fully deflated. It is also necessary to provide at least 115 mm of suspension lift to safely drive over speed bumps or other road irregularities.

- Cardan shaft and ball joints. The support mounts can be moved quite far. The driveshaft also does not “stick out” from the transmission tunnel to its full length. Your task is to determine these quantities and take them into account.

- Gap around air springs. The only rule: the cylinders should never rub against anything.

The listed factors require significant constructive research, because they all must be met. The advantage of air suspension is the ability to change the height of the body by pumping/bleeding air from the air cylinders in any speed range for a comprehensive assessment of the suspension design. Proper tuning of a conventional suspension is much more difficult.

Characteristic

So what is air suspension? This is a type of suspension that regulates the position of the body relative to the road due to elastic elements. Air cylinders are used as the latter. In fact, this is one of the main components of this system. Where is this suspension used? It is usually installed on expensive versions of SUVs and sedans. At the moment, air suspension can be found on Volkswagen Touareg, Audi Ku-7, BMW 7 Series, Lexus LS and others. Along with this, the air system is also installed on commercial vehicles. These are truck and mainline tractors from Volvo, Scania, MAN, Iveco and many others. This system is also used on trailers and semi-trailers (including Kegle and Schmitz).