Published: 10/20/2020

- Repair or replacement

- Replacing a car's rocker, eliminating play

- Signs of malfunction of the VAZ 2110 backstage

- How to replace the universal joint on a VAZ 2110-VAZ 2112?

- How to repair a gearbox shifter

- Replacing the backstage on VAZ 2110, VAZ 2111, VAZ 2112

- How to choose a new backstage?

- Adjustment

- Instructions for replacing the rocker on a VAZ-2110

- Backstage replacement and repair

- Repair

- Differences between a short-stroke link

Repair or replacement

Before deciding whether repair, adjustment or replacement of the link is necessary, it will have to be disassembled.

- Remove the cover on the gear shift knob;

- The machine must be installed on a jack or on an overpass (pit);

- Remove the front console, which is bolted on;

- Remove the rocker by unscrewing 6 bolts.

During this procedure, carefully inspect all parts. You definitely need to bend the boot and inspect the condition of the support, cardan shaft, and oil seal.

It may be necessary to use a rem. kit, and perhaps a more complex repair is needed.

If the bushing is deformed, it needs replacement. If the cardan has play, as well as if the hole in the lever axis is worn, a complete replacement of the link and repair belt is necessary. the kit clearly won't help.

It happens that the rocker pad is to blame for the rattling noise when changing gears. Replacing a pillow is a simple operation, but can be beneficial.

Replacing a car's rocker, eliminating play

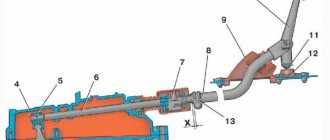

The design of the gear lever movement device is invented with the aim of uninterrupted operation of the gearbox. You can repair the backstage yourself or with the help of a partner for convenience. Most car enthusiasts are inclined to replace the standard rocker with a short-throw one. Installing a short-throw rocker is a type of tuning that allows you to reduce the limit of movement of the gear shift lever.

When using such a link, gear shifting occurs clearly and quickly. The process of replacing a regular link with a short-stroke one is quite simple. It is necessary to lift the fastening of the iron rod that runs from the gearbox to the shift lever in the passenger compartment. In this case, it is not necessary to remove the link; you only need to disassemble the spherical support.

Then open the iron ring until the plastic tabs move apart and the ball is released. After this, loosen the clamp near the gearbox, disconnect the rod and drag it in using the dirt cover. While in the pit, cut off the parts and weld a pipe into a rod, no more than 2-3 mm thick, and a piece of sheet metal, 5-6 mm thick. The rod is usually cut off by 2-4 cm.

A simpler option, but quite expensive, is purchasing a new rod. A short-stroke slide costs about 700 rubles.

Large play on the rocker is a disease of the car model in question, the cause is the original gearbox driveshaft. To carry out repairs, you need to purchase the cardan itself. For this car, it is suitable from Kalina; it is purchased together with the boot. For the repair itself, a minimum of tools is required: keys “13” and “10”, a screwdriver and a hammer.

https://youtube.com/watch?v=4E5QvJcfEf4

Repair or replacement is carried out on an inspection pit or lift. You will need the assistance of an assistant to make subsequent adjustments to the shift lever. Using two keys set to “13”, stretch the clamp on the rod and pull the drive off the rocker rod. Use a screwdriver to push the boot towards the gearbox or remove it completely.

Unscrew the bolt and knock down the cardan with weak blows of a hammer. Installation of a new one is carried out in the reverse order, that is, first you need to put the boot on and the cardan on the shaft. After the bolt aligns exactly with the recess on the shaft, put the boot on the universal joint.

Making a short-stroke slide with your own hands

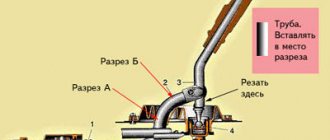

The diagram shows in detail where you need to cut with a grinder, and where you need to cook.

So, let's begin the modernization process:

- We raise the place of attachment of the piece of iron that goes from the gearbox to the lever inside the VAZ 2110 interior.

- You can do without dismantling the rocker, the main thing is to disassemble the ball joint.

- Now we need to ensure that the plastic paws release the ball.

To do this, you need to unclench the metal ring. We disconnect the rod and carefully drag it inside through the cover, which is responsible for protecting it from dirt. It will be much more convenient to work if the clamp near the gearbox is loosened. Adjustment is made using this lever.

Guided by the diagram, we cut off the parts using a grinder. It is necessary to weld a piece of metal pipe with a wall thickness of about 3 millimeters into the rod. To avoid skew, it is necessary to use identical pieces. The rod can be lengthened by 2-4 centimeters. All that remains is to raise the hinge with a hook, which serves to prevent an erroneous shift to reverse gear 2110.

Replacement is carried out according to the same scheme. Only instead of welding, a freelance short-stroke rocker from another car is installed. Replacement is a more expensive solution, so doing it yourself is problematic. If you have experience working with gearboxes, then replacing and purchasing a new part will cost about 1,000 rubles.

How to replace the universal joint on a VAZ 2110-VAZ 2112?

It is possible to remove this hinge only on an overpass, inspection hole, or if you raise the car, because this hinge is located under the bottom and you will need to crawl under it to unscrew both bolts that secure it!

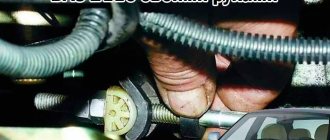

1) At the beginning, as you already understood, you will need to crawl under the car, after that, look for the boot there (Indicated by the arrow) and the hinge itself, which is located under this boot, so after that, take two keys in your hands and with one holding the bolt from turning, loosen slightly tighten the nut of this bolt as shown in the figure, and after the clamp nut is loosened, grab the rod with your hand and remove it from the hinge as shown in the small figure.

Before you start unscrewing the nut of the tie rod bolt, drag the boot towards the box so that it does not interfere, and after you disconnect the link, drag the boot towards it and thereby completely remove it from the car!

2) Now you will need to unscrew another bolt that secures the hinge in the front part to the gear selector rod, so after this bolt is unscrewed, you can pull the hinge and calmly remove it from the place where it is installed.

When you install the new joint, you will need to get these bolts into the hole in the gear selector rod, so remember approximately where this bolt is located after installing the new joint in the same place and screw it in so that it fits into the hole in the gear selector rod!

Installing a new hinge is carried out in the reverse order of removal, but only when you install the hinge will the linkage necessarily need to be adjusted, otherwise the gears will not engage clearly and instead of, for example, first gear as mentioned earlier, the reverse gear may easily engage. (For information on how to adjust the rocker, see the article entitled: “Replacing the rocker on a VAZ”)

If you want to study in more detail how the hinge is removed and installed, then watch the video below that clearly shows everything:

I had this driveshaft from a viburnum, and it came to the point that I won’t be able to install it again due to the fact that it transmits all the vibration to the gearshift knob, which is why it constantly cracks.

Top 5 (By votes)

- home

- Articles

- VAZ 2108, VAZ 2109, VAZ 2110, VAZ 1117 Kalina, VAZ 2170 Priora

- We are making a replacement. We are making a replacement.

On VAZ-2108, VAZ-2109, VAZ-21099, VAZ-2110 cars, there is a lot of play in the gearbox and, as a result, unclear gear shifting is not uncommon. We can say that this is a disease or a lack of cars of these brands. And the reason for this “illness”, first of all, lies in the original gearbox driveshaft. If you are interested in how to eliminate this drawback, reduce play in the rocker and increase the comfort of gear shifting on your “eight”, “nine” or “99”, then read the article further...

Installing a gearbox driveshaft from Kalina

- The gearbox control rod joint is hidden under the boot.

- We remove the boot and move it to the gearbox.

- Loosen the clamp bolt to 13, loosen it a little and pull the link off the hinge. Then unscrew the 10mm bolt that secures the hinge on the gear selector rod and remove the hinge.

- We install a new hinge without play on the gear selector rod and secure it with a 10-point bolt. To prevent it from turning away from vibrations, we lubricate it with a thread locker.

Impressions from the backlash-free driveshaft of the Lada Kalina on a VAZ 2110

xn--2111-43da1a8c.xn--p1ai

How to repair a gearbox shifter

Let's look at the removal and repair of a gearbox using the example of a manual transmission selector. The automatic transmission gear shift lever is removed in the same way.

Since the design of the lever is quite complex, and its repair requires the use of special tools, the best option would be to contact a car service center.

If you decide to repair the gearbox yourself, stock up on a 10-size wrench, a 12-size wrench and socket head, a 6-size hex key, an extension cord, a wrench, and pliers.

Before starting repairs, remove the gearbox rocker as follows.

Dismantle the lining of the floor tunnel, disconnect the ends of the transmission control drive cables from the levers with which gears are selected and shifted, remove the bracket that secures the cable shells in the sockets of the gearbox selector rocker, remove the cable ends from the sockets of the mechanism.

Next, you need to unscrew the bolts used to secure the gearbox rocker to the base of the body and dismantle the mechanism. Repair of the mechanism is carried out according to the following algorithm.

The tightening of the nut on the selector axis is loosened, while the axis is kept from turning using a hex wrench. The nut is unscrewed, the spring and flat washers are removed from the axle, the axle is removed from the holes in the rocker, as well as the flat and spring washers, the selector lever is removed along with the return spring and the flat washer placed under the lever.

The rubber damping bushing of the return spring is removed from the threaded end of the bolt that secures the transmission lever support cover. If the bushing is significantly deformed, torn or in a hardened state, it should be replaced.

The nut that tightens the bolt that secures the gearbox selector support cover is loosened. Then it is unscrewed, while the bolt is held from turning with a second key, the spring and flat washers located below are removed, the bolt is removed together with the flat washer from the holes of the rocker.

The cover of the manual transmission selector support is dismantled, the lever is removed from the rocker support.

If necessary, plastic crackers are removed from the ball ends of the gear selector knob.

Dismantled parts are carefully inspected. In case of deformation or weakening of the return spring, significant wear of the plastic bushings of the gear selector lever, deformation of the lever, wear or damage to the cotters of the manual transmission lever, they do not need to be repaired, but replaced.

If it is necessary to replace damaged or hardened bushings of the gearbox support, the spacer metal bushings are removed from the holes of the rubber bushings, and then the rubber elements are removed from the holes of the gearbox rocker.

After repair, assembly and installation of the transmission lever linkage is carried out in the reverse order.

What to do if the gearshift lever on a VAZ 2109 and 2110 is loose? We can fix everything

- Designer error. The metal bushing clings to the rod when moving. The result is a rattling sound. There is no way to fix the problem;

- Bushing failure;

- Lever from Lada Kalina;

- Malfunction of the backstage cardan;

- Wear of the box or its fastenings.

AutoFlit.ru

Replacing the backstage on VAZ 2110, VAZ 2111, VAZ 2112

Welcome! The rocker - it is responsible for changing gears in the car, it stands under the bottom of the car and goes into the interior, at the end of the rocker (on its rod) a cover is put on, which is popularly called the gearshift knob cover, you also grab this cover when changing gears in the car .

Note! To replace the rocker on a car of the tenth family, you will need to stock up on: A set of wrenches, as well as an extension cord with a socket head and a screwdriver!

Where is the backstage? As mentioned earlier, it is hidden under a cover (Indicated by an arrow), so to get to it you will need to first pry the cover in the front part with your nails and then remove it from the backstage and then you will have almost complete access to it, and practically because that the rest of the rocker is located under the bottom of the car.

When do you need to change the backstage? Many people at the very last moment think about the rocker, because if the rocker is incorrectly adjusted or worn out, such things happen to the car that the first thing that comes to mind is a malfunction of the box, but still, let's look at these things that will tell you that the rocker is not adjusted correctly or needs to be replaced, firstly, the rocker may stop engaging the first gear, and with the exception of all the others except the first, the fifth may not engage, and the last sign that also indicates a malfunction of the rocker is when you get into the car, engage first gear and then give the gas to take off beautifully, but instead of your car starting to move forward, it suddenly goes back into the car parked behind, of course I don’t want you to find yourself in such a situation, well, the point is that when malfunction or if the rocker is incorrectly adjusted, after engaging first gear, reverse gear can easily engage and you will go back without expecting it.

Diagnosis of the problem

The gearbox linkage in a car is necessary so that the unit cannot independently change gears as a result of the simultaneous movement of the sliders. This mechanism requires careful care, as well as periodic and high-quality adjustments. If the adjustment is performed poorly or some time has passed, this may manifest itself while the car is moving and the driver will feel discomfort.

VAZ 2110 car

In practice, as a result of constant use of a car with a rocker drive that requires adjustment, the vehicle may be at risk of breaking the entire transmission system. Therefore, attention should be paid to the quality of the unit’s operation and problems that arise during operation should not be neglected.

To understand that in your VAZ 2110 you need to adjust the rocker shaft, you just need to pay attention to the operation of the gearbox unit. Symptoms of the malfunction will be as follows:

- There were problems with engaging first gear. In particular, it will be impossible to turn on the gearshift lever, and sometimes it will be impossible to switch from first speed to second.

- Instead of first gear, reverse gear is engaged. Imagine: you are about to start moving and engage first gear, but instead your vehicle starts moving backwards. Perhaps after switching to “neutral” the problem will disappear, but over time it may happen again. In this case, in 98% of cases the problem lies precisely in the rocker shaft, that is, this has nothing to do with the speed lever.

- There may be problems with engaging first and fifth speeds. At the same time, all transmissions will work normally.

New component of the VAZ 2110 transmission system - A large amount of play has appeared in the gearbox selector, that is, when switching the lever, you noticed that a gap has appeared. Apparently, the rocker in your vehicle is out of order and adjusting it will no longer help: you will have to repair the mechanism.

- A new extraneous noise has appeared, uncharacteristic of the gearbox of your VAZ 2110. In particular, the rocker began to ring, that is, you feel a distinct ringing from under the unit. This problem can be called the VAZ 2110 disease, since many car enthusiasts have encountered it. In this case, the cause of the breakdown may be an inaccuracy made during the assembly of the car at the enterprise or errors made by the car owner or a mechanic at a service station when adjusting the mechanism. It is also worth noting that the ringing often appears after repair work has been carried out on the chassis.

- The speed may simply jump out. That is, you have engaged a gear, but when accelerating, the car immediately loses power because the gearshift lever automatically engages neutral speed. This will require some fine adjustments.

- Vibrations of the gearshift lever. If the linkage is faulty, the driver may feel increased vibration of the gearbox selector. Often this indicates the appearance of a small gap in the hinges of the gearbox unit.

Loading …

How to choose a new backstage?

What kind of rocker should I put on a Niva Chevrolet? This question came to the mind of every Niva car owner who had to deal with a malfunction of this element. In fact, there is nothing difficult in choosing a component.

In practice, many car owners of the above car models install mechanisms from classic Fiat cars on their vehicles. According to reviews on the Internet, these devices are completely suitable for installation in a Chevrolet Niva. However, there is also a negative side. In practice, Niva cars equipped with a mechanism from Fiat cars require more careful adjustment of the element. In addition, despite Italian quality, these components of the transmission system are more susceptible to wear and tear.

Therefore, when choosing a mechanism, you should not “be fooled” by the stories of handicraft “garage” craftsmen and come up with a new headache for yourself. For installation in a Chevrolet Niva, it is better to purchase a standard rocker, which is equipped with basic models of Niva cars.

New rocker for Niva Chevrolet

Replacing an element

As a rule, the need to repair this component arises after installing or repairing the gear shift drive. If you have replaced the drive, but when driving you feel how the vibration of the gearbox lever remains, then, most likely, there is increased play in the lever hinge mechanism. This means that the hinges should be repaired, and accordingly, it may be necessary to replace the rocker.

Read more: Steering wheel anti-theft lock

If you decide to replace a component at home yourself, then prepare in advance everything that you may need during the work process. In particular, we are talking about:

- wrenches on "12";

- wrench set to “14”;

- socket wrench at “10”;

- clamp for securing the gearshift lever cover;

- stationery knife;

- Phillips screwdriver.

Of course, you will also need a new mechanism if you decide to replace it.

First of all, open the hood of your Chevrolet Niva and find the connection between the tip of the gearshift lever and the gear shift rod. Once you see this connection, take the appropriate wrench and loosen the nut of the mounting screw. After this, remove the turnbuckle and its protective cover. Now get into the car and remove the front part of the floor covering. Next, remove the gearshift lever cover frame

Be careful, you will need to remove it carefully to avoid damaging the clips. Next, you will need to turn the shift lever boot inside out. Having done this, you will see the cover fastening clamp

Take pliers or a regular stationery knife and cut through this clamp. After this, the cover can be removed from the lever. Please note: the gearbox lever mounting clamp is disposable. That is, if you bite it with pliers or cut it with a knife, you won’t be able to reinstall the part in its original place. Therefore, when assembling the parts, you will need to install a new clamp. Next, you will need to remove the front portion of the floor tunnel lining. Depending on the year of manufacture of your Chevrolet Niva, the instructions for dismantling the floor tunnel lining may differ. Therefore, we recommend that you use the instruction manual specific to your car. Now look at the gearshift lever. You will see that the axle lock is attached to it: this element must be disconnected from the lever. Having done this, the lever axis can be dismantled, simultaneously removing this axis from the holes of the gear shift lever and the rocker. When the axle is removed, you need to remove the gearshift lever. To do this, you will need to pull the lever itself up. Then take a screwdriver and push the plastic bushing inside the gear lever housing. You need to move this element along the shaft. Now, using a wrench, you need to unscrew several screws securing the gearshift lever housing to the car body. By unscrewing and dismantling the bolts, you can remove the housing and remove the gearbox shaft from it. Next, remove the guide rod from the shaft. Now you will see your backstage. If you see a large play in the hinges of the element that cannot be adjusted, or the hole for the lever axis is too worn, then you need to remove the mechanism and replace it with a new one. Since the process of replacing this element is not so easy, we recommend that you visually inspect all dismantled parts. If you have any doubts about their performance or reliability, it is better to replace them immediately. After replacing the backstage, all parts must be assembled in the reverse order. Don't forget to install a new shift lever clamp.

After installing the rocker, you will need to adjust the gearbox shift drive.

Parts and tools required for replacement

Before you start replacing the crosspiece, you need to purchase the necessary parts and arm yourself with tools. So, when buying an outboard bearing, you first need to check the smoothness and elasticity of the rubber. If suddenly the bearing rotates with a kind of snag, then it is better not to buy one. And in general, there are many secrets. You need to understand the details and spare parts in order to avoid mistakes. Likewise with rubber, if it is too hard, then after installing the cardan and crosspiece, the car will vibrate while driving, since insufficiently elastic rubber will transmit oscillatory movements. As for the crosspiece, it is better to take a new one from VAZ, and do not forget to purchase retaining rings at the same time, because it will no longer be possible to install the old ones, since they will either quickly fail or are no longer suitable for use.

Now let's look at what tools you need to prepare. To replace the suspension bearing and crosspieces on a VAZ, you will need to arm yourself with the following tools:

- wrenches and spanners 12, 13, 27;

- copper or aluminum insert;

- hammer;

- compression pliers for working with retaining rings;

- tension puller;

- flexible coupling flange.

Replacing the cross

We begin work, as always, by lifting the car onto the inspection hole. You can also use the overpass. It is worth considering that when working in a pit, you will have to use a jack when you need to unscrew the cardan mounting nuts from the rear side.

Removing the cardan

So let's begin:

- remove the parking brake cable spring;

- using a center punch we apply marks where the cardan is connected to the gearbox;

- take a 13mm wrench and unscrew the bolts securing the suspension bearing to the transverse support;

- unscrew the nuts that secure the cardan to the rear axle;

- when unscrewing bolts and nuts, it is recommended to hold the cardan with a screwdriver to avoid twisting;

- First, remove one end of the cardan;

- using a center punch we mark the position of the centering flange of the EF and the cardan to each other;

- bend the locking tabs on the seal ring in the place where the ESP is located;

- we move the cage towards the cardan together with the seal;

- take the 13mm head and use it to unscrew the nuts securing the safety bar;

- remove it;

- move on to the outboard bearing plate;

- take a 13mm wrench and unscrew the nuts securing the part;

- remove the cardan from the EF splines;

- we extract it.

At this stage, the removal of the propeller shaft is completed. This video will help you do everything right

Cardan disassembly

Before disassembling the driveshaft, it is necessary to mark the relative positions of the parts with a center punch or chisel. You can also use paint for these purposes. A mark is made so that the initial balancing is not changed. So:

- we mark the placement of the forks and shaft relative to each other;

- remove the retaining rings using pliers;

- take a puller and install it on the crosspiece fork;

- press out the bearing, which should fall into the puller cup.

It is worth remembering that a bearing of this type extends out of the fork only a third of its height.

- the opposite bearing should be pressed out accordingly;

- take a hammer and a screwdriver and knock out the pressed bearings completely from the fork body (the screwdriver needs to be rested against the edge of the bearing);

- remove the fork from the cross;

- press out the other pair of bearings in the same way.

That's all. We finish disassembling the cardan. All retaining rings must be removed, all lugs must be cleaned of rust and dirt, as well as the grooves for the retaining rings.

Installing a new cross

Installing the crosspieces will not be difficult. You will need to remove two cups from the opposite side of the crosses and insert new ones into the springs. Begin:

- take plastic plugs and install them together with seals;

- bearings should be lubricated with Fiol;

- using a removable device, press the bearings into place;

- install the retaining ring;

- press in the second bearing on the other side of the fork so that the first rests against the retaining ring;

- after that we install the second retaining ring;

- take a hammer and a bit (a screwdriver will do);

- With light blows you need to drive the locking rings all the way;

- take a special feeler gauge and measure the gap.

Attention: It is worth noting that a gap of 0.04 mm between the retaining ring and the bearing is considered normal. As you know, retaining rings come in different sizes. Their difference is not only in diameter, but also in thickness. Each type and size of locking rings has its own color, which helps the consumer when choosing. Thus, completely unpainted rings are the thinnest in thickness, and yellow ones are the thickest.

Removal and repair of outboard bearing

Typically, the suspension bearing (pictured above) comes in two types: removable and non-removable. It is clear that in the first case no problems should arise, but in the second it will be necessary to change the driveshaft assembly, which will not be very cheap. The malfunction of the removable outboard bearing can be determined with your own hands, based on the following steps:

- when driving, you can hear a kind of hum that comes from nowhere;

- the car is lifted onto an inspection pit or overpass, where a specialist or driver makes sure that the noise is coming from the part of the car where the suspension bearing is located (it must be taken into account that the noise is often accompanied by vibration);

- the universal joint fastening bolt is unscrewed and lowered to the ground (in this case, you need to do everything carefully, as required by the instructions, so that all the oil does not leak out in vain);

- We check the bearing for play, which is the main criterion for evaluating performance.

Replacing the outboard bearing is not that difficult. It is done after the driveshaft is removed (how to remove it is discussed above). It would be a good idea to arm yourself with vinegar or a special liquid that will help decarbonize the bolts and nuts that may be rusty. So, let's start:

- remove the rear driveshaft and, of course, the crosspiece;

- take the 27mm socket and use it to unscrew the nut securing the front cardan fork;

- take a puller that is placed on the fork;

- press the fork off the spitz;

- take a 13mm wrench and unscrew the bolts securing the outboard bearing, which secure it to the plate;

- knock out the bearing from the shaft, resting it on the corners;

- the cardan is assembled in the reverse order;

- The slots must be lubricated with Fiol-1 grease and the previously marked marks must be aligned;

- the seal ring is assembled after installing the splined part of the cardan;

- the locking tendrils are bent after the clip moves forward.

The step-by-step instructions presented to the reader above will help all motorists repair their car. As you know, the price of repair services today is not cheap and it would be simply inappropriate not to use the advice given above. All the tips and recommendations given above were put into practice not only by specialists, but also by ordinary novice motorists.

Adjustment

The backstage adjustment should be made in several cases:

- after dismantling the gearbox;

- when the cardan has been replaced or the fixing clamps have become loose;

- if the linkage rotates on the hinge.

Of course, this will also be advisable if you have recorded signs of a malfunction of the element, which are described in the previous paragraph.

What to cook?

Before you begin repairs, prepare in advance:

- wrench to loosen the clamp;

- wheel chocks or bricks.

Universal wrench

You will need wheel chocks...

...or the most ordinary bricks

Step by step instructions

To perform repairs, that is, adjustments, you need to perform the following steps:

- First, drive your VAZ 2110 into a garage with a pit or onto an overpass.

- Place bricks or special wheel chocks under the car. Apply the handbrake.

- Climb under the bottom of the car and find the clamp that secures the linkage and hinge.

- Use a wrench to loosen the clamp.

- Then sit in the driver's seat and put the car into reverse. Remember that the lever must be in the extreme left position. Therefore, set it the way you think it should ideally be when engaging reverse gear. It is advisable to do this work with an assistant so that he holds the gearbox lever in the position you set it.

- Now again climb under the bottom of the car and firmly fix the clamp in this position.

Reach under the bottom and loosen the clamp, then set the gearbox lever to the reverse gear position

This completes the adjustment of the device. Take a test drive and check the operation of the unit. If necessary, repeat all steps again.

Backstage adjustment:

Note! Before you go to the auto store and buy a new rocker, be sure to try to adjust the old one first so as not to waste money, maybe everything is fine with the old rocker!

1) At the very beginning of the operation, we will tell you why the adjustment of the rocker may go wrong, namely, after removing the box, after replacing the cardan shaft, or after unscrewing the nuts and bolts that secure the tension clamps of the rods that come from the rocker, and in other cases.

2) Now let’s move on to the actual adjustments, firstly, you will need to first drive the car into a pit or lift it using a lift, then climb under the bottom of the car and there you will find the boot under which the driveshaft itself is located (the boot is indicated by a red arrow), next to with this cardan and the boot that covers it, the end of the rod coming from the rocker itself will be attached, and this end will be attached using a tie clamp, so take two screwdrivers in your hands and with their help loosen the bolt nut a little (the nut is indicated by a blue arrow, and the bolt green), while when you loosen, hold the bolt itself with one wrench so that it does not turn, and with the other at this time loosen the nut, after the nut is slightly loosened, take a screwdriver in your hands and insert it into two holes, namely in the hole between the tie clamp (Indicated by a yellow arrow) and into the hole of the rod itself (Indicated by a white arrow), thereby widening both holes (In fact, these are not holes but a groove, so in the future we will use this word) so that the link rod can easily move relative to gear selector rod.

Note! Before you crawl under the car, put the car into first gear!

3) After you loosen the tension clamp, get out from under the car and return to the car interior. In the cabin, move the gear shift lever all the way to the left, but forward or backward and do not even try to pull it.

4) And to complete the operation, again climb under the car and tighten the nut of the same bolt that secured the tie rod of the rocker link.

Note! When all the operations are completed, test the gearshift lever for functionality, namely, check whether all gears engage clearly, start the car, drive it a little and if the shifter is working, then everything will be fine and you won’t even need to change anything!

By the way, another way (almost the same method) of adjusting the rocker, see the video clip below, in this video an example is shown on a VAZ 2109 car, but don’t pay attention to this, since the entire gear shift mechanism is on front-wheel drive cars VAZ, including the top ten, is practically no different from each other!

Reasons for replacement

There are several situations when the owner of a VAZ 2109 has or wants to get into the design of the gearbox and specifically work with the rocker:

- Oil is leaking due to a damaged rocker seal. It must be replaced;

- The old drawstring was out of order;

- I would like to exchange the long-stroke for a short-stroke in view of its advantages.

Now to the question of when replacing or repairing the backstage is a necessary measure.

- The backlash of the gearbox selector has increased significantly.

- Gears change with difficulty, and when changing speed, extraneous sounds appear.

- It is possible to change gears, but with a lot of effort.

- Speeds change incorrectly. Instead of one, a completely different one turns on.

- It is impossible to turn on all or part of the gears at all.

Even if the resulting play is still insignificant, it is advisable to immediately begin repairs or completely change the drawstring.

Replacing the oil seal

If you find that the oil in the gearbox is gradually disappearing, you can suspect the rocker seal. There is nothing else left to do but change the element.

- First, buy a new shift rod seal. It costs about 70-100 rubles.

- Drain the oil from the box, having prepared a clean container in advance. This is in case you refill the same oil. Although this is an excellent reason for you to change the transmission lubricant at the same time.

- To make sure the oil flows out better, first unscrew the filler plug or remove the speedometer gear. After draining the oil, screw the cap back on.

- We climb under the car and disconnect the fasteners of the gearbox lever driveshaft.

- Pull the boot off the cardan, unscrew the bolts securing it to the gearshift rod. Problematic fasteners that you will have to tinker with.

- After removing the cardan shaft, remove the rod boot.

- We remove the damaged oil seal using an awl or suitable available tools. The main thing here is the stock itself.

- We install a new one in place of the old oil seal and press it with a tube of the appropriate diameter.

- Put the boot back in place and rotate the driveshaft.

- Please note that the bolt securing the cardan to the rod is an adjustment bolt. Therefore, screw it in exactly the same way as before dismantling. Otherwise, some speeds may not turn on.

After the work done, do not forget to check the result.

Replacing the cardan

Practice shows that if problems arise with the slide, it is not at all necessary to completely change it.

The instructions for replacing the cardan are as follows.

- Using two 13mm spanners, unscrew the clamp that relates to the speed switch drive rod.

- Pull the boot off with a screwdriver, moving towards the box. If you want, remove it completely. So it definitely won’t interfere with the repair process.

- Using a 10mm wrench, unscrew the fixing bolt on the cardan.

- Apply several gentle, not strong blows with a hammer to knock the cardholder off the shaft. Remove the boot to the side if you have not done so before.

- We replace the old cardan with a part from Kalina. It is more reliable, efficient and durable.

- For reassembly you will need the help of a friend. Do not rush to tighten the clamp immediately at the end.

- The assistant will set the position of the gearshift lever at the optimal points from inside the cabin. First you need to catch the center, then move the lever a little to the right while you tighten the clamps from below.

- Check if the gears engage well. If yes, then we continue assembling the unit and check the updated gearbox under real road conditions.

The experience of VAZ 2109 owners shows that when there are problems with the rocker, the essence often lies in an unsuccessful factory cardan. By replacing it with an analogue from Kalina, you will be able to get rid of discomfort and continue to confidently operate your car. By replacing the cardan shaft, the design of the gearbox will improve significantly.

Adjustment

After changing the link or cardan, you should definitely adjust the operation of the unit.

- Engage reverse gear, loosen the clamp tension.

- Set the gearbox selector to the position in which it should ideally be located when engaging reverse.

- Tighten the clamp back.

- A similar operation is performed with other speeds.

There are situations among VAZ 2109 owners when difficulties arise when engaging reverse gear. This is where adjustment can help.

- Set the gear lever to first gear;

- Loosen the rocker clamp;

- Turn the rocker drive counterclockwise;

- Turn the drive until the selector is pressed against the plastic stopper for the reverse gear. You will feel this without any problems;

- Resting against the stopper, tighten the clamp under the bottom. That's it, the adjustment is done.

Instructions for replacing the rocker on a VAZ-2110

If adjusting the part does not give positive results, there is only one thing left to do - replace the part or try to resurrect it through repair, but in the latter case you will need the help of knowledgeable repairmen.

Replacing the VAZ-2110 backstage looks like this:

- Prepare the necessary tools in advance so that you don’t have to be distracted from your work later. What you will definitely need:

- screwdriver;

- side cutters;

- set of wrenches.

You won't be able to cope without a repair kit designed specifically for the VAZ-2110.

- Now that everything is at hand, open the hood and find the nut connecting the transmission rod and the tip of the handle.

- Remove the special protective cover from the nut and tighten the turnbuckle.

- Get back into the car and take out the frame that fits the lever that controls the transmission. Clamps may interfere with this work, but you can’t get rid of them, spend a little time and everything will work out.

- Turn the cover inside out.

- Using a sharp knife, cut the clamp to secure it and remove the cover. It's okay if you couldn't avoid damaging the integrity of the clamp. It is disposable, so the clamp will still have to be replaced with a new one.

- Get rid of the tunnel lining on the floor.

- Disconnect the axle retaining part from the gearbox handle.

- Pull out the gear knob by pulling the lever up.

- Slide the sleeve inside the lever, which is responsible for the direction of the part.

- Remove the 4 mounting bolts holding the guide bushing in place.

- Remove the housing and remove the shaft.

- Now look at the nodes. If there are signs of wear on the rubber part, the bushing cannot be repaired and must be replaced. If the hole located under the handle axis is severely worn out or the play is noticeable to the naked eye, it’s time to change the link.

- Return all parts to their original place and adjust the operation of the gearbox.

Video on how to replace the rocker on a VAZ-2110:

Installing a gearbox driveshaft from Kalina

- The gearbox control rod joint is hidden under the boot.

- We remove the boot and move it to the gearbox.

- Loosen the clamp bolt to 13, loosen it a little and pull the link off the hinge. Then unscrew the 10mm bolt that secures the hinge on the gear selector rod and remove the hinge.

- We install a new hinge without play on the gear selector rod and secure it with a 10-point bolt. To prevent it from turning away from vibrations, we lubricate it with a thread locker.

Impressions from the backlash-free driveshaft of the Lada Kalina on a VAZ 2110

xn--2111-43da1a8c.xn--p1ai

Backstage replacement and repair

Taking into account the fact that during operation of a car, the rocker on a VAZ or on any other car experiences constant loads, the mechanism wears out, and adjustments get lost

For this reason, it is important to understand what in a particular case would be the optimal solution: repair, adjustment or replacement of the rocker with a standard new one or a short-stroke one

In any case, it is necessary to first disassemble the mechanism. To do this you will need:

- remove the cover on the gearshift knob;

- drive the car onto a pit or overpass/lift;

- remove the tunnel where the gearshift knob is installed by unscrewing the bolts;

- dismantle the rocker itself (on a VAZ 2110 it is secured with six bolts).

During the disassembly process, you need to carefully check the condition of each individual part, you should also bend the boot, check the condition of the support, oil seal, cardan, etc.

If, for example, the oil seal has failed, then it is enough to have a repair kit where such an oil seal is included. This kit will also come in handy if more complex repairs to the backstage are required.

We also note that a common problem that drivers note during operation is the rattling of the rocker. Typically, in this case, if there are no other complaints, the drawstring cushion is often the culprit.

At the same time, replacing the rocker cushion is not a complicated procedure, but the result is often positive and significantly increases the comfort when operating the vehicle.

Another important procedure in the process of servicing the rocker is replacing the rocker rod oil seal. It is important to understand that the serviceability of not only the operation of the scenes, but also the gearbox directly depends on its condition

If drops of transmission oil are visible under the car, this often indicates that the seal is leaking. As a rule, problems with the VAZ 2110 rocker seal appear in the form of a crunching noise when switching.

As for replacing the oil seal, the car needs to be driven into a pit or raised on a lift. Next, you should inspect the rubber boot. If it is not sealed or is torn, traces of oil will be visible.

Then you should bend the boot, disconnect the cardan and thus gain access to the cuff. Now the cardan is removed from the lever, after which it is disconnected from the rocker. After removal, you can get to the oil seal and then use an awl or hook to remove the gearbox cuff.

In fact, such repairs allow you to avoid oil leaks in the gearbox and improve the operation of the gear shift mechanism

Finally, we note that it is also important to carry out adjustments and settings after repairs.

The fact is that even a serviceable, but incorrectly configured rocker will not work properly. By the way, on a VAZ 2110 it’s difficult to set up the rocker yourself. To make the process easier, it is better to immediately invite an assistant.

Making a short-stroke slide with your own hands

The diagram shows in detail where you need to cut with a grinder, and where you need to cook.

So, let's begin the modernization process:

- We raise the place of attachment of the piece of iron that goes from the gearbox to the lever inside the VAZ 2110 interior.

- You can do without dismantling the rocker, the main thing is to disassemble the ball joint.

- Now we need to ensure that the plastic paws release the ball. To do this, you need to unclench the metal ring. We disconnect the rod and carefully drag it inside through the cover, which is responsible for protecting it from dirt. It will be much more convenient to work if the clamp near the gearbox is loosened. Adjustment is made using this lever.

- Guided by the diagram, we cut off the parts using a grinder. It is necessary to weld a piece of metal pipe with a wall thickness of about 3 millimeters into the rod. To avoid skew, it is necessary to use identical pieces. The pull can be lengthened by 2-4 centimeters.

- All that remains is to raise the hinge with the hook, which serves to prevent an erroneous shift to reverse gear 2110.

Replacement is carried out according to the same scheme. Only instead of welding, a freelance short-stroke rocker from another car is installed. Replacement is a more expensive solution, so doing it yourself is problematic. If you have experience working with gearboxes, then replacing and purchasing a new part will cost about 1,000 rubles.

Repair

Regardless of what exactly you do with the rocker - repair, adjust or change, you will still need to disassemble this unit.

Disassembly is performed as follows.

- Remove the cover from your gear shift knob.

- Place the car on a pit, or raise the front end with a jack.

- Remove the front console. It is held in place by mounting bolts.

- Now remove the curtain itself. To fix it, AvtoVAZ used 6 bolts in the case of the VAZ 2110 model.

- When carrying out dismantling work, be sure to examine the condition of all elements.

- By bending the boot, you will gain access to the support, oil seal and cardan shaft.

Changing the boot

Now regarding the repairs. There may be several recommendations in this regard, depending on the current state of the node and its components.

- At best, repairs will require the use of a repair kit for the backstage. It doesn't cost much.

- If the bushing is deformed, it will need to be replaced with a new one.

- Check the lever shaft bore for wear.

- Make sure there is no play in the driveshaft. Otherwise, a regular repair kit will no longer be enough, that is, a complete replacement of the entire backstage will be required.

- Often the culprit of extraneous noise and rattling when shifting gears in gearboxes is the rocker pad. Changing it is quite simple, and even a beginner can perform the operation.

Replacing the oil seal

Quite often, VAZ 2110 owners are faced with a situation where, after parking under the car, they find traces of oil. There are two options here - the oil filter has worn out or there are problems with the oil seal.

As you replace the oil seal, you will be able to simultaneously inspect and change such elements as the cushion, cardan shaft, and boot.

Dismantling works

But let's talk about everything in order. First of all, check whether it is really an oil seal and not a filter. If everything is fine with the filter, then we drive the car into a pit or find another way to end up under the bottom of your VAZ 2110. Beforehand, it would be a good idea to watch video materials regarding your current situation.

- Carefully inspect the boot. If oil leaks from the gearbox through the oil seal on your car, traces of it will definitely remain on the boot.

- Bend back the boot. This way you can get to the cardan, disconnect it and gain access to the cuff.

- You first need to dismantle the cardan from the lever, and only then from the rocker itself. Not the other way around.

- The cardan has been removed, so we move to the oil seal.

- The cuff is removed from the gearbox using a hook and an awl. Therefore, make sure you have these tools at hand in advance.

- Now a new one is installed in place of the old oil seal. Craftsmen have adapted to using ordinary plastic bottle caps. If you get used to it, it turns out to be very easy to change the oil seal.

- After replacing the element, return all dismantled components to their places. If some of them need replacing or signs of wear are already visible, it is better to replace them immediately. It is unlikely that you will want to repeat the same operation in a couple of weeks and lie under your own car.

Repair will not give the desired result if the adjustment was carried out with errors. To do everything carefully and competently, use the help of a partner. One will work under the car, the second will help from inside.

The gearbox is one of the most complex components of a vehicle. However, this does not mean that its repair cannot be done at home on your own. Now we will tell you what the VAZ 2110 rocker is, what may be the reasons for its malfunction and how to repair the mechanism.

Replacing rocker seals

Nothing frustrates a car owner more than traces of oil under the bottom while parked. The cause of this manifestation may be a worn out oil filter or a faulty oil seal. When installing a new oil seal, you can see and evaluate the condition of the rocker pad, cardan and boot.

Before you begin disassembling all components of the car, you need to find out the reason for the leakage of the oil mixture. If the reason is not the oil filter, you need to make sure that the oil seal is in good condition. To do this, the car is installed on a platform or lift. If the work of replacing and installing a new oil seal is being carried out for the first time, previewing a video on this topic will be very helpful.

- Climb under the car and make a visual assessment of the boot. If oil leaks through the oil seal, the boot will reveal this and there will be traces of oil leaks on it;

- Having bent the boot, you need to get to the cardan. Disconnecting the driveshaft will open the way to the cuff;

- The sequence of removing the cardan is strictly from the lever to the rocker, the reverse order is prohibited;

- After dismantling the cardan shaft, access to the oil seal opens;

- To remove the cuff you will need a hook and spike;

- A seal that has become unusable is replaced with a new one. Garage repair gurus use a plastic bottle cap as an auxiliary tool for this;

- After installing the new oil seal, the unit is reassembled. In this case, the condition of each element is necessarily checked for wear, and if necessary, the part is also replaced.

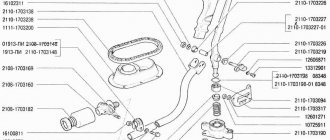

The backstage is a new model (Prior).

In general, I accidentally saw this miracle on the Internet, I wanted to find it and install it for myself. I bought parts from a 2014 Lada Priora, all assembled with levers and other fittings)

The clip is ten-size, the levers are completely similar to the old ones. The most interesting thing is the rocker, the handle is like on the new Priors and Grants with a manual transmission. In technical terms, it is similar to the viburnum wing, perhaps one to one.

It’s hard to say how she’s doing at work. But I would like to note right away that the reviews about this design are different, some are very negative! Someone has some play between parts 17 and 20; apparently the metal bushing in the center (part 18) is in the way.

It does not allow the metal discs (part 16) to be properly pressed against the plastic spacers (17) and the lever itself (20). Theoretically, if you sharpen it, there should be no more problems.

The scheme is Kalinov’s, but the essence is the same. Let's go and see!) Gearbox lever cage for VAZ 2110. I'll put the priority one with scanty mileage aside for now.

None

None

Tie rod joint for Lada Sport. There is exactly the same one only for 2108-2110. There are no repair kits for the stock joint, only this damper.

If the plastic bushings (2110-1703189) are still worn out, then it will not save the situation.

It’s very interesting how long it took for the old parts to last?!

The clip has fallen apart, there is play in the hinge. Photos of the installed goodies)

From the bottom everything is as it was, with the exception of updated spare parts)

Promised photo of the tunnel

Backstage restyling

None ps: I couldn’t pull the handle off. It is not clear how it is removed at all. I looked at other people’s posts and it turns out that on a grant, when replacing the handle with an alternative standard one, they simply saw and remove it... cruel, IMHO: D.

- avtozam.com

- vaz-2110.ru

- www.drive2.ru

- 24techno-guide.ru

Differences between a short-stroke link

The main differences can be seen even in photographs. We see that the short-stroke rocker has smaller dimensions, namely length. To reduce the stroke length at startup, the length of the transmission under the hinge should be increased. Due to this, we can not only get shorter gears, but also maintain the traction axis in its original position.

The photo shows a self-modernized backstage. As an alternative, you can use a part from other VAZ models.

It is worth understanding that after such tuning, you will need to put more effort when changing speeds. After upgrading, switching will resemble joystick control, which is undoubtedly a plus. In addition to the rocker, you can install a backlash-free cardan, which will also have a positive effect on the smooth operation of the gearbox.

Video instruction

Content

The gearbox in VAZ 2110 cars is one of the most involved dynamic elements. Because of this, the unit often becomes loose, which makes operating the car inconvenient. A shaking gear shift lever is a fairly common occurrence in domestic cars. There are two ways to combat this defect: constantly adjust the gearbox or make the rocker short-stroke - the process can be done independently. You can also purchase a gearbox repair kit from another VAZ model, which initially comes with a short-throw driveshaft.

This is what the installed short-stroke rocker looks like on a VAZ 2110 car.

What is so good about a short-stroke rocker? Firstly, it guarantees reliable operation of the gearbox over a long period of time. Secondly, the short-stroke version helps to increase the clarity of VAZ gear changes, including in the 2110 model. This is quite enough to make the operation of the power plant more comfortable, because smoothness, stroke and clarity of gear shifting are important for the gearbox.