Comments: no Published: 02/01/2016

Rating:

Tags:VAZ 2113/2114/2115 Headlight corrector

All VAZ models, starting with the “fives”, are equipped with a device that allows you to adjust the direction of the luminous flux of the headlights in the vertical plane. Simply put, the driver, without leaving his seat, can lower/raise the reflector while driving to optimally direct the light. The VAZ 2114 headlight hydraulic corrector is installed on models 2113-2115. Owners of these cars will be interested in learning how to determine whether the headlight range control is faulty and, if necessary, replace it.

Installation diagram of the VAZ 2114 headlight hydraulic corrector

What is a proofreader for?

Probably every driver has found himself in a situation where an oncoming car is blinding and it is impossible to see anything. Vision is restored only after some time. To prevent this from happening, headlight spotters are installed on cars. The device maintains the position of the optical axis during changes in the position of the vehicle body. The light generated by the optics should be adjusted when the machine is not yet loaded. After loading, the light flux changes direction, moving relative to the optical axis. To correct the situation, a correction system is needed.

If the trunk of the car is heavily loaded, the front part of the body necessarily rises a little. The light from the headlights goes up and can blind the driver of an oncoming car. The auto-corrector adjusts the tilt of the light - the beam remains at the same level when the trunk of the car is overloaded or for some reason its front part is raised.

Why is it important to adjust headlights?

Adjusting the headlights of the VAZ 2114 is very important for creating safe conditions on the road for road users, this is especially true in conditions of poor visibility. Russia is characterized by poor quality of roads. Due to the constant shaking, the light gets confused and falls at the wrong angle. Therefore it requires adjustment.

If the light is not adjusted correctly, the following problems may occur:

- the road surface is not fully illuminated;

- insufficient road visibility range;

- the risk of creating an emergency situation due to blinding drivers of oncoming cars;

- formation of a light wall in front of a moving vehicle.

It is recommended to adjust the headlights on the VAZ 2114 every two months.

Causes of hydraulic corrector malfunction, repair

Most often, the corrector stops working during periods of sudden changes in external temperatures, when the rubber seals on the cylinders can crack and leak. Damage to the connecting tubes can also lead to loss of fluid from the system. Whatever the reason, the working cylinders freeze in one position and do not respond to switching.

It will not be possible to repair the hydraulic system itself, since the manufacturer does not provide such a possibility. Therefore, if an all-season fluid leaks, the hydraulic corrector assembly must be replaced with a new one. However, there may be a situation when the reflectors stop rotating due to something other than a faulty corrector. This occurs if the adjustment lever that transmits force to the headlight reflector loses contact with the working cylinder rod. The presence of such a malfunction can be suggested by the fact that one of the reflectors has stopped turning.

Adjusting the hydraulic corrector rod

In order to eliminate such a breakdown, it is necessary to restore the engagement of the working rod (there is a recess on it) with the spherical end of the adjustment lever. You should do the following:

- Tighten the bolt that regulates the position of the lever fulcrum until it stops.

- Move the reflector to its lowest position.

- Align the lever ball and the rod notch, then unscrew the adjusting bolt to the required position.

How to identify problems with optics

The need to adjust the light will be required in the following cases:

- lamps shine strongly up or down;

- the beam is shifted to one side;

- uneven brightness of headlights when inspecting the car;

- insufficient light intensity, a clear jackdaw is not visible;

- One of the headlights does not work.

The tuned optics of the VAZ 2114 or model 2115 cope perfectly with any weather conditions. To identify deficiencies, a visual inspection of the performance of the lamps should be carried out once a week, and adjustments should be made at least once a season.

Hydrocorrector of headlights VAZ 2114 Depending on the vehicle load, the headlights can be directed lower or higher. To adjust the light flux, special devices called hydrocorrectors are used. If the car is loaded, it is better to lower the headlights so that the light output is directed towards the road and not up. This way you will provide the necessary illumination of the road surface and prevent the driver from being dazzled by oncoming traffic. With a minimum load of the car, when the rear of the car is raised, the headlights can be raised slightly.

[custom_ads_shortcode3]

Replacing headlight hydraulic corrector

If you decide to install a hydraulic corrector, which is installed standard on Lada cars of previous years of production, you can do the work yourself. On more modern cars (Priora, Kalina, Granta, etc.) electrical systems can be installed.

Parsing and removing old

Algorithm of actions for dismantling the hydraulic corrector:

- unscrew the screws on the clamps securing the tubes to the corrector parts;

- disconnect the actuators attached to the snap-on latches from the headlight units;

- from the passenger compartment, remove the rotating handle of the hydraulic regulator from its place (it is located directly on the main cylinder);

- unscrew the plastic nut with which the main cylinder is screwed to the “torpedo”;

- pull it out (after pushing the rubber seal into the cabin) complete with plastic tubes and actuators.

Hydraulic corrector in the cabin with the handle removed

Installation and connection of a new

Installation of a hydraulic corrector instead of a faulty one is carried out in the reverse order of dismantling - nothing complicated is observed here.

If you decide to install an electric device (it is ideal instead of a hydraulic one), the algorithm of actions will be slightly different:

- remove the negative terminal from the battery;

- dismantle the old hydraulic corrector along with the pipes, main and working cylinders;

- replace it with an electrical device;

- dismantle the lever of the old mechanism in the cabin;

- connect the “plus” of the electrical corrector to the 20th contact of the block, the “minus” can be “found” under any body stud in contact with the metal;

- instead of plastic tubes, lay the wires from the kit and, for reliability, secure them with dielectric clamps to the common wiring harness;

- attach the actuators to the headlight housings;

- Replace the removed negative battery terminal and check the operation of the system.

Installing a new device (master cylinder)

During the installation of the electric corrector, it makes sense to simultaneously check the efficiency of the optics. If you notice condensation inside the headlamp, it is better to replace it, because in the future the level of road illumination will only worsen.

More:

- a black coating inside indicates that the light bulb does not have long to “live”, so it needs to be replaced and it is better to do this in advance, and not on the way;

- if you notice peeling of the reflective layer, you will also have to buy a new headlight (it is better to change both units together);

- inspect the block lens - if the scratches and chips are serious, it is recommended to replace the old glass, using a special sealant when installing a new one;

- Before installation, clean the protective caps from dirt.

The best and most expensive option is to install an automatic correction system. In this case, the driver does not need to do anything: the device will automatically adjust the beam of light. The design includes sensors installed at the front and rear. Their task is to determine the ground clearance on both axles of the car. This allows you to “calculate” the tilt of the body and send the necessary information to the electronic control unit. He gives a command to the actuators, and, taking into account the speed of movement, the latter, through a gear motor, change the angle of inclination of the head optics. The system is quite complex and requires a professional approach during installation.

Light adjustment

After installing a new corrector (no matter hydraulic or electric), it makes sense to adjust the light beam. To do this, you need a flat wall, which must be marked in accordance with the manufacturer’s recommendations (see

in the car's operating instructions). The marking can be done independently, in accordance with the figure below.

Further:

- stop the car five meters from the marked wall;

- use the hydraulic corrector handle to set the correct light beam;

- Each headlight can be adjusted individually;

- if the “efforts” of the hydraulic corrector are not enough, use the mechanical levers located on the headlight unit.

Wall marking scheme for light adjustment

First adjustment method

The setup procedure follows the following principle:

- Drive the car onto the found horizontal surface that was chosen for setting up the lights.

- Stop the car directly in front of the wall.

- Using chalk, make marks on the wall that will correspond to the center point of the car and the centers of the lights.

- Mark the distance from the ground to each headlight.

- Mark the distance from the center axis of the car to each of the headlights.

- Draw a line five centimeters below.

Adjusting the headlights using the wall

- Next you need to drive away and stop at a distance of 7.5 m from the wall.

- Connect the points of the centers of the lanterns in the drawing with one straight line.

- Draw a pair of vertical lines through the same centers;

- Draw a line parallel to the ground through the center point of the machine.

- At this point, the drawing is considered complete - turn on the headlights close to you.

- The angle of inclination of the lanterns should coincide with the horizontal line, and the beginning where the border of the light will rise should be aligned with the intersection of the lines.

- Adjust the headlights by turning a pair of screws - you will find them on the rear panel in the engine compartment. The beam should be located slightly below the headlight point designation on the drawing.

Design and principle of operation of the headlight range control

It is worth noting that the operating principle of different types of headlight range control units is approximately the same. At the same time, a distinction is made between automatic and manual settings. In the latter version, the position of the headlights is adjusted using a special regulator installed inside the car, and with the help of its rotation, the driver independently changes the angle of the optics. In the first case, the electronics automatically configure everything itself, depending on the landing of the car.

Manual headlight range control

This headlight range control is installed on many budget cars, so it is familiar to a large number of car enthusiasts. As the name suggests, the corrector is activated directly by the driver. To do this, as a rule, you just need to turn the wheel, or as it is also called, the rotary switch. The electromechanical drive of the headlight range control is most often used, so we will consider it.

The adjustment wheel usually has digital or graphic markings that indicate the position of the headlights. Adjustments are made by the driver as necessary, depending on the vehicle’s load and changes in its tilt in the longitudinal direction relative to the center of gravity.

Simply put, if three people sat in the back seat, and you had to put four bags of potatoes for your mother-in-law in the trunk, then obviously the back of the car will lower and the front will rise, causing the headlights to shine too high and blind oncoming drivers.

To prevent this from happening, you need to turn the wheel so that the beam of light goes down.

Turning the knob gives the corresponding command to the gear motor, which is needed to turn the headlight to a certain angle. In fact, a gear motor is nothing more than a worm gear, which is necessary to convert the rotational movement of the electric motor (located inside the gear motor) into the translational movement of the rod, which directly acts on the headlight, changing its angle.

Structurally, the headlight is hinged at the top, and the rod with a ball end (resting against a spherical latch) holds the lower edge of the headlight. And it is the back and forth movement of the lower part of the headlight, with the upper attachment point remaining unchanged, that gives the necessary change in the angle of inclination.

A manual headlight leveler is very simple, very reliable and, most importantly, a useful device, but it has one very significant drawback: most drivers forget to use it and blind their colleagues, despite the fact that they have the opportunity not to do so.

Automatic headlight leveling system

Automatic headlight leveling is a more advanced technology because it does not require any action from the driver. The cut-off line is adjusted automatically based on sensor readings.

Automatic headlight leveling can be installed on vehicles equipped with either halogen or xenon headlights. For xenon, this is even necessary, since this type of headlight emits light of very high intensity, and in the absence of auto-corrector, it can pose a serious threat to traffic safety.

As for the design of the headlight auto-corrector, the following elements can be distinguished:

- Control block;

- sensors that measure the vehicle's ground clearance at various points;

- device that adjusts the headlights (actuator).

Typically, the system uses two or three sensors that measure ground clearance. Either one sensor or a pair can be installed at the front. And one sensor is located at the back.

Early systems used potentiometric sensors, but they were not reliable enough, so they have now been replaced by non-contact angle sensors.

The operating principle of these sensors is based on the Hall effect. The mechanism of operation of the sensor is quite simple.

Structurally, the sensor consists of a rotor (moving part), with permanent magnets built into it, and a stator (fixed part), which, in fact, is a Hall sensor.

The sensor is attached to the bottom and is connected to the suspension using a rod. The change in suspension travel is transmitted through the rod to the rotor, which rotates, causing a change in the magnetic flux, which is detected by the Hall sensor.

The magnitude of the change in the magnetic flux is subsequently recalculated by the control unit into the required angle of rotation of the headlights, and the corresponding signal is sent to the actuator. In its work, the control unit takes into account not only the angle of inclination of the vehicle, but also the speed, as well as the nature of the vehicle’s movement.

Do-it-yourself adjustment and tuning of VAZ 2114 headlights

Most motorists prefer not to interfere with the optics until they fail. Because of this attitude, many accidents occur at night, as well as during weather conditions that affect visibility. Near the road you can often notice curved reinforcement, which is difficult to crash into even if you wanted to. Experience shows that unadjusted headlights impair visibility at night or in bad weather. With constant shaking, the mechanism gets confused and the light falls at the wrong angle, as a result - a decrease in the visibility distance and a serious threat not only to the owner of the VAZ 2114, but also to other motorists and pedestrians.

To protect yourself and others, it is enough to make adjustments every two months. The process is simple, so the driver of the VAZ 2114 can make adjustments in the garage or box. The price list of car workshops also includes a service such as light adjustment. Before you adjust your optics, you need to understand what characteristics a properly adjusted optic should have:

The main task is to illuminate the road in front of the car

Attention: it is the road, not the surrounding area. The driver must see a clear line of light in front of him. The luminous flux should not hit the windshield of oncoming cars. The headlights should be at such a height that the range is maximum.

What does the automatic headlight leveling system consist of and how does it work?

The autocorrector system can install from one to three ride height sensors; they are placed in front and behind the body. In addition, the system uses a non-contact rotation angle sensor, the operating principle of which is based on the Hall effect. The sensors are attached to the body and connected to the suspension using special rods. The sensor itself consists of a moving rotor with permanent magnets and a stationary stator in the form of a Hall sensor.

The position of the body in relation to the suspension is recognized thanks to sensors and a rod that changes its position by turning the rotor, which in turn changes the magnetic flux. This flow is taken into account by the Hall sensor, after which the headlights are adjusted taking into account the specified algorithms. Cheaper automatic headlight leveling systems use only one sensor - ultrasonic. The only sensor is mounted in the rear of the body according to the principle described above. The signal that comes from the sensors is received by the ECU (electronic control unit) of the automatic headlight leveling. The control unit is guided by certain algorithms that take into account information about the current speed of the vehicle, as well as the state of the sensors. After this, the ECU issues a command regarding the angle at which the headlights need to be raised or lowered.

Such a simple and at the same time useful system allows you to always keep the headlights in the correct position, eliminating the possibility of dazzling other road users. More perfect and advanced in terms of traffic safety and automatic headlight adjustment is the adaptive lighting system, which allows you to adjust the light beam not only in the vertical, but also in the horizontal direction, but that, as they say, is a completely different story...

I have everything, I hope everything is clear to you? Thank you for your attention, and see you again at Fara Info

Do-it-yourself headlight adjustment technology

The adjustment must be carried out on a flat surface without tilting. The test screen can be installed at a distance of 5-6 meters. If you don't have a screen, you can use a flat brick wall, a garage door, or a large sheet of plywood. Headlight glasses must be clean, without cracks or chips.

Also pay attention to the condition of the reflectors

The design of optical devices has two adjustment screws, one of which directs the light beam in a vertical position, and the other in a horizontal position. With their help, we make adjustments as indicated in the diagram.

The headlight beam should be directed by the adjusting screw to point E

For convenience, we draw vertical lines A, O and B on the wall with chalk. They will serve as the necessary guidelines when adjusting the optics. We also draw horizontal lines 1 and 2. The distance between them should be 65 centimeters.

Next, we go into the interior and set the headlight hydrocorrector control to position 0. This is necessary to eliminate the influence of the device on the luminous flux during adjustment. The regulator is located under the dashboard, to the right of the steering wheel.

The procedure is as follows:

- We cover one headlight with dense material that does not transmit light.

- We turn on the near one.

- Open the hood and find the regulators on the back side of the headlight (in the figure below, numbered 1 and 2). One of them responds to the vertical movement of the light beam, and the second to the horizontal movement.

- Using adjusting screws 1 and 2, we direct the beam of light to point E. We adjust the indicator to the desired value. By turning the screws counterclockwise or clockwise, we position the beam of light at the desired point

- We repeat the procedure, turning on the high beams.

- We carry out a similar adjustment for the other headlight.

Video settings on the VAZ-2114

Adjusting the headlights does not take much time, so in poor lighting, do not delay this procedure. When working, you should take the advice of experts. In this case, you can adjust the light beam as accurately as possible.

Alexander Orda

Proper operation of optics in a car is the key to safe driving and good visibility at any time of the day. In the VAZ-2114 model, sometimes it is necessary to adjust the headlights so that the light flux is directed towards the road and does not interfere with oncoming drivers. You can check and adjust the light at home with your own hands; this work does not require much time or special tools. A useful video will speed up the setup process.

OPERATING PRINCIPLE

When the driver decides that the headlights need to be adjusted, he turns a special knob inside the car to do this. It controls the pressure in the corrector piping system. Accordingly, when it is necessary for the headlights to go down, everything happens as follows:

- The handle turns down;

The switch in the cabin looks like this - The pressure in the system drops;

- The operating rod enters the housing;

- The headlight goes down.

Based on this, we can say that most of the time high pressure is maintained in the working mechanisms; this is necessary to maintain the horizontal position of the headlight.

In winter, or during the transition period, when the temperatures outside and in the engine compartment are very different from each other, pipelines and rubber seals can delaminate, and working fluid can leak out. In this case, the headlight range control will most likely fail, and the working cylinders will jam and require complete replacement.

In terms of calibrating the device, the instructions from any domestic hydrocorrector will do. This is due to the fact that structurally they are all made very similar and you can figure out any of them yourself.

The case described above is the only malfunction that can be eliminated. In other cases, you will have to change the hydraulic corrector. There is nothing complicated here either. The first thing to do is remove the faulty device. To do this, unscrew the screws with which the pipeline clamps are attached to the brackets.

Now you should install a working device. There is nothing complicated here either. We take a new hydraulic corrector and install it in place of the old one. All actions here are carried out in reverse order. It should also be noted that many owners of “fourteeners”, faced with such a problem, make certain improvements to the design.

In particular, instead of a hydraulic one, they install an electric headlight range control. The latter is more reliable and durable, but it also costs more. The best option for the VAZ-2114 is an electrical corrector of the Silich Zenit type. The thing is that it fits perfectly into its regular place. Accordingly, no problems or difficulties will arise here.

Next you need to remove the adjusting lever. It, as mentioned above, is located in the cabin. After this, the negative terminal of the device must be fixed on one of the body studs located under the dashboard, and the positive terminal must be connected to the block socket number 20. The wiring of the electrical corrector is laid along the power supply harness.

When the driver decides that the headlights need to be adjusted, he turns a special knob inside the car to do this. It controls the pressure in the corrector piping system. Accordingly, when you need the headlights to go down, everything happens as follows:

The handle turns down;

The switch in the cabin looks like this

In winter, or during the transition period, when the temperatures outside and in the space under the hood are very different from each other, pipelines and rubber seals can delaminate, and working fluid can leak out. In this case, the headlight range control will most likely fail, and the working cylinders will jam and require complete replacement.

Adjusting the headlights of the VAZ 2114. How to adjust it yourself.

Most motorists prefer not to interfere with the optics until they fail. Because of this attitude, many accidents occur at night, as well as during weather conditions that affect visibility. Near the road you can often notice curved reinforcement, which is difficult to crash into even if you wanted to. Experience shows that unadjusted headlights impair visibility at night or in bad weather. With constant shaking, the mechanism gets confused and the light falls at the wrong angle, as a result - a decrease in the visibility distance and a serious threat not only to the owner of the VAZ 2114, but also to other motorists and pedestrians.

To protect yourself and others, it is enough to make adjustments every two months. The process is simple, so the driver of the VAZ 2114 can make adjustments in the garage or box. The price list of car workshops also includes a service such as light adjustment. Before you adjust your optics, you need to understand what characteristics a properly adjusted optic should have:

The main task is to illuminate the road in front of the car

Attention: it is the road, not the surrounding area. The driver must see a clear line of light in front of him. The luminous flux should not hit the windshield of oncoming cars

Headlights should be at such a height that the range is maximum

The luminous flux should not hit the windshield of oncoming cars. The headlights should be at such a height that the range is maximum.

Preparing to adjust the headlights

Preparation involves cleaning the headlights and looking for defects, which can also cause poor performance of the optics. Before adjusting the headlights, you need to clean them with detergent - the glass of the optics of domestic cars is quite thick, so if the light stream is dirty, it may not penetrate. Reflectors and glass should be checked for defects.

After using detergent, rinse the glass again with a clean sponge and allow the surface to dry. If chips or cracks are found, the headlight glass needs to be replaced. The same applies to the reflector, there is a defect - replacement.

Helpful advice: to increase lighting efficiency, you can install fog elements, xenon or halogen headlights on the VAZ 2114. Today on the market there is a whole list designed for domestic cars.

In the VAZ 2114, light adjustment is done using screws. Some screws are responsible for the vertical plane, and the second for the horizontal. Due to rotation, the optical element changes its position. In car services, technicians use optical devices to adjust the light. In garage conditions, the VAZ owner can make adjustments using the screen.

Step-by-step instruction

- The adjustment is made with the low beam on. The VAZ 2114 should be placed opposite a flat wall. The distance from the headlights to the plane should be exactly 5 meters. A load weighing about 80 kilograms must be placed on the driver's seat. It is also worth making sure that the tank is filled. Light adjustment is carried out with a standard machine load;

- When the VAZ 2114 is loaded and prepared, you need to start drawing the “screen”. On the wall with chalk and a ruler, you need to draw a vertical line-axis that will correspond to the center of the car. After it, two more vertical lines are drawn, parallel to the axis - they should be at the optics level. Next, you should draw a horizontal line at the level of the headlights. Below, 6.5 cm, a line is drawn to indicate the centers of light spots;

- Adjustments are made one by one. It is better to cover the headlight, which is not involved in the adjustment, with cardboard;

- The process can be completed when the upper boundary coincides with the level of the center axis, as shown in the diagram. The intersection points of vertical straight lines and the centers of the spots must correspond to the points of intersection of the inclined and horizontal sections of the spots; Explanation of optical adjustment using the screen

Bottom line

After completing all the steps, the driver of the VAZ 2114 will receive the ideal light that will illuminate the movement. Other road users will also be pleased with the adjusted optics - the light flux will not hit the eyes.

Headlight range control demonstration:

note

Malfunctions and why it breaks

- Loss of tightness in tubes, places where they are attached to the cylinders, leaks in the cuffs of the main or working cylinders;

- Jamming of working pistons

The main problem in the system of hydraulic adjustment of the reflector position is depressurization. Since it uses liquid as a working medium, its leaks lead to the fact that pressure is not transmitted from the master cylinder in the car interior to the workers on the headlights. No matter how much you turn the regulator, the position of the light beam will not change.

The second reason is souring of the pistons of the hydraulic corrector cylinders in certain positions. For example, if the piston is “stuck” in the maximally extended position, then the light will shine upward, while in a recessed position it will shine downward. When rotating the handle of the regulator, a lot of tension will be felt and when it is released, it will return to its original position and will not be fixed as necessary.

This happens because the pressure changes as the regulator rotates and the pistons cannot move. When you release the handle, the system tries to return to its initial state, equalize the pressure, the handle returns to the position from which you started turning it.

The listed types of breakdowns are prone only to the hydraulic drive of the corrector. Let the manufacturer claim that it is not repairable, but this is not so. There are examples of self-repair of a hydraulic corrector, which we will discuss in the following articles. In order not to bother with restoring it or replacing it with a new one, it is recommended to install alternative types of headlight range control units.

Setting the fog lights

Adjusting the fog lights involves several steps:

- vehicle preparation;

- drawing up a diagram;

- adjustment.

The preparatory steps are no different from the actions performed before adjusting the main headlights. The fog lights should be clean, the tires should be inflated, and the trunk should be empty. When setting up fog lights, you should use a special diagram that you create yourself. This requires:

- Place the car at a distance of 5-10 meters from the wall.

- Measure the height of the center of the headlight and mark it with a line on the diagram.

- Transfer the marks of the center of the car and the fog lamps to the wall.

- Draw a line 10-12 centimeters below the height mark of the fog lights.

To adjust the optics, you need to turn the screw until the beam reaches the level marked on the plan. If the headlight cannot be adjusted, you should clean the bolt head and inspect it for souring. You can use WD-40 aerosol to lubricate the parts. If the bolt rotates but the reflector remains in place, you will need to dismantle the fog lamp and check the integrity of the mechanism.

Purpose of the Zenit Automatic Headlight Level Corrector

Auto-corrector "Zenith" keeps the headlights in one position, regardless of changes in the load on the vehicle's axles. The tilt of the headlights is adjusted through the standard electric headlight leveler using standard gear motors located in the headlights.

Automatic headlight leveler "Zenit" is intended for installation on vehicles equipped with a manual electric headlight leveler using a single-wire circuit.

In most cases, on a foreign car, its work will be no different from the standard autocorrector, i.e. "Zenith" is a direct replacement for the standard one. Most often, the sensor from the standard autocorrector fits the Zenit and our sensor fits the standard one, the connectors are just different.

The reliability of the Zenit Autocorrector is ensured by the use of a non-contact axis loading sensor based on a Hall sensor and a rotating magnet; there are no variable resistors with sliding contacts inside. In Russian conditions of dirty roads, it is much more durable than ultrasonic sensors.

Who needs the Zenit automatic headlight leveler?

Luxury cars are usually equipped from the assembly line with xenon or LED headlights, auto leveling and headlight washers. No one doubts the advantages of these light sources anymore

It is important that on the conveyor all light parameters comply with technical regulations

Owners of middle-class foreign cars, which also have luxury segment trim levels, always have the option of replacing halogen headlights with xenon ones and installing standard auto-corrector and headlight washers. Another thing is that the prices of official dealers stop many people.

Owners of economy-class foreign cars and all Russian cars in possible factory configurations do not have xenon light. Therefore, it is not possible to use standard solutions.

It is precisely for the last two categories, which solved the issue with xenon headlights and washer, that the Zenith Automatic Headlight Corrector is intended. Automatic headlight corrector "Zenith" is the most affordable solution on the market.

How exactly xenon headlights, washer and auto-leveling headlights are installed on various cars is described in the articles, links to which are given on the left in the menu. At the same time, it is quite possible to register the installation with the traffic police as fully complying with the technical regulations. The photo on the right shows the registration certificate for the 2110 with the changes made.

Automatic headlight leveling system "Zenith" - with one or two axle load sensors?

In most cases, one sensor installed on the rear axle is sufficient. The autocorrector itself has two sensor channels, the second one can be connected later if necessary.

Step-by-step instruction

Adjusting the headlights of a VAZ 2114 or 2115 with your own hands is a simple procedure. With proper preparation of the car, you can achieve optimal results that will not differ from adjustments on an optical machine. Before setting the headlights, an auxiliary diagram is drawn. To do this you need:

- Install the VAZ 2114 at a distance of 5 meters from the wall. The measurement is made strictly from the headlight glass.

- The height of the lamp relative to the asphalt is measured with a tape measure.

- The value is marked on the wall with a horizontal line.

- A vertical stripe marks the center of the car.

- From the horizontal mark, an indentation is made downwards by 65 mm and a mark is made where the cut-off strip should be located.

- To identify the center of the beam, the transition points into daws are used.

- The centers of the jackdaws are marked on the wall with vertical lines, the distance between which should be 964 mm.

A schematic sketch is recommended by the manufacturer as the most accurate method for adjusting the optics. Headlight adjustment:

- Turn off the car engine.

- Turn on low beam.

- Set the headlight hydraulic adjustment lever to position 0.

- Open the hood.

- Cover one headlight with cardboard or a thick rag. This improves the visibility of the beam boundary.

- Using the built-in screws, adjust the direction of light first on one headlight, then on the other.

- Rock the car and check that the settings are correct again.

When performing work, the vehicle must be without passengers. You can put a load weighing 50-70 kilograms on the driver's seat, but this is not necessary. Installation on the handbrake often changes the position of the body relative to the road surface, so you should use a wheel support or a regular stick.

By adjusting each headlight separately, you can achieve the most accurate result of the beam position. Correctly configured VAZ optics will not blind oncoming traffic participants and provide high-quality illumination of the road surface.

[custom_ads_shortcode2]

Connecting the electrical corrector BUK02-01 to a VAZ-2110

Installation of the BUK02-01 autocorrector on a VAZ-2110 (2111) car is carried out without modifications to standard places. In this case, you must first change the length and adjust the stroke of the rod depending on the specific model:

- VAZ-2110: stroke 2.0 with length 34.0.

- VAZ-2111: stroke 3.63 with length 34.0.

The stroke of the BUK02-01 rod is 7.0 with an offset of 38.8. Therefore, you will have to cut off the rod and reduce its stroke.

To cut the length of the rod, connect power to the drive so that the rod extends to its maximum stroke. First, we cut off part of the rod, then grind it off with a 9 mm file. After this, we glue the sawn-off part back with superglue.

The headlight electric corrector is adjusted in the “0” position, which meets the technical inspection requirements. Each division of the switch allows you to shift the axis of the light flux by 0.06 m, provided that the adjustment stand is installed at a distance of 1.2 m from the car headlights.

Adjusting the fog lights

In order to adjust these lighting devices, you will need to perform the following steps:

- for a car prepared in the same way as mentioned above, measure with a tape measure the distance between the ground surface and the center of the PTF;

- at this height a horizontal line is drawn on the wall, another one 10 centimeters lower.

- the adjusting screws for the fog lighting are located outside, and during operation you will need a screwdriver;

- as before, the lighting is adjusted individually (the PTF that is not needed at this time is covered);

- the center of the light beam should be at the level of the lower horizontal line and clearly parallel to the headlight.

How exactly to adjust the headlights on a VAZ-2115 is described in the video below:

- https://vaz-russia.com/remont-vaz-2113/regulirovka-sveta-far-na-vaz-2113-vaz-2114-vaz-2115.html

- https://infokuzov.ru/remont/regulirovka-far-na-vaz-2114

- https://ladaautos.ru/vaz-2115/kak-proisxodit-regulirovka-far-na-vaz-2115.html

Hydrocorrector

In the article “Why the headlight range control does not work,” we examined the main malfunctions of the system, as well as the repair method by completely replacing all components of the system. However, in most cases the hydraulic corrector is perfectly repairable. In order for the hydraulic corrector to stop working normally, the loss of even a small amount of working fluid is sufficient. You can make up for the loss with regular antifreeze.

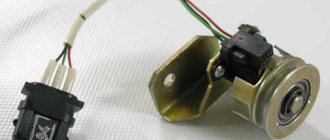

6 – knob for adjusting the light beam; 1 – main adjustment mechanism; 2 – working cylinders with a rod acting on the headlight reflector.

Barbaric repair method

Many drivers do not burden themselves with either repair or replacement of the hydraulic corrector. When the headlights begin to shine downwards, they simply screw in screws from the back of the working cylinder. Adjustment of the position of the rod and the level of the headlights is carried out by screwing in and unscrewing screws. After such a repair, the concept of a headlight range control is no longer applicable to the system, since the possibility of quickly adjusting the angle of the headlight reflector from the interior disappears. But such repairs have a right to life if the malfunction caught you on the road and there is simply no other way to raise the headlights.

Recovery without removal

- Pull the actuators out of the headlight assembly.

- Remove the tubes from their seats, and then secure the tubes so that the remaining working fluid does not leak out of them. It is better to preheat the landing site, but you can simply cut the tubes at the edge of the landing sites. Check the stroke of the actuator cylinders by moving them by the rod using pliers. The pistons should move without jamming.

- Each actuator has a plug for bleeding the system, which must first be pulled out.

- Turn the switch on the dashboard to position O. Fill the tubes with antifreeze so that a small drop remains on top, then put them on the fittings of the actuators.

- Position the slave cylinder bodies so that the bleeder hole is the highest point.

- Holding the rod in the maximum retracted position, fill the working cylinder with liquid until a small “hill” forms above the bleeder hole.

- Close the plug.

The system should work, but since the seals of the connections at the main cylinder, the regulator at the dashboard and the seals of the working cylinders were not checked, one cannot be sure of the long service life of the hydraulic corrector after such repairs. This restoration method will not work if the system is airy at the master cylinder in the cabin.

Restoration of headlight hydraulic corrector

You need to know where the headlight hydraulic corrector is located and how to remove it, since for a complete troubleshooting you will need to dismantle the working cylinders and the main adjustment mechanism. Take 2 small pieces of tube to connect the working cylinders to the main mechanism after removal, fill the system with water. If the device is operational, set the switch to the maximum headlight raise mode and leave the mechanisms in this position for several hours. If no leaks have appeared during this time, the system can be filled with antifreeze and installed on the car. If the leak does not appear in the pipe connections, it is better to replace the hydraulic corrector with a new one or install an electric corrector instead.

Only new coolant should be used so that dirt particles do not interfere with the normal movement of the pistons. Remember that the system must be completely filled with working fluid. To restore, you will need a syringe and a blunt needle so as not to damage the cylinder seals. Do-it-yourself repairs, the assembly and disassembly process are perfectly shown in the video.

Read with this

- Features of self-adjustment of headlights on a gazelle

- Headlight adjustment

- How to repair headlights yourself? Let's look at different ways

- How do Audi LED matrix headlights work?

- How to polish headlights with your own hands? polishing headlights at home

- DIY taillight tinting

- How to seal a headlight on a car

- Types of car lamp bases and their markings

- How to improve the light on a VAZ 2107

- Wheel width

Preparing to independently adjust headlights

Before you start making adjustments, you need to prepare the tools and the car.

It is important to note that achieving accuracy in adjustment depends on compliance with all recommendations and regulations

The first thing you should pay attention to before making adjustments is the location. It should be level (it is advisable to check the area by level), without additional lighting (or with the ability to make this place dark), there should be a flat plane opposite the headlights (wall, fence, etc.) All of the above affects the accuracy of the adjustment

Adjusting screws for headlights: 1 – screw for adjusting the light beam in the vertical plane; 2 – screw for adjusting the light beam in the horizontal plane; 3 – casing fastening screws; 4 – protective casing

If adjustment is planned outside, the weather should be dry and windless.

Headlight adjustment diagram

The car is prepared in accordance with the following indicators:

- The car is clean. There is no dirt on the body and fender liners.

- The trunk is empty.

- The spare is in place.

- Fuel tank is full, or filled to the cut-off point.

- The pressure in all wheels is 2.0 or 2.1 bar.

- The optical glass is free of cracks, chips and defects.

- The headlight mounts to the body are intact and not loose.

If the glass has cracks or chips, the light beam is refracted distortedly, as a result of which some of the light will distract other drivers or be directed to the side. Also, the optical mounts should be replaced before adjustment, since the angle of the headlight depends on the mounts.

Before starting the adjustment, the following equipment must be prepared:

| Clean rag |

| Detergent for windows and glass |

| Cardboard or thick fabric |

| Felt pen |

| Building level |

| Roulette |

| Wheel stop stick |

Based on the list presented above, it should be concluded that to independently adjust the headlights on a VAZ 2114, you do not need special equipment; this requires only those tools that are available in every garage.

Installation and modification

To install a new corrector, follow these steps:

- Having loosened the clamps, remove them from the pipes with the working fluid;

- in the cabin we dismantle the handle on the main cylinder;

- Having unscrewed the mounting bolts, remove the main cylinder;

- At the last stage, we remove all the working cylinders and take them out through the interior.

Refinement and repair of the headlight hydraulic corrector consists of checking the position of the adjusting bolt. It must be set so that the light can be adjusted with minimal effort.

Debugg

How to change the headlight range control on a VAZ 2114? To remove it, you need to disconnect the clamps from the wire fastening clamps; before doing this, it is recommended to remove the terminals from the battery. Further:

- Remove the cylinder (regulator) handle by pulling it slightly towards you.

- Unscrew the cylinder nut on the panel.

- Remove the lever trim.

- Remove the mechanism from under the panel.

- Remove the corrector cylinders from the housings by pressing their latches.

- Next, you need to remove the mounting hoses with clamps on the car body.

- Push the rubber seal into the middle of the cabin and place two more cylinders with tubes there.

Removing the hydraulic corrector on a VAZ 2114

Continuing the repair of the headlight hydraulic corrector, we carefully place the new, proven unit on the VAZ 2114 into the mechanism socket, only in the reverse order.

Maintenance and operation of the product

The design of the headlight hydraulic corrector is non-separable; in the event of a malfunction, it can be replaced entirely. The main thing is to remove it completely, and not cut it off, to make it easier to install a new device.

If the angle of the headlights increases, you can try to adjust the mechanism. What should be done?

- When the car is loaded, the headlights need to be turned down so that the light beam is directed at the roadway.

- If the vehicle load is minimal and the rear part of the frame is in a raised state, the headlights should be projected upward.

Design and principle of operation

The device is a non-separable device that regulates the position of the light beam by changing the fluid pressure inside the nozzles. The unit cannot be disassembled, so if it breaks, it is replaced with a new device. The design of the corrector consists of the following elements:

- master cylinder;

- working fluid;

- pipes containing liquid;

- cylinders

The headlights are adjusted using a hydraulic corrector by the driver using the corrector wheel located on the dashboard. By turning the wheel you can raise or lower the lamp.

What else can be done to more effectively illuminate the road when a car is moving?

In other words, how to improve the headlights on a VAZ 2114? What should be done?

- Replace existing lamps with improved ones that have a larger light output angle. You can install xenon.

- If the car's reflective surface peels off from the metal body, then it would be correct to install a new headlight instead of the old, non-functional one.

- Regular cleaning of headlight covers from dirt; protective film can be used as a preventative measure.

- If black deposits appear on the headlight bulb, the quality of lighting decreases. Therefore, you need to replace the lamp in time.

- If condensation gets inside the lamp, the level of efficiency of road lighting decreases. To avoid an accident, the correct solution would be to replace the defective headlight.

Dear motorists, check the quality of functioning of car headlights in a timely manner and place increased demands on the operation of these units. Eliminate all possible causes and remember that traffic safety guarantees peace and order to all road users.

Have a good trip and easy repairs!

DIY repair

If the hydraulic corrector completely fails, all that can be done is to completely replace it with a new one and that’s it. But if the headlight hydrocorrector does not work, then you can carry out certain manipulations and find out exactly what is the cause of the breakdown, and perhaps you will be able to return them to functionality without wasting money on new components.

So, if the machine has changed its tilt angle, but it is not possible to change the direction of the light beam, then the performance is checked in this way:

First of all, you need to carefully examine the condition of all the tubes and rubber bands. Even the slightest smudges are unacceptable;

If no leaks were found or their elimination did not bring results, then you need to examine the condition of each working cylinder. To make it more convenient to adjust the headlights, you need to remove the working cylinders from each headlight. Then the stroke of each rod is measured - under normal conditions it is 6.5 - 7.5 mm;

If these diagnostic measures did not force the VAZ 2114 headlight hydraulic corrector to work normally, then the breakdown lies in the main unit, and then it is better to simply replace the entire mechanism with a new one.