Do you experience misfires at idle or under load? Misfire is one of the most common problems when it comes to modern gasoline engines. The spark is critical to the operation of the engine.

There are many reasons that can cause a misfire. They are not easy to eliminate, especially if you don’t know where to look for them.

In this guide, we'll look at the symptoms of misfires, their causes, and how to best troubleshoot them.

What is a misfire?

To know what a skip actually is, we first have to start with the basics of how a car engine works.

Here you can see a good illustration of how the pistons and crankshaft move inside the cylinder when the engine is running. The pistons are pushed down by an explosion inside the cylinder. The piston, moving down, rotates the crankshaft. The operation of an engine can be divided into four stages, which is why this type of engine is called a four-stroke engine.

- The piston moves down, filling the cylinder with the air-fuel mixture from the intake.

- The piston goes up, compressing the air-fuel mixture to high pressure.

- A spark from the spark plug ignites the air-fuel mixture and the explosion pushes the piston down, rotating the crankshaft.

- The piston rises up, squeezing the burnt air-fuel mixture through the outlet.

- Repeat the process from step 1.

This is a description of the operation of a four-stroke engine, which is installed in almost all modern cars. There are some older cars that use a 2-stroke engine, but we won't cover them.

A misfire occurs when one or more of these steps are incorrect or missing.

- The air/fuel mixture is too lean or too rich.

- Bad ignition spark, incorrect ignition timing.

- Low compression, accounting for the air-fuel mixture.

- Incorrect timing of intake or release of the air-fuel mixture.

Now you know the basics of how a cylinder works in a car engine and at what stages misfire can occur. With this knowledge it is much easier to find the reason why misfire occurs.

As you can see, in theory there are not many reasons. But when you start diagnosing your car, you'll realize that it's not always that easy to find the problem. Let's continue to learn how to diagnose and how to fix misfires at home.

Cylinder failure: causes and diagnostic methods

Issues discussed in the material:

- Why does cylinder failure occur in an engine?

- What is the danger of cylinder failure?

- How to independently identify the cause of cylinder failure

While driving a car, did you feel that the power unit was vibrating, while its power dropped, and it began to consume more fuel? Does the car start only the second or third time? These signs indicate that a cylinder failure has occurred. In our article today we will look at how to fix this problem.

Signs of misfire

There are several different symptoms that you may experience when it comes to engine misfire. Here are some of the most common ones.

Uneven acceleration

When a misfire occurs, you may feel it as a slight or strong jolt coming from the engine. These misfires often occur while the engine is running under load and you are accelerating at high RPMs and high gears. Acceleration problems are a common sign that your engine is misfiring.

Unstable idle

Sometimes there will be passes at idle. The engine sensors receive incorrect readings and the air/fuel mixture becomes incorrect. This can result in a very rough idle. The revolutions can fluctuate up and down until the engine stops.

Vibrations

The car engine is balanced at the factory using various balancers to get as little vibration as possible from it. When one cylinder is not firing properly, the engine becomes unbalanced and this can cause severe vibrations in the cabin during acceleration or idling.

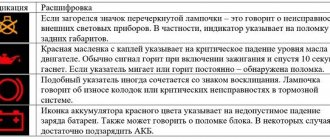

Check Engine light on

Modern cars monitor the status of all engine sensors. If the sensor fails or it senses that something is wrong with the engine, it will send information to the control unit. When the ECU receives the data, it will decide whether the problem is serious or not. If the problem occurs repeatedly, the control unit will turn on the Check Engine Light so you can take action.

Slow acceleration

As we said earlier, skipping can cause the oxygen sensors to receive erroneous information and create a mixture that is too rich or too lean.

A mixture that is too lean or too rich can cause sluggish acceleration and even put your car into limp (safety) mode. This will cause the engine to not spin above 3500 rpm and the ECU will turn off the turbo.

Changing the engine sound

If you know a little about cars, you will have noticed that there is a difference in the sound of different engines. V8 engines have a very different tone than a four-cylinder engine.

If your 4 cylinder engine is misfiring in one cylinder, it may sound like a 3 cylinder. If your car sounds unusual, it's most likely misfiring.

What does P0301 mean?

In most cars the engine has 4-6 cylinders. A spark plug fires sequentially in each cylinder, igniting the fuel mixture. Energy is then released from the fuel to drive the crankshaft, which must rotate smoothly as the vehicle moves.

All cylinders work together to ensure continuous rotation of the crankshaft. If a cylinder misfires, it will cause the crankshaft speed (RPM) to increase or decrease.

If the crankshaft speed increases or decreases by 2 percent or more, P0301 will remain in the PCM (automatic transmission control module) memory.

If the RPM increases or decreases by 2 to 10 percent, the Check Engine Light will illuminate on your vehicle's dashboard. If the deviation percentage exceeds 10 percent, the Check Engine light will flash, indicating a more serious problem is present.

Trouble code P0301 indicates that cylinder 1 is misfiring.

Causes of misfires

Now that you suspect a misfire, where should you start looking for the problem? Here are the most common reasons for absences, ranked from most common to least common.

1. Faulty ignition coil or distributor-breaker (distributor)

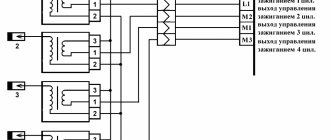

If you have an older car, this is the most common reason. Some vehicles have a separate ignition coil for each plug, while others have a single coil with ignition cable for each plug.

Older cars have a breaker and in some cases also an ignition coil. If you have separate coils, then disconnect each one to find out which cylinder is misfiring. Replace the faulty ignition coil.

Faulty spark plugs

The second most common cause of misfires is bad spark plugs. Spark plugs ignite the mixture in the cylinders, and they wear out over time. Spark plugs are inexpensive and easy to replace. If you can't remember the last time you changed your spark plugs, it might be time for it.

Intake manifold leaking

Leaks near cylinder heads are also very common when it comes to spark plugs. This problem was common in older cars without steel intake manifold gaskets.

If you have an old engine, you can check this. If you have a new car, check for other signs of leaks around the intake manifold gasket. Check for damaged vacuum hoses.

Low fuel pressure

May be caused by a faulty fuel pressure regulator, faulty fuel pump, or clogged fuel filter. Low fuel pressure will cause the engine to lean, causing misfire in all cylinders. If you have ignition fault codes on all cylinders, check the fuel pressure.

Injectors

Another problem that used to be common was problems with injectors. A faulty fuel injector can cause a misfire.

This is quite difficult to diagnose without checking the injector operation. Injector problems are not common on new cars, so check for other possible causes first.

Low compression/damage inside the engine

If you've checked everything else, you may have low compression or damage inside the engine. A worn timing belt can also cause low compression - check this first.

What does driving with an inoperative engine cylinder lead to?

When a cylinder fails, the fuel mixture entering it does not burn. The fuel is mixed with oil, removing it from the cylinder bore. The mixture will then penetrate into the crankcase. Due to the fact that the surface of the cylinder is dry, scoring occurs on it. In addition, oil mixed with fuel does not lubricate healthy cylinders well.

As a result of the failure of the first cylinder, the others will also stop working normally. Where will all this lead? The car owner will be forced to spend a large sum on boring the cylinder block or even on lining.

The next problem that will happen if the cylinder fails is that the engine will overheat. The change in its operating temperature is due to the fact that the lubricant does not perform its functions. And, as you know, motor oil not only lubricates surfaces, but also removes heat.

All of the above is sufficient reason to declare: under no circumstances should you operate a car after a cylinder failure!

Is it safe to drive with a misfire?

If a leak occurs, the air-fuel mixture entering the engine will come out unburnt. Modern cars have a catalytic converter that reduces emissions from the car. The catalyst can heat up to 600 degrees during operation.

And what happens when the unburnt air-fuel mixture gets into it? That's right, it will explode inside the catalyst. Explosions inside the catalytic converter can damage it. And a new catalyst is not a cheap pleasure.

In addition, misfires can also damage other sensors in the engine, such as oxygen sensors. We would never recommend driving a vehicle with a misfire, especially over long distances. Short distances to a service station without stress on the engine are normal, but don't ignore gaps and continue driving.

Why does the engine troit?

Some car owners do not know why the engine idles at idle. If you are an inexperienced driver, you need to identify this malfunction and then find the reason why it occurred.

Cylinder failure is a good reason for the engine to misfire. The cylinders may stop functioning alternately. Moreover, you don’t even need to search for a breakdown, because it will immediately become clear that a cylinder failure has occurred. The engine will shake and vibrate, the speed will begin to jump, it will be difficult to start the car, and the car will begin to consume more fuel. It is simply impossible to ignore such symptoms. For example, if one cylinder fails in an engine that has only 4 of them, the speed will drop by 25%. Even an inexperienced driver will notice this malfunction.

How does the ECU know when misfires occur?

The ECM may detect misfires differently depending on the vehicle model and engine. The ECU uses many sensors to know when to fire the spark plug, when to inject fuel into the cylinder, and how to change the air-fuel mixture. To detect misfires, the control unit often uses a crankshaft sensor.

Engine ECU

The crankshaft sensor measures the position of the crankshaft and calculates its revolutions per minute. The crankshaft sensor uses the camshaft sensor to determine which cylinder is at top dead center and ready to ignite.

Pushing the pistons down causes a slight increase in crankshaft speed. If the crankshaft sensor does not recognize this increase in speed, the engine control unit will store a fault code on the cylinder on which the misfire occurred.

Sometimes the control unit cannot determine which cylinder is misfiring and it stores the error code P0300 (random misfire).

Some ECUs use ignition coil resistance. When ignition does not occur, the control unit understands this through the electrical wiring, which leads to an error. This method is not as common as detection using the crankshaft sensor.

How to detect a malfunction yourself

We also recommend reading our expert’s article, in which he talks in detail about what a contactless ignition system is.

Be sure to read our specialist’s article, which tells you how to set the ignition correctly.

In cars with ECU

In cars with an ECU, troubleshooting is a fairly easy task. To do this, you need to connect an autotester and find the error code. If among the error codes there is an indication of a specific cylinder, then you should pay special attention to the condition of the element. Perhaps the problem is hidden in the armor wires or spark plugs that go to this cylinder. The gaskets may also need to be replaced. If a complex error (p0300) is issued, then you should pay special attention to the quality of the fuel and the filter.

Even domestic cars now have electronic units installed. If the car initially has an ECU, but its performance leaves much to be desired, then you can replace the part at a certified service station. The new “brains” must be compatible with the previous model. Thanks to the new electronic control units, you can easily find misfires in the 1st and 4th cylinders of the VAZ-2114 or on any old foreign car, as well as diagnose the operation of the 2nd and 3rd cylinders without unnecessary hassle.

How to diagnose and fix omissions

If you read the article from the beginning, you now know what can cause gaps. If you came straight to this point, then we will briefly write down the possible reasons for you. Omissions occur when one of the following is missing or occurs at the wrong time:

- Ignition.

- Fuel-air mixture.

- Compression.

To diagnose omissions, we must check everything. But some mistakes are more common than others. Starting in the right direction can save you a lot of time. Let's write a short guide on what to do when trying to find the cause of a misfire.

Reading errors

The first thing to do is read the errors from the ECU. You can do this yourself using a diagnostic scanner or an ELM327 adapter with Torque or ScanMaster software.

If you find errors in the controller code memory, write them down and erase them. We will need them in the next step.

2. Use the information you receive

Now that you know the error code, you need to understand what it says. Further diagnosis depends on this.

Case 1: You have counted many misfire error codes on different cylinders. Additionally, there are errors related to the air-fuel mixture.

For example. If you have two or more of these trouble codes:

- P0171 - lean mixture;

- P0300 - random misfires;

- P0301, P0302, P0303, P0304 - misfires in cylinders 1-4.

In this case, if the engine is running rough or unstable, you should start repairs with the air-fuel mixture. Most likely problems with it are caused by omissions. If you have looked for a code related to the air/fuel mixture along with a skip code, always start your search with the mixture. There are times when mixture errors occur due to omissions, but this happens rarely.

Common causes should be checked. Start with air leaks around the intake manifold and check the hoses for cracks. You can use brake cleaner or "quick start" spray to gently spray around the intake while the engine is idling. If the rpm goes up, there is an air leak. Remember that these sprays burn very easily, so have a fire extinguisher ready just in case.

If there are no intake leaks, the next step is to look into the trouble code related to the air-fuel mixture. You can use Google to find the possible causes of this fault code and how to resolve it.

Case 2: You read a fault code on a specific cylinder again and again despite erasing it

If you're getting an error on a specific cylinder all the time, or just misfire errors with no other associated trouble code, just read on. This problem is much easier to solve. We'll cover this in the next step.

Check ignition

It's time to check the ignition. Because in most cases the problem is caused by a faulty ignition. Here's where we'll start. If you have an older car with an ignition distributor, always start by checking the inside of the distributor. It is often worn out.

If the engine idles rough and if you have an engine with separate ignition coils. You need to start it, let it run at XX, and then disconnect one coil in series. Remember that ignition coils have very high voltage and you must be very careful.

If you disconnect the ignition coil and do not feel any difference in engine performance, you have found a cylinder that is misfiring.

You can use this same procedure with older vehicles that use multipoint ignition. Disconnect the spark plug wires until you know which cylinder is not firing.

During work, you must use insulated tools or protective equipment. If you disconnect wires with your hands without any insulation, you may become exposed to voltage. Always use the correct tools or disconnect wires with the engine off.

Video on how to check the spark:

Now that you know exactly which cylinder is not working, you can change the ignition coil (wires) with the working cylinder. If the problem moves to another cylinder, replace the ignition coil (cable).

If the problem remains on the same cylinder, you can do the same with the spark plugs. Change the spark plugs between the two cylinders. If the problem moves, replace the spark plugs.

Misfire

The engine trembles, shakes and does not move - a problem that is easy to describe in words, but difficult to find.

A more technical name for this problem is “misfire.” Let's talk about why it occurs, how it can be diagnosed, and how the ELM327 scanner in combination with the Motordata OBD program will help with this. The essence of the problem

First of all, let's define the terms. Some people call this problem “the car is shaking and won’t move”, some say “the car is shaking”, others call it “misfire”. Whatever you call it, the symptoms are the same - increased vibrations, decreased power. Or maybe the problem does not always appear, but randomly, for some reason mainly when it is necessary to speed up.

All this may indicate misfire. That’s right, since the term “misfire” implies problems with the ignition system - spark plugs, coils, and so on. And the motor can “triple” for other reasons, which we will list below. Actually, in English this phenomenon is called “misfire”, which is much more accurate and concise. However, for convenience, the text below will also sometimes use the more familiar term “misfire.”

Why does the control unit need to register misfires?

Misfires are bad not only because they create discomfort for the driver, but also because unburned fuel ends up in the exhaust. This is not very good for the environment. But that's not all. Fuel washes away the oil film from the cylinder walls, and this can lead to increased wear on the cylinder and piston.

In addition, the vast majority of cars on our roads are equipped with a catalytic converter (colloquially known as a “catalyst”) - a device in which toxic exhaust components are oxidized to harmless compounds. The catalyst is a metal or ceramic “honeycomb” coated with a layer of noble metals, in the presence of which oxidation occurs faster (hence, in fact, the name of the device). The catalyst operates at high temperatures (400-800°C). If there is a misfire, when unburned gasoline gets on it, the temperature of the catalyst rises to 1400°C, which leads to its melting or destruction. And this is again a problem. A melted catalyst stops passing exhaust gases, which leads to new problems - it is more difficult for the engine to start, and power decreases even more. If the catalyst is destroyed, the resulting crumbs can be drawn into the cylinders, where they act as an abrasive, very quickly leading to the need for a major engine overhaul.

In any case, after the catalyst is destroyed, it must either be changed or removed. Removing the catalyst is a questionable action both from an environmental point of view and from the point of view of the consumer qualities of the car. Starting from the fact that the exhaust smells quite strongly without neutralizing toxic substances, and ending with the fact that it is necessary to “deceive” the control unit in some way, which is not always possible to do correctly. A new catalyst is quite expensive, even if you replace it not entirely in the housing, but separately in the honeycomb.

Catalyst without housing. To replace it, the body (“can” in common parlance) of the catalyst is opened, the honeycombs of the old (melted or crumbled) catalyst are removed, and the new catalyst is welded in its place.

Based on the foregoing, it is clear that the control unit must register misfires both for environmental reasons and to avoid damage to the engine and catalyst. It is difficult to say which of the two reasons was the main one, but according to the OBD2/EOBD standard, modern control units have the ability to register omissions. However, the implementation of this requirement is different for everyone. There are units and vehicles that do not register misfires even when the cylinder is completely deactivated.

How does the control unit register a problem?

With the question “do I need to register?” We figured it out, now we need to figure out exactly how to do it. Unfortunately, there is no sensor that can clearly determine whether there was ignition in the cylinder. Therefore, the control units contain a registration algorithm based on indirect signs. Most often, the control unit analyzes the uniformity of rotation of the crankshaft using signals from the DPKV (crankshaft position sensor). Uneven rotation under certain conditions is considered a sign of misfire. As a rule, deviations of more than 0.2% are taken as deviations.

In addition, on cars with individual ignition coils, the coil control circuits are monitored - if you remove the connector from one coil, the control unit will a priori mark this cylinder as inoperative.

In a number of systems, other signs may be used to register passes.

Even if misfires were recorded reliably, and not based on indirect signs, it would be incorrect to turn off a cylinder based on one detected misfire. Therefore, the control unit has a “misfire counter” parameter for each cylinder. As a rule, the control unit decides that misfires are present and the cylinder must be turned off if the number of misfires on any of the cylinders exceeds a certain threshold set by the developers.

Actions taken by control units when misfires are detected

The first and most important thing the unit does when it detects misfires is to start flashing the Check Engine light at the time it detects them. This is one of the few reasons when the “check” is flashing. So few that we can conclude with almost 100% certainty: the “check” is flashing—misfire.

The second thing the block does, as already mentioned, is to cut off the fuel supply to the cylinder in which the leaks are recorded. The corresponding injector simply stops receiving opening signals.

Finally, thirdly, the control unit generates and stores an error code in memory, and also lights up the Check Engine constantly. As a rule, this is a P0301-P0308 error if it was possible to identify specific cylinders with misfires. The last digit exactly corresponds to the cylinder number. If it is not possible to determine which cylinder is misfiring, or if multiple cylinders are misfiring, code P0300 is set.

In some control units, not standard codes P0300-P0308 are generated, but codes with other numbers, from the category specific to a particular manufacturer. For example, this happens on a Lada X-Ray car with a VAZ-21179 engine. Despite this, their meaning and decoding are similar to standard P0300-P0308.

For the situation mentioned above with the coil control circuit, another error code is generated that is not directly related to misfires.

How to look for a problem

Without special tools, it can be difficult to distinguish a misfire from another problem. As a rule, three signs are available to the driver - vibrations, reduced power and a flashing (burning) Check Engine light. None of the signs is sufficient to unambiguously confirm omissions.

There is good news - among special tools, a simple ELM327 scanner in combination with a program that can communicate with the car using the OBD2 protocol, or even better, using the factory protocol, is often sufficient. We consider Motordata OBD as such a program, since it can work using both protocols and does it well.

The first and obvious thing to do is read the errors. There may already be an error stored in memory that points to the specific cylinder with the problem. For example, this is what the error will look like when the coil is turned off on a Ford Focus 2 with a 2.0 liter engine:

Coil control circuit error

We see that error P0352 has been recorded - this is a malfunction of the coil circuit of the second cylinder. The logic here is the same as with errors P0301-P0308 - the last digit indicates the number of the cylinder for which the problem was detected. So, P0351 will mean a problem with the coil circuit of the first cylinder. Also in this case, the error is accompanied by a freeze frame, which preserves the conditions under which the error was recorded. In principle, it does not have any special value, but from the value of pressure in the intake manifold one can understand that it is already recorded when the engine is running, otherwise there would be no vacuum in the intake and there would be a value of 100 kPa.

If the control unit is unable to register misfires or for some other reason does not generate an error code, you can try to look at the composition of the mixture, that is, at the readings of the lambda probe. Since no combustion occurs in the problem cylinder, fuel and air leave it without changing its composition. This means that the oxygen concentration at the outlet is about 21%, which is a very high figure for the lambda probe, and as a result it will show a value corresponding to a lean mixture. For a threshold lambda probe this will be a value of about 0 V:

Lambda probe readings for misfires

Let's jump ahead a little and clarify - a lean mixture may not be a consequence, but a cause of the problem - when there is too much air, the mixture may not always ignite, which will ultimately result in the same misfires, but this will have nothing to do with the ignition system.

It is also possible that there is no error for a specific cylinder, but you can view misfire counters for all cylinders. Depending on the specific car, this may be available via both the OBD2 protocol and the factory protocol:

Misfire counters on a BMW car

If, nevertheless, it was possible to localize the cylinder with which the error is associated, then you need to figure out why the ignition in it disappears. There are not so many reasons, if in a large cell:

- spark.

- fuel supply.

- compression.

Based on practice, most often the reason lies in the ignition system. Cases of injector failure are very rare, so we will not describe checking them here. Well, checking compression is a procedure on gasoline engines that is simple enough to be described here.

Let's focus on checking the ignition system. Here the culprits could be in turn:

1) spark plugs due to an increased gap or breakdown of the insulator. To check, unscrew the spark plug, measure the gap and carefully inspect the porcelain insulator for breakdowns:

Spark plug breakdown through insulator

If there is an excessively increased gap or signs of breakdown, the spark plugs must be replaced to continue the diagnosis.

But the characteristic brown “belt” at the junction of the insulator with the metal part of the spark plug, contrary to popular belief, is not a sign of any problems with the spark plug. Its presence can only indicate the presence of oil in the spark plug well, but this does not in any way affect the operation of the ignition system.

"belt" on the spark plug insulator

2) Tips of spark plug wires or coils, put on spark plugs. They also need to be inspected from the inside for breakdowns or, for example, signs of corrosion - such cases have also been encountered.

3) The problem may also be related to the internal state of high-voltage wires or ignition coils. The wires can be tested with a multimeter, their resistance should be approximately in the range from 500 Ohms to 20 kOhms - the specific normal value depends on the make and model of the car.

If the car has individual ignition coils, then the easiest way is to swap the coils from the problematic and working cylinder. If the error code begins to indicate a different cylinder, this clearly indicates a problem with the coil.

You can do the same with high-voltage wires if their length allows you to change their places. The reality, however, is that for systems with one coil and high-voltage wires, the cost of replacing the system (coil + wires + spark plugs) is most often comparable to the cost of troubleshooting work - especially in cases where it is necessary to remove the intake manifold to access the spark plugs.

An alternative way to check the coil and wires is the “old-fashioned” method, in which you need to unscrew the spark plug from the cylinder, insert it into the coil, lean the thread against any unpainted metal part under the hood, and turn it with the starter. In this situation, you can see with your eyes whether there is a spark or not.

A difficult case for diagnosis are cars on which the ignition coils of all cylinders are combined into one non-separable module. This is a very common solution. There is obviously no way to swap the coils for testing.

It is convenient if it is possible to take a known-good coil from another car, as is often practiced among members of clubs united by one brand - classically, this is how members of Saab clubs checked the ignition “cassette” at a time when cars of this brand were not yet uncommon in the world. roads.

In principle, even on such a module it is possible to visually check for the presence of a spark, but it will look cumbersome and rather strange:

Check for the presence of a spark on the ignition module. A metal scrap is pressed against the threaded parts of the spark plugs and connected by a wire to the negative terminal. The ignition module is normally connected to the car wiring

Other Possible Causes

Situations are also possible when the problem is not related to the ignition, injectors, or compression. Moreover, often a misfire error can occur when ignition is actually present. Here are some examples of such situations:

- If there are problems with the DPKV, its wiring or the master disk, there may be a distortion of the signal from the sensor, which the control unit will perceive as uneven rotation and, based on this sign, will record a misfire.

- There are known cases of destruction of a dual-mass flywheel, due to which there was indeed uneven rotation of the engine. This externally looked like a throbbing engine, and was perceived by the control unit as such, but in fact it had nothing to do with the combustion processes in the cylinders.

- As already mentioned, ignition problems can be associated with mixture formation and the supply of mixture to the cylinders. For example, although strong air leaks can be compensated by fuel correction, but only to certain limits. Well, a lean mixture has every right to ignite poorly.

Another reason for this situation may be simply incorrect timing phases, due to which ignition will also occur at the wrong time.

Considering all of the above, we can state: in determining the causes of misfires, as in other diagnostics, the main role is played not by the available tool, but by an understanding of the processes occurring under the hood and in the control unit. However, it is most often impossible to make a diagnosis with knowledge alone, and a tool is needed to obtain at least primary information. To remove coils and spark plugs, these will be wrenches, to check the shape and levels of signals - an oscilloscope, and to obtain information from the control unit, the Motordata OBD car diagnostic application is ideal.

Video for this article:

Bochkanov Evgeniy Aleksandrovich

© Legion-Avtodata

Moscow, Zelenograd [email protected]

Conclusion

- Ignition coils and bad spark plugs are the most common problem if you have a misfire.

- Intake leaks are a common problem if you have a trouble code related to the air-fuel mixture.

- If you have an air mixture fault code, always start checking there.

I hope you learned something and solved your misfire problems.

Previous post Idle air control (IAC) - how it works, malfunctions, symptoms, testing

Next entry Error P0339 - what it means, symptoms, causes, diagnosis, solution

On which cars is this problem most common?

The problem with code P0301 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Audi (Audi a3, Audi a4, Audi A5, Audi a6, Audi TT)

- BMW (BMW X3, BMW X5, E60)

- Chery

- Chevrolet (Chevrolet Aveo, Impala, Captiva, Cruz, Lacetti, Orlando, Spark)

- Chrysler (Chrysler Town Country, 300c)

- Citroen

- Daewoo (Daewoo Nexia)

- Dodge (Dodge Caravan, Stratus)

- Fiat

- Ford (Ford Mondeo, Ranger, Taurus, Focus, Escort)

- Geely (Gili Emgrand)

- Honda (Honda Accord, Pilot, SRV, Civic, Element)

- Hummer H3

- Hyundai (Hyundai Accent, Getz, Santa Fe, Solaris, Tucson, Elantra)

- Infiniti

- Jeep (Jeep Grand Cherokee)

- Kia (Kia Rio, Sid, Sportage)

- Lexus (Lexus rx300, rx350)

- Mazda (Mazda 3, Mazda 6, Mazda cx7, Mazda cx9)

- Mercedes (Mercedes w203)

- Mitsubishi (Mitsubishi Outlander, Galant, Lancer, Pajero, L200)

- Nissan (Nissan Almera, Qashqai, Murano, Tiida, X-Trail)

- Opel (Opel Antara, Astra, Vectra, Zafira, Insignia, Corsa, Meriva)

- Peugeot (Peugeot Boxer)

- Renault (Renault Duster, Logan, Sandero)

- Saturn (Saturn SC)

- Skoda (Skoda Yeti, Octavia, Fabia)

- Ssangyong (Sangyong Kyron)

- Subaru (Subaru Forester)

- Suzuki (Suzuki Grand Vitara, sx4)

- Toyota (Toyota Avensis, Camry, Corolla, Prius, Rav4, Highlander)

- Volkswagen (Volkswagen Golf, Passat, Polo Sedan, Touareg, Tiguan)

- Volvo

- VAZ 2107, 2110, 2112, 2114, 2115

- Volga Cyber

- Gazelle Business, umz 4216

- Lada Vesta, Granta, Kalina, Largus, Niva, Priora

- UAZ Patriot

With fault code P0301, you can sometimes encounter other errors. The most common ones are: P0118, P0134, P0175, P0300, P0302, P0303, P0304, P0305, P0306, P0202, P0507.

Diagnostic methods

When you find out that the motor is not working, you should diagnose it. This is the only way you can find out which cylinder failed and why. You can do this yourself, or go to a car service center. There the engine will be checked using a computer. However, most often you will be able to find out on your own why the engine is tripping. However, if there is a cylinder failure, and the reason is a decrease in compression, you should find a competent specialist who will solve your problem.

Act one. We find the cylinder that failed. To do this, we diagnose the engine after it starts. Be extremely careful when performing this work. Turn the ignition key, the hood should be open. Let's listen to the sounds coming from the engine compartment. Pay attention to how the engine works. Now, one by one, we disconnect the explosive wires that go to the spark plugs.

If you disable a cylinder that is working properly, the engine will run rough. If a cylinder fails after the spark plug is disconnected, the power unit will operate without changes.

How else can you perform diagnostics? We do not touch the explosive wires. We simply turn off the chips one by one that control the fuel supply from the injectors to the cylinders. If you disconnect the chip, but the motor runs without changes, it means that this cylinder has failed.

Act two. We carry out diagnostics of explosive wires, as well as spark plugs. First of all, you should disconnect the wire and carry out an inspection. Is the insulation damaged? This indicates that the problem is in the BB wire. Then we check whether the conductive core is intact. Did you find that it has kinks or is burnt out? This means that a breakdown or internal resistance may occur. To measure it, use a multimeter. The data obtained must satisfy the acceptable readings. Otherwise, current will not flow normally to the spark plug.

Did you find out that everything is fine with the wire? Then we unscrew and diagnose the spark plug.

Is the spark plug base or its electrodes deformed or do they have carbon deposits on them? A new spark plug needs to be installed. If everything is fine with it, then the reason for the engine tripping is not a cylinder failure.

Act three. We determine how much air penetrates the cylinder. If it is not enough, then the fuel mixture will be over-rich, which means the engine will start to stall. The air supply system must not be depressurized. To check whether this is so, you should shut off the intake pipe, and then use a compressor to supply air into the cylinder through a vacuum hose. Supply pressure 0.5–0.7 atmospheres. Pay attention to the sounds you hear when doing this. Is there a hissing sound? This indicates that the air supply system is leaking.

Where to look for the cause of cylinder failure

Important!

You will have to look for the cause of engine cylinder failure in a garage. There are two possible ways here: check the mechanics or the electrical, that is, the ignition. Let's start with the simplest thing and diagnose the electrical system.

- Spark plug . Let's use a proven method to check their functioning. Look at the side electrode and insulator, their color should be light brown, not black. There should also be no soot. If there is soot, it means the mixture is over-enriched or there is oil on it. Now let's start checking sparking. Place the spark plug on the high-voltage wire, and then bring it to the cylinder block, the distance between them should be 1-2 cm. Turn the starter. Did the spark travel that distance? This indicates that the spark plug is working properly, otherwise it should be replaced.

- BB wires . They may be damaged. How to check this? Pay attention to the tip of the high-voltage wire. Did you see a light gray coating on it? This means he is operating at the limit. Use a special multimeter to check the resistance of the high-voltage wire. Please note that depending on the motor, the wire length and resistance may vary. When there are no additional instructions, 20 kOhm is taken as a constant resistance value. If this value is exceeded, then the problem is in the high-voltage wire.

- Ignition distributor . When the spark plug does not work properly, a breakdown occurs in the ignition distributor cap. In this case, it is necessary to diagnose the ember; stretching the spring will also help.

- High voltage wires are mixed up . If a cylinder failure occurs, the cause may be in the explosive wires.

We recommend

Now let's check the mechanics.

- Injector . A malfunction in its operation may be one of the reasons for the failure of the cylinder. For example, an injector is broken, or the injector is clogged with a poor quality fuel mixture. Note! Damage can result from the use of the latest fuel purifiers, which can be purchased at any specialized auto store. It is best to diagnose and clean the injectors at a trusted service center.

- Gas distribution mechanism . The fuel mixture enters the cylinders in the wrong quantity and quality. This can happen for various reasons. For example, the timing belt was installed incorrectly, the tensioners or oil seal became unusable. The camshaft may also break, or the hydraulic lifters may need to be replaced.

Because the engine constantly overheats, the cylinder head gasket may burn out. This happens because the car owner does not monitor the antifreeze level or drives the car at high speed.

All of the above can cause the cylinder to fail. By the way, not everything that can lead to such a breakdown is listed here. Only by understanding why one cylinder in the engine failed will you be able to eliminate the problem. You can do this yourself or by visiting a specialized service center.