Purpose of the voltage regulator relay

Regardless of experience and driving style, the car owner cannot ensure the same engine speed at different times. That is, the crankshaft of the internal combustion engine, which transmits torque to the generator, rotates at different speeds. Accordingly, the generator produces different voltages, which is extremely dangerous for the battery and other consumers of the on-board network.

Therefore, replacing the alternator regulator relay should be done when the battery is undercharged or overcharged, the light is on, the headlights are flashing and other interruptions in the power supply to the on-board network.

Interconnection of car current sources

The vehicle contains at least two sources of electricity:

- battery - required at the moment of starting the internal combustion engine and the primary excitation of the generator winding; it does not create energy, but only consumes and accumulates at the time of recharging

- generator – powers the on-board network at any speed and recharges the battery only at high speeds

Both of these sources must be connected to the on-board network for the correct operation of the engine and other electricity consumers. If the generator breaks down, the battery will last for a maximum of 2 hours, and without the battery, the engine driving the generator rotor will not start.

There are exceptions - for example, due to the residual magnetization of the excitation winding, the standard GAZ-21 generator starts on its own, subject to constant operation of the machine. You can start a car “from a pusher” if it has a DC generator installed; with an AC device, such a trick is impossible.

Voltage regulator tasks

From a school physics course, every car enthusiast should remember the principle of operation of a generator:

- when the frame and the surrounding magnetic field move mutually, an electromotive force arises in it

- The stators serve as the electromagnet of DC generators, the EMF, accordingly, arises in the armature, the current is removed from the collector rings

- In the alternating current generator, the armature is magnetized, electricity appears in the stator windings

In a simplified way, we can imagine that the magnitude of the voltage output from the generator is influenced by the value of the magnetic force and the speed of rotation of the field. The main problem of DC generators - burning and sticking of brushes when removing large currents from the armature - has been solved by switching to alternating current generators. The excitation current supplied to the rotor to excite magnetic induction is an order of magnitude lower, making it much easier to remove electricity from a stationary stator.

However, instead of terminals “–” and “+” constantly located in space, car manufacturers received a constant change in plus and minus. Recharging the battery with alternating current is not possible in principle, so it is first rectified with a diode bridge.

From these nuances the tasks solved by the generator relay flow smoothly:

- adjusting the current in the excitation winding

- maintaining a range of 13.5 - 14.5 V in the on-board network and at the battery terminals

- cutting off the power to the excitation winding from the battery when the engine is turned off

Therefore, the voltage regulator is also called a charging relay, and the panel displays a warning light for the battery charging process. The design of alternating current generators includes a reverse current cut-off function by default.

Checking an Individual Regulator

Checking the voltage regulator of the G-222 generator: 1 - battery; 2 - voltage regulator; 3 - control lamp.

As a rule, separate voltage regulators were installed on old cars, including domestic VAZs. But some manufacturers continue to do this to this day. The verification process is similar. To do this, you need to have a power supply with a voltage regulator, a 12 V light bulb, a multimeter and a directly tested regulator.

To check, you need to assemble the circuit shown in the figure. The process itself is similar to the one above. In normal condition (at a voltage of 12 V), the light bulb lights up. When the voltage value increases to 14.5 V, it goes out, and when it decreases, it lights up again. If during the process the lamp lights up or goes out at other values, it means that the regulator has failed.

Checking relay type 591.3702-01

Relay test diagram type 591.3702-01

You can also still find a voltage regulator of type 591.3702-01, which was installed on rear-wheel drive VAZs (from VAZ 2101 to VAZ 2107), GAZ and Moskvich. The device is mounted separately and installed on the body. In general, the test is similar to that described above, but the differences are in the contacts used.

In particular, it has two main contacts - “67” and “15”. The first of them is a minus, and the second is a plus. Accordingly, to check it is necessary to assemble the circuit shown in the figure. The verification principle remains the same. In normal condition, at a voltage of 12 V, the light bulb lights up, and when the corresponding value increases to 14.5 V, it goes out. When the value returns to its original value, the light comes on again.

A classic regulator of this type is a device of the PP-380 brand, installed on VAZ 2101 and VAZ 2102 cars. We provide reference data regarding this regulator.

| Adjustable voltage at regulator and ambient temperature (50±3)° C, V: | |

| at the first stage | no more than 0.7 |

| on the second stage | 14,2 ± 0,3 |

| Resistance between plug “15” and ground, Ohm | 17,7 ± 2 |

| Resistance between plug “15” and plug “67” with open contacts, Ohm | 5,65 ± 0,3 |

| Air gap between armature and core, mm | 1,4 ± 0,07 |

| Distance between second stage contacts, mm | 0,45 ± 0,1 |

Testing a three-level relay

Regulated power supply

Some car owners install on their cars, instead of standard “chocolate bars,” three-level relays, which are technologically more advanced. Their difference is the presence of three voltage levels at which the battery power is cut off (for example, 13.7 V, 14.2 V and 14.7 V). The appropriate level can be set manually using a special regulator.

Such relays are more reliable and allow flexible adjustment of the cutoff voltage level. As for checking such a regulator, it is completely similar to the procedures described above. Just do not forget about the value that is set on the relay, and accordingly, check it with a multimeter.

Generator check

There is one method by which you can check the performance of a car generator equipped with a regulator relay 591.3702-01 with diagnostic elements. It is as follows:

- disconnect the wires that went to pins 67 and 15 of the voltage regulator;

- connect a light bulb to it (excluding the regulator from the circuit);

- Remove the wire from the positive terminal of the battery.

If, as a result of these actions, the engine does not stall, then we can say that the car’s generator is in order. Otherwise, it is faulty and needs to be checked and replaced.

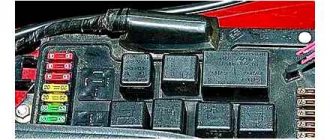

Types of regulator relays

Before you independently repair the voltage regulation device, you must take into account that there are several types of regulators:

- external – increase the maintainability of the generator

- built-in – in the rectifier plate or brush assembly

- regulating by minus - an additional wire appears

- positive regulating – economical connection scheme

- for alternating current generators - there is no function for limiting the voltage on the excitation winding, since it is built into the generator itself

- for DC generators – an additional option for cutting off the battery when the internal combustion engine is not working

- two-level - obsolete, rarely used, adjustment by springs and a small lever

- three-level – supplemented with a special comparison device board and a matching indicator

- multi-level - the circuit has 3 - 5 additional resistors and a tracking system

- transistor - not used in modern cars

- relay – improved feedback

- relay-transistor - universal circuit

- microprocessor - small dimensions, smooth adjustment of the lower/upper threshold of operation

- integral - built into brush holders, therefore they are replaced after the brushes wear out

Attention: Without modification of the circuit, the “plus” and “minus” voltage regulators are not interchangeable devices.

DC generator relay

Thus, the connection diagram for the voltage regulator when operating a DC generator is more complicated. Since in the parking mode of the car, when the internal combustion engine is turned off, it is necessary to disconnect the generator from the battery.

During diagnostics, the relay is checked to perform its three functions:

- Battery cut off when the car is parked

- limiting the maximum current at the generator output

- voltage adjustment for field winding

Any malfunction requires repair.

Alternator relay

Unlike the previous case, diagnosing the alternator regulator yourself is a little simpler. The design of the “automotive power station” already includes the function of cutting off power from the battery while parked. All that remains is to check the voltage at the excitation winding and at the output from the generator.

If the car has an alternating current generator, it is impossible to start it by accelerating down a hill. Since there is no residual magnetization on the exciting winding here by default.

Built-in and external regulators

It is important for a car enthusiast to know that they measure and begin to regulate the relay voltage at a specific location where they are installed. Therefore, built-in modifications act directly on the generator, while external modifications “do not know” about its presence in the machine.

For example, if a remote relay is connected to the ignition coil, its work will be aimed at regulating the voltage only in this section of the on-board network. Therefore, before you learn how to test a remote-type relay, you should make sure that it is connected correctly.

Control by “+” and “–”

In principle, the control circuits for “minus” and “plus” differ only in the connection diagram:

- when installing the relay in the “+” gap, one brush is connected to “ground”, the other to the regulator terminal

- if you connect the relay to the “–” gap, then one brush needs to be connected to the “plus”, the other to the regulator

Three-level regulation system

The quality of regulation of such structures is much higher than that of those previously discussed. Previously, mechanical designs were used, but today non-contact devices are more common. All elements used in this system are the same as those discussed above. But the operating principle is slightly different. First, voltage is applied through a divider to a special circuit in which information is processed. It is possible to install such a generator voltage regulator relay (Ford Sierra can also be equipped with similar equipment) on any car if you know the device and connection diagram.

Here the actual value is compared with the minimum and maximum. If the voltage deviates from the value that is set, then a certain signal appears. It is called a mismatch signal. It is used to regulate the current flowing to the excitation winding. The difference from a two-level system is that there are several additional resistances.

Operating principle of the regulator relay

Thanks to built-in resistors and special circuits, the relay is able to compare the amount of voltage generated by the generator. After which, too high a value leads to the relay being turned off, so as not to overcharge the battery and damage electrical appliances connected to the on-board network.

Any malfunctions lead to precisely these consequences: the battery becomes faulty or the operating budget increases sharply.

Summer/winter switch

Regardless of the season and air temperature, the operation of the generator is always stable. As soon as its pulley begins to rotate, electric current is generated by default. However, in winter the insides of the battery freeze, and it replenishes the charge much worse than in summer.

The summer/winter switches are either on the body of the voltage regulator, or the corresponding connectors are marked with this designation, which you need to find and connect the wiring to them depending on the season.

There is nothing unusual in this switch, these are just rough settings of the regulator relay, which allows you to increase the voltage at the battery terminals to 15 V.

Connection to the generator's on-board network

If, when replacing a generator, you connect a new device yourself, you need to take into account the following nuances:

- First you should check the integrity and reliability of the contact of the wire from the car body to the generator housing

- then you can connect terminal B of the regulator relay with the “+” of the generator

- Instead of “twists” that begin to heat up after 1–2 years of operation, it is better to use soldering of wires

- the factory wire must be replaced with a cable with a minimum cross-section of 6 mm2 if, instead of a standard generator, an electrical appliance rated for a current of more than 60 A is installed

- The ammeter in the generator/battery circuit shows which power source is currently higher in the on-board network

Ammeters are necessary devices with which you can determine the battery charge and the performance of the generator. It is not recommended to remove them from the scheme without special reasons.

Remote controller connection diagrams

An external generator voltage regulator relay is installed only after determining which wire it should be connected to. For example:

- on old RAFs, Gazelles and Bullheads, relays 13.3702 are used in a polymer or steel case with two contacts and two brushes, mounted in a “–” open circuit, the terminals are always marked, “+” is usually taken from the ignition coil (B-VK terminal) , contact Ш of the regulator is connected to the free terminal of the brush assembly

- in “Zhiguli” relay regulators 121.3702 of white and black colors are used, there are double modifications in which, if one device fails, the operation of the second device continues by simply switching to it, mounted in the “+” gap with terminal 15 to the terminal of the ignition coil B-VK, terminal 67 is attached to the brush assembly with a wire

Car enthusiasts call built-in relay regulators “chocolate bars”, labeled Y112. They are mounted in special brush holders, pressed with screws and additionally protected with a cover.

On VAZ cars, relays are usually built into the brush assembly, full marking Y212A11, connected to the ignition switch. If the owner replaces the standard generator on an old domestic VAZ with an AC device from a foreign car or a modern Lada, the connection is made according to a different scheme:

- The car owner decides on the issue of fastening the body independently.

- The analogue of the “plus” terminal here is contact B or B+; it is connected to the on-board network via an ammeter

- Remote relay regulators are usually not used here, but built-in ones are already integrated into the brush assembly, from them comes a single wire marked D or D+, which is connected to the ignition switch (to the coil terminal B-VK)

For diesel internal combustion engines, generators may have a W terminal, which is connected to the tachometer; it is ignored when installed on a car with a gasoline engine.

Checking the connection

After installing a three-level or other relay regulator, a performance check is necessary:

- the engine starts

- The voltage in the on-board network is controlled at different speeds

After installing the alternator and connecting it according to the above diagram, the owner can expect a “surprise”:

- when the internal combustion engine is turned on, the generator starts, the voltage is measured at medium, high and low speeds

- after turning off the ignition with the key... the engine continues to run

In this case, you can turn off the internal combustion engine either by removing the excitation wire, or by releasing the clutch while simultaneously pressing the brake. It's all about the presence of residual magnetization and constant self-excitation of the generator winding. The problem is solved by installing the light bulb's exciting wire into the gap:

- it lights up when the generator is not running

- goes out after it starts

- the current passing through the lamp is insufficient to excite the generator winding

This lamp automatically becomes an indicator that the battery is charging.

Recommendations for increasing the service life of the regulator

In order to increase the service life of the voltage regulator, it is necessary to adhere to several simple rules aimed at implementing preventive measures. Among them:

- do not allow excessive contamination of the generator, periodically inspect its condition, and, if necessary, dismantle and clean the unit;

- check the tension of the alternator belt, tighten it if necessary (either yourself or in a car service);

- monitor the condition of the generator windings, in particular, do not allow them to darken;

- check the contact on the control wire of the relay-regulator, both its quality and the presence of oxidation on it;

- Perform periodic voltage checks on the vehicle battery with the engine running.

Following these simple rules will allow you to increase the resource and service life of both the generator and the vehicle voltage regulator.

Results

Checking the voltage regulator relay is not a difficult task, and almost any car enthusiast with basic repair skills can handle it. The main thing is to have the appropriate tools for this - a multimeter, a power supply with a voltage regulator (although you can connect it to a battery with a charger), a 12 V lamp and pieces of wires for mounting the appropriate circuit.

If during the inspection you find out that the regulator is out of order, then it must be replaced (repair work is usually not carried out). The main thing is not to make a mistake when choosing it and purchase the part that is suitable specifically for your car.

The electrical network of any car is powered by a generator, which is driven by the engine using a belt drive. Its revolutions are constantly changing, ranging from 900 to several thousand, causing the rotor to rotate accordingly. For the normal operation of all electrical appliances and charging the battery, the voltage in the on-board network must be stable, which is ensured by the relay regulator. Being the weakest link in the power supply system, the device first of all needs to be checked when problems with battery charging and other breakdowns in the vehicle's electrical network are detected.

Purpose of the voltage regulator relay on the VAZ 2106

As you know, the power supply system of the VAZ 2106 consists of two important elements: a battery and an alternator. A diode bridge is built into the generator, which motorists in the old fashioned way call a rectifier block. Its job is to convert alternating current into direct current. And to ensure that the voltage of this current is stable, does not depend on the rotation speed of the generator and does not “float” much, a device called a generator voltage relay regulator is used.

This device provides constant voltage throughout the entire on-board network of the VAZ 2106. If there is no relay regulator, the voltage will deviate abruptly from the average value of 12 volts, and it can “float” in a very wide range - from 9 to 32 volts. And since all energy consumers on board the VAZ 2106 are designed to operate under a voltage of 12 volts, without proper regulation of the supply voltage they will simply burn out.

Design of the relay regulator

On the very first VAZ 2106, contact regulators were installed. It is almost impossible to see such a device today, since it is hopelessly outdated, and it has been replaced by an electronic regulator. But to get acquainted with this device, we will have to consider the contact external regulator, since its example reveals the design most fully.

So, the main element of such a regulator is a winding of brass wire (about 1200 turns) with a copper core inside. The resistance of this winding is constant and is 16 Ohms. In addition, the regulator design includes a system of tungsten contacts, an adjustment plate and a magnetic shunt. There is also a system of resistors, the connection method of which can change depending on the required voltage. The highest resistance these resistors can provide is 75 ohms. This entire system is housed in a rectangular PCB body with contact pads for connecting wiring brought out.

Operating principle of the relay regulator

When the driver starts the VAZ 2106 engine, not only the crankshaft in the engine begins to rotate, but also the rotor in the generator. If the rotation speed of the rotor and crankshaft does not exceed 2 thousand revolutions per minute, then the voltage at the generator outputs does not exceed 13 volts. The regulator does not turn on at this voltage, and the current goes directly to the excitation winding. But if the speed of rotation of the crankshaft and rotor increases, the regulator automatically turns on.

The winding, which is connected to the generator brushes, instantly reacts to an increase in crankshaft speed and is magnetized. The core located in it is pulled inward, after which the contacts on some internal resistors are opened, and the contacts are closed on others. For example, when the engine is running at low speeds, only one resistor is used in the regulator. When the engine reaches maximum speed, three resistors are turned on, and the voltage on the excitation winding drops sharply.

What is a generator

Any car generator consists of several parts:

1. A rotor with an excitation winding, around which an electromagnetic field is created during operation.

2. A stator with three windings connected in a star configuration (alternating voltage is removed from them in the range from 12 to 30 Volts).

3. In addition, the design contains a three-phase rectifier consisting of six semiconductor diodes. It is worth noting that the VAZ 2107 generator voltage relay-regulator (injector or carburetor in the injection system) is the same.

But the generator will not be able to operate without a voltage regulation device. The reason for this is the voltage change over a very wide range. Therefore, it is necessary to use an automatic control system. It consists of a comparison device, control, executive, master and special sensor. The main element is the regulatory body. It can be either electrical or mechanical.

Signs of a broken voltage regulator

When the voltage regulator fails, it no longer keeps the voltage supplied to the battery within the required range. As a result, the following problems occur:

- The battery is not fully charged. Moreover, the picture is observed even when the battery is completely new. This indicates a break in the relay regulator;

- the battery is boiling. This is another problem indicating a breakdown of the relay regulator. When a breakdown occurs, the current supplied to the battery can be several times higher than the normal value. This leads to the battery overcharging and boiling.

In both the first and second cases, the car owner must check the regulator and, if a breakdown is detected, replace it.

Malfunctions

Most often, the relay regulator fails for the following reasons:

- When the battery is working properly, there is no charging current, which is why it does not charge. This happens when the wires are poorly connected to the relay terminals or when the circuit from the generator to the battery is broken. Eliminated by fixing the wire in the circuit, checking and adjusting the voltage regulator and relay regulator.

- Insufficient charging current with a discharged battery or high current with a fully charged battery is caused by a malfunction of the voltage regulator. It can be eliminated by adjusting the device or replacing it.

- Burning and burnout of lamps with excessive heat occurs when the adjustment of the relay regulator is violated or the contacts are closed. Eliminated by disconnecting and cleaning the closed contacts, adjusting or replacing the voltage regulator.

- High discharge current after stopping the motor. Occurs when the relay-regulator contacts close (contacts sintering, armature spring breaks) or the electrical wire short circuits. It is repaired by finding and eliminating a short circuit with the battery disconnected, checking and adjusting the current limiter, opening and cleaning the contacts, replacing the spring and adjusting its clearance and tension.

Device check

The relay-regulator of the voltage of the VAZ 2106 generator, “kopecks”, and foreign cars is checked equally. As soon as you remove it, look at the brushes - they should be more than 5 millimeters long. If this parameter is different, the device must be replaced. To carry out diagnostics, you will need a constant voltage source. It would be desirable to be able to change the output characteristic. You can use a battery and a couple of AA batteries as a power source. You also need a lamp, it must run on 12 Volts. You can use a voltmeter instead. Connect the plus from the power supply to the voltage regulator connector.

Accordingly, connect the negative contact to the common plate of the device. Connect a light bulb or voltmeter to the brushes. In this state, voltage should be present between the brushes if 12-13 Volts are supplied to the input. But if you supply more than 15 Volts to the input, there should be no voltage between the brushes. This is a sign that the device is working properly. And it doesn’t matter at all whether the voltage regulator relay of the VAZ 2107 generator or another car is diagnosed. If the control lamp lights up at any voltage value or does not light up at all, it means that there is a malfunction of the unit.

Modern voltage regulation systems

If the voltage regulator relay for the generator of a Chinese scooter is two-level, then more advanced devices are used on expensive cars. Multilevel control systems can contain 3, 4, 5 or more additional resistances. There are also tracking automatic control systems. In some designs, you can refuse to use additional resistances.

Instead, the frequency of operation of the electronic key increases. It is simply impossible to use circuits with electromagnetic relays in servo control systems. One of the latest developments is a multi-level control system that uses frequency modulation. In such designs, additional resistances are required, which are used to control logic elements.

conclusions

In the electrical system of a car, the voltage regulator relay of the Bosch generator (as, indeed, of any other company) plays a very important role. Monitor its condition as often as possible and check for damage and defects. Cases of failure of such a device are not uncommon. In this case, in the best case, the battery will be discharged. And in the worst case, the supply voltage in the on-board network may increase. This will lead to the failure of most electricity consumers. In addition, the generator itself may fail. And its repair will cost a tidy sum, and considering that the battery will fail very quickly, the costs will be astronomical. It is also worth noting that the Bosch generator voltage regulator relay is one of the leaders in sales. It has high reliability and durability, and its characteristics are as stable as possible.