The weak link of the VAZ 2107 brake system is the rubber hoses connecting the metal liquid tubes to the working cylinders of the front and rear wheels. The pipes are bent many times during the operation of the car, which is why the rubber begins to crack and leak liquid. The problem cannot be ignored - over time, the level in the expansion tank will drop to a critical level and the brakes will simply fail. Replacing defective hoses on the “seven” is not difficult and is often performed by car enthusiasts in garage conditions.

- When to change hoses

Video: diagnostics of flexible brake pipes

- Video: how to distinguish counterfeit parts

- Installing the front hoses

Video: Tips for replacing front hoses

- Video: replacing the rear axle brake hose

Self-replacement of brake hoses on a VAZ 2107

Brake hoses in the VAZ 2107 are made of rubber, and they need to be changed periodically.

Over time, they become brittle, the rubber wears out, and the brake fluid begins to leave the reservoir. If you don’t monitor its level, one day you may end up in a situation where the brakes simply fail, and it’s good if this happens on a deserted street. To avoid this problem, monitoring the condition of rubber parts and brake fluid levels should be carried out regularly, regardless of service life. Replacing brake pipes in a VAZ is a process that you can easily do yourself in the garage, using the advice of professionals.

About grooving brake drums

As mentioned above, some defects that arose during the operation of brake drums can be eliminated using the so-called groove. It should be said right away that it is not possible to sharpen a drum yourself in a garage. Because for this, firstly, you need a lathe, and secondly, you need the skill of working on this machine, and a serious skill at that. A novice driver can hardly boast of having a machine in his garage and the corresponding skills. Therefore, he has only one option left: to seek help from a qualified turner.

For high-quality drum turning, you can’t do without a lathe.

So what is a brake drum groove? It usually consists of three stages:

- preparatory stage. The turner removes about half a millimeter of metal from the inner walls of the drum. After this, the machine is turned off, and the drum is carefully inspected for internal defects. The preparatory stage allows you to determine the general level of wear of the drum and the feasibility of further work. Sometimes, after the preparatory stage, it turns out that the groove is useless due to severe wear, and it is easier to replace the drum than to grind it;

- main stage. If, after preliminary processing, it turns out that the drum is not very worn, then the main stage of turning begins, during which the turner smoothes and grinds all small cracks and grooves. During this work, about 0.3 mm of metal will be removed from the inner walls of the drum;

- The final stage. At this stage, the sanded surface is polished using a special paste. This procedure eliminates even the smallest defects that are not visible to the naked eye, and the surface becomes perfectly smooth.

It should be noted here that the groove will help get rid of internal defects on the drum, but it will be useless if the geometry of the drum is broken. For example, the drum was warped due to an impact or due to severe overheating. If the drum is cast iron, then it will have to be changed, since it is extremely difficult to straighten brittle cast iron using metalworking tools. If the drum on the “seven” is light alloy, then you can try to straighten it. And only after that start grooving.

Replacement instructions

Before you start replacing the hoses, it is better to remove the brake fluid from the central reservoir using a syringe or enema bulb so that it does not spill out during the replacement process.

Installing the front hoses

The wheel on the other side is removed in the same way and the hoses are changed. After replacing the wheels, you should not put them on immediately; first you need to bleed the brakes.

Replacing front hoses (Video)

How to change the rear pipe

In classic VAZ models, replacing the rear pipe is almost no different from the front, which greatly simplifies the task. The work must be done in the same sequence:

Changing the rear axle pipes (video)

Removal and repair

To remove, repair and reinstall, you will need a minimum of tools:

- key to 13;

- special wrench for brake pipes;

- flat screwdriver;

- brake master cylinder repair kit;

- brake fluid container;

- syringe;

- brake fluid.

To avoid spilling brake fluid from the reservoir, it must be poured into a prepared container using a syringe. The procedure for removing the cylinder is as follows:

- loosen the rubber hose clamps on the brake cylinder fittings;

- remove the hoses coming from the brake fluid reservoir to the cylinder fittings;

use a special wrench to unscrew the three brake pipes;

- unscrew the nuts securing the main brake cylinder to the vacuum booster;

- remove the brake cylinder.

Now it is necessary to disassemble the master brake cylinder and inspect it for scratches or shells; if they are not found, if the mirror is clean, then repair is possible, otherwise, replace the master brake cylinder with a new one. At this stage there should not be any problems - you need to unscrew the locking screws one by one, starting from the plug. When you unscrew the second screw, hold the piston so that it does not fly out under the force of the spring. The first piston will come out on its own, the second will need to be knocked out, tap the body on a piece of wood.

- remove all o-rings from the pistons and thoroughly wipe all parts - pistons, springs, housing;

- replace the rubber seals on the pistons;

- Assemble the master cylinder parts and tighten the plug nut.

Screw it to the vacuum body, connect the tubes and hoses from the tank. The tubes should not be screwed in completely; fill the reservoir with brake fluid and, as soon as it begins to flow out from under the tubes, screw them in completely. After final assembly, the system will most likely need to be bled to remove air from it, and the fluid will be completely replaced.

We check the connections and the main brake itself for leaks. It is also necessary to check the effectiveness of the brakes. If everything is fine, then your car is ready for further use.

Bleeding the brakes

An important step after replacing parts. If the work was carried out alone, then an assistant will be needed for pumping. He must constantly press and hold the brake while air is removed through the fittings using a transparent hose. On each wheel, the procedure should be carried out until there are no air bubbles left.

Replacing brake hoses on a VAZ 2107 is not difficult; you can do it yourself. It is most convenient to do this on an overpass, or from a garage pit, but it is possible to carry out an emergency replacement on a flat area, although this is very inconvenient. Of course, it is better not to lead to such situations, so you need to regularly check vital spare parts for integrity and performance.

Source

Installing the brake caliper

Installation of the brake caliper on the VAZ 2107 is carried out in the reverse order of its dismantling.

After installing the brake caliper, it is imperative to bleed the brake system, removing air from it. Until this operation is completed, operating the vehicle is strictly prohibited.

The left and right wheel calipers are slightly different, so you need to pay attention to this when purchasing new ones. After repairing and installing the VAZ 2107 brake caliper, it is necessary to check the brake system for fluid leaks and, if necessary, repair them. After repairing and installing the VAZ 2107 brake caliper, it is necessary to check the brake system for fluid leaks and, if necessary, repair them

After repairing and installing the VAZ 2107 brake caliper, it is necessary to check the brake system for fluid leaks and, if necessary, repair them.

How to replace brake hoses on a VAZ 2107 car

To supply brake fluid from the master cylinder to the workers, not only steel lines are used, but also rubber hoses in the design of the VAZ 2107. If a fluid leak is detected at the junction of these elements, then you will need to replace the brake hoses on the VAZ 2107. This is not difficult to do. , but for beginners it will be useful to know the instructions for replacing these elements.

How to repair brake pipes

This process requires the car enthusiast to have extensive locksmith skills and the ability to use special tools. Repairs are carried out in cases where it is not possible to replace the damaged line; it involves saving money on the purchase of a new pipe system and extends the service life of the old one.

To carry out repairs you must:

1. Unscrew the damaged tube from the cylinder or brake caliper.

2. After disconnecting, it is necessary to cut off the damaged area using a pipe cutter.

3. Clamp the tube 50 millimeters from the edge of the cut and chamfer the edge of the tube using a drill.

4. Remove all that remains of the chips and insert a fitting intended for connecting the tube to the brake operating mechanism into the cut area.

5. Insert the end of the tube into the special equipment and flare it. The main line that has undergone repairs must be purged with compressed air. And only after this is it installed with a working mechanism or another pipeline system using an adapter.

As for the length of the tube, this parameter depends on the car model. On some cars, the brake pipes have a reserve that allows you to shorten the pipe and reconnect it to the working mechanism. The metal from which the brake tube is made is flexible, so there should not be any difficulties with its position.

Purpose of flexible pipes

All drivers know how the brake system works on a VAZ 2107 car. The principle of its operation is simple, and is implemented through a set of parts that create the system. One of the important parts is a short flexible rubber hose (piping) connecting a metal tube (coming from the main brake cylinder) to the working cylinders (calipers) of each wheel. There are a total of three hoses installed on the machine, consisting of a rubber sheath, which ensures flexibility.

Why can't a car design do without rubber hoses in the brake system? The wheels are connected to the body through a suspension that is designed to smooth out vibrations. If you do not use rubber hoses, then under the influence of constant loads experienced by the wheels, their accelerated damage would occur.

For the manufacture of flexible hoses, reinforced rubber is used, which is highly resistant to moisture and oils. The front wheels use two flexible hoses, while the rear wheels only have one. On the front wheels they are connected directly to the calipers, but their rear design is somewhat different. Using a flexible connector, the metal tube running along the rear axle to both rear cylinders is connected to the tube on the car body.

This is interesting! The design of the VAZ 2107 brake system also contains rubber hoses connecting the expansion tank to the main cylinder, but they are rarely changed, since they are practically not tested.

Device design

There is nothing complicated in the design of a flexible connector, as it might seem at first glance, but it is this element of the system that is subject to heavy loads. After all, this connection not only experiences constant vibrations when the car moves, but also heavy loads in the form of high pressure. To prevent the hose from causing an accident, they must be changed regularly, without waiting for complete wear. On average, their service life does not exceed 3-4 years.

The use of tubes in the design of vehicles

Modern machines use several hydraulic systems with different main lines. One of them is the braking system. The working fluid moving through it must be isolated from the external environment due to tightness.

The success of reliable connections depends on the quality of the flaring. This operation uniformly increases the diameter of one tube tip. At the counter tube, the diameter of the tip is reduced to ensure rolling (entering a small diameter into a larger one and holding the pair in this position for a long time).

If the tubes in any of the sections receive mechanical damage, then due to depressurization of the system, part of the main wiring must be replaced. At a car factory, flaring is done using special equipment that contains hydraulic, electrical and mechanical drives. In garage conditions, a device for flaring brake pipes is most often mechanically driven by the muscular strength of the performer.

Guide to self-replacement of brake hoses of a VAZ 2107 car

The weak link of the VAZ 2107 brake system is the rubber hoses connecting the metal liquid tubes to the working cylinders of the front and rear wheels. The pipes are bent many times during the operation of the car, which is why the rubber begins to crack and leak liquid. The problem cannot be ignored - over time, the level in the expansion tank will drop to a critical level and the brakes will simply fail. Replacing defective hoses on the “seven” is not difficult and is often performed by car enthusiasts in garage conditions.

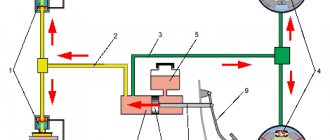

The principle of operation of the braking system

- Press the brake pedal

- It is secured by a rod with the piston of the main brake cylinder (MBC)

- The force from the pedal is transmitted through the rod to the piston, which compresses the brake fluid located in the tubes and cylinders

- Compression energy is transmitted to the working cylinders, which move the pistons along with the brake pads to the disc. He starts to slow down.

The harder we press the pedal, the more the brake fluid is compressed and the more energy is transferred to the pads, which means the faster the car will slow down, until it comes to a complete stop.

The principle of operation is perfectly demonstrated in the video below:

Purpose of flexible pipes

The contours of the VAZ 2107 liquid brakes are made of metal tubes leading from the master cylinder (abbreviated as GTZ) to all wheels. It is impossible to connect these lines directly to the working cylinders, since the wheel brake mechanisms are constantly moving relative to the body - the chassis absorbs unevenness, and the front wheels also turn left and right.

To connect rigid tubes to the calipers, flexible connections are used - brake hoses made of moisture-resistant reinforced rubber. The “seven” has 3 pipes - two on the front wheels, the third supplies fluid to the brake pressure regulator of the rear axle. Short thin hoses between the expansion tank and the gas turbine engine do not count - they do not have high pressure, spare parts rarely become unusable.

Flexible eyeliner consists of 3 elements:

The first end of the hose, connecting to the circuit tube, is always attached with a fixing bracket to a special bracket on the body. On the rear axle the second tip remains free, on the front wheels it is additionally fixed to the calipers with overhead brackets. To prevent liquid from seeping through the threaded connection, 2 copper sealing washers are put on the bolt.

Please note: the hose eyelet for the front wheels is made at an angle relative to the longitudinal axis of the pipe, as shown in the drawing.

Disassembly and assembly of wheel cylinders

| Rice. 7–16. Wheel cylinder: 1 — pad stop; 2 — protective cap; 3 - cylinder body; 4 - piston; 5 - seal; 6 — support cup; 7 - spring; 8 - crackers; 9 — thrust ring; 10 - thrust screw; 11 - fitting; A - slot on the thrust ring |

| Rice. 7–17. Wheel cylinder parts: 1 - piston assembly; 2 — cylinder body; 3 - thrust screw; 4 - thrust ring; 5 - crackers; 6 - spring; 7 — support cup; 8 - seal; 9 - piston; 10 - protective cap |

Install the piston assembly with the automatic device on a special device so that the protrusions of the device cover the head of the thrust screw 3 (Fig. 7–17). Using a special screwdriver, turning piston 9, unscrew the stop screw 3 from the piston. Remove seal 8 with support cup 7 and crackers 5 from the screw. Separate thrust ring 4 and thrust screw 3.

How to replace the rear brake hose of a VAZ.

Assemble the automatic device for adjusting the gap between the shoes and the drum and the wheel cylinder itself in the reverse order, taking into account the following:

— tighten the piston thrust screws with a torque of 3.9–6.9 N·m (0.4–0.7 kgf·m); Slot A (see Fig. 7–16) on the rings should be directed vertically upward; deviation from the vertical is allowed no more than 30°. This arrangement of the slot ensures more complete removal of air from the wheel brake drive when bleeding the brake;

— to pre-compress the thrust rings, press the pistons into the cylinder body using a special device shaped like a cylinder with a conical internal hole;

— the force of pressing the piston into the cylinder must be at least 343 N (35 kgf); if the force is less than 343 N (35 kgf), replace the thrust ring;

— when pressing the piston into the cylinder, it is necessary to maintain dimensions of 4.5–4.8 mm and 67 mm (maximum) (see Fig. 7–16) for a free fit of the brake drum;

— before installing parts into the cylinder body, lubricate them generously with brake fluid.

After assembly, check the movement of each piston in the cylinder body. They should move easily within 1.25–1.65 mm. Replace the protective caps 2 last.

Repair of VAZ rear brake cylinder. Budget renovation.

Replacement of rear brake cylinder cuffs of VAZ 2102

How to replace cuffs on a rear brake cylinder

Checking wheel cylinder parts

Pads

- Carefully check the pads for damage or deformation.

- Check the elasticity of the tension springs, both upper and lower; if necessary, replace them with new ones.

- The springs must not have residual deformations when stretched with a force of 343 N (35 kgf) for the lower springs and 411 N (42 kgf) for the upper ones.

Check the cleanliness of the linings, if dirt or traces of grease are found, thoroughly clean the linings with a wire brush and rinse with white spirit, in addition, check for any leakage of grease or oil inside the drum; eliminate the faults. Replace the pads with new ones if the thickness of the linings is less than 1.5–2 mm.

LADA Kalina engine cooling system diagram

Rice. Rear brake working cylinder: 1 — piston assembly; 2 — fitting for removing air; 3 - cylinder body; 4 - thrust screw; 5 - thrust (split) ring; 6 - crackers; 7 - spring; 8 — support cup; 9 — seal (rubber cuff); 10 - piston; 11.protective cap (“boot”)

On the VAZ-2104, VAZ-2105, VAZ-2106 (since 1986), VAZ-2107 and their modifications, automatic adjustment of the gap in the rear brakes is carried out using split thrust rings 5 (Fig.), pressed into the cylinder.

Therefore, when disassembling, first remove the anthers 11, and then apply light blows with a hammer through a soft metal drift to the piston 10 so that another piston, complete with ring, cuff and other parts 1, comes out from the opposite side.

Then a drift is inserted from the side of the removed piston and the one that was hit first is pressed out. During the operation, the drift should not touch the walls of the cylinder so as not to scratch it. The requirements for cleanliness are the same as when disassembling a VAZ-2101 cylinder (see above).

Then, holding the thrust screw with 4 pliers, using a screwdriver inserted into the slot of the piston 10, we unscrew the parts.

After replacing cuff 9, we assemble the assembly by moistening the parts with fresh brake fluid. The tightening torque of the thrust screw is 0.4-0.7 kgf-M. The pistons are pressed on each side.

When installing in place, ring 5 must be compressed, for which a small clamp is sometimes used.

Remember that the slot on the thrust rings 5 must be directed vertically upward (permissible deviation no more than 30°), otherwise air will not be removed from the cylinder.

After assembling the unit, check the stroke of the pistons. They should move easily by about one and a half millimeters (more precisely 1.4-1.6 mm). If this does not happen, the rear wheels will not release the brakes. Most likely the reason is improper assembly or contamination of parts.

When to change hoses

The service life of brake rubber pipes is about 3 years if the car is used regularly. A poor-quality hose may leak after six months or 2-3 thousand kilometers, or even earlier.

In order not to lose the brakes while driving and not become the culprit of an accident, the owner of the “seven” must constantly monitor the technical condition of the flexible hoses and immediately change them if the following signs are detected:

To identify cracks, the pipe must be bent by hand, otherwise defects may go unnoticed. A friend of mine discovered a fistula in the hose in this way, and quite by accident - he was about to change the upper ball joint, while disassembling it, he touched a rubber tube with his hand, and brake fluid flowed from there. Until then, the hose and surrounding undercarriage components remained dry.

If you ignore the above signs and drive further, the flexible line will break completely. Consequences: the fluid will quickly leak out of the circuit, the pressure in the system will drop sharply, and the brake pedal will fall to the floor when pressed. To minimize the risk of a collision in the event of a brake system failure, take the following steps promptly:

The advice regarding turning off the engine is only suitable for Zhiguli cars of the VAZ 2101-07 series, which are not equipped with hydraulic or electric power steering. In modern cars, you should not turn off the engine - the steering wheel will instantly become heavy.

Video: diagnostics of flexible brake pipes

BRAKE PADS PROBLEMS

The parts of the braking system in question have to be changed not only when they wear out, but also when malfunctions occur that are associated with the use of low-quality consumables or too active driving. The following characteristic signs indicate problems with the pads:

- creaking, grinding and other extraneous sounds when braking;

- car skidding when pressing the brake pedal;

- to operate the pedal you have to exert more or less force than usual;

- beating of the pedal when braking;

- after releasing the pedal, it does not return to its original position;

- the presence of black dust on the rims.

EXTERNAL SOUNDS

Modern brake pads are equipped with special indicators that indicate wear of these car parts. The indicator is a metal strip that is attached below the friction lining. When most of the material is worn out, but the pad is still able to decelerate, a characteristic grinding or whistling sound appears when the brake pedal is applied. If the pads are not equipped with such indicators, the presence of extraneous sounds indicates obvious wear of the elements in the brake mechanism and the need to replace them.

Pad wear can manifest itself in different ways, and one of the signs is extraneous sounds when braking.

SKID

If the car skids to one side when braking, then the likely cause is wear on one of the pads. The car can skid until it turns around, even on a dry surface. In addition to the pads, skidding can occur due to scuffing or deformation of the brake discs.

VIDEO: WHY DOES THE CAR PULL TO THE SIDEWAY WHEN BRAKING

Some time ago I was faced with a situation where the car began to pull to the side when braking. It didn't take long to find the reason for this behavior. After a quick inspection of the car's underside, it was discovered that one of the rear brake wheel cylinders was leaking. This caused brake fluid to get on the working surface of the pad and drum, as a result of which the mechanism was unable to perform its function. The problem was resolved by replacing the cylinder and bleeding the brakes. If you encounter a similar situation, I recommend replacing the entire cylinder rather than installing a repair kit, since the quality of rubber products today leaves much to be desired.

INCREASING OR DECREASING PEDAL FORCE

If the pedal has to be pressed unusually hard or lightly, the problem may be caused by worn or dirty pads. If everything is in order with them, then you should check the integrity of the entire brake system for fluid leaks.

VIBRATION

If there is vibration when you press the brake pedal, then a possible reason is that dirt has gotten between the brake disc and the pads, or a crack or chips have appeared on the latter. As a result, parts are subject to premature wear. However, you should be aware that a similar phenomenon is also possible due to problems with the hub or hydraulic cylinders of the brake system.

THE PEDAL IS DOWN

Sometimes it happens that the brake pedal does not move back after being pressed. This indicates that the pads are “stuck” to the disc. This phenomenon can be observed at sub-zero temperatures when moisture gets on the pads. In addition, air may enter the braking system, which requires inspection and subsequent repair or bleeding of the brakes.

RAID ON DISCS

Plaque on wheel rims is black dust, which indicates wear on the pads. If the dust contains metal particles, then not only the pads are erased, but also the brake disc itself. If such a situation arises, you should not delay inspecting the brake mechanism, as well as replacing failed parts.

The appearance of black deposits on wheels can be caused by active driving or natural wear of the pads.

One day I noticed that the front wheel rims were covered with black dust, and it was not road dust. It is no longer known what brake pads were installed at that time, but after replacing them with factory ones from AvtoVAZ, the situation remained unchanged

Therefore, I came to the conclusion that the appearance of black dust is a normal phenomenon, indicating natural wear of the pads.

Which spare parts are better

The main problem when choosing brake hoses is the saturation of the market with counterfeit parts of low quality. Such eyeliners do not last long, quickly become covered with cracks or begin to leak near the pressed tips literally a week after installation. How to choose the right rubber pipes:

An additional sign of a quality product is 2 pressing contours instead of one. Counterfeit pipes are not made with such care.

Trusted brands that produce brake pipes of decent quality:

Hoses from the Balakovo plant are considered original. The parts are sold in transparent packaging with a hologram, the marking is in relief (molded along with the rubber product), and not a colored inscription with paint.

Along with a set of front pipes, it is worth buying 4 new O-rings made of copper 1.5 mm thick, since the old ones are probably flattened from strong tightening. It also doesn’t hurt to make sure there are fixing brackets screwed to the calipers - many drivers don’t bother installing them.

Choice

We will give some recommendations for choosing a new vacuum amplifier.

The cost of a good vacuum cleaner is now about 2.5 thousand rubles. These are not the most expensive, but not the cheapest Chinese options. Optimal for VAZ 2109

Original OEM packaging is made from corrugated cardboard.

The label must be legible. batch number, date of manufacture of the part and name of the manufacturer.

The vacuum tank corresponding to the technical parameters of the VAZ 2109 has article number 2108-3510010TM.

We choose wisely

READ Replacement Radiator Heater Gas 31105

There are a lot of fakes on the market now. Such parts cost the same as the originals, but are much cheaper.

Replacing the front brake discs of a VAZ 2109

Remove the brake discs from the VAZ 2109, put the car on the parking brake, lift and support the front of the car and remove the wheels.

Using an antenna screwdriver, bend the lock washers of the two guide pin bolts and unscrew the lower guide pin bolt, holding it with a hex key.

Remove the caliper with the wheel cylinder from the base, lift the caliper and unscrew the upper mounting bolt in the same way.

Hang the caliper with the wheel cylinder on the cable from the front suspension spring. At the same time, make sure that the brake hose is not twisted or too tight, and then remove the brake pads of the VAZ 2109. At the same time, place the pads to install them in their original places.

Unscrew the two locking pins and remove the brake disc. Installation of the front discs of the VAZ 2109 is carried out in the reverse order of removal; before driving, do not forget to bleed the brake system by pressing the brake pedal 3-5 times so that the piston of the VAZ 2109 calipers is in working condition.

Instructions for replacing liners

Worn or damaged brake hoses cannot be repaired. If any defect is detected, a replacement will be made. Causes:

To disassemble and install new flexible hoses, it is advisable to drive the car onto an inspection hole or overpass. If the front pipes can still be changed without a ditch, then getting to the rear is much more difficult - you will have to lie under the car, lifting the left side with a jack.

While on a long trip, my friend encountered a leak in the rear pipe (the car is a VAZ 2104, the brake system is identical to the “seven”). He bought a new spare part at a roadside store and installed it without an inspection ditch, on a flat area. The operation is simple, but extremely inconvenient - during disassembly, a drop of brake fluid got into a friend’s eye. I had to urgently get out from under the car and wash my eyes with clean water.

To change worn pipes, you must have the following tools:

To unscrew metal brake pipes, it is recommended to use a special clamping wrench with a slot for a 10 mm nut. If you work with a regular open-end wrench, you can easily lick the edges on the coupling. The nut will have to be loosened using a barbaric method - a hand vice or a pipe wrench, and then change the tube.

During the replacement process, brake fluid loss is inevitable. Prepare a supply of this material for refilling and buy a rubber boot (these are placed on the brake caliper fittings) to block the flow of fluid from the unscrewed iron tube.

Installing the front hoses

Before starting repair work, prepare the liquid brake system of the VAZ 2107 for disassembly:

Now, when the system depressurizes (due to disassembly), a vacuum is formed in the tank, preventing liquid from escaping through the removed tube. If you work carefully and follow further recommendations, air will not enter the disassembled circuit, and very little liquid will leak out.

Having prepared the system for depressurization, install the wheel chocks and remove the front wheel from the desired side. Further work order:

When connecting a new pipe to the main pipe, do not fuss or rush, otherwise you risk distorting the coupling and breaking the thread. It is better to add a portion of liquid than to buy and replace damaged tubes.

After installing the pipe, return the expansion tank cap to its place and try pressing the brake several times. If the pedal does not fail, then the operation was successful - no air entered the system. Otherwise, proceed to bleeding or replacing the remaining hoses.

Video: Tips for replacing front hoses

How to change the rear pipe

The algorithm for replacing this hose differs little from the installation of front rubber products. There is a slight difference in the mounting method - the rear tip of the pipe is made in the form of a cone, which is screwed into the tee. The latter is installed on the rear axle housing. The work order looks like this:

Since the flare fitting rotates with the hose, it will not be possible to squeeze out air with the fluid. The tip is twisted with the tee first, then the main tube is attached. The rear circuit will have to be pumped.

Video: replacing the rear axle brake hose

How often should you change front pads?

Let's start with the fact that on the VAZ 2107 the front brakes are represented by a disc system, which in some ways is much better than a drum one, but that’s not about that now. There are 2 pads on each caliper at the front, which are responsible for effective braking of the car. The front brake pads of the VAZ 2107 have the following appearance, shown in the photo above.

Essentially, the products are a steel plate onto which a special friction layer is applied. It is this friction layer that is the basis for car braking. When this layer wears off, which depends not only on the frequency of use of the brake pedal, but also on the nature of driving, then the car owner urgently needs to replace the brake pads on the VAZ 2107. If this is not done in a timely manner, then you understand what the outcome may be.

How often it is necessary to change the parts in question depends on the following factors:

- condition of the brake system;

- character and driving habits;

- product manufacturer;

- regular maintenance.

But our mentality is such that we don’t pay attention to how often we need to change the pads, and we do it when it’s pressing. The reasons that indicate that the car requires repair work on the brake system are due to the following symptoms:

- the appearance of extraneous sounds when you press the brake pedal: creaking or grinding;

- to brake, you need to apply force;

- When braking, the car begins to skid.

Approximately, it is necessary to replace the front pads on a car every 25-30 thousand km. But this range is average, since someone can travel 50 thousand km without replacing products, but they can only do 10. Let’s look at what it is to replace the front brake pads of a VAZ 2107 in more detail.

Detailed description of replacing front pads on a VAZ 2107

Replacing pads on a VAZ 2107 is a simple process that needs to be taken seriously. First you need to purchase new products. You need to buy them as a set, and replacement should be done on both wheels at once. After this, make sure that you have a basic list of tools:

- screwdriver;

- hammer and chisel;

- pliers;

- standard set of wrenches;

- WD-40 lubricant;

- Brake Cleaner (optional).

Let's start the workflow:

- Initially, some of the fluid should be removed from the brake reservoir, which is done to prevent it from overflowing and entering the engine compartment.

- Place shoes under the wheels, then install a jack and lift the front end. Afterwards, the wheel is removed, and then the surface of the caliper is cleaned of dirt and dust.

- Using a thin screwdriver, remove the two visible cotter pins. These cotter pins are designed to hold the pad rods. The photo below shows the location of these two cotter pins.

- Using a screwdriver, you need to press out the pad rods. If your own efforts are not enough, then you can use a hammer and a punch.

- The products are additionally held by spring structures, which can be seen in the photo above. They also need to be dismantled, for which you need to use pliers.

- When the rods and springs are removed, you can begin to dismantle the products themselves. Usually the pads do not sit tightly, so you just need to pry them off with a screwdriver and remove them, as shown in the photo below.

- Once the pads are removed, it is recommended to clean the seat using special products, and you can begin installing new ones.

- To do this, using a mounting tool or a screwdriver, you need to separate both cylinders, thereby preparing a place for new (thicker) pads. At the same time, do not forget to monitor the level of the displaced liquid in the barrel and, if necessary, remove it.

After installing the new products in their places, install the rods and mounting springs in the reverse order. This completes the replacement of the front pads on the popular VAZ 2107 car. As you can see, there is nothing complicated at all. Everything is simple and clear, but the main thing is to perform all the steps in the order described above. After installing new system elements according to the instructions, there is no need to bleed the brakes.

If you decide to replace worn-out products, then it is recommended to purchase new ones from companies such as Ferodo, ATE or Nippon. They will last much longer and will also delight you with their quality and braking performance. If you still don’t know how to change the front brake pads on a Zhiguli, then this material will be a good help. And remember that you will always have time to overpay the mechanic at the service station, but only then will you not be able to gain invaluable experience in repairing your car.

About bleeding the brakes

To carry out the operation in the traditional way, you will need the services of an assistant. Its job is to press and hold the brake pedal repeatedly while you bleed air through the fittings on each wheel. The procedure is repeated until there are no air bubbles left in the transparent tube connected to the fitting.

Before pumping, do not forget to add fluid to the reservoir. Waste material with air bubbles that you have drained from the brake mechanisms cannot be reused.

To bleed the brakes without an assistant, you need to have a mini-compressor for inflating tires and make a fitting - an adapter in the form of an expansion tank plug. The supercharger is connected to the spool and pumps up a pressure of 1 bar, simulating pressing the brake pedal. Your task is to loosen the fittings, release air and add new fluid.

The integrity of the brake hoses must be constantly monitored, especially when the elements are well worn. If you notice a network of small cracks or a tear with protruding textiles, purchase and install a new pipe. Spare parts do not have to be replaced in pairs; hoses can be installed individually.

Source

Basic faults

The brake system itself is quite simple, but some of its elements require special attention. Main types of faults:

- The brake fluid leaks, resulting in a drop in pressure in the system. If a preliminary inspection does not find a leak, it is necessary to check the brake master cylinder. We bend the noise-insulating mat located under the brake pedal and inspect for streaks in the area of the rubber seal of the master cylinder. The presence of drips will indicate that the cause has been found and requires disassembling the cylinder and then replacing the cuff. If there is a vacuum booster, the brake master cylinder must be removed and inspected.

- When you release the brake pedal, the car drives sluggishly. Reason: the rear or front pads are jammed. Seized pads are identified by checking the heat of the corresponding wheel. We touch each disk - the hottest one will be jammed. In the case when these are the front wheels, you can, after removing the wheel, move the brake cylinder. If this fails, you will have to replace it with a new one. In the case of rear pads, the brake wheel cylinder will need to be replaced.

- When you press the pedal, braking does not occur, but it does when you press it several times in a row. This may indicate the presence of air in the system. The solution to the problem is to bleed the brakes to remove air.

- Problem with the handbrake. Most often this problem occurs in winter. It manifests itself in the fact that after a long period of parking, when the handbrake is released, the wheels remain locked. The reason is that the parking brake cable is frozen. During its operation, moisture gets there and freezes in winter. If the casing is severely damaged, it will have to be replaced.

Brake master cylinder diagram

Vibration when braking

This is a fairly common malfunction that is associated solely with critical or uneven wear of the discs or drums, and the repair will consist of replacing them.

Car shifts to the side when braking

The malfunction is due to either a failure of the working (wheel) cylinder or wear of the pads. Replacing them (or repairing them) will solve the problem.

The VAZ 2107 brake pedal fails: the main reasons

The brake system must be sealed and free of air. If the pedal begins to fail, then, with a greater degree of probability, we can say that depressurization has occurred, that is, air has entered the system.

Other reasons:

- rust formation on the pedal linkage;

- failure of the vacuum booster;

- unadjusted distance between the cylinder piston and the pedal itself;

- lack of fuel fluid in the system.

It is also important to remember that brake fluid is an aggressive substance that can destroy thin pipes and even lines. That is why it is important to use only high-quality TZ

Low-quality liquid can form cracks through which it then flows out safely. But the flip side of the coin is that when you press the brake pedal, air leaks through these cracks.

Replacing brake hoses on VAZ 2101-VAZ 2107

Welcome! Brake hoses are an important part of the braking system and in no case should you skimp on them, and even this is stupid, there have already been many cases when the brakes of cars failed, many people think that this happens mainly in trucks, but this rarely happens with cars, in fact, this is a deep misconception, it’s just easier to stop passenger vehicles than trucks, which is why there are much fewer accidents with passenger cars (Below we have attached a video in which the brake system of a car failed), by the way, one of the main reasons is the brake hoses, and so the main brake cylinder (it fails less often), the hoses break from time to time and therefore even in books it is written that it is extremely undesirable to operate a car with hoses that are more than 3 years old, and all because the rubber ages and it is stronger subject to deformation, unlike when the tires are completely new (i.e. the brake hoses have been replaced in the car).

Note! To replace the brake hoses, you will need: A special wrench, which we strongly recommend that you buy, because the nuts of the brake pipes turn sour over time and it becomes almost impossible to unscrew them with a regular wrench, but with a special wrench this is as easy as shelling pears (It is indicated by the red arrow on photo below), in addition to this key, stock up on good brake hoses, pliers, screwdrivers and a set of all kinds of keys, which will include keys “10”, “14”, “15”, “17”!

Summary:

Where are the brake hoses located? There are three hoses in total, two in the front and one in the rear, you will most likely have a question, why one in the rear and two in the front (We are just often asked about this), we explain, in the front part the brake pipes immediately go hoses (see left photo), when in the rear part this is simply not needed, there is just one brake hose (see right photo) and it is connected to a tee on the rear axle housing and from this tee, brake pipes already come out and go on both rear wheels of the car.

Auto repair school – DIY car repair

Jun 14, 2022 VAZ 2101, VAZ 2102, VAZ 2105, VAZ 2106, VAZ 2107, Zhiguli, Classics by admin

Let's return to our immortal and beloved Classics! In this article we will look at the process of replacing the front brake hose on VAZ-2101, VAZ-2102, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic cars. I hope that it will be useful to you and after reading it, you will be able (or will have information) on how to replace the front brake hoses yourself. I, in turn, will try to describe the replacement process in as much detail as possible and warn you about possible problems that may arise during operation.

Pay special attention to the list of necessary tools and the quality of purchased spare parts. In general, please...

Let's start, perhaps, with the tool that you will need to replace the front brake hose on a VAZ-2101, VAZ-2102, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic car: 14mm socket wrench, socket wrench for 10, pliers, an open-end wrench for 17, a rubber cap from the bleeder fitting (after disconnecting the tube and hose, it will be necessary to “plug” the brake pipe to prevent brake fluid leakage), special keys for unscrewing the brake fittings for 10 - split or crimped (photo 1).

The presence of at least one special key is necessary. Without it, in 9 out of 10 cases, you will not unscrew the brake pipe fitting!

What you should pay attention to when purchasing spare parts... First, we buy brake hoses from “Balakovo” or “Dimitrovgrad” production. Hoses from these manufacturers, although not cheap, are of high quality and durable

As they say - time-tested.

Included with the front brake hose you should buy two new copper sealing washers

When purchasing washers, you should pay attention to their thickness. According to the standard, the thickness should be 1.5 mm

But unscrupulous sellers may sell washers of thinner thickness (see photos 2 and 3), using which you will not be able to tightly tighten the brake hose bolt.

We can also advise you to buy a new brake hose mounting bolt. This is not necessary, but believe me, this cheap detail can save quite a lot of nerves. Since the old bolts are generally very stretched (photo 4) and even with new copper sealing washers, such a bolt will have to be pulled long and hard until there is no brake fluid leakage (and don’t forget that the threads in an aluminum brake cylinder are very easy to break).

We're done with the tools and spare parts. Now let's move on to a step-by-step description of replacing the front brake hose on VAZ-2101, VAZ-2102, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic cars:

1. Use pliers to pull out the fixing bracket (photo 5)

2. Using an open-end wrench size 17 and a special clamp wrench 10, unscrew the brake pipe fitting (photo 6). We disconnect the hose and brake pipe, and put a rubber cap on the end of the pipe.

3. Using a 10 mm spanner, unscrew the fastening bolt securing the brake hose bracket (photo 7), if you have one, of course))).

4. Using a 14 mm socket wrench, unscrew the bolt securing the brake hose to the brake cylinder (photo 8). We remove traces of dirt and sand from the brake cylinder.

We carry out assembly in reverse order. We install the brake hose as shown in photo 9, with the bevel down. We install two sealing copper washers. When tightening the brake hose and tube, tighten the tube fitting and do not twist the hose, thereby preventing the brake hose from twisting.

When using an article or photographs, an active direct hyperlink to the website www.avtorem.info is required!