The gearbox is a rather complex vehicle unit that requires appropriate attention and high-quality diagnostics. If the gearbox malfunctions, driving a car becomes not only uncomfortable, but also unsafe.

Today, the main problem associated with gearbox malfunction is poor gear shifting. It should be noted that this most often concerns used cars, although problems of this kind are also no exception on new cars in the budget segment.

The second gearbox of the VAZ 2109 is not included: reasons

So you put it in second gear, but it doesn't stay in place and gets pushed out of neutral every time? The design of the gearbox is not simple, but there are three main reasons for this problem:

- Worn out or clutch has reached its lifespan

- The plug is loose and the plug won't close

- It is quite possible that the power unit will shift from the mounts, this is what involves knocking out the gears

First, inspect the engine for any random movement from its intended location. Also make sure that the gearbox is securely connected to the motor. If necessary, tighten the fasteners until the connection is really tight and complete.

Engine mounts

Personally, I have never had this happen, but many people write that this is a fairly common problem. Actually, the problem is that the engine hangs on cushions, the gearbox is connected to it (by the way, cushions belong to a manual gearbox). Sometimes the fastener breaks or comes loose. The engine or “box” may sag and may break the stage or damage something.

This is another not very serious problem. these are pillows! If programs don't turn on, we watch them.

THESE PROBLEMS LIKE I AM NOT ALL THE PROBLEM! Anyone can identify them in holes or lifts, and do it fairly quickly. Personally, I came across scenes and cables, for example VAZ, clutch cable.

However, if you have checked everything and the gears do not engage on an early engine. Then you have to consider the box itself and the associated applications. Well, let's move on to complex faults.

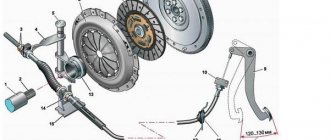

Check the condition of the main gearbox mechanisms

Place the car in the hole and check the condition of the clutch. All teeth must be intact and undamaged. Find behind the scenes and pull more tightly, securing your attachment. If everything is good at this stage, then you will have to watch the programs. Wear of the gear teeth leads to the fact that the transmission of torque is disrupted.

You push the lever with your hand so the clutch has to fit snugly, which causes the gear to shift. As soon as you release your hand, the handle will loosen and the handle will stop. These are the main reasons why second gear

not included on VAZ 2109. I came across this and in my case replacing the coupling helped.

Drive and clutch cables

For rear-wheel drive models (VAZ 2101 - 2107), the gears are engaged hydraulically. That is, when you press the clutch, the fluid pushes the piston, which in turn pushes the clutch fork, which retracts the disc. For front-wheel drive models (VAZ 2108 - 2115), there is no hydraulic connection; everything is done here by mechanics, or rather by the clutch cable, which is connected to the pedals. If your slave cylinder leaks on a rear-wheel drive car or the cable breaks on a front-wheel drive car, the car will not engage in gear. The “fork” simply won’t work. We just check and replace damaged parts.

Reasons for transmission failure

The complex mechanism constantly works under load and under extreme conditions. Constant vibrations, rising temperatures, dust and dirt. If one or more speeds do not work, check:

- Cable tension and integrity;

- Hidden installation;

- Output to the clutch disc;

- Petals on a basket;

- Load-bearing integrity;

- Plug condition.

Clutch

When the clutch discs wear, the pedal rises to a higher position than others. In this case, when you turn it on, you may hear a crunching sound and the lever does not move, as if it is resting on an obstacle. Do not insert the device as this may cause more serious damage and cause the mechanism to fly.

For such wear, it is typical that the clutch pedal falls to the floor, and you can hear from drivers that the speeds are not included in the VAZ 2109. Usually this applies to all gears, but only the first and reverse gears can fail.

You can check by removing the rubber plug. Fibers, like tangled strands of hair, emerge from the damaged disc. In this case, it is necessary to install a new clutch disc.

Due to constant loads, the cable stretches and must be periodically adjusted and tightened. In this case, the first and second speeds are not included in the VAZ 21093, the rear part may also fail. To repair the damage, you need to go down into the hole and tighten the cable. If worn, replace immediately. You can do it yourself.

This failure can also occur if the gears are disengaged while the engine is running. Sliding on the slots is limited, and locking does not occur.

Baskets

The reason for difficulty shifting individual gears, especially if you simultaneously hear a crack that gradually disappears while driving, may be the destruction of the spacer ring in the basket. Notice the drops of oil on the outside. Then remove the basket and check the ring and disc blades. Be careful when purchasing new parts as some models do not have a disc and you will have to fit the pins and install them yourself.

READ Which oil is best for Kia RIO

Wings

Loose links need to be tightened with an assistant. It doesn't require any special knowledge or skills, just the ability to hold the lever in place while you reach under the car and tighten the bolts. When the plot weakens on the VAZ 2109

The speeds do not turn on, especially the reverse ones.

Place the car in the pit or elevator to gain access to the dungeon. Set the lever to neutral if multiple speeds are not in use. When only reverse gear

, adjust it. An assistant must hold the shift knob in the desired position without throwing it anywhere.

It is necessary to loosen the bolt 13 from below, check the gear mesh and, having installed everything in place, tighten the bolt. If there is a problem with several gears, everything is also done, but it is set to neutral, or rather the shift knob is in the middle position. You can watch the video on how to do this.

Fork

Most often it breaks down on the road. You need to brake at a traffic light, but the continuation speed is not turned on. A crack formed on the fork body can lead to its destruction at any time, even under light loads.

Messages 20

1 Topic by Makar 2008-12-21 13:54:26 (2009-05-18 22:22:22 edited)

- Makar

- User

- Offline

- Registered: 2008-11-24

- Messages: 5

- Reputation: [ 0 | 0 ]

Subject: Gears won't turn on

The gears do not engage when the engine is running, and when the engine is not running, all gears engage well, what could it be? a basket? I tried pulling the clutch cable, it didn’t help

2 Reply from Yurik 2008-12-21 14:05:42

- Yurik

- User

- Offline

- Registered: 2008-11-09

- Messages: 411

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

THE CLUTCH HAS BEEN CONFINED! but as? Did they suddenly stop turning on, or gradually?

3 Reply from Makar 2008-12-21 14:09:44

- Makar

- User

- Offline

- Registered: 2008-11-24

- Messages: 5

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

Yes, abruptly, I started moving the railway and the gear didn’t engage anymore, I turned off the car, put it in 1st gear and somehow got there

4 Reply from Yurik 2008-12-21 19:03:02

- Yurik

- User

- Offline

- Registered: 2008-11-09

- Messages: 411

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

Mmm. change the clutch. It will cost you somewhere from 1200 rubles if you do it yourself. and also plus 1500 for the work.

5 Reply from Driver 2008-12-21 20:17:46

- Driver

- User

- Offline

- Registered: 2008-12-08

- Messages: 460

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

Is the clutch pedal elastic? Maybe a release rocker?

6 Reply from Sir YareG 2008-12-21 20:20:05

- Sir YareG

- User

- Offline

- Registered: 2008-11-08

- Messages: 3,047

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

The clutch is definitely dead.

7 Reply from Yurik 2008-12-22 10:40:57

- Yurik

- User

- Offline

- Registered: 2008-11-09

- Messages: 411

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

put VALEO. advice. or Luke

8 Reply from DIMON_21099 2008-12-22 15:29:53

- DIMON_21099

- User

- Offline

- Registered: 2008-12-22

- Messages: 14

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

It was exactly the same bullshit! I solved my problem by replacing the basket (the petals burst), and at the same time change the release lever (it’s not expensive and it’s somehow quieter)!

9 Reply from Makar 2008-12-22 18:41:48

- Makar

- User

- Offline

- Registered: 2008-11-24

- Messages: 5

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

Exactly! I changed the clutch basket and everything was fine! Thanks for the advice

10 Reply from manter 2009-05-18 20:34:39

- manter

- User

- Offline

- Registered: 2009-03-20

- Messages: 14

- Reputation: [ 0 | 0 ]

Re: Gears won't engage

It all started with the fact that after parking for the night I was unable to engage first gear! As if it was hitting something, after engaging the second gear, the first gear engaged immediately without any problems! Everything would have been fine if it had only happened once, but about a week ago it started jamming like this at intersections, and plus the reverse gear also started acting up! This all started about a month ago! Two months ago the clutch was completely replaced, maybe that’s why it happened?? Or what else could this be for?

11 Reply from XPum827 2009-05-25 20:16:06

- XPum827

- User

- Offline

- Registered: 2008-11-08

- Messages: 934

- Reputation: [ 1 | 0 ]

Re: Gears won't engage

It all started with the fact that after parking for the night I was unable to engage first gear! As if it was hitting something, after engaging the second gear, the first gear engaged immediately without any problems! Everything would have been fine if it had only happened once, but about a week ago it started jamming like this at intersections, and plus the reverse gear also started acting up! This all started about a month ago! Two months ago the clutch was completely replaced, maybe that’s why it happened?? Or what else could this be for?

The first reason why first and reverse gears are poorly engaged is a dying clutch.

First, try adjusting the clutch cable.

First speed not fixed

When you start driving in first gear, especially on heavy ground such as sand and snow, you will have to hold the gear lever as it does not hold on its own, the transmission shifts to neutral. There could be three reasons for this failure:

- The wings are loose and the fork does not fix;

- Wear of gears and clutch;

- Engine power is on the cushions and knocking out of the box.

It is necessary to completely check the condition of the fastenings of all parts and assemblies. The gearbox is rigidly mounted to the engine. However, when the engine slides over the airbags, first gear

may be knocked out. Tighten all bolts and check the rigidity of the mounting on the body. You can do this work yourself.

Secure the drawbar firmly to the shift lever, select the game as it is responsible for locking the lever in the correct position. To do this, place the car in the pit. Open the lid and audit. Pay special attention to the condition of the gears.

When worn, the gears can slip and jump out without transmitting torque. When you press the lever with your hand, the clutch fits snugly and engages.

New box

Problems arise when they pick up the car from the service station, and the VAZ 21093 gearbox speed is not included. At the same time, when the engine is not running, the shift lever moves smoothly without cracking. As soon as the car starts, the transmission stops engaging. First of all, check the movement of the gears and forks along the grooves - along the axis of the shaft. Since you have opened the window, pay attention to the position of the driven disk to see if it is installed correctly.

If a problem is discovered shortly after servicing the vehicle, do not worry about it yourself. Send your car back and let the locksmith find and fix the problems himself. Remember that you don't have to pay for poor quality repairs.

Adjustment

If the slide shows the very first signs indicating a deterioration in its working condition, then it should be adjusted. Almost everyone can do this correctly if you follow the algorithm below:

- At the very beginning, you need to make every effort to activate first gear.

- To ensure maximum safety, the car should be secured on the overpass, and then put on the hand brake and place additional supports under the wheels. This will ensure that the vehicle is insured against involuntary movement.

- We do not turn off first gear.

- You need to get under the hood of the vehicle to find a special clamp at the bottom that simultaneously holds and secures the rocker. Finding the gearbox will not take extra effort, after which you need to try to loosen the clamp.

- If all manipulations were carried out as correctly as possible, you should return to the salon to move the lever to the left all the way. If you move it in any other direction, the slide will definitely come off. This is undesirable, so extreme care should be taken.

- We return to the starting position and tighten the clamp back.

- It should be noted that it is often enough to move the rocker in relation to the cardan by just a couple of millimeters.

During this process, the condition of the driveshaft should not be neglected; on the contrary, it is advisable to evaluate its current condition, since it may require replacement if it is severely worn.

Reverse speed VAZ 2109 is not included

Placing the rear speed in the extreme position often leads to its refusal to engage. Since several models have absolutely identical boxes, the VAZ 21093 does not include a return speed for the same reason. It may be a short lever and the tension cord is not in the correct position.

Just look at the photo of the transmission below to determine the cause. The repair must be done in the pit because everything will have to be done from below. The wings must be loosened. Align the gears in the opposite direction and tighten the bolt. The lever must be in the reverse position.

First gear is not engaged when driving

Often when you put the car into first gear while the car is moving, it gets stuck and doesn't work. Once you start moving there is no problem. Some "experts" have even theorized that first gear should just start moving and should not be used during maneuvers.

This problem occurs because the injectors do not have time to equalize the torque of the gears, and the driver forcibly tries to connect them. The flywheel rotates much faster than the drive shaft and the teeth can fly if the force is high.

READ Timing Replacement Peugeot 308 Ep6

Don't be in a hurry to press the lever. Move it to neutral, push it lightly into the first gear position and wait for the synchronizers to do their job and the transmission begins.

For old boxes there are instructions for replacing gas. When downshifting while driving, move the lever to neutral, press the accelerator to increase speed, and then shift smoothly. This method is used by owners of preserved vintage cars, the price of which has increased significantly in recent years.

Source

Often, trying to engage the transmission will result in a loud grinding noise from the gears, and if the transmission can be engaged, the transmission will make noise when moving in reverse. Other owners encounter a situation where the gearshift scenes are fully advanced, but the rear derailleur does not work. No complaints about the forward shift.

Changing the gearbox oil

Replacing the gear selection mechanism

Comments and reviews

Hand bearings

And the last thing could be these bearings. Although they are very strong there in the box, it happens that they also “get jammed.” The box will work like a tractor, especially when warming up.

In any case, if you have problems with the transmission itself, this is already an expensive repair. It is also better to trust professionals because the gearbox. very complex mechanism.

As you can see, there are many reasons, but it should be noted that manual transmissions. a fairly reliable unit, they themselves break down quite rarely, especially if you change the transmission fluid on time and use a brand of very good quality.

If the gears are not engaged, then most likely there is an “attached” problem, ranging from the fenders and cables to the pressure plate, clutch disc and flywheel.

Now a short video version of my article, check it out.

And that's ALL for me! I think the information will be extremely useful, read it in our AUTOBlog.

( 15 votes, average: 4.40 out of 5)

Similar news

How to change the oil in an automatic transmission (automatic transmission) or in a variator (CVT).

How much does it cost to change the oil in an automatic transmission (automatic). Details of the case.

Why does the automatic transmission (automatic) knock and pull? Or when switching.

Source

Causes

Reasons why reversals are bad or difficult may include:

- Loosening of the mounting clamp of the steps, due to which the rod is not long enough to fully engage;

- Reverse speed lock jammed;

- Spring breaks and dirt get into the guide grooves of the gear selection mechanism;

- Unauthorized loosening of the selector mechanism mounting bolts;

- Clamp bolt cut off;

- Worn clutch disc and exhaust bearing;

- Incorrect adjustment of the clutch and clutch pedal;

- The oil level in the box is low or it needs to be replaced.

Replacing the backstage oil seal of a VAZ 2110

- Loosen the drive rod clamp.

- Pull the cover off the hinge. If you plan to replace the boot, cut it lengthwise to save time.

- Unscrew the locking screw.

- The assistant, while driving, presses the clutch pedal and changes gears. In this case, the drive supplies thrust towards the box and back. The master, pressing the cardan to the gearbox, disconnects the drive assembly.

- Remove the hinge.

- Remove the cover.

- Remove the oil seal, carefully, without crimping the cuffs, insert a new seal.

- Pull the boot.

- Install and secure the hinge. Important point. Rotate the adapter within a few degrees around the axis and insert the locking screw into the hole on the shaft.

- Refill the cover.

- Connect the rod to the cardan.

- Adjust gear shifting.

Problem solving

Many transmission malfunctions that lead to the disappearance or failure of the rear derailleur can be eliminated without removing the unit from the car.

If the cause is a loose coupling bolt securing the clamp to the rod, then to fix the problem you need to:

- Place the car on the lift.

- Loosen the clamp nut completely.

- Place the gear lever in full reverse gear.

- Fully engage reverse gear on the transmission using the crankcase switch.

- Tighten the clamp bolt.

Adjustments behind the scenes

If tightening the clamp does not solve the problem, you need to check the condition of the drive switch parts. One of the reasons why you cannot engage reverse gear may be poorly adjusted traction.

To make changes to the mechanism, you may need the following tools:

- Two 13mm wrenches, preferably ring type;

- Any 10mm wrench or socket;

- Small hammer;

- Slotted screwdriver.

Since behind-the-scenes failure may be caused by worn parts, spare parts may be required:

- Backstage frame;

- Sometimes the stem seal may need to be replaced.

Two people are required to adjust the slides or replace parts. One person must shift gears from the cab, and another must adjust the shift rod stroke.

The procedure looks like this:

- Provide access to the underbody of the car by placing it on a pit or lift.

- Use a 13mm wrench to unscrew the clamp mounted on the rod.

- Remove the rod from the box rod.

- Carefully remove the block using a screwdriver.

- Use a 10mm wrench to loosen the mounting bolt on the power take-off shaft.

- Knock down the cardan shaft with light blows of a hammer. It is important not to damage the shaft.

- Remove the sealing block from the universal connection.

- In case of oil leakage, the oil seal on the box rod must be replaced.

- Install a new shoe (or leave the old one if it is not damaged) and install the universal joint on the shaft.

- Align the hole on the driveshaft with the notch on the shaft.

- Tighten the 10mm clamp and install the pad completely.

- Install the universal joint rod and adjust the travel of the gear shift lever.

- The second person should sit in the driver's seat, place the gear shift in neutral, move it slightly to the right and hold it in this position.

- Then tighten the 13mm clamp nut.

Typically, this type of gear repair starts to start without problems. In addition, the operation of the entire gear selection mechanism on the VAZ-2109 becomes clearer.

Video from the author MegaMeyhem shows the replacement process behind the scenes.

Changing the gearbox oil

If the seal on the rod is damaged, oil will leak out of the box body and dirt may get into the box itself. These factors may be the reason why the postback is no longer closed. In addition, the oil in the box loses its properties during operation, so it must first be replaced at least once every 35-40 thousand kilometers. Before replacing, check the condition of the oil in the box. To do this, remove the oil plate installed in the gearbox housing and visually assess the quality of the oil. The presence of metal particles and dirt in the oil on the probe is unacceptable. The oil itself should be quite liquid and not stick to your hands in a thick layer.

READ Replacing Camshaft Studs VAZ 2106

Oil glue

You will need the following materials and tools for replacement:

- New oil. When purchasing oil, you need to consider the type of gearbox. The rather rare four-speed transmission requires three liters of oil, the newer five-speed requires 3.3 liters. The oil itself must have a tolerance of 80W-85, this is not important for the manufacturer.

- A tank for draining old oil with a volume of at least 4 liters.

- Funnel with hose for filling new oil or syringe.

- Wrenches 12 and 17 mm of any type.

- Rags and cleaning solvent.

The procedure itself is like this:

- Place the machine with the heated box in the pit.

- Remove the rubber plug from the transmission bleeder valve at the top of the crankcase.

- Clean the valve and plug from dust and dirt. It is convenient to clean parts with thin wire and rags.

- Install clean parts.

- Wipe the bottom of the box with dirt. Unscrew the plug at the bottom of the crankcase.

- Place a container under the drain hole and drain the oil. It drains completely in at least 20-25 minutes.

- Then screw on the drain plug and carefully tighten it with a wrench. The plug and hole should be thoroughly wiped with a rag.

- Fill in fresh oil through the hole in the oil level dipstick in the box.

- When filling, check the oil level, which should usually be between o and “MAX” on the drive shaft.

- If there is an overflow, the oil can be pumped out using a large medical syringe with a tube on the nose.

- It is advisable to check the oil level and appearance within a few days after the change. You should also make sure there are no leaks at the plug and box seals.

In earlier versions of the VAZ transmission, there is no hole for the probe on the front wheel. To fill the crankcase of such boxes with oil, there is a control hole closed with a threaded plug. Filling is carried out using an oil syringe. The oil level is considered normal when the lower edge of the inspection hole is reached.

Replacing the gear selection mechanism

One of the common reasons why the rear gearbox of a VAZ 2109 does not engage is the breakdown of spring 2 installed in a separate mechanism.

Gear selection mechanism

To gain access to it, it is necessary to remove and repair the mechanism itself, located inside the box.

A short list of necessary actions:

- Turn off the car.

- Remove the air filter completely.

- Remove the left wheel and unscrew the CV hub nut.

- Drain the oil from the crankcase.

- Remove the two bolts that secure the left joint to the steering cam.

- Unlock and remove the steering knuckle.

- Remove the fist from the braided seams.

- Remove the left disk completely.

- Remove the starter and negative cable from the crankcase.

- Remove the shift and clutch levers.

- Unscrew the cable to drive the speedometer.

- Place the stand under the box body and remove the box support fasteners

- Remove the transmission from the vehicle and disassemble it.

When disassembling the gearbox, it is necessary to check the condition of the gearbox locks, since wear is the main reason why the reverse gear involuntarily jumps out of the gearbox. You can reach the latch without removing or disassembling the box; it is located on the side of the crankcase and is closed with a screw plug. Disassembling the gearbox and reviewing the gear selection mechanism will also help solve the problem in which the reverse gear does not turn off on a VAZ- 2109

.

Spring replacement

Often, owners change the entire prefabricated assembly, which costs on average about 2 thousand rubles. But you can disassemble the mechanism and get it by replacing the spring, which costs up to 50 rubles.

You must do the following:

- Remove the plug from the locking axle and remove the axle itself.

- Unscrew the lever shaft nut.

- Remove the axle and replace the spring.

- Reassemble in reverse order.