In most cases, there is one reason for the appearance of a whistle, squeak, squeak or squeal from under the hood of a car - the alternator belt or timing belt is whistling. On modern cars, in addition to the generator, the drive belt can also rotate the pulleys of the power steering, air conditioning compressor, engine cooling pump and other attachments.

The reasons for whistling may vary. For example, a whistling alternator belt in wet weather can be caused by moisture getting on the belt and pulleys. And if the generator belt whistles when cold, this may be due to thickened lubricant in the generator bearings or tension rollers.

In this article we will talk about why the alternator belt whistles, what to do in such cases, and how to eliminate the drive belt whistle yourself.

The whistling may appear for a while and then disappear (for example, the whistling of the alternator belt when the engine is cold, during rain or when the air conditioner is turned on), or it may be constant. What to do and where to start looking for the cause of the whistle?

What can you do?

As you can see, the main reason lies in the drive element itself, therefore, when third-party sharp sounds appear, you must:

- Check the belt tension and adjust it if necessary.

- Assess the condition of the working surface of the drive element (there should be no cracks, delamination or other defects).

- Check the tension roller (play and jamming during rotation are not allowed).

- Diagnose the condition of attachment bearings for play and wedging.

- Removal and detailed inspection of the flexible element for damage, delamination, and traces of technical fluids.

You can do the listed work yourself, but if you have difficulties with self-repair, compare at https://autoreshenie.ru/zamena-remnya-generatora-711/ the prices for replacing the alternator belt among all car services in Moscow, read the reviews on them and pick the closest one!

Many car owners note that unpleasant third-party sounds appear only under certain conditions or after replacing the drive element. It is noted that the belt tension is normal, but there is a whistle.

This is usually due to poor quality of the product and its increased hardness.

To solve the problem, you can use two methods - change the alternator belt to a high-quality one or try to treat it with chemicals.

Lubricants

To lubricate the alternator belt, use only approved fluids.

Below are several types of them:

- LIQUI MOLY KEILRIEMEN-SPRAY is a product for treating V-belt and poly-V-belt drives. The manufacturer claims that this spray increases elasticity, improves traction properties and reduces the likelihood of slipping, protects rubber from negative influences, increasing service life, increases the overall efficiency of flexible transmission, and eliminates squeaks.

- HI-GEAR BELT DRESSING – spray conditioner for drive belts. The product allows you to improve the adhesion properties of flexible gears, increases their service life by 1.5-2 times, protects against drying out and cracks, and reduces noise.

- VERYLUB is a spray product designed to care for belt drives. The liquid cleans working surfaces well from dirt, eliminates slippage, and protects from negative influences.

The above are some of the most common means for lubricating the generator drive, but there are many other options on the auto chemical market:

- Weicon;

- LOCTITE 8005;

- Forch P325;

- Gunk M206;

- Permatex PR-80073;

- ABRO;

- PITON

- Wurth.

All of these products are inexpensive, but can really help eliminate unpleasant sound.

Silicone lubricant in the form of a spray for treating rubber elements and the Hi-Gear conditioner have proven themselves to be effective.

The use of these means increases the elasticity and “sticking” of the drive to the pulleys.

But the use of WD-40 for these purposes is not recommended. This spray contains petroleum products that can have a negative effect on rubber and lead to its rapid aging.

This treatment can really help eliminate whistles under the hood, but only temporarily, and after a certain period they will return again. Therefore, only replacing the alternator belt will help you get rid of third-party sounds for a long time.

What is a generator belt, its purpose and features

The alternator belt can be classified as the most vulnerable element in a car's design. The biggest consequences are caused not even by breakdowns of the main components, but by neglect of control over lubricants, technical substances, care of filters and boots, and the generator belt.

Today, the principle of operation of the alternator belt is considered one of the most reliable and simplest ways to connect the operation of the crankshaft and the generator. This is due to the simple technical design and low production costs.

The elastic band, if broken or worn excessively, can immobilize the vehicle. To avoid such a problem, it is better not to neglect timely inspection and replacement of the alternator belt.

When the engine is running, a very large load is placed on the belt. Therefore, a good part must meet all quality indicators: geometric characteristics, material of manufacture, certification.

For manufacturing, high-strength rubber (or other elastic material) is used, which is reinforced with polymer threads and lined from the inside with a multilayer fabric base. Thanks to its complex structure, the belt provides excellent adhesion to pulleys and rollers without losing elasticity.

To ensure better grip, the belts have different shapes:

Is it possible to charge a battery without removing the terminals?

- Wedges. They connect one or two elements and are intended for reverse bending. In cross-section they have a trapezoidal shape and can withstand very heavy loads.

- Serrated. In some cases, such an alternator belt can replace a timing belt. Has excellent accuracy in transmitting torque. The structure has transverse slots.

- Polycline. Visually they differ in the presence of longitudinal grooves and a significantly larger width.

Preliminary work

Before tightening the alternator belt on Kalina, carry out a number of preliminary works:

1. Clean the tensioner nuts on the generator from dust and dirt using an alloy brush; you can spray them with WD-40 so it will be easier to turn them.

2. Prepare the necessary tool. To work, you will need a nineteen and eight mm wrench.

If you find a loose belt, do not delay the work. Please note that due to such a malfunction, the efficiency of the generator is reduced, interruptions in the voltage in the on-board network, loud “slipping” of the belt on the pulley and other unpleasant problems occur.

Why does the alternator belt whistle?

An annoying sound can occur constantly or periodically, when the engine is cold, in wet weather or under other conditions. And if at high speeds the belt stops whistling, this does not at all indicate that the malfunction has self-corrected; the issue does not resolve itself. The whistling of the alternator belt with a cold engine is a fairly common phenomenon, also with low mileage, and although it is not always possible to immediately understand why the part makes this nasty sound, by looking under the hood and examining the source of the whistling, the motorist will most often independently determine the cause in order to then get rid of the problem. Often even an inexperienced driver can cope with the task, so it is not at all necessary to drive in the direction of the service.

The resource of the alternator belt is limited; in fact, it is a consumable material and requires periodic replacement (manufacturers indicate 60,000 km), and under intense loads it can wear out much earlier than expected. At the same time, everything is clear with an old consumable, you just need to replace it and the whistling will stop, but we are not always talking about a part that has expired. Often the new alternator belt whistles; in such circumstances, the causes of the malfunction are not so obvious and require clarification. Actually, the whistle itself is created by the slipping of the belt, and its inability to turn the generator pulley or other device and, as a result, the friction of the element on the tension rollers. A thorough inspection of the entire belt drive will help you understand what’s wrong, identify the source of the problem and eliminate it.

Alternator and alternator belt

Possible causes of alternator belt whistling:

entry of foreign substances into the space (dirt, water, oil, antifreeze and other liquids)

For correct operation of parts, it is important to ensure cleanliness in the friction area. If accidentally ingressed water causes a whistle as a temporary phenomenon, and when the drops dry, the problem disappears, then in other cases, in order to restore the adhesion of the belt to the shaft surface and eliminate slippage, you will need to work hard to remove traces of oil, dirt, etc.; insufficient or excessive tension

An incorrectly tensioned belt immediately makes itself felt under loads or in wet weather (then the sagging is especially noticeable); wear of a part or poor quality of the product. During normal wear and tear, the part inevitably loses its original properties, but a completely new belt may well be made of low-quality material, which leads to its inability to cope with its task. You should not chase the cheapness of the product; it is better to purchase original spare parts, this will help to avoid many problems; Heavy loads on a car generator often cause incorrect operation of the belt drive. Often a whistle can be heard when starting the engine “cold”, when many electricity consumers are turned on. When the generator is loaded, the resistance of the stator magnetic field also increases, which provokes braking of the belt, and as a result, friction of the surfaces, manifested in the form of a whistle; failure of the generator bearing or tension roller. If there are no extraneous sounds when starting the engine at idle, and the drive belt whistles when moving and increasing speed, you can determine whether the generator rotor is stuck, then there is a need to replace the bearing; displacement of the location of the axes of the elements from one line also leads to incorrect operation, accompanied by a characteristic whistle.

There are many reasons why the alternator belt squeaks; the malfunction may lie either in the belt itself or in other structural elements, and the motorist needs to immediately find out what exactly triggered the sound. There is nothing catastrophic in this whistle, but still you shouldn’t delay resolving the issue, since extraneous sounds when the engine is turned on and during its further operation can signal various malfunctions that, one way or another, require elimination. In addition, belt slippage greatly increases the wear of the part, regardless of the squeak provocateur and can soon lead to its breaking.

What else can knock, make noise or whistle in the engine after starting?

As you can see, there are quite a lot of reasons for the appearance of knocks and noises. It should be added that when starting a cold engine, especially in winter, increased noise and chirping can be produced by the injection nozzles themselves on units with a pressure fuel injection system.

In some cases, this does not indicate any malfunction, since after a slight warm-up the noise intensity decreases or the extraneous sound completely disappears. A knock can also occur at the moment of starting in the cold due to heavily hardened ICE cushions (the engine is conditionally driven when the starter rotates slightly forward, and after starting it “bounces” back).

You should also not forget about the air conditioning compressor, especially if the engine is started in parallel with the air conditioning turned on or the climate control is activated immediately after starting. The compressor drive or the compressor itself is often the cause of extraneous noise.

The appearance of unnecessary sounds can also be associated with faulty gearboxes or clutch elements. For example, a hum after starting the engine may well come from a release bearing. It should also be taken into account that on many cars the gearbox is located directly in the engine compartment near the internal combustion engine. If it is the transmission that is humming, then this noise needs to be differentiated separately, since the engine and attachments in this case do not require additional diagnostics.

The main reasons why the timing belt whistles

The reason why the timing belt whistles when the engine is started is seen by car owners in the low quality of parts. However, the whistle may not appear because the spare part has become unusable. There are many factors that affect the functioning of the gas distribution mechanism. Therefore, do not rush to immediately go to the auto store for a new strap. After all, there are 4 main reasons why the timing belt whistles:

1. The strap whistles because it is worn out.

Belt (or tensioner) wear is the most common cause of squealing. Due to the fact that the teeth are worn out, they slip along the surface of the pulleys.

In this case, the strap whistles quite loudly. Experts advise installing a new part immediately - otherwise the belt may break. If it is not possible to replace the strap, increase the tension. This way you can temporarily get rid of the whistling. Even if the extraneous sounds are gone, you need to visit a car service center as soon as possible or replace this part yourself.

2. The timing belt whistles because fluid has gotten on it.

Even if the timing belt is working properly, if liquid gets on it, it will whistle. In this case, many car owners decide that the part is faulty. There are several reasons why the timing belt whistles: antifreeze or engine oil can get on it. This usually happens with old cars.

If the timing belt whistles, make sure that all pipes and connecting hoses are intact. Most likely, engine oil or antifreeze is leaking.

However, a leak can occur not only in the lubrication or cooling system of the car. It is not uncommon for brake fluid to get on the timing belt. Sometimes it even leaks onto the pulleys. If the disc is covered with brake fluid, it must be cleaned immediately, otherwise the timing mechanism will not work properly.

3. The timing belt whistles when cold.

Car owners sometimes don’t understand why the timing belt whistles when it’s cold. A man turns the ignition key and hears a loud whistle. Any motorist at this moment thinks only about one thing: he will have to do expensive major car repairs.

This happens because the part slips. This problem should be resolved as quickly as possible. Otherwise, the teeth of the strap will become unusable.

The generator pulley unwinds to the values set by the manufacturer. This is possible due to the fact that the crankshaft torque is quite large.

Why does the timing belt whistle when cold? Extraneous noise and vibration may occur for the following reasons:

- There is not enough lubrication on the mechanism bearing

. Or the wrong lubricant is used. After all, when the temperature is low, the oil becomes denser in consistency. As a result, the mechanism cannot spin up to the required performance. When the engine warms up well, the lubricant becomes thinner and the timing belt stops whistling. - Insufficient strap tension

. It will not be able to spin up until the engine picks up speed and warms up. - Timing belt whistles because low quality parts are used

.

To detect a problem, you should inspect the installed parts. When replacing engine components, some car owners for some reason choose inexpensive analogues rather than original spare parts. The service life of such parts is short; they may fail when you are out of town or while traveling. In order not to find yourself in a similar situation and to avoid costly repairs, experienced craftsmen recommend purchasing original parts from a reliable manufacturer. The machine will work properly only if the installed spare parts are of high quality.

Troubleshooting

Belt lubrication

If a whistle appears when starting the engine after replacing the drive belt, lubricating the element with a special aerosol can help. This solution is temporary and only takes a few minutes.

- Take a special aerosol and open the hood of your car.

- Using a suitable wrench, remove the bolts that secure the mechanism guard and remove it.

- For greater efficiency, start the car and carefully aim to get the fluid onto the belt teeth. To make sure you hit all the teeth, continue lubricating the element for 5-10 seconds.

- After this, you can turn off the engine and replace the mechanism cover.

Repairing the leak

If the whistle appears due to liquid ingress, you need to eliminate possible leaks. We determine what kind of liquid it is and solve the problem in an appropriate way:

- Engine oil. We check the cylinder head for leaks. If there is even a slight deviation, you will have to dismantle the head and grind it, and then change the sealing element.

- Antifreeze. You need to check the tightness of the cylinder head and the cooling system pipes.

- Brake fluid or air conditioning fluid. To identify all possible leaks, monitor the timing mechanism in working order. It may be possible to identify the problem without removing the belt.

The vehicle constantly requires proper care and constant maintenance of its main components. Often malfunctions in car operation are detected based on the sound that is characteristic of certain breakdowns. So, for example, it is easy to determine when the timing belt whistles.

How to eliminate a whistling alternator belt

You can get rid of the generator belt whistling by eliminating the reasons that cause it to slip on the pulleys.

If there are signs of belt slipping, accompanied by an unpleasant whistle, we suggest eliminating it in the following order:

- Stop the engine, open and secure the hood to prevent it from closing spontaneously;

- Carefully inspect the alternator belt without removing it from the car. There should be no tears, protruding threads or other visible damage on its surface. If they are detected, the belt must be replaced with a new one.

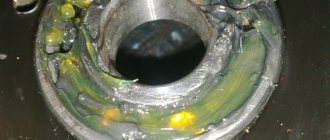

- Both the inner and outer sides of the belt must be dry and clean, without traces of dirt, oil and other vehicle technical fluids. The same applies to pulleys.

- Check the degree of belt tension - in most cases, the cause of a whistle from under the hood is precisely the weak tension of the generator belt. We wrote about how to properly check the tension level of the alternator belt here.

For information on the optimal degree of tension of your car's alternator belt, refer to its operating instructions.

- If necessary, adjust the belt tension. A good video instruction for adjusting the alternator belt is at the bottom of this page.

- If all of the above did not help and the alternator belt continues to squeak obnoxiously, then with the engine running and good lighting, carefully inspect the line of pulleys for alignment.

An indirect sign of pulley misalignment is the poly V-belt jumping from track to track and sliding off the pulley.

Pay attention to the linearity of rotation of the pulleys - if any pulley rotates in a figure eight, it will tear and throw off the belt. Most often, pulleys with a rubber damper behave this way, which over time loses elasticity and ceases to perform its functions.

And so, if the generator belt has not stopped whistling, but it is intact, clean, well tensioned, and the pulleys rotate smoothly and smoothly, then you can try to correct the situation using another method:

- Remove the alternator belt and carefully inspect it again for damage and dirt. If the belt is intact, then you need to clean its surface from the inside and outside (you can use gasoline or kerosene); if damage is found, buy a new belt.

- With the generator belt removed, thoroughly clean the pulleys from dirt and dust. This is best done with a wire brush. You can also use gasoline or kerosene.

- Place a clean belt on the clean pulleys and adjust its tension. After this, the whistling of the alternator belt should disappear.

If all of the above did not help and the belt whistle has not gone away, then the problem lies either in the quality of the belt itself or in the equipment that is driven by it: tension rollers, generator, power steering pump, air conditioning compressor, etc. Perhaps the grease in the bearings has simply thickened or they have failed, or perhaps the reason is much more serious, so in this case it would be better to seek help from a car service specialist.

You can try to temporarily eliminate the whistling noise using special auto chemicals, so-called conditioner-tensioners for drive belts. This, of course, will not solve the problem, but the whistling will disappear for a while.

Specific problems for different brands of cars

Ford Focus 2

First, let's take the above-mentioned Ford Focus 2. On this car with 1.4 and 1.6 liter power units, the designers did not use a tensioner, considering that the attachment itself would do a good job of tensioning the belt. And this is true, but for now it is new and unworn.

During operation, the drive gradually stretches and this stretching on the Ford Focus 2 cannot be corrected in any way, since there is no tension roller.

Therefore, the whistling of the alternator belt on this car often appears due to insufficient tension of the element, and this problem can only be eliminated by replacing the product.

READ ON THE TOPIC: How to replace the Ford Focus 2 alternator belt.

On the same car, but with 1.8 and 2.0 liter engines, a tension roller is structurally provided, but on the restyled Focus 2 models there is a rather interesting technical solution - there is a roller, but it does not have a tension mechanism (instead there is a regular bracket, which the part is attached to the engine).

It turns out that there seems to be a roller, but it is useless, and when the belt is stretched, its tension will decrease and a whistle will appear. But this problem is completely solvable - pre-restyling models use a roller with a tension mechanism, which can be installed on the restyled version.

Otherwise, the reasons for whistling of the generator drive and working equipment on the Ford Focus 2 are the same as for other cars - dirt, ingress of technical fluids, wear of equipment bearings, etc.

Daewoo Lanos

For example, in Daewoo Lanos, the belt drives only the generator. That is, in most cases the drive element itself becomes the cause of the whistle.

But sometimes there is a problem such as a violation of the position of the pulleys or a slight misalignment of one of them (most often the generator, due to wear of the bearings).

And because of this, unpleasant sounds will be made under the hood. Therefore, if everything is in order with the generator belt, then you should pay attention to the pulleys.

Hyundai Tucson

Hyundai Tucson has its own specific problems, these include:

- The surfaces of the belt and pulleys are not worn in (the sound appears after replacing the first element). The whistle disappears on its own as the products rub against each other);

- Incorrect installation - the belt on this car is located along a complex path and covers many pulleys and rollers, so when replacing it is very easy to confuse the laying path and place the flexible element incorrectly;

- Worn bearing of the additional guide roller (parasitic).

If we add standard problems to this, then establishing the cause of the whistle on the Hyundai Tucson is not so easy.

Lada Priora and Kalina

These car brands have different types of power plants.

At the same time, the configuration of the generator drive and attachments (if included in the package) is also different.

But in any version of the motor, in order to ensure proper tension of the drive, the design has a tension roller. And if the cause of the whistle does not lie in the belt, then the next element that should be checked is the tension roller.

Lada Priora has no specific reasons for the whistling of the generator drive, they are all common, but there are design features that are important to consider.

This car not only does not have an automatic belt tensioning mechanism, but also to adjust the tension you need a special key that turns the eccentric element, which is why the tension occurs.

Drive of auxiliary units on the Lada Priora car.

Check sequence on VAZ cars

If we take earlier versions of the VAZ, for example, 2114 or 2110, then their belt drives only the generator, so even the tensioner is not used (tensioning is done by displacing the generator itself). There are no specific reasons for whistling in these cars, they are all standard - incorrect tension, dirt, bearings, etc.

But on even earlier models - 2107 or 2108, the use of a V-belt alternator can be considered a feature. This type of drive is considered more reliable, but in terms of flexibility it is much inferior to a poly-wedge (multi-strand) drive, which is why it is not used on modern cars.

On these cars there is one specific reason for the appearance of a whistle - wear on the working surfaces of the pulleys. As a result, the belt sinks very deeply into the groove, which causes it to jam, accompanied by a squeal.

Moreover, replacing the flexible element solves the problem for a short time (until it wears in). To completely eliminate the cause of the whistle, you need to change the pulleys.

How to more accurately determine what caused the squeal, let's look at the examples of different cars.

To begin with, let's take a VAZ-2109 car. These cars were equipped with power plants with a single camshaft (that is, 8-valve).

What is described below is also suitable for other cars with this type of timing belt - VAZ-2110, VAZ-2114.

So, a whistle appeared under the hood, and to find its cause we proceed as follows:

- We remove the alternator belt and start the engine to make sure that the sounds are coming from under the timing cover;

- We dismantle the timing cover and assess the condition of the belt. It should not show signs of significant wear or traces of technical fluids. If one-sided wear is noted, there is definitely a misalignment in the rollers or pump, and you can immediately remove the drive element to check the remaining elements;

- We evaluate the belt tension (in the area between the crankshaft and the timing gear, turn your fingers around the axis. A normally tensioned belt should not turn more than 90 degrees). If necessary, adjust the tension and check if the sound has disappeared;

- We remove the belt and check the condition of the tension roller bearing and pump. There should be no play in these elements, and no jamming or wedging when turning.

By consistently checking all the elements that are involved in the timing drive, you can easily identify the cause of the sounds.

If significant wear is detected on the belt, tension element or water pump, they must be replaced. All these components cannot be repaired.

The above instructions are also suitable for the Lada Priora or Kalina, which are equipped with power units with two camshafts (16-valve versions), but there are some nuances:

- In such engines it is much more difficult to remove the drive cover;

- In a number of motors, the tension roller is equipped with an automatic tensioning mechanism. And it happens that it is this mechanism that jams, not providing proper belt tension;

- In addition to the pump and tension roller, the parasitic roller should also be checked. Play in it is also not allowed, and severe wear of the bearing of this element is another reason for the appearance of noise.

- In these cars, when replacing the belt, both rollers must be changed.

Everything described applies to other cars, for example, Renault Logan. This car is equipped with both 8-valve and 16-valve power plants, the timing drive of which is practically no different from those used on the VAZ.

Mitsubishi Lancer 9

The 9th generation Mitsubishi Lancer has another problem, the power steering pump, which operates from a belt and is located almost on the same level with the generator pulley, while there is no drive protection.

As a result of a not very successful design solution, dirt and moisture gets onto the working surface of the belt during operation, which causes slipping.

And it is almost impossible to solve such a problem, so short-term belt whistling in such a car is considered a “disease”.

Reno Logan

Reno Logan also has its own specific design features of the generator drive, which may cause a whistle to appear.

The first of them is the use of 6-groove pulleys, while the belt itself is 5-groove, and here when replacing it is very important to put it on correctly, otherwise the line of its position will be violated, in fact, a skew will appear, which is why a whistle will appear.

At the same time, with different numbers of attachments, the drive is installed in its own way.

On models equipped with power steering, the outer groove of the pulleys should remain unclaimed (the belt should be moved closer to the engine and components).

But in versions with power steering and air conditioning, on the contrary, the rivulets on the inside of the pulleys are not used.

The second feature is the absence of an automatic tensioning mechanism on models equipped with power steering. Therefore, on these Logans, when a whistle occurs, first of all, you should check the belt tension and, if necessary, tighten it.

The main causes of whistling alternator belt

To understand why the generator belt (RG, generator belt) squeaks, you need to understand the mechanism and purpose of the drive belt.

The generator belt is the connecting link between the engine crankshaft and the generator shaft. Its main function is to transmit torque from the crankshaft to the generator. That is, if the tension weakens or the belt fails in some other way (breaks, falls off), then the operation of the generator will also be in question. In addition, the alternator belt can transmit rotation through pulleys to the power steering (power steering) and/or air conditioning pump. Its malfunction can lead to the stoppage of the specified vehicle mechanisms.

Car generator working unit

Auto mechanics and ordinary motorists who have encountered the problem of a whistling alternator belt cite the following reasons for this malfunction.

Weak roller tension

If the belt whistles when cold, i.e. A whistling sound is heard immediately when starting the car engine, then most likely it is loosely tensioned. The source of the malfunction is usually the stretching of the belt mechanism due to prolonged use. The problem can easily be solved independently by tensioning the belt drive roller.

Weak belt tension leads to whistling or squeaking noises

Water on the belt

In most cars, the belt drive is not covered and is not equipped with special protection against water ingress. Therefore, after rain, in high humidity, when the engine warms up, it may whistle. If the sound stops after 5-10 seconds. after turning on the engine, there was definitely moisture on the belt drive, which evaporated after warming up.

Whistle when starting the car engine. Diagnostics and determination of faults.

Liquid leakage

During operation of the internal combustion engine, various liquids from other engine mechanisms may enter the belt drive, for example, oil from the oil filter or ATF fluid. Usually, in these cases, the alternator belt squeaks rarely. But, with a long service life, it stretches. As a result of various liquids leaking into the belt strips, the belt can run at a slant or move out. This causes a whistle.

Distortions, jamming of tension mechanisms

Quite often, the whistling sound is caused by the fact that the pulleys on which the belt mechanism or tensioners rotate due to various factors work out of alignment, and sometimes they simply jam. Because of this, the rotation does not occur parallel to the engine; the belt drive can touch other surfaces and parts, resulting in a characteristic whistle.

The power steering may fail due to the generator pulley wedge.

Overrunning clutch jams or fails

Modern generators are equipped with an overrunning clutch, which is fixed to its anchor and is responsible for the uniform rotation of the generator belt without vibrations or jerks. If the overrunning clutch breaks or jams, then rotation occurs with a high amplitude of up/down oscillations. Vibrations are transmitted from the crankshaft, causing the belt drive to whistle.

In modern generators, the overrunning clutch may whistle

Pollution, clogging of pulleys and belt

When a car drives off-road or in puddles after rain, dust and dirt get into the engine mechanism. All this gradually accumulates on the pulleys of the crankshaft and generator, and is compacted on them by the rotation of the generator belt. Dirt and small particles of dust can also accumulate on the belt itself. Thus, the toothed grooves of the pulleys and the belt strips become clogged, causing the belt to run unevenly, slip, slip and begin to whistle.

Contamination on the pulleys leads to uneven belt movement, whistling and squeaking.

Worn part or new belt of poor quality

Each auto part has a certain service life. The alternator belt is no exception. A good belt mechanism on modern cars can withstand up to 100 - 120 thousand kilometers. After this mileage, any belt mechanism will make a whistle due to wear on the part. In addition, sometimes an inexperienced driver can purchase a “fake” made from poor, inelastic material. In this case, the new part will squeak from the moment it is installed in the engine.

Due to wear, the belt may stretch, crack or peel.

Let's sum it up

As we have seen, adjusting the tension of the belt drive in the Lada Kalina is possible even for an inexperienced car owner. The main thing is to remember to timely and periodically check the condition of this element. If you neglect this, you can personally provoke breakdowns that are more expensive in terms of repair. Carry out the tension correctly, based on the aspects given in this material, and then the alternator belt will serve you for a long time. At the first sign of wear on the belt drive, take measures to replace it. Operation of a worn-out component is fraught with its sudden breakage.

Clutch is a frequent source of whistles and rattles

A slipping clutch is a fairly common problem in modern cars. Our mode of operation of transport is quite complicated; cars have a hard time in cities. It is the clutch that especially suffers from urban travel, as it constantly overheats and is forced to suffer from continuous use. Clutch problems are difficult to fix on your own, but you can identify them as follows:

The clutch will have to be repaired at a service station. Even with some experience in plumbing, it is very difficult to understand modern clutch and gearbox systems. Therefore, it is easier to entrust the work to specialists and not waste your time. The most reasonable solution for domestic cars is to replace the complete clutch. For many modern foreign cars, this process will be too expensive and require huge expenses. So the owner will have to make a decision based on the budget.

Source

Whistle when starting the engine, unrelated to the generator

Any squeaking or whistling sounds are usually attributed to belts somewhere in the engine. So if you notice these types of noises, it's a good idea to check all the other belts in the car. While in modern cars, the alternator and most components are driven by serpentine belts, older cars often use V-belts. In addition, the timing belt may also produce a squeaking sound. A squeaking or whistling sound is always a sign that the belt is worn or improperly tightened.

Adjust the tension of all belts or replace them if any belts are cracked or simply worn out. When this does not help get rid of the squeak, you should contact a mechanic.

conclusions

Perhaps every car enthusiast who has experience driving a car and who has devoted a sufficient amount of time and attention to his car can determine the cause and breakdown by sound alone.

After all, when one or another part fails, it can disrupt the operation of the entire auto mechanism, leading to the appearance of sound and external signs of a malfunction of one or another unit in the car. Often, a sign of a malfunction in a car is evidenced by: sharp sounds or vibration (triple movement), which can also be evidence of serious malfunctions and breakdowns of your car.