- Introduction

- What is disc ejection?

- What kind of departures are there?

- Zero departure

Positive departure

- Negative departure

- ET number

- Can I change the offset without changing the disk?

- How does an incorrect offset affect a car?

- Why change the disc offset?

- How to measure disc offset? Recommendations

- conclusions

Disc ejection: what is it?

Disc offset, or ET indicator, is a dimensional parameter that is indicated on the rim of the product, regardless of its radius or material of manufacture (stamped, cast or forged), and indicates the distance from the mating plane of the wheel to the attachment point to the hub.

This dimension is usually set by the car manufacturer. First of all, the wheel must be completely hidden under the wheel arch, and it is the ET indicator that regulates its position - the larger it is, the more the wheel is recessed under the wing; the smaller, the more noticeably the disk protrudes beyond the dimensions of the body.

ET offset on wheels: what is it and how does it affect the suspension and other parts in the car? Depending on the wheel offset, the load on the hub and the bending moment applied relative to it at the base of the suspension are distributed differently. Thus, each automobile concern dictates the strength limit for its parts, which determines the range of wheel offsets.

Some cars, especially when it comes to SUVs and sports cars, are equipped with additional plastic mud flaps, which determine the wheel offset, which in such cases can be zero or even negative, which gives the “iron horse” a very impressive look.

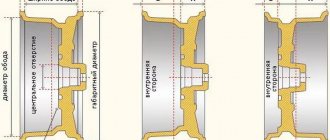

ET departure using 3 indicators as an exampleImportant! Before purchasing a wheel rim, the driver needs to read the owner's manual for his car or study detailed information on numerous Internet resources in order to make the right choice and not regret it later.

Types and mechanical characteristics

There are 3 types of wheel offset:

- null;

- positive;

- negative.

The offset coding (ET) is located on the surface of the rim, and the numbers located next to it indicate its parameters.

A positive offset value means that the vertical axis of the wheel rim is at a certain distance from the point of contact with the hub.

The zero ET parameter indicates that the disk axis and its mating plane are identical.

With a negative ET parameter, the disk attachment surface to the hub moves beyond the vertical axis of the disk.

The most common disc offset is a offset with a positive value; a negative offset, on the contrary, is extremely rare.

The offset size is a significant nuance when designing wheel rims, so a special formula is used to calculate it to eliminate possible errors.

How is ET disc offset measured?

The parameter is measured only in millimeters. You will need a ruler and a wooden (or metal) strip, the length of which coincides with the radius of the wheel.

- First of all, you need to remove the wheel from the car and put the car on the handbrake. If the wheels have alloy wheels, the procedure will be greatly simplified, since all the nuts on them are open. Otherwise you will have to remove the cap.

- Now you can remove the disc from the wheel. This must be done with a sharp movement.

- The wheel should be placed on the ground with the side opposite the hub. We place a wooden strip on top of the disc rim.

- Then, using a ruler, measure the distance from the surface in contact with the hub to the bottom of the rack - this will be distance A.

- Next, we turn the other side of the wheel towards the ground, and also place the rack on the rim.

- We measure the distance from the bottom of the rack to the plane beyond which the hub is distance B.

Formula and labeling

The term disc overhang is designated by the letters ET from the German Einpress Tief (extrusion depth). Its calculation formula is as follows:

ET=ab/2

where a is the distance between the inner plane of the disk and the part that comes into contact with the hub, b is the width of the disk. You can see it most clearly in the figure below.

The calculation is made in millimeters. In some cases, instead of the letters ET, the disc offset is marked with the following inscriptions: DEPORT or OFFSET. For example, the following values may be: ET0, ET30, ET-15.

Varieties of departure

There are three types of offset, each of which is assigned a corresponding marking (painted on the inside of the disk):

- ET20 (zero offset) - when the surface with which the disc is pressed against the hub coincides with the central plane of the wheel,

- ET0 (positive offset) – the vertically located axis of the disk is distant from the point of contact with the hub by a certain distance,

- ET-20 (negative offset) - when the surface with which the disc is attached to the hub is carried beyond its vertical axis.

Today the most common disc offset is ET0. Negative and zero offsets, on the contrary, are rare. Wheels with such an offset are installed on specially prepared cars, for example, for racing, both off-road and on tracks.

The offset parameters are regulated by vehicle manufacturers, and, as they say, there should not be any deviations (even a few mm). Otherwise, the operating conditions of all suspension units change, which under critical load conditions can lead to tragedy.

Labeling and formula

Calculations should be made using the formula:

ET=(A+B) / 2

The values obtained during the measurement must be substituted into it.

The ET value is prescribed individually for each machine. All the necessary information on this matter is in the car’s operating instructions. Wheels will not fit the vehicle if the measured value differs from the data in this document. “Non-native” components are not worth buying, even if the seller actively convinces you otherwise.

The markings on the discs must be carefully studied - this is the only way to make sure that they are safe to use. Product markings are standard. In any case, the designation contains the letter I or S. The letter I means that the wheel is “identical” and is installed on production cars. S indicates that the wheel is special, that is, its certification is not tied to a specific brand of car. In some cases, there is no letter designation - instead, the name of the plant where the car was made and its catalog number are applied to the rim.

As an example, consider the rim marker 7.5 j x16 H2 5/112 ET 35 d 66.6:

- The first numbers are the width of the disk. For example, 7.5 means the width is 7.5 inches. To convert to centimeters, you need to multiply by 2.54.

- The letter J means that the wheel has some design features. This information is of no interest to consumers.

- X indicates the indivisibility of the disk.

- The number 16 is the wheel caliber corresponding to the tire caliber.

- H2 reports that there are 2 humps on the rim.

- The number 5 is the number of holes for fasteners, 112 is the diameter at which they are located.

- ET 35 speaks of a plus offset, the size of which is 35 mm.

- d 66.6 - central hole gauge. Ideally it should be identical to the hub caliber. If this is not the case, an additional ring must be used to center the fit. It is also called transitional.

What does disc ejection affect?

The following quantities are associated with departure:

- Wheelbase.

- Torque applied to a wheel bearing.

Both parameters need to be considered in detail.

Depends on the wheelbase:

- Sustainability. Improves with increasing distance between wheels. For this reason, SUVs have zero or negative offset.

- Controllability. It is the best for the wheelbase that the designers laid down.

The moment acting on the wheel bearing is calculated as the product of 2 quantities:

- The force with which the road acts on the wheel.

- Arm - the distance from the direction of action of the force to the point relative to which it causes rotation.

The road affects the wheel along the entire contact patch, and the total force vector passes through its midpoint. If the tires are not worn out and the wheel alignment is adjusted, this point lies in the central plane of the disk.

Thus, the further the vertical axis of the wheel is from the bearing, the greater the moment acting on it.

What problems can arise due to incorrect selection of disks?

The danger of incorrect selection of this dimension is especially relevant when operating expensive modern cars. Thus, the position of the vehicle on the road is carefully monitored by the on-board computer and various sensors. If a tire goes flat, the driver receives a signal about a loss of pressure; when the brake pedal is pressed sharply, the wheels do not lock, as the ABS is activated.

The same can be said about the directional stability stabilizer, which controls the position of the car on the road and the straightness of its movement, and also prevents skidding on the road, alternately blocking one or another wheel. In this computer, as a rule, engineers enter certain indicators of the wheel rim dimensions - ET, and as the final result - the values of bending moments.

Measuring the jack of the disc

Why install wheels with a different offset?

Installing wheels with a reduced offset helps to increase stability and, as a result, the wheelbase of the car. Thus, the car is able to turn confidently and has high road stability. Some changes to the suspension improve overall ride comfort, but it also changes the operation of springs, levers, brakes, bearing wear, hub wear and other handling parameters.

Sometimes installing wheels with a smaller, relatively standard offset allows you to reduce the weight of the suspension and thereby improve dynamics and fuel consumption in certain modes.

As the offset increases, the track decreases, and if you do this without preliminary calculations, the wheel may simply rest against the brake caliper or touch the inside of the wheel arch.

The increased reach also affects the operation of the suspension units and the chassis of the vehicle. As a rule, wheels of smaller size and diameter are installed on some versions of cars during winter operation, but the effectiveness of this phenomenon has not been proven, and smaller versions are practically not used in the tuning process.

If we talk about which wheels to choose, then in this case it all depends on the car model, tuning capabilities and other factors. There are disks that are made by hot stamping, others - under high pressure and metal processing.

Forged ones are stronger and lighter, but this does not mean that they are suitable for all car models, it all depends on the situation. When choosing a disk, it is necessary to take into account the meanings and interpretation of the markings in accordance with international standards, where:

- ET – Disc Overhang may be designated as Offset Internal or Extending

- B is a measure of the width of the rim between the edges of the rims (measured in inches. 1 inch = 2.34 centimeters

- “J” is a special service symbol that indicates the design features of a particular model

- “D” – diameter of the mounting rail, “d” – diameter of the hole for the wheel hub

It should be added that there are cases when wheels with an increased or decreased offset fit on a standard wheel hub without problems. However, this does not mean that their use will be safe for various suspension elements.

Automaker engineers carefully calculate all aspects of the behavior of the wheel, hubs, shock absorbers, steering ends, levers, etc., so using discs with sizes not recommended by the manufacturer can significantly reduce the overall life of all these parts.

conclusions

- the ET parameter is one of the key geometric parameters of the disk, which is important to remember when choosing a new set of disks for your car;

- the offset can be negative, positive, zero - for each car model, the manufacturer sets its own value, as well as permissible deviations from it;

- It is not recommended to change the offset of the discs too much - this is fraught with disruptions in the operation of the suspension and chassis, can negatively affect the handling of the car and will automatically remove the car from warranty.

The video clearly shows how to measure the disc offset:

Large offset (15,35,40,45) and its increase using a spacer

The suspension of a truck or car is clearly standardized and calculated by the manufacturer and the designers developing it. However, if you approach this tuning wisely, then in the end the increased wheelbase of the car and its track can increase the stability of the car.

And also the wheels protruding beyond the edges of the car will be a plus when supplementing it with plastic modifiers. The main thing that a car enthusiast needs to clearly understand is that the service life for which a given wheel bearing is designed decreases in direct proportion to the difference in the distance of the displaced disk and the original one recommended by the manufacturer.

- To increase the disc overhang, a so-called spacer element is used. It is installed tightly between the disc and the drum, or the hub, it all depends on the model and design of the car’s brakes. The dimensions of these elements are of great importance; there are several types:

- Thickness up to 6 mm is considered small, but often the length of the original mounting bolt is enough to properly fix the disc together with the iron spacer.

- Thickness up to 25 mm. they already have a centering hub, which eliminates the option of destabilizing the balancing of the wheel parameter. The car acquires notes of a sporty, aggressive character and the spacers installed on it are visually identified.

- The thickness of the spacer is from 25 to 50 mm, which is considered quite large. They are attached to the hub or drum not only with bolts, but also with studs. Bolts are recommended for VAZ cars, fastening with a stud for brands such as Niva or UAZ.

The spacer to increase the offset must be made of durable metal. Therefore, before a car enthusiast starts making them manually, it is worth considering the risks and consequences of their installation. Still, it is recommended by experts to purchase high-quality factory spacers and offset wheels, which will be made from the required grade of steel, and also meet all reliability and safety requirements. Naturally, when choosing and specifying the parameters of disks and spacers, it is worth taking into account the number of mounting bolts and their length.

Wheel spacers

As already mentioned, the use of wheel spacers is a way to reduce the offset to the standard value. Spacers are flat metal pancakes that are installed between the disk and the hub and act as a kind of spacers. Thus, if a car enthusiast has his eye on wheels that meet all parameters (width, diameter, centering hole, number and diameter of the axle placement of bolt holes), except for the offset value, he can easily use these wheels by installing wheel spacers of the required thickness.

Wheel spacers are used not only to bring the offset value into line with the recommended parameters, but also to change it in one direction or another (extending the wheelbase during tuning), or in the event that the number and location of the holes for the hub bolts does not match the disk .

There are two main types of wheel spacers:

- The first ones have through holes and a thickness of 6–12 mm; to install them, it is necessary to select bolts that are longer than the standard ones by the thickness of the spacer;

- The second ones (thickness 12 - 20mm) have holes for the hub bolts, as well as separately for the bolts that secure the gasket to the disk. That is, such spacers can be used if the mounting holes on the disk (size, number, distance) do not match the holes on the hub. In addition, spacers of this type have an additional centering hole, and when purchasing, you need to make sure that this hole coincides with the centering hole of the disk.

There is also a difference between the ways to use wheel spacers:

- Bringing departure parameters to standard values;

- Adaptation of the disk to the hub (if the mounting holes do not match);

- Change in offset relative to the standard value (widening or narrowing of the wheelbase).

The feasibility of using spacers directly depends on their quality, as well as the method of use. Thus, poor-quality wheel spacers (errors in the dimensions of the mounting holes, unsuitable metal) can cause a sudden accident or contribute to the rapid failure of the suspension. If we are talking about intentional changes in departure relative to standard parameters, then the consequences that such modifications can lead to were discussed above.

Too positive/negative offset: impact on the car

Excessive positive overhang can cause damage to the inner suspension and brake components at the inner edge. This can result in poor handling, making the vehicle unstable at speed. Sometimes friction occurs on the thin inner sidewall of the wheel, causing the tire to burst.

Too much negative offset can also result in poor handling due to additional stress on the suspension components. The steering wheel can tip back during hard cornering, causing unstable steering and a possible crash.

SPECIALIST ADVICE IS REALLY NEEDED.

Friends, I really need the opinion of a competent car owner. How critical is the difference between wheels with 40 and 45 offset? After purchasing 45, it turned out that according to the factory parameters, a forty was needed. Some people say to change it urgently, otherwise the suspension will be destroyed :( Is it really fraught with such consequences? What do you say?

Don't worry, there are no problems. The main thing is that they all have the same offset.

The load on the wheel bearings will increase slightly, but in principle you can drive without problems :)

5 mm of offset will not cause harm. If after the wheels with an offset of 45 you put in wheels with an offset of 15. Then yes.

It seems like wheels with a 45 offset will sit DEEPER than those with a 40 offset. The smaller the offset, the more the wheels are outward. Or am I wrong?

Forces acting on suspension elements

Absolutely any element of the suspension is subject to several multidirectional forces. And it is quite natural that this list increases with the complexity of the design, which is very different from modern machines. Therefore, we offer for consideration the simplest example, where the hub is attached to the body by means of a lever and a strut with a shock absorber (McPherson system).

The force exerted on the wheels is directed upward from the plane along which the car is moving, and the mass of the car is distributed between all wheels. In this case, the points of application of these forces are the centers of the tire contact patch area. And if we assume that the suspension and camber angles are in ideal condition, and the wheels are well balanced, then these centers will be located on the axis of symmetry of each wheel. It is in this place that the axis of the shock absorber strut should fall.

Everything else is simple. The acting force corresponds to the proportion of the car's mass attributable to the wheel. It is directed away from the ground and creates moments in the levers, wheel bearing, and struts with shock absorbers. In the first two cases it will be tension, and in the last case it will be compression. All these points are carefully calculated at the design and construction stage. Naturally, a safety margin is provided for each part, but it was already mentioned above that it is constantly decreasing due to the widespread desire to reduce production costs.

When the calculated offset changes, the forces change their magnitude and direction, because a decrease in offset expands the wheelbase, and an increase - narrows it. This entails a displacement of the steering axis and a change in the parameters of steering wheel rotation, moments of forces and vectors of their application. This aspect also negatively affects the wear resistance of tires, maneuverability and controllability of the vehicle. Taken together, all of these factors lead to the fact that the suspension is operated in a mode that was not intended by the automaker. The level of driving safety decreases, and the service life of most structural elements decreases sharply.

In conclusion, let's say the following. If a new wheel with an offset that does not coincide with the standard one easily fits on the hub of your car, this is not a reason to use it without fear. It cannot be said that the operation of vehicles in such equipment will be safe. Wheel spacers can be a solution, but only if the offset is greater than standard, and you were able to find suitable spacers, which is often very problematic.

If you really want it

But what if you really need or really want to change the appearance of your car using wheels of non-standard geometry? For such cases, there is a reasonable alternative - wheel spacers. This engineering solution allows you to reduce the offset (increase the distance between the hub and the disk), and thus move the wheels outward. In addition, spacers make it possible to install even disks in which the number or location of mounting holes does not coincide with the fastenings on the hub itself.

There are two types of wheel spacers on sale, differing in thickness and functionality.

The first type of spacers are ordinary metal washers 6-12 mm thick with through holes. To install them, you will need to select hub bolts that are longer than the standard ones by the thickness of the spacer.

The second type is an already improved version with technological holes both for the hub bolts and for the bolts for separate fastening of the spacer to the disk in case of mismatch of fastenings. Their thickness can be from 12 to 20 mm.

Wheel spacers can be used for:

- adjusting the offset value to the recommended values;

- mounting the disk on the hub if the mounting holes do not match;

- changes in the offset value relative to the values recommended by the manufacturer.

Disc offset 40 and 45: what is the difference

Disc offset, or as it is commonly referred to as ET, is one of its most important parameters, showing the distance between the area where the wheel rim is adjacent to the hub and its vertical plane, which is responsible for symmetry.

Thanks to this parameter, the car enthusiast can immediately understand whether the wheel will fit on his iron horse or not. But we will try to look at the example of disk offset 40 and 45 (what is the difference, possible deviations, etc.) in the article below.

How to calculate the indicator using the formula?

As mentioned earlier, by the ET indicator you can determine whether the selected “sneakers” will fit on the car or not. And this procedure is carried out according to the following formula: ET=A-B2, where:

- A – the distance from the inner surface of the wheel rim to the area of its contact with the hub (indicated in mm);

- B – rim width.

The result can have three parameters: good, zero and bad. With the first result, there will be a small gap between the area where the wheel touches the hubs and the hubs themselves, which means that such a wheel will be ideal for this vehicle.

If the calculation according to the formula showed a zero result, then, in principle, such “sneakers” can also be installed on a car.

But, in this case, the above-mentioned clearance between it and the hubs will not be observed, which will significantly increase the load from the impacts received (if the wheel falls into a hole, or hits an uneven surface).

But with a negative projection, the wheel cannot even be installed on the car, since the hubs simply will not allow it to fit under the wheel arch.

Permissible deviations

We have already looked at what a protrusion is and how it is calculated. And before moving on to the question of what is the difference between the ribs ET 40 and ET 45, let's consider in advance the permissible deviations of this indicator in the table below:

Based on the table, you can understand that the answer to the question will depend on the size of the wheel rim offset: will the measured wheel fit on the car? Well, if you ignore this parameter, then the likelihood of throwing your money away will be very high.

Having found out what the permissible disc offset is and how to calculate it using the formula, you can safely move on to the next, most important question that many car enthusiasts are interested in: what is the difference between the ET 40 and ET 45 protrusions? And the answer will be the following: firstly, when installing a wheel rim with a smaller rib on a car, the load on its wheel bearings will increase slightly. And this, in turn, will reduce the wear resistance of parts, preventing them from serving their intended life.

However, if we compare the protrusion of 40 and 45 mm, then such a negative phenomenon will practically not be noticeable. But when comparing ET 20 and ET 50 rims, reduced wear resistance will make itself felt within 2-3 months. Well, in addition to this phenomenon, the stiffness of the suspension will also increase, due to the lack of play between the wheel and the hubs.

Secondly, the vehicle will have visual differences. Namely: when installing the ET 40 rim, the wheels will practically not stick out from under the arches of the car, while the ET 45 will make them stick out as much as 5 mm, which will be visually very noticeable.

But, unfortunately, it will not be possible to unanimously assert that such a change will be negative. After all, some car enthusiasts specifically choose wheels with a large protrusion (within the permitted limits) so that the wheelbase of the car appears wider. Otherwise, there will be no difference between disc offset 40 and 45.

This means that you can safely install both options on your machine without fear of any consequences.

Expert opinion

Despite the fact that a 5 mm deviation of the protrusion is not considered significant, car manufacturers persistently do not recommend that motorists install such “sneakers” on their iron horse.

And they argue this by saying that with a changed rim offset (different from that recommended by the manufacturer), the technical and dynamic qualities of the vehicle change significantly.

Well, in addition to this negative phenomenon there is also a reduced service life of the part, which does not correspond to the warranty.

But sellers have a completely opposite opinion on this matter. And they explain it by saying that it is very difficult to select a specific disc with an offset.

But given acceptable deviations, the range of shoes for cars increases significantly, which benefits both buyers and sellers.

Well, you can decide for yourself which ledge is suitable for your iron horse, based on the information provided above.

Manufacturers' recommendations

There is no consensus among automakers regarding the permissible deviation from the offset and some insist on full compliance with their recommendations, others allow the deviation within +/– 5 mm, and still others independently indicate several offset options. What is the reason for such a big difference in opinions?

Reduced wheel offset

The fact is that in a competitive environment, automakers are forced to save their resources, so the loads on all machine elements are calculated with extreme accuracy. So even a slight discrepancy with the declared characteristics can lead to damage to the part.

By the way, experts have calculated that if you reduce the disc offset by 50 mm, this will lead to an increase in the load on the suspension by 1.5 times more than normal. This also explains the difference in reach for cars of the same model, but with different modifications of power plants.

Acceptable table of deviations for the most common car brands (Mercedes, Toyota, UAZ)

Each specific car brand has its own permissible deviations, which are best not violated.

| No. | Automobile model | Allowable disc overhang, mm |

| 1 | Chevrolet Camaro | 38-50 |

| 2 | Chevrolet Corvette | 38-50 |

| 3 | Chevrolet Aveo 1.6 | 39 |

| 4 | Alfa Romeo 33 | 30-38 |

| 5 | Alfa Romeo GTV | 28 |

| 6 | Alfa Romeo 145 | 38 |

| 7 | Alfa Romeo 146 | 38 |

| 8 | Alfa Romeo 166 | 35-40 |

| 9 | Alfa Romeo 155 | 38 |

| 10 | Alfa Romeo 156 | 28-30 |

| 11 | Audi A4 | 35 |

| 12 | Audi A8 | 35 |

| 13 | Audi A6 | 35 |

| 14 | Audi 80 | 35-42 |

| 15 | Audi 100 | 35-42 |

| 16 | Audi TT | 28-30 |

| 17 | Audi Quattro | 35-42 |

| 18 | Audi A3 | 30-40 |

| 19 | BMW 3 | 15-25 |

| 20 | BMW 3 (E36) | 35-42 |

| 21 | BMW M3 | 18-20 |

| 22 | BMW 5 | 18-20 |

| 23 | BMW 7 | 18-20 |

| 24 | BMW 7 (E32) | 18-20 |

| 25 | BMW 8 | 18-20 |

| 26 | Citroen Berlingo | 15-22 |

| 27 | Citroen Jumper | 35 |

| 28 | Citroen Evasion | 28 – 30 |

| 29 | Citroen Xsara | 15 – 22 |

| 30 | Citroen Xantia | 15 – 22 |

| 31 | Daewoo Nexia | 38 – 42 |

| 32 | Daewoo Espero | 38 – 42 |

| 33 | Daewoo Lanos | 38 – 42 |

| 34 | Daewoo Matiz | 38 |

| 35 | Daewoo Leganza | 35 – 42 |

| 36 | Daewoo Nubira | 38 – 42 |

| 37 | Dodge Magnum 2.7 V6 | 24 |

| 38 | Dodge Avenger 2.0i | 35 – 39 |

| 39 | Dodge Caliber 2.0 | 35 |

| 40 | Dodge Caliber SRT4 2.4i | 40 |

| 41 | Dodge Caravan 2.4i | 35 – 40 |

| 42 | Dodge Challenger 6.1 V8 | 40 |

| 43 | Dodge Durango 3.7 V6 | 15 |

| 44 | Fiat Qubo 1.3 | 40-44 |

| 45 | Fiat Bravo 1.4i | 31 – 32 |

| 46 | Fiat Croma 2.2 | 35 – 41 |

| 47 | Fiat Doblo 1.9JTD 263 | 32 |

| 48 | Fiat Doblo 1.9JTD 223 | 32 |

| 49 | Ford Scorpio | 35 – 38 |

| 50 | Ford Cougar | 35 – 38 |

| 51 | Ford Explorer | 0 – 3 |

| 52 | Ford Escort | 35 – 38 |

| 53 | Ford Focus | 35 – 38 |

| 54 | Ford Focus 2 | 35 – 38 |

| 55 | Ford Fiesta | 35 – 38 |

| 56 | Ford Granada | 35 – 38 |

| 57 | Ford Galaxy | 42 – 45 |

| 58 | Ford Ka | 35 – 38 |

| 59 | Ford Mondeo 1 | 35 – 42 |

| 60 | Ford Mondeo 2 | 35 – 42 |

| 61 | Ford Mustang | 35 – 38 |

| 62 | Ford Sierra | 35 – 38 |

| 63 | Ford Scorpio | 35 – 38 |

| 64 | Ford Orion | 35 – 38 |

| 65 | Ford Puma | 35 – 38 |

| 66 | Ford Windstar | 35 – 38 |

| 67 | Ford Transit | 35 – 38 |

| 68 | Honda Shuttle | 35 – 38 |

| 69 | Honda CRX | 35 – 38 |

| 70 | Honda Accord | 35 – 38 |

| 71 | Honda Integra | 35 – 38 |

| 72 | Honda Civic | 35 – 38 |

| 73 | Honda Civic VTEC | 38 |

| 74 | Honda Concerto | 35 – 38 |

| 75 | Honda Jazz | 35 – 38 |

| 76 | Honda Prelude | 38 |

| 77 | Honda Legend | 35 – 38 |

| 78 | Honda CRV 5 | 40 – 45 |

| 79 | Hyundai Pony | 35 – 38 |

| 80 | Hyundai Accent | 35 – 38 |

| 81 | Hyundai Coupe | 35 – 38 |

| 82 | Hyundai Lantra | 35 – 38 |

| 83 | Hyundai Sonata | 35 – 38 |

| 84 | Hyundai Excel | 35 – 38 |

| 85 | Kia Shuma | 35 – 38 |

| 86 | Kia Ceed | 38 – 42 |

| 87 | Kia Leo | 35 – 38 |

| 88 | Kia Clarus | 35 – 38 |

| 89 | Kia Sephia | 35 – 38 |

| 90 | Kia Concord | 35 – 38 |

| 91 | Kia Sportage | 0 – 3 |

| 92 | Kia Mentor | 35 – 38 |

| 93 | Mercedes-Benz Sprinter | 45 |

| 94 | MercedesBenz A Class | 45 – 50 |

| 95 | MercedesBenz B-Class | 47 – 52 |

| 96 | MercedesBenz C-Class | 43 – 47 |

| 97 | MercedesBenz E-Class | 48 – 54 |

| 98 | MercedesBenz G-Class | 43, 50, 63 |

| 99 | MercedesBenz M-Class | 46 – 50, 60 |

| 100 | MercedesBenz S-Class | 36 – 43,5 |

| 101 | MercedesBenz SLK | 45 – 50 |

| 102 | MercedesBenz 600SL | 18 – 25 |

| 103 | MercedesBenz 280SL | 18 – 25 |

| 104 | MercedesBenz Vito | 45 – 50 |

| 105 | Mitsubishi Lancer | 35 – 42 |

Sources

- https://kolesa.guru/diski/vylet.html

- https://krutigayki.ru/vylet-diska-chto-takoe-et-i-na-chto-on-vliyaet/

- https://mashinapro.ru/1794-vylet-diska-et.html

- https://autochainik.ru/vylet-kolesnogo-diska.html

- https://AvtoKart.ru/dvigateli/chto-znachit-vylet-diska.html

- https://motorstory.ru/care/diski/chto-takoe-vylet-diska-i-kak-ego-razmery-vliyayut-na-xarakteristiki-mashiny/

- https://BlackTyres.ru/informaciya/informatsija-o-diskah/kak-uznat-vylet-diska/

- https://wheel-info.ru/vylet-diska.html

- https://VoDetal.ru/instrumenty/vylet-diska-chto-takoe-et-i-na-chto-on-vliyaet-v-chem-raznitsa-vyleta-35-i-45.html

- https://www.avtogide.ru/v-dannoj-state-budet-rassmotren-takoj-parametr-kak-vylet-diska-et-na-chto-vliyaet-etot-parametr-i-na-skolko-mozhno- ego-menyat-kakie-budut-posledstviya-ob-etom-i-pojdet-rech-dalee-na-chto-vliyae.html

Diameter

15 - (D) - Disc diameter in inches. Note that rim diameter is not the outer diameter of the rim from edge to edge, and like width, it is the diameter of the rim “flange” on which the tire bead rests.

Therefore, if you want to measure the outer diameter of a car rim with a tape measure, you must take into account that in fact its actual value is slightly smaller. And to convert the diameter of the disk from centimeters to inches, you need to divide the resulting value by 2.54.

Those. if you measured 40.6 cm, then:

Disc diameter = 40.6 / 2.54 = 16 inches

H2 - Design code and number of humps (variations of humps: H - simple hump, H2 - double, FH - flat (Flat Hump), AH - asymmetric (Asymmetric Hump), CH - combined (Combi Hump)) Humps - small annular protrusions serve to keep the tubeless tire from jumping off the rim. This parameter is not taken into account when selecting disks.