The VAZ 2114 air filter is a key component of the internal combustion engine protection system. The filter does not allow dust, debris, or other foreign bodies to enter the working chambers of the motor; helps maintain its functional state.

The air filter is a consumable item: during operation it becomes clogged, is exposed to various influences and over time there is a need to replace it. The declared resource of the “air vent” is 30,000 km, but operational practice shows that in reality the filter is changed every 15-20 thousand mileage.

The “2114” model is equipped with panel-type air filters. In the era of carburetor engines, large round filters were installed on cars. The panel design made it possible to optimize the dimensions of the part and improve the performance properties of the filter element.

Article number and cost of the original VAZ 2114 air filter and its analogues

The branded air filter for the VAZ 2114 has catalog number 2112-1109080. Its price ranges from 240 to 300 rubles. When purchasing an original consumable, the car owner knows for sure that the filter will fit well into the seat and there is no need to use an adapter. In this case, the filter element is attached in the normal way.

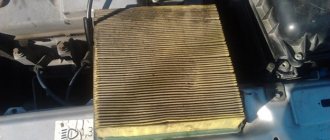

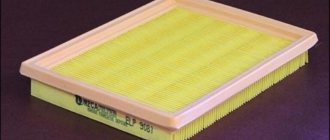

Old and new filter elements VAZ 2114

In addition to the branded air filter on the VAZ 2114, it is possible to use its analogues. Some of them are of very good quality and attractive prices. The table below shows the best alternatives to native consumables in terms of cost to quality ratio.

Table - Alternatives to branded air filter 2112-1109080

| Brands of analogues of the original air filter | Article number | Estimated cost, ruble |

| Febi | 1510 | 260-300 |

| Champion | CAF100505P | 350-450 |

| Knecht-Mahle | LX220 | 450-550 |

| Japan Cars | B2W004PR | 120-160 |

| JC Premium | B2W004PR | 320-430 |

| Bosch | 1457429061 | 370-410 |

| Starline | SFVF2246 | 150-220 |

| Denckermann | A140027 | 160-190 |

| Filtron | AP006 | 200-270 |

Buying a new part

A new filter for the “fourteenth” costs no more than 300 rubles. Spare parts are sold in any stores specializing in the domestic automobile industry. It should be noted that the air filter housing for the VAZ 2114 is a separate part and must be purchased additionally. Low prices for components make installing a VAZ 2114 air filter a feasible task for any owner of a “chepyrka”.

Some craftsmen manage to clean used filter elements with their own hands, but in essence, the result is zero. The service life of remanufactured filters is extremely short, and manual cleaning requires a lot of time, so initially this idea is impractical.

Most car enthusiasts prefer a standard part marked VF-14. Sold at any car market for 150-200 rubles. If you are interested in the maximum service life of the filter element, we recommend purchasing components from German manufacturers (products from MANN and HENGST are available on the market).

So-called “zero resistance filters” are also commercially available. “Nuleviki” significantly increase engine power, but their installation requires additional modifications to the power unit.

Frequency of replacing the air filter on a VAZ 2114

The service life of the filter element is directly related to the operating conditions of the vehicle. According to official recommendations, replacement of consumables is required every 20-30 thousand km. In this case, for a number of reasons, there may be a need for an unscheduled installation of a new filter element.

An indirect sign that the filter needs to be changed is a deterioration in the dynamic performance of the vehicle. A “strangled” engine is not capable of energetically accelerating the car. In addition to the drop in power, the engine begins to consume more fuel. Therefore, if such symptoms appear, you should check the condition of the air filter and, if necessary, replace it.

During the operation of the vehicle, for one reason or another, the filter element may be damaged. Through the resulting hole, dust and abrasive particles enter the combustion chamber. Therefore, if damage is detected, a completely new filter should be installed immediately.

Consequences of short-term operation of a machine with a damaged air filter

Deformations of the filter element often lead to deterioration in throughput. The injector operates with a lack of air, which affects the proportions of the working mixture. In this case, the filter element should also be replaced without waiting for a deadline.

A clogged air filter is a common culprit for unstable operation of the power unit. There are many reasons for floating speed, but it is better to start checking with the condition of the air filter. If the consumable is clogged with dust and dirt, then a new filter element should be installed instead.

The filter should be replaced immediately after purchasing a used car. This is due to the fact that it is unknown how the previous owner carried out maintenance, as well as at what mileage the consumable was previously installed.

What's the result?

As our tests have repeatedly shown, the cost of a component and the promotion of a brand are not the determining indicators of its quality and operational efficiency, but they can guarantee the necessary indicator of reliability.

Generally speaking, we consider the Mahle air filter to be the best in this test. In terms of two important parameters (dust holding capacity and efficiency), it took first and fourth places, which, at a price slightly above average, makes it optimal in all respects.

Second place is shared by a whole group of filters whose parameters are worthy of a good review, although each of them is not a leader in individual tests. These are products from BIG Filter, Mann-Filter and Champion. Note that BIG Filter has the lowest price with good results. And if it weren’t for Mann-Filter’s unfortunate loss in efficiency, perhaps the leader of this test would have been different.

Outsiders include Bosch, Filtron, Sakura and Fram filters. However, the lag of these brands can be called relatively conditional - 1-2 points from the second group. Only the Sakura filter stands out, which, with low parameters, turns out to be the most expensive in the test.

The FILTRON company makes some of the best filters for LADA (BA3) 2113/2114/2115 (Samara 2)(1.3) in the world, which is why many car owners trust their choice of this company. For LADA (BA3) 2113/2114/2115 ( Samara 2)(1.3) FILTRON currently offers 3 type(s) of filters: AIR FILTERS, OIL FILTERS, FUEL FILTERS.

Table of contents

Timely replacement of filters is one of the most important components of the long service life of your LADA (BA3) 2113/2114/2115 (Samara 2)(1.3). Below is a selection of filters from FILTRON for your vehicle. When the time comes to replace the oil, air or cabin filters, almost all car owners ask themselves the question, which filter to install? It is not always possible to pull out this or that filter and see what is in the car. Difficulties also arise if you buy a car second-hand, because the previous owner may have taken poor care of the car and installed the cheapest filters; in this case, you should not rely on the filters already in the car.

Selection and correct replacement of the air filter on the VAZ 2114

Combustion of any type of fuel is impossible without access to air. This fully applies to internal combustion engines. Gasoline in its pure form does not enter the engine cylinders, but an air-fuel mixture consisting of one part gasoline and 15 parts air is supplied. The air filter on the VAZ 2114 is responsible for the flow of air into the injector in its pure form, without various small particles and other impurities. The same air purification system is provided for the VAZ 2113, VAZ 2115.

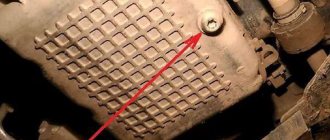

Air filter (orange-yellow) and the box where it is placed (shown by the arrow)

Why does oil get in?

To understand why oil particles appear in the air filter, consider the following carburetor operation algorithm:

- When fuel burns, crankcase gases are formed;

- In the normal state of the engine, they are completely removed from the cylinders;

- If the engine is worn out, coked, or has other problems, some of the crankcase gases remain inside;

- This provokes the creation of high blood pressure;

- Due to increased pressure, the condition of the seals deteriorates and they cannot perform their functions properly;

- If the oil seals are damaged, oil consumption increases and it begins to flow into the VF.

Oil in VF

There are several main reasons why the VF becomes contaminated with oil.

| Cause | Nuances |

| The piston rings of the power unit are worn out | This leads to a disruption in the proper functioning of the collection of excess lubricant that enters the crankcase from the cylinder. Pressure increases, oil is squeezed out by the oil deflector and vent valve. A clogged oil deflector drain does not allow the lubricant to return back to the crankcase, so it escapes along with the gases |

| The crankcase gas outlet paths are clogged | If the paths are clogged, gases from the crankcase cannot fully escape the throttle limits. As a result, we get lubricant and gases in the air filter |

| Air cleaning material is clogged | The engine does not receive enough air, so it begins to suck it in from all available sources. Not rarely - from the crankcase. As a result, it turns out that the filter is flooded with oil. |

Piston rings

A little about the design of the VAZ air filter

The power supply system of an injection engine differs from the same system of a carburetor engine. The injector is controlled by an on-board computer, so the air supply system has built-in sensors that communicate with the control system.

The main task of the air filter element in any internal combustion engine is to clean the incoming air flow from dust, moisture and other unwanted impurities. At the same time, it must provide the engine with the necessary volume of air to operate in any mode.

The air-type body on the VAZ 2114 is made of plastic. Unlike carburetor engine models, where it was round in shape, it now has a panel-type shape. Filter paper is placed in it in dense rows, which is fastened with polymer rings.

The air entering the engine compartment carries with it a large amount of impurities. All of them remain on the walls of the paper filter element. After some time, such a large number of them can accumulate that the flow of air will be very difficult. In this case, the technical characteristics of the engine change for the worse.

Compression check

After checking the compression, you can breathe a sigh of relief or worry, since the cost of the repair depends on the result.

Impaired compression often causes the presence of oil in the VF, and also causes a number of other problems.

Compression check

To work you will need:

- Compressometer;

- A rag in oil, which you will use to determine the compression stroke;

- Adapter for spark plug holes. It is used when checking the combustion chamber for leaks;

- Compressor.

Now let's start checking.

- Warm up the engine to operating temperature, then turn off the fuel supply.

- In the case of a carburetor, you need to remove the hose, clamp or squeeze it with something, or lower it into a container.

- If you have an injector, remove the fuel pump fuse, start the engine and let it run. As soon as the fuel in the fuel rail runs out, it will stall on its own.

- Disconnect the ignition system by removing the center wire from the distributor (on the carburetor). The crankshaft position sensor at the injector must be disconnected.

- Remove all debris from the spark plug wells so that it does not end up inside the cylinders. Unscrew the spark plugs.

- Insert the compression gauge fitting while an assistant starts the engine. The starter should rotate the engine until the pressure gauge needle stops in one position.

- By analogy, measurements are carried out on each cylinder, the results are recorded on paper.

- To calculate ideal compression, use the formula - 1.2 * Compression ratio.

See your owner's manual for the compression ratio of your engine. Please also note that measurements may have some error.

What you need to know about verification

- If the indicator is 12 atmospheres, this indicates that your engine is almost in perfect condition.

- When checking the compression on a cold engine, the compression readings will be significantly lower. Perform the test only on the engine at operating temperature.

- If the battery is partially discharged, the test data will also not be accurate.

- The increase in compression occurs due to the combustion of oil in the cylinders.

What the results say

We take the paper where you wrote down the data of the check, carried out according to all the rules, and study what is wrong with the motor.

- Indicators in the range of 0-4 atm indicate a high probability of burnout of the piston, head gasket or valve.

- Compression of 4-6 atmospheres indicates that the piston rings or the partition between them have broken.

- If you get about 8-10 atm in each cylinder, the cylinder-piston group is worn out. Major repairs will soon have to be carried out.

- 12-12.5 atm - these are the indicators that occur in a new, run-in power unit.

- If the car has serious mileage, and the check data shows numbers equal to or exceeding the norm, oil has probably entered the cylinders due to wear of the cylinder-piston group or valve liners.

Obviously, the presence of oil in the filter does not bode well. But the problem can still be prevented if measures are taken in time.

Right choice

Retail chains, car markets and service centers offer a large number of such products to choose from. Their difference lies mainly in the price and manufacturer of the products. Various research centers, including the laboratory of the magazine “Behind the Wheel,” conduct tests of air filters.

If you look at one of the latest reports, you can see that the products of the following manufacturers performed best:

- “MANN”, produced in Germany, code C22117;

- "HENGST", also made in Germany, its code is E22L;

- The “AF” element is also produced in Russia, code 2112-1109080-02.

- Russian manufacturers produce the “BIG” filter, code BG 9597С;

The filter marking is BIG

All of them do not belong to the category of scarce spare parts; their cost ranges from 80 to 300 rubles per piece.

Scheme of operation of the VF in the system

Injection and carburetor engines have some differences in terms of air movement through the engine system. On injectors, injection is controlled electronically. Therefore, the system contains sensors that interact with the on-board computer.

We advise you to familiarize yourself with the air flow diagram and the participation of the air filter in this process.

- Air is drawn through the cooling system fan and supplied to the panel filter. The carburetors had large round filters, the effectiveness of which is quite questionable.

- Injection filters, although more compact, provide better air purification and create optimal air flow. For the injector, the quality of the air entering the intake pipe plays an important role.

- At the outlet of the filter, between it and the corrugated hose coming from the inlet pipe, there is a mass air flow sensor (MAF) - a mass air flow sensor. It calculates the amount of air that is sucked in by the engine.

- After the sensor, the air goes into the corrugated pipe of the intake pipe and moves to the receiver. In front of it there are a couple more sensors - the idle air control and the throttle position sensor. The receiver serves to accumulate air and provide compensation for fluctuations in air masses.

- Air is taken from the receiver via a hose by a fuel pressure regulator, which is located on the fuel rail.

- The bulk of the air leaving the receiver goes into the inlet pipe of the power unit manifold.

Purpose

The air filter has two main tasks:

- Qualitatively clean the air entering the cylinders from dust, dirt and moisture;

- Provide maximum air flow capacity.

The specified parameters in the form of data are clearly indicated in product passports

Therefore, when choosing a new filter, it is very important to choose the optimal unit

Design

The filter housing is made of plastic. Inside it there are rows of filter paper elements. Special polymer rings ensure compaction of the rows of paper filters.

Over time, when the filter takes a long time to clean and accumulates a large amount of contaminants on the walls, air ceases to flow in its original volume, which negatively affects the engine power and the stability of the power unit.

VF Corps

VF selection

Experts regularly conduct various tests and checks, trying to determine the most effective air filters today.

Since we are talking about the VAZ 2114 model, let's find out which VFs are ideal for this car today. The choice of specialists is based on several of the most significant parameters:

- Lifetime;

- Resistance to air flow;

- Quality of materials used, etc.

As a result, we can give an example of several of the most successful VF options for today specifically for the VAZ 2114.

| Manufacturer | Item code | average cost |

| MANN company, Germany | From 22117 | 250 rubles |

| HENGST company, Germany | E 22 L | 200 rubles |

| BIG, Russia | GB 9597 C | 100 rubles |

| AF, Russia | 2112-1109080-02 | 80 rubles |

In order to increase motor power, many decide to install a zero-resistance filter. But you should be careful with it and find out in more detail what such a modification may entail.

Zero resistance filter

Today, more and more often you can find car owners who replace a conventional VF with a zero-resistance filter. It is believed that it has a positive effect on increasing the power of the power unit. But let's find out all the ins and outs of it.

In addition to installing such a filter, you will have to modify the intake system, carry out chip tuning and more.

Also, such filters are very delicate and require increased attention, regular maintenance, and impregnation with special compounds. If you spill this composition on the mass air flow sensor, you will disrupt its functionality, which will lead to malfunctions of the engine.

Zero filter

Obviously, a zero-resistance filter has a lot of disadvantages, so most experts do not recommend installing it instead of a standard VF.

How to change the air filter

It seems like we have decided on the choice of element for air filtration, let's talk about when and how to replace the air filter on a VAZ 2114. The car's operating instructions prescribe this operation after 10-15 thousand kilometers. The mileage of the car should in no case be more than 30 thousand km.

The service life is greatly influenced by the conditions in which it has to work. Sometimes the air filter on a VAZ 2114 is replaced much earlier. This can be caused by long-term operation of the machine in highly dusty conditions. Some experts recommend blowing it out to extend its service life. This can be done, but as a temporary way out of the current situation. In the near future, the “blown” element needs to be replaced. In order to correctly replace the air filter on a VAZ 2114 injector, you need to prepare the tools and everything else for replacement:

- New air filter;

- Work clothes;

- Phillips screwdriver for opening the case;

- A rag for wiping the body.

If all this is prepared, you can get to work. This can be done this way:

- It is necessary to open the hood and disconnect the terminals from the battery;

- Next, you need to release the latches on the housing and disconnect the mass air flow sensor. This is done in order to prevent its accidental breakdown.

- Then you need to disconnect the inlet pipe. To do this, just loosen the clamp on it. Experienced drivers do not do this, but simply carefully lift the housing cover along with the pipe.

- To remove the housing cover, you need to unscrew the four screws that secure it to the housing using a Phillips screwdriver.

- When the cover is removed, take out the old filter.

- There is small debris, dust and dirt in the case; they must be removed using any available method.

- The next step is to install the air filter into the housing. It also has its own small features. How to install the air filter correctly is written in the operating instructions, but just in case we will remind you. Inside the housing there is an arrow-shaped indicator for the correct location of the filter element. Position the filter corrugations in the desired direction and place it in the housing;

- Before installing the cover in its place, it is necessary to pay attention to the condition of the sealing rubber gasket. If necessary, it must be replaced with a new one;

- Place the housing cover in place and screw in the bolts securing it.

- Next, the driver needs to put the mass air flow sensor and pipe in place. This completes the work of replacing the filter.

In conclusion, I would like to say a few words about such a newfangled hobby for car enthusiasts as installing an air filter with zero resistance. Its installation allows you to increase engine power due to increased filling of the working cylinders with the air-fuel mixture.

Before a decision is made on such a modification, it is necessary to weigh the pros and cons of such a modernization. Installing a “nulevik” entails modification of the intake system, chip tuning of the control unit and other work.

Such an element needs to be impregnated with a special solution, and this must be done with extreme caution. If this liquid gets on the mass air flow sensor, it will not be able to adequately respond to changes in air flow and engine interruptions will begin.

Installation procedure

- Before installation, remove the rubber support for the rear air filter mount from the housing hole. We replace the damaged rack.

Using a screwdriver, insert the rear rubber strut into the hole in the bracket.

Wet the rubber stand with soapy water. We install the air filter housing in place so that the strut fits into the hole intended for it, and the brackets for the front rubber struts are located under the hood lock rod. While pressing down on the filter housing, use pliers to pull the stand up until the housing is fixed in the annular groove of the stand.- We connect the air supply hose to the throttle valve to the mass air flow sensor.

- We connect the wiring harness block to the mass air flow sensor.

- We fix the hose tip in the bracket.