The ignition switch in a VAZ 2110 car , like on any other, is designed to switch electrical circuits and turn on the starter. Therefore, if it fails, then you will no longer be able to start the car.

It should be noted that the ignition switch is a tool for starting / stopping the engine, it can open or close certain groups of contacts, so when the lock is broken, the engine will not be powered. So if you have problems with it, then you will definitely need an electrical circuit diagram and a wiring diagram for the lock on the VAZ 2110 in order to check and repair it.

The connecting link of the whole organism

There is a misconception among most car owners that the main thing in a car is the engine, transmission, and chassis. Someone will ask, why is it wrong? It is necessary to consider the machine as a single, whole organism. And all components and assemblies are exclusively components.

For example, a breakdown of the starting system will lead to the fact that the vehicle will stop and will not be able to continue moving. Requires prompt repair. How well the example was chosen is the topic of today’s article. However, whether or not the reader agrees with my statement is up to him to decide individually.

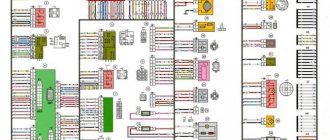

VAZ-2112 diagram

The VAZ-2112 car was produced at AvtoVAZ from 1998 to 2009, in Ukraine from 2009 to 2014. The following are color wiring diagrams (injector and carburetor) with a description of all elements for various modifications. The information is intended for self-repair of cars. Electrical circuits are divided into several blocks for ease of viewing via a computer or smartphone; there are also circuits in the form of a single picture with a description of the elements - for printing on a printer in one sheet.

Board layout and layout

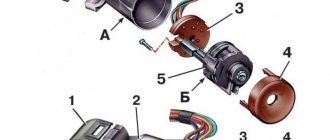

For the entire Lada line, the lock is located on the right side of the steering wheel, sewn into a plastic box, presented in the form of a complete block made of duralumin alloy. On the back side there is a board with contact connectors (8 in total). The contact group of wires has strictly its purpose, the diagram (pinout) is as follows:

- Key microswitch;

- Driver's door weight;

- Circuit for starter to supply “plus”;

- 12 W. for supply to the starting system;

- Zero on the key when it is in the keyhole;

- Illuminated lock slot;

- Voltage directly from the battery;

- Reserve socket for connecting other devices at the driver’s discretion.

Despite the fact that old and new locks are sold, with and without backlighting, the structure of the core and contact board is absolutely identical. When the wire connection diagram does not match, carefully refer to the operating instructions.

Device Features

Let's start with some basic things you should be aware of before embarking on a replacement or repair.

- The ignition switch (IZ) is the main element of the car's starting system. You will not be able to start the engine without it.

- The lock has a built-in anti-theft system. Therefore, if the protection does not work, the risk of becoming a victim of car thieves increases significantly.

- The ZZ is capable of blocking the starter from being turned on again, but without initially turning off the ignition.

- For tens, the key can be removed from the lock when it is in the “zero” position. By taking it out, you will thereby extend a special rod, which is responsible for the anti-theft functions.

- If the key moves from position zero to “one”, then the locking rod goes away and the ignition contacts close.

- When the car is started, all electrical equipment receives power and is energized. This applies to the dashboard, headlights, generator, windshield wipers, power windows, heater, turn signals, etc.

- By turning the key to position “two”, you thereby close another group of contacts, which makes it possible to apply voltage to the starter relay. This will start the engine and you can drive.

”

Key position

- The main position is “0” when the system is completely de-energized;

- O will indicate that the system is active and turned on. It is possible to turn on the dimensions, headlights, direction indicators, windshield wipers, the informative instrument panel lights up, the stove heater is activated, the heated filaments of the rear window of the car glow, a lamp on the console shows the status of the units;

- Key on: the car's power unit is started. But to start the engine itself, moving the key to position “II” is not enough. You need to turn it a little further until it stops. Voltage will be supplied to the car starter, which will start the engine. After a successful start, the key will return to position “II”, the starter will turn off, and the internal combustion engine will continue to operate. Sometimes the engine does not start the first time.

The engine won't start?

If, as a result of the check, it became clear that the spark hits the spark plugs, but the VAZ 2110 injector engine still does not start, then it is also necessary to diagnose it. The faults that cause this problem can be serious or not very serious.

At the same time, it is sometimes possible to cope with their solution without anyone’s help:

- It is necessary to purchase a spark gap and a Hall Sensor, which is inexpensive, but has an irreplaceable purpose. With their help, you can find out about the presence of a spark in the candles;

- Check the spark plugs to see if they are OK. A spark gap can be used for this purpose. However, you need to remember that the controller will be broken if candles are placed on its body;

- Perform fuel pump diagnostics. When you try to start a VAZ 2110 car, a characteristic sound will appear from under the rear seat. If there is no sound, then you need to check the fuses and the main relay. In a VAZ 2110 car they are located behind the side cover of the driver's seat.

If, after diagnostics, problems were identified with one of these elements, then you can fix them yourself. Usually the spark plugs begin to work after proper wiping, although this does not always happen, so they have to be replaced.

Symptoms of a problem

- After starting the engine, the car key does not return to position “II”. This indicates that the ignition switch cylinder is already very worn, the return spring is weak, and the resistance has decreased. At this moment, the starter and motor work simultaneously, which is detrimental to both components of the car. Systematic such “starts” will lead to the fact that the owner will have to buy new “brushes” for the starter, worse when the starter is entirely. And this is not a cheap pleasure. The spring cannot be repaired, so purchasing a new one is required.

- Mechanical damage due to an attempt to steal a vehicle by intruders;

- The entire system does not work: due to careless handling by the driver himself. It's no secret that each of us has our own manners and driving style. Some treat their “favorites” with care, others change them like gloves.

Solutions

Drivers without experience, as practice shows, at the first breakdown, run to service stations or car markets to buy a new ignition switch, giving away their hard-earned money. My advice is, don't rush to do this. Perhaps the reason is completely trivial, not worth such waste. Do-it-yourself replacement will take no more than 5 minutes. If you are not sure, contact a highly qualified electrician at a service station to carry out diagnostics and identify the fault. Having the skills, disassemble the lock and repair the damage. The lock from Priora is similar in design to the younger and older models, for example, the VAZ 2107, and the VAZ 2114 has a similar structure.

Dismantling

If previous activities have shown that intervention in the design of the ignition switch is required, work in any case will begin with dismantling the device.

We have special step-by-step instructions for this.

- To begin, disconnect the negative terminal from the battery of your VAZ 2110. This way you will ensure your safety and the safety of all wiring. You know what the consequences of a short circuit are.

- Next, remove the casing on the steering column. This is how you gain access to the castle.

- If you feel that the rotary switches will interfere with your work, it is better to remove them immediately. The work does not last for a couple of minutes, so all irritants should be put aside.

- Armed with a chisel and hammer, unscrew the mounting bolts with round heads. Don't get confused, they are the only ones there. Try to perform this operation as carefully as possible so as not to knock off the bolt head.

- Now take the pliers and remove the bolts.

- Insert the key into the ignition and turn it to position zero. This will disable the anti-theft system.

- Next in line is the bracket that held the previously removed bolts and the ignition switch itself.

- Mark the contact wires using different colored markers. Otherwise, you can easily mix them up during reassembly.

- Often it is not necessary to completely replace the lock, but only partial repairs. For example, change the backlight bulb, or fix a microswitch problem.

- Disconnect the connectors that used to operate the ignition switch.

- To replace the backlight bulb, disconnect the corresponding connectors, and then use pliers to remove the bulb.

- To replace the contacts, use a screwdriver to press out the special latches.

- Using a shaped screwdriver, unscrew three screws, after which you can remove the rod.

- Use a regular flathead screwdriver to pry out the clips and remove the microswitch.

- Next, new ones are inserted in place of the dismantled elements.

Checking status

Installation

Now that all preliminary repair work has been carried out, there are two options:

- Install a completely new ignition switch with wires and contacts, since the old one is unsuitable for further use;

- Return the old lock to its place, since the repairs have borne fruit.

Before installation, be sure to purchase special bolts equipped with break-away heads. They are designed to prevent your vehicle from being stolen.

Regardless of the option, the lock installation sequence is identical.

- Insert the key into the ignition, then turn it to position one.

- Secure the bracket to the steering column, and then replace the mounting bolts.

- Remove the key from the lock and check that the shaft lock works properly. If it's a new lock, there shouldn't be any problems. If we are talking about a refurbished old one, troubles may arise, since in reality it is better not to skimp and immediately replace the spare parts with a device of good quality.

- If everything works as it should, then you can complete the installation of the lock by tightening special bolts that are equipped with tear-off heads.

At the moment, the cost of a new ignition switch is about 20-25 dollars. These are small expenses, but sometimes simply necessary. Whether to do the repairs yourself or trust the car to a service station is a personal choice for everyone.

>

How to replace and disassemble?

- Remove the terminal on the battery from the o. If there is a central toggle switch in the car, you can turn it off.

- Using a Phillips screwdriver, unscrew the screws at the bottom of the steering wheel housing.

- We directly remove the casing itself.

- Using an “8” spanner, unscrew the ignition switch mounting bolts and disconnect the contact board.

- If the failure is in the core, then we replace it entirely with a new one; if the contact is damaged, then we replace the board.

- Assembly is carried out in a similar manner, only in reverse order. Electrical wiring must be packaged carefully and without damage.

For those who are unsure, you can use the car's operating manual, which describes in detail this or that unit, connection diagram, assembly, and photos are attached. Agree that the difference in price is significant, whether to buy the entire lock, or just the core.

Recommendation: good quality spare parts and components from the Dimitrovgrad Automotive Assembly Plant (DAAZ). Buy it, you won't regret it. The online store will help you quickly buy a part directly from the manufacturer. To choose a particular brand, be sure to read customer reviews and watch video tutorials.

The main thing when starting the car is to use the original key that “comes” from the factory. Since the immobilizer is a kind of anti-theft device that will prevent the engine from starting. The electrical circuit is connected to the car alarm or central locking.

Installation of a new larva

Ignition switch daewoo nexia and matiz: replacing the assembly, contact group and cylinder To change the lock core due to mechanical failure, remove it from the car as described above. Then follow this algorithm:

- Insert the key into the slot and use a Phillips screwdriver to unscrew the 3 screws holding the 2 halves of the lock body together.

- Separate the housing while holding it with the key facing up. If you hold the lock in a different position during disassembly and do not insert the key, the insides will spill out and you will not understand how to put them back together. In this case, the ball with springs may get lost.

- Remove the locking mechanism, which consists of two spring-loaded parts, and pull out the spring itself.

- After removing the key, carefully remove the core so that the ball with the spring (located on the side of the cylinder) is not lost.

To disassemble the case, you need to unscrew 3 screws

Before replacing, it is necessary to remove the return spring from the old cylinder, since it is not sold complete with a new core. The spring is inside the part on the back side in a cocked state; it must be installed in the same form on the new cylinder. Also, do not forget to remove the thin spring from the hole where the ball is inserted.

The locking mechanism tongue peeks out from the bottom of the case

The larva must be pulled out so as not to lose the details

When installing the core, you need to move the spring for the ball into the hole and insert the part into the body. Then push the larva all the way, while simultaneously inserting the ball into the socket. After that, all that remains is to assemble the locking mechanism and tighten the housing with screws. When finished, check the operation of the ignition switch by turning the key to different positions.

The ejection spring from the old core needs to be moved to the new one

Troubleshooting

Before tackling the question of how to change the ignition switch on a VAZ 2110, you need to find out the nature of the malfunctions. How to check the ignition switch of a VAZ 2110 is described in the instructions.

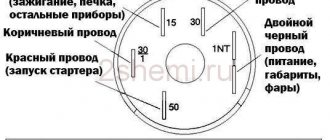

1-reserve; 2-minus backlight; 3-starter; 4-plus after the ignition switch; 5-reserve; 6-plus backlight; 7-constant plus; 8 is a constant plus.

| 1-5 | On the VAZ 2110 it is used for the immobilizer. You can connect any device you wish. |

| 1-6 | Castle lighting. |

| INT | On the VAZ 2107, these are lighting, wipers, and washer - a constant plus. |

| 50 | Starter. |

| 30/1 | A constant plus. |

| 15 | A plus appears when the ignition switch is turned on. |

Troubleshooting the ignition switch on a VAZ 2110 is carried out in the following steps:

- The battery will be disconnected.

- The casing is removed from the steering wheel shaft column. To do this, unscrew several screws.

- The lock connector is removed from the back.

- Using a multimeter, the voltages in the contact groups are checked. The installed key switches in different positions.

- Voltage on pins 8 and 30 is present only when the key is in zero position.

- In position 1, the servicing devices are turned on: turns, headlights and heated glass.

- In position 2, voltage is supplied to devices related to engine operation.

- In position 3, the starter is activated. The key then returns to its original position.

If there are interruptions during the verification process, then the ignition switch on the VAZ 2110 requires disassembly and repair.

Order of Operations

It is worth immediately noting that independently replacing the ignition switch cylinder of VAZ 2110, 2111 and 2112 is problematic. This part is difficult to find on sale, and working with it requires special skills. An incorrectly performed operation will result in unstable operation of the ignition system. In this case, you need to purchase the assembly and change it completely:

- Since there is work to be done on the on-board electrical system, you need to disconnect the battery; to do this, disconnect the negative terminal of the battery. In addition, it is rational to provide good lighting in the work area, so you will spend less time performing operations.

- Now you need to lower the steering column all the way and remove the plastic casing, after unscrewing the screws.

- Using a chisel, unscrew the bolts with cut heads and pull them out with pliers. Hammer blows should be directed clockwise.

- Now you can remove the bracket and the lock itself from the steering column by disconnecting the electrical connector.

- If the backlight lamp needs to be replaced, the contact is disconnected and its socket is removed with pliers. Installing a new device.

- To replace the contact group of the ignition switch of a VAZ 2110, 2111 or 2112, the clamps are released.

- If the microswitch stops working, unscrew the screws, remove the rod, and pull out the latch. We install a working device.

- We replace the contact group of the ignition switch of VAZ 2110, 2111 or 2112.

- Now the operations are performed in reverse order. We install the assembled unit on the steering shaft, clamp it with a strap and tighten it with bolts. They need to be screwed in all the way; for this you can use a 10mm spanner or a socket with a knob. IMG8

- Without breaking off the heads from the fasteners, we begin to adjust the steering wheel: the key is located opposite the I icon, and the steering shaft is in the same position. If the shaft does not lock and the steering wheel continues to rotate freely, you need to find the correct location of the lock so that its latch engages the groove in the shaft.

- Now you can break off the heads from the bolts.

- Once again we test the functionality of the mechanism. If everything is in order, you can connect the contacts.

- We connect the lock with the battery by replacing the negative terminal. And again we test the performance of the node. If the results are positive, the decorative plastic casing is mounted in its original place.

Failure of the lock may be due to normal oxidation of the contacts in the group. In this case, you only need to clean with fine sandpaper. This malfunction can be determined using a multimeter in ohmmeter mode. Each pair must be tested for short circuits.

Repair of the ignition switch for VAZ 2110, 2111 and 2112 can be seen in this video:

This is interesting: Replacing generator bearings on a VAZ-2110 - which bearings?

Disassembly and replacement procedure

When the source of the malfunction is identified, the question immediately arises: how to disassemble the ignition switch on a VAZ 2110.

To do this, first it is removed. Since the preparatory work has already been done, the following actions remain:

- The housing mounting bolts are unscrewed.

- The lid made of plastic material is removed. The lock is removed.

Replacing the larva

Before changing the ignition switch on a VAZ, sometimes it is enough to replace the cylinder.

The process consists of several steps:

- A small diameter pin holding the cylinder is removed from the side. The work is carried out using a thin screwdriver and a hammer.

- The old larva is removed and the new one is installed.

- To check, the steering wheel is turned and the reliability of the jamming is checked.

- Sometimes the blocking is adjusted.

After replacing the used element, you need to know how to assemble the ignition switch of a VAZ 2110. This process occurs exactly in the reverse order.

Replacing the contact group

Knowing how to change the ignition switch on a VAZ 2110 with your own hands, this is not always necessary. Ingod the contact group fails, which, like the larva, changes.

Its replacement is carried out in the following order:

- All contacts are numbered before they are disconnected.

- Then they are disconnected.

- 2 latches are removed.

- The old group is removed and a new one is installed in its place.

- Then, in the reverse order, the assembly is assembled.

Complete lock replacement

Craftsmen who know how to change the ignition switch on a VAZ 2110 with their own hands have long realized that this process is much easier than replacing individual structural parts.

After disconnecting the battery, removing the steering casing and unscrewing the bolts, the plug is disconnected and the lock is removed. This completes the operation to remove the old node. A new product is installed in its place.

If you still have questions about how to change the ignition switch on a VAZ 2110 with your own hands, I recommend watching this video:

Replacing the contact group

In the event that, as a result of diagnostics, a malfunction of the contact group is detected, you will still have to remove the ignition switch, since it will not be possible to get to it in any other way. After removing the element, disassemble it using the following algorithm:

- Disconnect the connectors with the backlight power wires.

- Remove the decorative plastic cover by releasing the 4 latches. Work carefully because these clips are easy to break off, and buying a cover separately is quite a task. It is not advisable to change the entire lock because of it.

- By bending the 2 clamps holding the contact group, remove it from the ignition switch.

The plastic cover can be removed using a screwdriver

The contact group is located immediately under the cover

First of all, examine the status of the contacts. If they have darkened (oxidized), then clean the current-carrying surfaces with fine sandpaper P1000. Then put the group in place and, without installing the lock, connect it to the vehicle's on-board electrical system to check its functionality. If unsuccessful, the part must be replaced. The same will have to be done if the contacts are burnt or the group does not work without any external signs of malfunction.

The part is removed after bending two latches

Professional advice

Such advice is as follows:

- Even having an understanding of the rules for replacing larvae and contact groups, it is better to refrain from this work. The repair process is complex and time-consuming. If you have an idea of how to change the ignition switch on a VAZ 2110, then it is better to replace the entire assembly.

- Graphite grease is used as a lubricant for the cylinder. It reduces the risk of biting the part.

- Even knowing how to change the ignition switch on a VAZ 2110, as well as how to change the door lock on a VAZ 2110, in the process of work you should give preference to branded products.

The procedure for replacing the ignition switch on a VAZ 2110 is a simple type of repair work. Even a beginner will not experience big problems. The main thing is to have the necessary equipment and tools on hand, and also to read the instructions well.

Ignition switch VAZ 2110

When the car does not respond to turning the key in the lock, the engine does not start, the instruments do not turn on, or the key itself rotates with jamming, then repairing the VAZ 2110 ignition switch will solve the problem. There are two ways to solve this problem: replacement and repair. Repairing the lock yourself will cost less than replacing it, but replacement will probably be faster and, of course, more reliable. In any case, you shouldn’t jump to conclusions; it’s better to first find out the cause of the malfunction.

Design and principle of operation of the ignition switch contact group

The need to use a contact group in a car’s ignition system is dictated, first of all, by convenience, reliability of the connection and grouping of wires included in the electrical circuit. In addition, the use of a contact group as an intermediate link between the consumer and the ignition switch increases the degree of maintainability of the latter.

The design of the ignition switch installed on classic VAZ models is nothing more than a traditional electrical circuit breaker. The key in this design plays the role of a contact position regulator, capable of performing several standard contact closure options corresponding to certain vehicle operating modes:

- starting the power unit;

- connecting power to electrical devices;

- stopping the power plant

The connection of wires of the “socket-plug” type ensures high reliability of contact, and special fasteners in the plastic housing of the group act as an insulator (distributor) that prevents the occurrence of short circuits. Thus, the contact group of the ignition switch is nothing more than a device that connects all consumers into a single system via electrical wires (see figure).

The contact ignition system used on classic models of VAZ cars can be of two types: generator and battery. The difference between these systems is that one of them has an autonomous power source (battery), which allows the use of electrical appliances when the engine is not running.

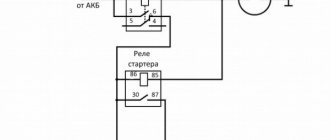

The operation of the ignition switch contact group is based on the following principle. Turning the key closes the electrical circuit from the “-” terminal of the battery through the ignition coil to the “+” terminal of the battery. The current passing through the coil is converted into a high voltage pulse, generating a spark discharge at the spark plug electrode. Consequently, turning the key initiates the start of the car’s power unit. The inclusion of other electrical circuits that ensure the functioning of elements of the electrical equipment of the vehicle is carried out by installing the ignition key in the appropriate positions, causing the closure of certain groups of contacts.

Depending on the car model, the same key positions in the ignition switch may correspond to different groups of contacts, and, consequently, different operating modes of electrical equipment. An option is possible in which voltage is supplied at the moment the key is installed in the ignition switch, that is, the key itself closes the circuit that supplies the supply voltage. The functioning of anti-theft and alarm systems, devices that block car doors, etc. is organized in a similar way.

Purpose of the lock

The lock is a breaker that opens and closes the contacts necessary to start and operate the motor. It was originally intended to protect the car from theft. Now, when car thieves are able to break into even the most complex electronic locks and new generation anti-theft systems, it has lost its significance as an anti-theft agent. The breakdown of this device creates a lot of trouble for drivers, and some even replace it with a “start” button. Let's look at how to diagnose the ignition switch of a VAZ 2110, repair or replacement, decide for yourself.

The most common causes of failure

Electrical diagram of the lock

Replacing the ignition switch may be necessary in the following cases:

- Criminals tried to take possession of the vehicle, resulting in significant mechanical damage to the ignition switch.

- The car key was stolen or lost by the owner of the car.

- The contact group of the node is unstable or has completely failed.

Determining faults

To identify faults in the lock, it is enough to test it (check it with a tester), to do this:

- Remove the terminals from the battery

- Unscrew the casing around the steering column

- Disconnect the lock connector

- We insert the key and use an ohmmeter to check the resistance of its contacts when switching modes 1, 2, 3 using the key

- When the ignition switch is fully operational, the resistance of the contacts we have selected should be zero

Using a tester we check the resistance of the lock contacts

Let's consider circuits that open and close at different key positions; in the photo below the table we show a diagram:

| The key is in position | Contacts (diagram below) live | Closable circuits |

| Position 0 (means off) | Contact 30 | None |

| Position I (ignition) | Contacts 30-15 | Ignition system circuit, generator excitation is started, power is supplied to headlights, turn signals, control panel, windshield wipers and glass washers, the heater fan motor is powered, the rear window heating and cigarette lighter are turned on |

| Position II (starter) | Contacts 30-15 and 30-50 | Starting the starter, all position devices are also energized |

Electrical diagram of the VAZ2110 lock operation

Lock pinout diagram:

- Pin 1 - 12V comes to the micro switch of the inserted key

- Contact 2 - ground arrives (zero) when the driver's door is opened

- Pin 3 - 12V goes to the starter (to pin 50)

- Pin 4 - 12V goes out after connecting the ignition (to pin 15)

- Contact 5 - 12 Volts go out when a key is inserted into the lock at 5 to the BSK contact

- Contact 6 - 12 Volts are supplied to the lock cylinder illumination

- Pin 7 - 12V comes from the battery (to pin 30)

- Pin 8 - not used

Common mistakes during diagnostics

Most people, due to ignorance of the VAZ 2110 injector machine, make many mistakes in the process of identifying problems.

Let's look at some of them:

- Many people make a common mistake: when they see that there is no spark, they want to check it for breaks. For this purpose, they place the wire close to the ground of the machine. But when performing such actions, the ignition module may break, so under no circumstances should you do this;

- Another problem is checking the spark discharge. If you place spark plugs on the engine body, a large induction current may appear. This occurs even due to slight contact of the spark plug with the ground, as a result of which the controller can also be damaged. Therefore, it is necessary to use a spark gap that will not allow the distribution of ignition with the same supply of high voltage to two spark plugs at once.

Removing the lock

After we have checked the condition of the lock using the electrical diagram, it is time to remove the ignition switch from the VAZ 2110; it is more convenient to carry out repairs with the lock removed:

- And so we have already removed the terminals from the battery, as well as the plastic covers from the steering column (to do this, unscrew the fastening screws from below)

- Disconnect under the steering switches (to do this, simply unclip the latches) and take a simple tool - a hammer, chisel and pliers

- For greater safety, the bolts securing the ignition switch have sheared heads.

- Therefore, you will have to unscrew them using a chisel and hammer

Unscrew the lock bolts using a chisel and hammer

- Now you can unscrew the bolts with pliers

- Remove the bracket from the column

- Remove the ignition switch

Instructions for removing the element

For disassembly you need to prepare a simple set of tools:

- 10 mm head and ratchet drive;

- Phillips screwdriver;

- narrow chisel (width 5-8 mm);

- hammer;

- round nose pliers with tapered, curved ends.

Ignition switch replacement tool

To successfully install a new or repaired lock in place, it is advisable to purchase 4 special fastening bolts with M6 threads with a head size of 10 mm and a length of 20 mm. Their feature is the heads that come off with a key at a certain tightening torque. After tearing off the heads, semicircular caps remain on the surface, which are much more difficult to unscrew for an untrained person. But you will have to do this during disassembly.

The battery must be disconnected before starting work.

Like any event related to tampering with the electrical part of the car, dismantling the ignition switch begins with disconnecting the negative terminal of the battery. Then proceed in this order:

- Using a Phillips screwdriver, remove the screws holding the two halves of the plastic frame of the steering column together.

- Lower the handle that fixes the position of the steering wheel during adjustment all the way down and remove the plastic panels. Disconnect the ignition switch block and carefully cut the tape connecting your bundle of wires to the common harness. In order not to cling to the steering column switch during operation, it can also be pulled out of the connector.

- On the metal casing of the steering column you will see a lock mount consisting of two clamps. They are held together by 4 bolts with the heads torn off (visible on the left side). Pointing the chisel at the semicircular caps, use a hammer to loosen the tightening of these bolts one by one.

- Using pliers and then your hands, unscrew all 4 bolts and remove the ignition switch.

Unscrewing the plastic steering column cover

Bolts with intact heads can be unscrewed with a wrench

At the stage of disconnecting the connectors, it becomes possible to check the functionality of the contact group by measuring resistance, as described in the previous section. If you remove the lock due to the loss of the keys and want to move on, then after dismantling you need to do the following:

- On the “mother” block, which remains hanging after the lock is turned off, find contacts with thick wires of purple and blue color (the latter with a black stripe).

- Connect these terminals with any conductor, after which the ignition will turn on.

- The thick red wire leads to the starter. To start, its contact must be temporarily connected to the installed jumper. When the engine starts, the red wire must be disconnected.

This is how jumpers are inserted into the block to start the engine without a key.

After unscrewing the fasteners and disconnecting the wires, the lock can be easily removed from the car

Assembly is carried out in the reverse order, but taking into account the following precautions:

- do not tighten the fastening bolts until you have accurately aligned the position of the lock on the casing so that the facing plastic panel fits smoothly into place;

- before final tightening the bolts, make sure that the lock snaps into place when turning the steering wheel, otherwise adjust the position of the lock;

- The tightening torque should be such that the heads of the new bolts come off and the round heads remain.

When installing and tightening the bolts, their heads should come off

If you think that special fasteners are not an obstacle for car thieves, then you can screw in regular bolts with M6 threads and carefully tighten them.

Dismantling the VAZ 2110 lock in the photo

This connector must be disconnected to remove the lock.

The steering column switch is easily removed from its socket

Appearance of the mount. It can be seen that not all the bolts are broken

Bolts without heads are torn out of place with a chisel

After unscrewing, the left mounting clamp is removed

The lock with the right clamp is held on by wires that need to be disconnected

After breaking the bolts with a chisel, they can be easily unscrewed with pliers

Dismantling the lock

To replace the backlight bulb:

- Disconnect the connector

- Remove the light bulb socket using small pliers

To replace a contact group:

- Use a screwdriver to remove the latches

- Then we remove the entire contact group

To change the micro switch:

- You need to unscrew three screws using a Phillips screwdriver

- Remove the rod

- Press the latch

- We take out the micro switch

We remind you that the ignition switch has its own catalog number 2110-3704005 or KZ-881, in case you buy a new one. After the repair, we screw everything back in the reverse order; we recommend screwing the lock with bolts that have break-away heads, so as not to make it easier for thieves.

How the larva changes - video

The video demonstrates how to disassemble the mechanical part of the ignition switch of a VAZ 2170 (Lada Priora), but in design it does not differ from the elements installed on VAZ 2110-2112 cars.

As a rule, there is no need to change the entire ignition switch, although car enthusiasts often resort to this option to save time. The operation will take the technician at the service station no more than 20 minutes. Replacing it yourself will require more time, but you will be able to replace only the broken part (cylinder or contact group), thereby saving personal funds.

Replacing the lock cylinder

Sometimes troubles arise when the key turns poorly or is poorly inserted into the lock. The problem is solved by replacing the cylinder, the price of which is less than the full cost of the complete lock; for this you will need:

- Hammer

- Pliers

- Chisel

- Thin drill bit and drill

- Phillips screwdriver

- Thin screwdriver

- New larva with keys

Let's start replacing

Our instructions will help you replace the lock cylinder without any problems:

- We carry out all the steps, as in the previous article, de-energize the electrical system of the machine, remove the covers from the column

- You can start replacing the lock cylinder now without removing the lock itself

- To do this, you just need to pull out the side pin that holds it in the lock.

- For this we need a clock screwdriver, we knock out the pin by tapping it with a hammer

- When the pin cannot be removed so easily, you can drill out the cylinder using a drill and a thin drill bit

- To remove the lock before proceeding to replace the cylinder, then first unscrew the bolts that secure the ignition switch

- Their heads are cut off, so use a hammer and chisel, then pliers

- Then the bracket and the ignition switch itself are removed from the steering column, do not forget to disconnect the electrical connector

- We unscrew the screw securing the relay, pull it out from under the panel, then disconnect the connector

- Disconnect the ground wires from the relay

- Use a Phillips screwdriver to unscrew the screw and press out the latch

- Now remove the cover and group of contacts

- Removing the lock

- We take out the larva as described above

- We make a replacement

- Before putting the ignition switch in place, you need to insert the key into it and turn it to position “I” so that the latch, which will block the steering shaft mechanism, is hidden in the lock body

- We install the ignition switch on the steering column together with the fastening bracket and tighten the new bolts that have breakaway heads with the “10” key. We remove the key and check the operation of the steering shaft locking mechanism

- If the shaft does not lock, then it is necessary to adjust the location of the ignition switch relative to the steering column so that the lock latch fits exactly into the groove of the steering shaft

- Then tighten the breakaway bolts until the breakaway heads break off.

About the ignition switch on the VAZ-2110

This lock has been changed twice already. Auto editions.

The ignition switch is not the most complex unit and consists of a housing, a lock cylinder, a locking device and a contact group.

Any of the structural elements may fail for one reason or another, either from improper operation or due to poor workmanship

Articles

By the way, the most reliable locks are those made in Togliatti with catalog number 21100-3704005-30 (set)

The price of the complete lock with lighting is about 1,100 rubles, which, you see, is not that much, given the importance of the unit. The assembled Dimitrovgrad lock with the same article number DAAZ 2110-3704005-30 will cost a little less. They are asking 800-900 rubles for it.

Lock diagram

The anti-theft properties of a ten-key lock are far from perfect, so the car uses an immobilizer that prevents the engine from starting with a key other than the original one.

There is also an option to bypass the immobilizer lock to install an abnormal alarm. The connection diagram for the ignition switch is practically no different from all VAZ locks. Here she is.

A harness of eight wires comes out of the ignition switch housing, each of which corresponds to its own terminal. This is necessary to know in order to diagnose the contact group and not waste extra time and money on troubleshooting.

- Microswitch terminal that opens power to the circuit when the key is inserted.

- Negative contact of the lock light bulb.

- An important terminal for supplying power to the starter contacts. This contact only closes when the key is turned to the engine start position.

- Supply of general 12 volts to the contacts.

- Microswitch power supply.

- Power (plus) backlight.

- An important contact responsible for supplying 12 Volts from the battery.

- The terminal is usually empty and is intended for connecting additional equipment.

The electrical circuits of the ignition switch can be checked with a multimeter, measuring the resistance between the contacts when switching modes.

Typical breakdowns

Typical ignition switch failures are well known to experienced drivers - failure of the contact group and failure of the return device.

If the ignition key stops returning to its original position, the lock's return spring is most likely broken.

The last trouble is quite serious, since after starting the engine the key must return to the second position. If it does not return, power continues to be supplied to the starter while the engine is running.

- At best, this may result in the Bendix contacts burning out and breaking.

- If you're less lucky, you'll have to replace the starter completely.

This is why it is so important to identify the fault in time and replace the lock, preferably as an assembly.

Problems with the ignition module

The ignition module is an electronic analogue of a distributor (see VAZ distributor design: the difference between contact and non-contact ignition systems and ignition timing adjustment) and an ignition coil. A faulty module can fail at the wrong moment, according to the famous law of meanness. Checking it and identifying malfunctions will take no more than an hour, but it will allow you to determine the approach of serious problems in time.

VAZ2110 ignition module

- The main symptom of a module malfunction is the absence of a spark in one or several cylinders at once.

- In this case, the engine stalls or does not start at all.

- The second common phenomenon is a failure in the timing of the ignition cycle, due to which it is impossible to coordinate the interaction of the piston and gas distribution system with the module

- There are several methods for identifying module malfunctions

VAZ injector errors

Errors can relate to any part of the car:

- Sensors Most often, temperature sensors suffer, as they can overheat too much;

- Injectors. Mostly, problems are observed due to an open circuit, as a result of which they cannot light up in time. This leads to another problem - the spark has disappeared, so the engine does not start;

- Engine. The most common mistake is overheating. Most often, due to increased oiliness, the spark plugs also overheat, so a spark does not appear. As a result, the engine does not emit any signs of life;

- Valves. They can also be too dirty, which will cause them to close, so they will not pass the fuel-air mixture;

- Fans. If they do not work correctly, the machine overheats.

Checking for a spark

This method is most suitable for testing the module in “field” conditions. However, it requires having at least one new spark plug on hand in your car's inventory:

- One by one, remove the spark plug caps from the cylinder head cover, insert a new spark plug, which we ground to ground or to the body

- We rotate the starter, if there is no spark, then the problem does not lie in the spark plugs, and we should continue to study the ignition system

- Let's try to replace the armor wire on the cap on which there is a lack of spark.

- All wires are numbered on the module cover, so remove the wire from the non-working contact and put it on the working one (let's swap them)

- Thus, we will check the condition of the connecting contacts themselves and the integrity of the core

- If a spark appears after changing a non-working wire to a working one, then the problem was in the wire

- If the problem remains, it means that for the VAZ 2110, repair of the ignition module is inevitable, or replacement if repair is impossible

- If there is a complete absence of spark on all spark plugs, it means failure of the module or its high-voltage coil

- In cars with fuel injection, the electronic system that controls the ignition and fuel distribution may be damaged, signs of such a failure as if the ignition module breaks down

- To repair the module you will need a screwdriver, a soldering iron and spare parts, if you have nowhere to rush, then you can sit at home and calmly disassemble it and re-solder it, after watching a video on this issue

- It is often much faster to replace the ignition module or high-voltage armor wires with similar ones purchased or temporarily removed from a car of the same brand

- Replacement does not take long, the module can be removed easier than a distributor, the cylinder numbers are always marked on it

- This operation allows you to determine general faults of the entire system without unnecessary effort in some cases

That's all, we wish you success in self-repair and troubleshooting.

Basic principles

Regardless of the type of engine used, the basis of the wiring used in the VAZ 2110 car is the same. It's easy to find a diagram, but not so easy to understand.

Let's look at the basic principles of wiring.

- All equipment and devices powered by electricity in the VAZ 2110 are based on a single-wire connection. VAZ designers specially provided for wires of certain colors to each be responsible for their own functions. Therefore, certain equipment is connected using wires of their own color. This allows you to independently understand the wiring, make it easier to carry out repair work and not spend money on car repair services.

- The downside to the VAZ 2110 is that the mass is the car body itself.

- The positive wire of the batteries on the top ten always comes only in red. Therefore, when making repairs, try not to change the color of the wire, so as not to confuse yourself.

- For each system that is connected to the electrical system, it is equipped with its own separate wiring harness.

- The VAZ 2110 is designed in such a way that when the battery is turned on, all electrics and electrical equipment are energized. This is related to the most common recommendation, which you have seen more than once in our materials, where we described the repair or replacement of certain components - disconnecting the negative terminal from the battery.

- Do not forget about the existence of the so-called contactless system. This system is required to create a high-quality spark, which is simply necessary to ensure combustion of the air-fuel mixture. In order for a contactless system to function, high voltages are indispensable.

Carburetor models

The first versions of the VAZ 2110 model, which the domestic plant began to produce, were equipped exclusively with carburetor engines. Only after some time more modern injection versions appeared. They are objectively better. But this does not take away the fact that many have dozens of them under the hood with a carburetor.

Are there any significant differences in terms of electrical circuitry between a carburetor and an injector? We can say no. The carburetor systems used are almost entirely the same as on the more modern version.

Part of interior wiring

Also, you will not encounter serious problems in the form of electrical wiring if you suddenly want to replace a carburetor engine with an injection engine or equip the car with additional electrical equipment. You will even find identical plugs in the engine compartment.

The only nuance of switching from a carurator to an injector is the need to install additional wiring from the fuel pump to the on-board computer.

Injector

In addition to the wiring, which is identical for the carburetor and injector, the latter is additionally equipped with fuses and sensors.

In practice, due to the large number of regulators that ensure the operation of an electronic engine control unit of an injection type with 8 or 16 valves (there is none on the carburetor), the system turns out to be more complex. To repair it, you need to carefully understand all the components and their location.

Electrical diagram

Modifications of the VAZ-2112 car

VAZ-21120 . Modification with a 16-valve injection engine with a volume of 1.5 liters and a power of 93 horsepower. 14-inch wheels were installed on the car. This modification has a problem with valves bending when the timing belt breaks. The problem can be solved by increasing the depth of the grooves in the piston bottoms.

VAZ-21121 . The car was equipped with a VAZ-21114 8-valve injection engine with a volume of 1.6 liters and a power of 81 horsepower.

VAZ-21122 . Budget modification with an 8-valve injection engine VAZ-2111. The car was produced without electric windows, the wheels were 13 inches in size, and the brakes were unventilated from a VAZ-2108 car.

VAZ-21123 Coupe . Three-door, five-seater hatchback. The only two doors for entering the car are 200 millimeters wider than those of the five-door hatchback, and they are mounted on new, durable hinges. The rear arches of the car have become wider. The engine was installed with a 16-valve injection engine with a volume of 1.6 liters and a power of 90 horsepower. The car was produced from 2002 to 2006 in small quantities, the reason for this was the high cost of the car.

VAZ-21124 . Modification with a 16-valve injection engine VAZ-21124 with a volume of 1.6 liters. Produced from 2004 to 2008. For this type of engine, the problem with valve bending was solved. To do this, the depth of the grooves in the piston heads was increased (up to 6.5 mm). In addition, the design of the cylinder block was changed to achieve a working volume of 1.6 liters, for which its height was increased by 2.3 mm, and the radius of the crankshaft was increased by 2.3 mm accordingly. There were also a number of other minor changes.

VAZ-21128 . The luxury version of the car, produced by Super-auto JSC, was equipped with a 16-valve VAZ-21128 engine with a volume of 1.8 liters and a power of 105 horsepower.

VAZ-2112-37 . A racing modification of the VAZ-2112, prepared for the “ring” in the Lada Cup qualifying group. The car was equipped with a 1.5-liter VAZ-2112 engine with a power of 100 horsepower. The racing car was equipped with a safety cage, an external aerodynamic kit and a front extension of the strut support cups.

VAZ-2112-90 Tarzan . All-wheel drive modification with a VAZ-2112 body on a frame chassis with transmission and suspension parts from a VAZ-21213 Niva. It was also equipped with a 1.7 or 1.8 liter engine from the Niva.