01/26/2022 9,587 Sensors

Author: Ivan Baranov

Airbags (Airbags) are an integral element of the safety system of any modern vehicle. Therefore, in order to protect themselves and passengers while driving, the driver must always monitor the performance of this system. What functions does the airbag sensor perform and how to determine a malfunction in the system - find out from this material.

[Hide]

Where is the airbag crash sensor located?

The most effective element of passive safety is the use of airbag systems. The airbag system, combined with diagonal lap inertia seat belts, in the event of a frontal collision provides additional protection for the head and chest of the driver and front seat passenger and reduces the likelihood of severe injury and death in accidents by 40%.

Rice. Airbag system (using the example of an Audi A3): 1 – side airbag impact sensor behind the driver (C-pillar); 2 – squib cartridge for charging the gas generator of the driver’s upper airbag; 3 – squib cartridge for charging the gas generator of the driver’s seat belt tensioner; 4 – switch in the driver’s seat belt buckle; 5 – driver side airbag gas generator charge squib; 6 – driver side airbag impact sensor (front door): 7 – driver airbag gas generator squib; 8 – diagnostic socket; 9 – instrument panel with warning lamps for seat belts and airbags; 10 – engine control unit; 11 – driver’s front airbag impact sensor (left front part of the body); 12 – front passenger front airbag impact sensor (right front part of the body); 13 – warning lamp for disabling the front passenger airbag; 14 – switch for disabling the front passenger airbag, operated by key; 15 – diagnostic interface of the data bus (gateway); 16 – squib cartridge of the first and second charges of the front passenger airbag gas generator; 17 – airbag control unit; 18 – switch in the front passenger seat belt buckle; 19 – sensor for the presence of a passenger in the front seat; 20 – squib cartridge for charging the gas generator of the front passenger side airbag; 21 – side airbag impact sensor on the front passenger side (front door); 22 – squib cartridge for charging the gas generator of the front passenger seat belt tensioner; 23 – squib cartridge for charging the gas generator of the front passenger's upper airbag; 24 – side airbag impact sensor behind the front passenger (C-pillar); 25 – central control unit for comfort systems; 26 – gas generator charge squib to disconnect the battery

Vehicles equipped with an airbag system for the driver and front seat passenger can be identified by a lettering on the soft panel of the steering wheel and on the right side of the instrument panel.

The main elements of the Airbag system are:

- set of inertial electromechanical and electronic sensors (3….5)

- gas generator squibs (energy source)

- airbags for driver (in the steering wheel) and passenger (on the right in the instrument panel)

- electronic monitoring and control device

- warning lamp on the dashboard

Features of transporting children

Transporting children in a car equipped with airbags is a special driving mode. This is because deployed air bags can cause serious injury or even kill a child who is not wearing a seat belt.

That is why experts were united in developing special requirements for transporting children in a car with air bags.

Firstly, it is recommended to transport children only in a well-secured special seat and only in the back seat. » alt=»»> Secondly, if it is impossible to turn off the front passenger airbag, transporting children under 1 year in the front seat is excluded.

Thirdly, if you are driving with a child in a special seat in the front seat, the latter must be moved as far back as possible.

Sensors

Electromechanical shock sensors operate on the principle of a conventional limit switch - there is a metal ball in the tube, which, upon a sharp impact, overcomes the resistance of the springs and closes the contact, thereby forming an electrical circuit necessary for the operation of the system.

Currently, electronic sensors are used instead of mechanical ones. Such a sensor consists of a housing, a data processing unit and a micromechanical acceleration sensor, which can be piezoelectric, capacitor or other type.

A capacitor-type acceleration sensor is designed, to put it simply, like a capacitor. The individual plates of the capacitor are fixedly fixed. The elements associated with them are mobile and act as a seismic mass. During a collision, the seismic mass, in this case the moving plates, moves towards the stationary plates and the capacitance of such a capacitor changes. The data processing unit processes this information, converts it into digital form and transmits the data to the airbag control unit.

Rice. Scheme of operation of a capacitor-type acceleration sensor: 1 – fixed plate; 2 – movable plate; 3 – data processing unit; a – state of rest; b - collision

Instead of acceleration sensors for collision detection, some car manufacturers install pressure sensors . With these sensors, faster detection of impacts in the door area is achieved.

Inertial sensors are installed in the bumper, in the engine compartment, in pillars or in the armrest area. The sensors' memory contains parameters calculated in advance, which for a given car model mean exceeding the permissible impact. In the event of an accident, the sensors send a signal to the electronic control unit. In most modern systems, front sensors are designed for impact force at speeds of 25...50 km/h, while side sensors can be triggered by weaker impacts. From the electronic control unit, the signal is sent to the main module, which consists of a compactly laid pillow connected to a gas generator.

Control block

The control unit receives information from impact sensors and, based on them, sends signals to the required airbags. Essentially, it is a distributor that directs the signal from the sensor to a specific pillow. But since a modern system often includes additional tools, this block processes information from them, and also issues commands to trigger certain mechanisms.

The control unit is also involved in system diagnostics. After the engine starts, it sends control signals to the actuators, determining the integrity of the electrical circuit and the condition of the working elements. For example, if there is an open circuit, or the airbags have previously deployed, the unit will detect this and a warning light will light up on the dashboard, indicating that there is a problem in the safety system.

The diagnostic mode is not difficult, which is often used by car enthusiasts whose cars have faulty airbags or have deployed them.

Gas generator squib

The melting wire or flame front within the ignition element (primer) energizes the airbag gas generators. In modern designs, the capsule for igniting the gas generator is triggered by alternating current in order to prevent the occurrence of a short circuit in the vehicle's electrical DC power system (malfunction in the electrical wiring). To create alternating current, a capacitor is incorporated into the charging capsule and connected in series to the drive circuit, which charges, discharges, or recharges at approximately 100 kHz.

The gas generator, often called a squib (tablet) with a diameter of 10 cm and a thickness of 1 cm, uses crystals of solid fuel, the combustion of which releases gas that fills, or rather, inflates the pillow. The fuel is usually poisonous sodium azide (NaN3), 45% of the mass of which, when burned, turns into pure nitrogen, and the rest into carbon dioxide (CO2), carbon monoxide (CO), water (H2O) and particulate matter. An electrical impulse ignites the squib or melts the wire and the crystals turn into gas. The signal for triggering the squib is an electrical impulse from shock sensors (acceleration or pressure), arriving directly or through an electronic unit. Although the combustion process occurs quickly, it is not explosive. Combustion occurs in 3 stages: ignition, ignition for the fuse and combustion of the working charge. In a very short time the system develops power up to 60 kW, but no explosion occurs. Fuel combustion and inflation of the airbag with a volume of approximately 50...60 liters for the driver lasts 30...35 ms, the airbag for the passenger with a volume of approximately 100...140 liters is installed in the glove compartment area and inflates in approximately 50 ms. This time is less than the time it takes to blink an eye, which is 100 milliseconds.

To prevent injuries from inflating the driving pillow at a speed of 200...300 km/h towards the chest, modern pillows are inflated in two stages: first by about 70%, and when in contact with the body completely, two-stage gas generators are used for this.

Thanks to the radial straightening of the air bag and the sequential ignition of charges in such gas generators, the load that acts on the driver in an accident is significantly reduced. Depending on the severity and type of accident, the interval between the activation of both squibs can be approximately 5 ms. up to 50 ms. Both charges are always fired to eliminate cases when, after deployment of the airbag, there remains another squib that has not fired.

Gas generator

The main component of this system is the actuator - the gas generator. Its task is to generate a large amount of gas in a short time, which then fills the pillow itself.

The gas generator includes several components - a squib, a charge of a substance that releases gas, and the pillow itself.

Gas generator in the steering wheel

The squib is designed to ignite the charge. He can do this in two ways - by melting a wire placed in the combustion chamber, or by using a primer that creates a flame front in the chamber with the charge. It's simple - an electrical signal from the control unit is supplied to the squib, which leads to melting of the wiring or ignition of the capsule.

The combustion chamber of the gas generator is filled with a substance that can completely burn in the shortest possible time, releasing a large volume of gas that is safe for humans. Sodium azide (which, by the way, is poisonous) is usually used as such a substance. But during the combustion process, it breaks down into non-hazardous substances - nitrogen (45% of the total volume), water, carbon dioxide, and solid particles.

It is worth noting that sodium azide burns completely very quickly (30-50 milliseconds depending on the amount of substance), and the combustion is controlled and not explosive.

The resulting gas leaves the gas generator through special channels and enters a fabric bag. Before this, it is filtered through a special metal filter, which removes solid particles and also cools the gas.

Hybrid gas generator with charge and gas

Another type is a hybrid gas generator in which the main substance is gas under pressure (argon - 98%, helium - 2%). It also contains a squib and a small amount of ejection charge. When it is triggered, the gas supply channel to the pillow opens. Hybrid gas generators differ in the design of the opening of the channel, due to the piston being shifted by the charge at the moment of operation or destruction of the washer (membrane). There are other rarer designs.

Hybrid gas generator with pressurized gas

The bag is usually made of nylon. For ease of deployment when inflating, the surface of the fabric is coated with talcum powder and starch. The pillow must have perforations. The holes made in the bag are designed for deflation after operation, and also quickly (1-2 seconds). This eliminates suffocation and pinching of passengers in the car.

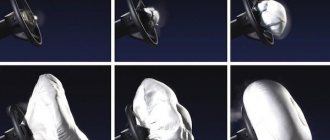

Airbag deployment

Often on modern cars, the airbag device includes a two-chamber gas generator, in which there are two squibs and two combustion chambers. The peculiarity of such a generator is the sequential use of squibs.

Upon impact, the charge located in the main chamber first ignites. In this case, the pillow fills 80%. That is, the bag turns out softer than when completely filled, which reduces injury when a person comes into contact with the pillow. After a certain period of time, the squib of the auxiliary chamber is triggered, and the pillow is refilled with gas, but after it has taken the body’s impact.

Airbags

In the event of an accident, the airbag control unit gives the command to ignite the first charge. The resulting pressure accelerates the piston, which opens the gas cylinder. The released gas fills and deploys the airbag. As a result of the combustion of the second charge, an additional amount of gas enters the air bag.

Rice. Squib cartridges with a gas cylinder: 1 – first fuse; 2 – first charge; 3 – rod with piston; 4 – protective film; 5 – channels for supplying gas to the airbag; 6 – gas cylinder; 7 – second charge; 8 – second fuse

The inflation speed of the airbag is selected in accordance with the time the driver (passenger) moves when colliding with the airbag. Immediately after filling, but more slowly, the pillow deflates within 200 milliseconds.

The optimal time for filling the pillow is 30...55 milliseconds. Gas (nitrogen or other safe for humans) enters the pillow through a special filter. The airbag remains in the deployed state for a very short time (up to 1 s), since gas quickly escapes into the passenger compartment through special openings so that the airbag does not suffocate the protected passenger.

Sensors are installed in the cabin, in the front of the car, or in the doors, and their number can range from three to ten. The response of the sensors is affected not only by the speed of the vehicle, but also by the nature of the collision (at what angle, with what obstacle). At the same time, emergency braking from any speed cannot trigger the shock sensor. In case of battery failure, some systems are equipped with a special capacitor, which releases the accumulated energy to open the airbags.

The pillow is made of 0.45 mm thick nylon. For tightness, the inner side is covered with a very thin layer of synthetic rubber - neoprene or special silicone rubber. Modern pillows are divided into three types: front, side and ceiling.

Filling the pillows in the cabin - and there are usually from 2 to 6 of them - is accompanied by increased noise, the level of which sometimes reaches 140 dB, which is dangerous for the eardrums. To reduce noise, only the necessary airbags are deployed, and then at different times: for example, 20 milliseconds after the collision - the driver's, another 17 milliseconds - the passenger's. Moreover, if there are no passengers in the cabin, the airbags do not deploy, since special sensors are installed in the seats that detect the presence of passengers.

Outside (external) air spring

In 2012, the designers of the Volvo automaker designed and implemented the concept of using air bags not only inside the car, but also outside it. We are talking about airbags designed to ensure maximum safety for pedestrians in direct frontal contact with the car. In particular, to prevent or minimize their injury. According to statistics, in such accidents, more than three quarters of deaths are caused by the fact that the pedestrian hits his head a second time on parts of the car’s exterior. Proof of this are numerous (unfortunately!) videos posted online by owners of car registrars.

This security system is designed using an airbag. which, if necessary, shoots out from under the hood. At the same time, the hood is raised using a specialized hinge release mechanism. An elastic rectangular shell filled with air covers the most dangerous sector of the windshield and the metal A-pillars of the car, softening the impact and preventing serious injuries to the pedestrian. The effectiveness of this system is clearly demonstrated in the video. » alt=»»> It is likely that such a mechanism is a promising future direction in the development of air bags.

Electronic monitoring and control device

Most current designs use an electronic unit that is installed in the passenger compartment to coordinate the operation of protection systems. The ECU's deceleration calculations are based on data from acceleration sensors used to monitor the deceleration forces that accompany a vehicle collision. The central electronic excitation unit must meet the requirements:

- identification of an accident or collision based on data received from an electronic acceleration sensor and a mechanical “safety detector” or from two electronic acceleration sensors (control with “fully electronic recognition” with redundancy circuitry)

- rapid response of control circuits, airbags and seat belt tensioners, based on special-purpose digital trigger algorithms, in response to various types of accidents (frontal collision, offset frontal collision, collision or collision at a certain angle, collision with a support, etc. .)

- stable voltage and power redundancy

- selective activation of the seat belt tensioner in accordance with the controlled state of the belt webbing - buckle assembly

- determining two response thresholds depending on whether the vehicle user actually uses a seat belt (high or low response threshold of the serial diagnostic interface)

How to check the serviceability of airbags and squib with a multimeter

Checking the steering wheel airbag with a multimeter

By setting the multimeter to ohmmeter mode , you can measure the resistance of the squib. Turning off the ignition and removing the terminals from the battery, we disassemble the airbag and measure the readings on the airbag connector. Standard indicators are different for different cars - it is important to find data specifically for your car. But in most cars these are values in the range of 2-3 ohms. If the measurements differ greatly from the factory ones, the squib is not working, it definitely needs to be changed. This may also indicate that an airbag has already been deployed.

This method can only be used if you are an experienced user and have a clear understanding of the operation of the airbag system and how your multimeter works. Incorrect actions may cause the working squib to fire and cause harm to your health.

Do squibs have an expiration date? Automakers do not have a clear recommendation to change this part after a certain period. And on the Internet you can find both information that after 8-10-15 years the squibs stop working reliably, as well as reviews from car owners of old cars in which this part worked normally in an accident. Therefore, the issue of the “shelf life” of squibs remains controversial.

Indicator light

A monitoring system can be used to monitor the health of the airbag system. When you turn on the ignition, the control light lights up for about 10 seconds, which should then go out. If the light does not light up, does not go out, or lights up while driving, this indicates a system malfunction.

Research by specialists shows that the risk of death of a pedestrian when hitting the hood of a car moving at a speed of only 40 km/h reaches 100%. To solve this problem, companies are actively working on developing airbags for pedestrians. This protection system includes two airbags - a large one that covers the front part of the car (bumper, radiator grille, headlights and hood edge) and a small one that is located near the windshield, protecting the pedestrian's head. Dangerous approaches to pedestrians and animals are detected by special sensors. These airbags will open immediately before a collision.

Today, airbags are an integral part of the safety system of any vehicle. They are needed to protect both the driver and passengers of the vehicle while driving. Therefore, the car owner needs to periodically check the functionality of this system. In particular, monitor the condition of the airbag impact sensors. We will talk about their features and functions. We will also figure out how to find out that the power supply units are faulty.

11.14.1. Design Features

The passive safety system (SRS) of the Renault Logan combines front airbags for the driver and front passenger and seat belts for the driver and all passengers. The cars are equipped as standard with a front airbag for the driver and inertial seat belts for the driver, front passenger and side passengers in the rear seat. There is a lap belt for the middle rear seat passenger. Upon request, the vehicle can be equipped with a front airbag for the front passenger, seat belt pretensioners for the driver and front passenger and a diagonal seat belt for the middle rear passenger.

| WARNING Airbags are not a replacement for seat belts. Moreover, when the car is moving, the driver and front passenger must be fastened with seat belts, since in the event of a traffic accident, the deployed airbag itself can cause serious injury to a person who is not wearing a seat belt. |

The SRS system includes the following elements:

– the driver’s airbag module, located in the steering wheel hub and consisting of a folded airbag shell, a gas generator and an accelerometer that measures the negative acceleration of the vehicle;

– the front passenger airbag module (installed depending on the vehicle configuration), located in the instrument panel on the passenger side and consisting of a folded airbag shell, a gas generator and an accelerometer that measures the negative acceleration of the vehicle;

– an electronic control unit installed under the floor tunnel lining and controlling the system;

- seat belts.

The force of impact during a traffic accident is determined by the electronic control unit (ECU) of the passive safety system using electronic accelerometers. Based on the signal from the accelerometers, the control unit activates the driver and passenger airbags.

If the vehicle is equipped with driver and front passenger seat belt pretensioners, the electronic unit, receiving a signal from the accelerometers, increases the belt tension before activating the airbags. Pretensioners provide a timely response to emergency deceleration of the vehicle, drawing the driver and passengers to the seat backs, and also prevent their further movement forward by inertia and injury from a deployed airbag. In the event of a frontal impact of a certain force, the safety system ECU issues a command to the pyrotechnic elements of the seat belt pretensioners.

| NOTE The seat belt pretensioner mechanism is always activated before the airbag. |

| previous page11.14. Passive Restraint System (SRS) | next page 11.14.2. Removing and installing the driver's airbag |

Requirements for PD

Airbags installed in a vehicle must meet the following minimum requirements:

- Must be filled with gas composition at a certain speed.

- Gas must also leave the PD at a certain speed.

- The pillow must have a volume that ensures the safety of the passenger.

- The device must be of the required shape and geometry.

- Correct placement of airbags in the car interior.

- Inflating the pillows at certain moments.

Required Items

Car airbags are a combination of the following elements:

- Pillow shell.

- The gas composition with which it is filled.

- Gas-forming substances.

- Side airbag crash sensor G179.

- Car seat position sensor.

- Driver side airbag crash sensor G179.

- Seat occupancy sensor.

- PB impact sensors located along the windshield, etc.

- Electronic control unit for this security system.

Varieties

Airbag crash sensors are not the only sensors in the SRS system. It is assumed that they work systematically together with other elements. Here the following stands out:

- Airbag crash sensor.

- Sensor for the presence of passengers in the vehicle.

- Satellite sensor.

Let's get to know them in more detail.

Shock sensor

Many car owners are interested in where the airbag impact sensors are located. But not everyone knows their purpose.

It also consists in detecting a collision and transmitting the corresponding impulse to the system control device. The design of such a sensor can be very different. It depends on the model of a particular car.

A common example is an electromechanical controller. Accordingly, in a certain situation it will close its contacts. What happens next? When the contacts close, current begins to flow through them. As a result, this leads to the activation of actuators. They are already initiating the filling of airbags with a special gas composition.

We looked at how the airbag impact sensor works. But we must remember that to initiate his actions, only a strong blow is needed. Only then will the process be started.

In the event that at the time of a road accident there is a disruption in the battery power supply, the power supply will still work - they will be filled with gas. What is the reason for this? The system contains a special capacitor device that can accumulate charge.

Sensor location

So where are the airbag crash sensors located? It all depends on the model of a particular car. The most common examples of controller layouts are here:

- Airbag control device.

- Inside the salon.

- In some cases, in the engine compartment of a car.

Where are the airbag crash sensors located? In the case of foreign cars, there is another additional shock sensor - this is to turn off the fuel pump. It often causes problems - in the event of a minor impact, the airbags do not deploy, but at the same time, the car cannot be started until this sensor is activated.

Passenger presence sensor

Now you know the location of the airbag crash sensors. Let's move on to consider the next variety.

The speed at which the airbag inflates completely depends on the weight of the person sitting in the car seat. Its regulation in the event of a car collision is necessary to quickly and timely create a gas layer between the passenger and the center console (in the event of a frontal collision). If the collision is lateral, then the system needs to create a gas layer between the door and the glass.

To carry out these functions, the safety system is primarily based on the weight of the passenger. The impact force is determined by taking into account the elasticity of the airbags themselves.

As for passenger presence sensors, they are located in all cars directly under the seats.

Additional funds

The SRS system device may additionally include a sensor for detecting the presence of a passenger and an emergency lowering mechanism for door windows. The control unit can also control the operation of belt pretensioners (with squibs).

A passenger detection sensor is needed so that the control unit does not activate the front passenger airbag if there is no one in the side seat. Previously, turning off this airbag was done manually, which was not entirely convenient. Installing the sensor solved the problem with the passenger airbag being forgotten on or off.

Passenger seat arrangement

The emergency window lowering mechanism is designed to eliminate pneumatic shock. When the windows are closed, the deployment of the pillows leads to a rapid decrease in the volume of the cabin (it is filled with bags). As a result, the air pressure in the cabin increases sharply and a pneumatic shock is formed, which is quite powerful and passengers can easily damage their eardrums. The mechanism for emergency lowering of the side windows eliminates the increase in pressure and the occurrence of pneumatic shock.

The seat belts of many cars are now equipped with pretensioners, which provide short-term tension of the belt during an accident, securing the body and eliminating its inertial movement. Moreover, the pretensioners are equipped with squibs, which are triggered by an impulse supplied from the airbag control unit.

Problems with sensors

Sensors for the presence of people in car seats are often a problem for vehicle owners. The most common is a decrease in the sensitivity of their controllers. So, if there is a child in the passenger seat, the system may simply not detect its presence due to its low weight. And this risks the fact that in the event of a collision, the airbags may simply not be filled with gas.

There is also another side to the problem. If the child’s weight is determined incorrectly by such controllers, the system will begin to inflate the SB at a speed that is too high for his weight. This may result in injury to the baby.

More about the sensor

The entire system must operate in such a way that if, God forbid, a traffic accident occurs, only the necessary airbags will deploy, not all at the same time. And for this you need to know the strength, character, vector of the blow.

This task is performed by sensors located in various parts of the body - in the front, in the pillars, in the doors, under the hood, in the cabin...

Obviously, it is extremely important that such devices are activated only during an accident. A false positive can be fatal. However, if earlier such problems arose with mechanical devices, then with modern electronic devices they are practically excluded. Unless they malfunction (read more in the FAQ section), but it is not so difficult to identify and fix, at least trusting experienced professionals.

Violation of the integrity of the PB

Car owners should be aware of how to test the airbag crash sensor. After all, the safety of their lives depends on its serviceability.

In most cases, the system itself “tells” the car owner that something is wrong with it. The Airbag or SRS indicator lights up on the dashboard. The most common cause of this problem is a violation of the integrity of the PB.

Because of this, the control device no longer receives impulses from shock sensors, other controllers, seat belts and other system components. In some cars, the seat belts themselves are equipped with sensors that can detect whether they are fastened or not. Therefore, if the driver or passenger forgets to buckle up, the indicator will also light up, signaling a problem with the system.

The fact is that the operation of the safety belt is relevant in the case when the people in the car are buckled up. Otherwise, if the driver does not fasten his seat belts and gets into a road accident, the PBs will fly out at a speed of 200 km/h. And this is already traumatic for a person. A collision with pillows in this case can be compared to hitting a concrete barrier at a speed of 25 km/h!

FAQ

Could airbag sensors be missing?

Yes, quite, on some, especially not modern, car models.

Why does the “Airbag SRS”, “Airbag” or “SRS” light appear on? How to fix the problem?

This is clearly a signal of a device malfunction. If you find it difficult to determine on your own, contact the service center. Most often, the essence is problems with the integrity of the power supply unit, lack of contacts or unreliable connection of elements, damage to any parts of the system, or moisture ingress. Each of these problems is resolved in its own way.

Fastening and not fastening seat belts

It must be said that many car manufacturers have taken into account this issue with fastening or not fastening seat belts. The problem was solved simply: in the case when an accident occurs and the people in the car are not fastened, the safety guards simply do not work. Here the system cannot guarantee you any security at all.

There are cases when drivers deliberately deceive the security system by pulling belts behind the backs of seats, installing emulators, but without actually buckling up. Accordingly, the system begins to “think” that people are wearing seat belts and, in the event of an accident, releases the airbag at maximum speed.

Such tricks are dangerous. Yes, you will ensure that the indicator on the panel stops lighting if the seat belts are not fastened. But in case of an accident, in this case, you will significantly reduce the chances of survival - both for yourself and for your passengers.

How to check a car before buying

You can check the car's history before purchasing using online services. For example, through the all-Russian Internet service “Autocode”. Here you can get information in 5 minutes about whether the vehicle you are interested in was involved in an accident or not. If the car has been in a serious accident, it means that the safety devices have already been activated. But they replaced them with new ones or installed a dummy - it’s up to the potential buyer to check.

To become the owner of information about road accidents in which the car was involved, enter the VIN or state registration number. vehicle number in the search form on the main page of the Autocode website. Within five minutes you will receive information about the type and date of the traffic accident. In addition, the diagram will indicate the location of the most significant damage to the body.

In addition, a detailed report contains information about the former owners of the car, the history of registration actions, the actual mileage of the car, the dates of technical inspections, information about the presence of traffic police restrictions and other useful information about the vehicle.

To be completely sure of the desired swallow, you should inspect it for any technical problems. However, if you do not have enough experience, or you are in another city, an auto expert will do it for you! To do this, just leave a request for an on-site inspection service on the Autocode website.

Other causes of malfunctions and their solutions

Let's analyze the main causes of problems and malfunctions associated with the car's security system, and present ways to solve them:

- Poor connection of elements in the PB electrical circuit or lack of contacts. Another reason for the constant light of the malfunction indicator is poor connection of the system connectors. The solution is to check all contacts, as well as the quality of the connection.

- Malfunction of shock controllers is another common cause of indicator lights on the dashboard. Perhaps they are not connected well. Check not only the quality of the connection of network elements, but also the connectors. What to do if all contacts are working? If the indicator on the dashboard continues to indicate a malfunction of the shock sensors, it means that these devices need to be replaced as soon as possible. Otherwise, the presence of PBs in your car can be considered useless - they will not react to an impact. How to check the airbag sensor with a multimeter is described in the instructions for the device.

- The next common cause of car security system malfunction is faulty contact in the doors. In most cases, this is a consequence of repair work or replacement of car doors. During this, as a rule, the connectors are disconnected. Therefore, the next time they are connected, all contacts must be checked. If the indicator in this case continues to light even after reconnection, then there is only one way out of the situation - to reset the memory of the security system control device.

- Another cause of malfunction is moisture ingress. It may end up on the contacts of electrical components or on seat belt buckles. This leads to either poor contact or even a short circuit. What to do with such a problem? The place where you find moisture must be thoroughly dried.

- Incorrect functioning of the control unit, its failure. The reason may be simple - the contacts have moved away. But if the essence of the malfunction lies in the device’s board, then the problem can be solved radically - by replacing this unit.

- Safety elements. If such devices fail, the indicator on the dashboard will also light up. The problem is quite common, since not many car owners pay due attention to fuses.

- Replacement of control panel or car seats. This can also lead to a malfunction of the machine's security system. The reason is that when replacing, the integrity of the electrical wiring may be damaged. In particular, connection points may be affected.

- In some cases, a similar malfunction also occurs when replacing the steering wheel. In particular, in cases where during such repairs the contacts of the security system are damaged. At this point, the security system malfunction indicator will light up without ceasing.

- If the airbags were deployed during a road accident, the airbag malfunction indicator in some cases continues to light even after the airbags have been restored. This indicates that information about the incident remains in the memory of the control unit. You can solve the situation by removing this error from there.

- The service life of the airbags is also the reason for the activation of the malfunction indicator. Remember that the average service life of a PB is 8-10 years. If it is exceeded, manufacturers of such systems cannot guarantee the performance of their products.

- Low voltage in the on-board vehicle network. How to solve a problem? First of all, check the battery, and then the generator.

Thus, the shock sensor is an integral part of the safety system. If it malfunctions, the PB will not open at the right time. Therefore, car owners should periodically check its performance. As well as the proper functioning of all other elements of this system. After all, the safety of the life of the driver and passengers of the vehicle depends on it.

As vehicle speeds increase, the danger of colliding with another vehicle or obstacle has increased significantly. It is known that speed affects impact force more than other factors. The kinetic energy of a moving body is directly proportional to the square of the speed. The consequences of a strong impact can be human death, serious damage and fractures. As a result, victims may become unable to work. For this reason, means have been developed that reduce the impact of traumatic factors and thereby increase the percentage of safety. One such means is airbags.

Principles and conditions for activation of air bags

The system is by no means a complicated device and is based on impact as the main indicator of its operation. The impact is detected by the corresponding sensors and signaled to the control unit. However, the main condition for the initiation of action is the impact force exceeding the level set by the system. If this occurs, the control unit activates the airbag module squib. The gas generator instantly (within 40 ms) fills the nylon shell with gas, which promotes its release towards the driver or passenger, preventing them from getting injured. The system understands impacts as indicators of airbag activation:

- actual impacts to the car body - direct or oblique, frontal or lateral;

- collisions with large obstacles (curbs; large holes, potholes, etc.);

- falling from a height, overturning, hard landing of the car.

The best demonstration of the functioning of air bags is, of course, video materials.

It is important to note! The system is configured on a rational operating principle: the activation and operation of specific air bags is determined by the specific location of the impact. In other words, of all the air bags, only the necessary ones are deployed. Thus, in the event of a frontal impact, the front airbags are necessarily deployed. In the event of a frontal-side impact, there is a high probability that the system will activate the front, side and head airbags. Accordingly, in case of a side impact, there are head and side airbags.

One of the indicators can be a sharp slowdown in the movement of the vehicle (for example, emergency braking). However, this factor is not decisive when the system operates. The fact is that the sensors that record the deceleration do not send an automatic command to the gas generator, but, as in the first case, they only “notify” the control device about an unusual situation. For the block in determining the direction of the system’s operation, such information is correlative, that is, it creates the conditions for the initiation of action (and most often, for warning of a possible danger).

Design and operation of airbags

As the name suggests, the device is needed to ensure the safety of the driver and passengers. To understand how this happens, it is necessary to consider their operating principle, which is inextricably linked with the requirements for them.

Airbag requirements

At the moment the car is moving, its speed relative to the road is the same as that of the passengers in it. If you stop the car abruptly, this will lead to an impact. A moving car will stop very quickly, and people moving at the same speed will also continue to move by inertia. In order to reduce speed as slowly as possible and avoid hitting hard objects, you need to brake your body smoothly. Airbags contribute to this. Based on these conditions, the following requirements are imposed on them:

- must inflate at a given speed;

- gas must also leave them at a certain speed;

- a certain volume;

- required shape (geometry);

- correct location;

- a certain moment of inflation.

All these requirements can be realized only with appropriate technical equipment.

Airbag operation

Fulfillment of the necessary requirements is ensured by the design features of the airbags.

The operation of this device is realized through the following elements:

- shell;

- the gas with which it is filled;

- shock sensor;

- gas-forming substance;

- electronic control unit;

- sensor for the presence of passengers on the seat;

- seat position sensor.

Depending on the design of the airbags, one or another gas-forming substance may be used. Some of the above items may not be available on different vehicle models.

Airbags are also not the same. Some of the cars are equipped with a full set, i.e. front, rear, side, knee, and head airbags.

At the moment of a collision, the corresponding impact sensor is activated. The signal from it is sent to an electronic unit, which gives an impulse to fill the desired airbag with gas. The input signals for this block can also be vehicle speed and deceleration data.

Depending on the magnitude of the signal from the impact sensor, the required airbags are inflated to a certain volume. One of the conditions for their work is the use of seat belts. If a person is not fastened, this is fraught with disastrous consequences, including fractures.

The sudden inflation initiated by the impact sensor can seriously deafen people inside the cabin, so the airbags do not fire all at once, but with a slight delay. After inflating, the pillow quickly releases gas so as not to suffocate the person.

Principle of operation

Knowing the design and functioning of all components, it is not difficult to understand the principle of operation of the airbag: in the event of a collision, sensors detect the impact and send a signal to the control unit. This, in turn, redirects the impulse to the desired gas generator. At the same time, the unit determines the presence of a passenger and decides whether to use the passenger airbag, and also activates the pretensioner squibs (if any) and turns on the window lowering mechanism (if equipped).

The signal received from the unit to the gas generator triggers the squib and the chemical charge ignites. The released gas enters the bag, it unfolds and then immediately descends thanks to the perforation.

Audi A3 SRS system diagram

Note that the main disadvantage of pillows is their disposability. That is, they only work once, after which they need to be changed. And replacement is very expensive, so car owners of cars on which they have worked use a “trick” so that the system is properly diagnosed when the engine starts and is not bothered by a constantly burning warning light.

Airbag sensor operation

To operate the airbag, the control unit input receives signals from the impact sensor and the presence of a passenger.

Shock sensor

The impact sensor serves to detect a collision and send a signal to the control unit. It varies in design. For example, there is an electromechanical sensor that closes contacts when a certain setpoint is reached. A current flows through the closed contacts, which triggers a kind of igniter, a chemical reaction occurs, resulting in the release of gas that fills the airbag. A weak blow will not be enough to start the process. If the power supply from the battery is interrupted, and this is quite possible in the event of an accident, the airbags will still be inflated due to the existing capacitor, which has accumulated an electrical charge.

The impact sensor can be located either inside the security system control unit or inside the passenger compartment. In some cases, it is located in the engine compartment and may not be alone.

It is a useful element, but when problems arise with it, you have to fix them yourself or contact specialists. As you get into your car one morning, you discover that the red airbag light has come on. This may be due to the following reasons:

- the shock sensor is faulty;

- poor contact in the connector;

- broken wires;

- one of the instrument panel warning lights is faulty;

- replacing the fuse with the ignition on;

- instrument panel malfunction.

The shock sensor rarely fails on its own. Usually, other reasons influence the indicator's lighting.

If there is high humidity in the places where the security unit connector is located, the contacts may simply oxidize. This means that the crash sensor or airbag is producing an incorrect signal due to changes in circuit resistance. This has a particularly strong effect on operation if a voltage signal arrives at the control unit. That is, the voltage drop it measures will be incorrect. In addition to humidity, a broken wire may be the cause of the fault indication. This happens when soundproofing is applied or other repair work is carried out in places where wires are laid.

If, when the ignition is turned on, the instrument panel goes out, and after that the indicator is constantly on, then the reason is precisely this operation of the panel.

You can reset an error that appears on your own if you connect to the electronic unit using a special adapter and a scanner program. If desired, it would be a good idea to find the shock sensor itself and at least visually verify its integrity. In this case, it is useful to periodically inspect, if possible, all contacts and connections accessible to the eye, as well as monitor the shock sensor for the integrity and condition of its connectors. But it should be borne in mind that disconnecting the circuits while the ignition is on will lead to an error. Therefore, you should not remove the fuse and clean the connectors at this moment.

You can purchase the necessary adapter and install the corresponding scanner program yourself. With its help you can check the shock sensor and the security system as a whole.

Another option for the development of events may be to simply ignore the malfunction. In this case, the airbag may not deploy at the right time. This is possible even if the shock sensor itself is working.

Passenger presence sensor

The speed at which the airbag inflates depends on the weight of the person sitting in the seat. Regulating the speed at the moment of impact is necessary in order to timely create a layer of gas between the passenger and the panel in the event of a frontal collision, and between the door and glass - a side one. Thus, the system calculates the impact force of a person of a certain mass, taking into account the elasticity of the pillow.

The occupancy sensor sometimes creates problems. This happens when its sensitivity decreases. A child in a seat will not be noticed by him, therefore, the airbag may not deploy. In some KIA RIO car models produced between 2006 and 2008, the passenger sensor had significant deficiencies that made themselves felt after some time. Here, on the contrary, the pillow inflated too quickly, which, in turn, could seriously injure the child, whose weight could not be detected by the sensor.

Source

Air bag maintenance

Is it possible to monitor and independently maintain the system? It seems that control over the operation of air bags is more than possible, thanks to the electronic indication of its condition. Thus, in the event of a malfunction, a special indicator light will warn the driver about the prospect of system failure and the need to visit a service center for the purpose of diagnosing and servicing it.

However, independent system repair is possible only with the involvement of highly specialized personnel from an authorized service center or center. The fact is that air bags are disposable devices, and after operation they can only be replaced with a new set. In this case, additional reconfiguration and diagnostics of the entire control system is necessary.

This is the author's translation, with comments from Russian practice, of the article " Air Bag Deployment Criteria ", published in 2014 by Kenneth Solomon and Jesse Kendall in The Forensic Examiner®, the official peer-reviewed scientific journal of the American College of Forensic Examiners, which has gained popularity and recognition as the world's leading forensic journal.

And since our people in the bakery by taxi don’t read such magazines, this article on Pravoruba will be useful to both road accident lawyers and auto experts who read it. For lawyers - as information for interrogating in court auto experts who do not read in order to explain to them their empty conclusions, and for auto experts who read - in order not to give conclusions based on shamanic rituals.

Introduction

Airbag control modules use sophisticated algorithms to make deployment decisions based on an assessment of the severity of the crash associated with changes in vehicle speed or deceleration over time. Due to the fact that the control algorithms are manufacturer know-how, their actual speed, acceleration, or deformation (path) thresholds for airbag deployment in a crash are not known. Car manufacturers do not disclose the values of these parameters and algorithms, limiting themselves to declarative “strong impact” or “impact of sufficient force” in the owners’ manuals, and dealers simply do not know them, while performing performances in front of clients with testing instrument control modules.

Indeed, such vague non-technical criteria create deadlocks when bringing legal claims from car owners whose airbags did not deploy in an accident, or deployed arbitrarily for no apparent reason. This also creates favorable conditions for fraudulent staging of road accidents, which consists of “transferring” panels with deployed airbags to a practically undeformed car.

However, the technical parameter values required for airbag deployment can be determined by examining the results of laboratory crash tests on vehicles from specific manufacturers.

Objectives of the article

The content of the article

Airbag deployment process

The purpose of an airbag is to provide a resilient, soft cushion between the occupants and the vehicle's interior. To achieve this goal, the airbags must be completely filled with gas within a short period of time and before passengers come into contact with them. Rapid airbag deployment has the potential to cause fatal injury to people if they are already in contact with the airbag during deployment. Therefore, airbags must have a control system that can correctly recognize that a collision is occurring. At the same time, it is recognized early enough so that the airbag has time to deploy safely.

The airbag deploys after an electrical signal to deploy is sent to the detonator from the airbag control module. This signal initiates a chemical reaction that quickly inflates the nylon fabric air bag with gas. The gas contains dust particles from the material used to lubricate the bag (usually talc and cornstarch). Once the cushion is fully deployed, the gas escapes through small vents. The holes are sized and positioned to reduce the volume of the bag at different rates depending on the type of vehicle.

History of shock sensors

Early airbag deployment systems used mechanical sensors to detect the impact, which were then phased out in the US market around 1994. Sensors such as "rolamite" contained metal rollers stabilized in the standby position by a spring or magnet.

Upon impact beyond the intended threshold, the spring or magnet could no longer hold the metal mass in place. The mass moved and pressed against the contact, sending an electrical signal to the airbag control module. Mechanical sensor systems tend to be inaccurate in interpreting small collisions. Mechanical sensors may not have enough movement in frontal collisions, causing delayed response. Modern shock sensors are now based on microelectromechanical systems (MEMS).

New impact detection systems

The new MEMS crash sensors measure acceleration with an accelerometer, which sends a continuous stream of data to the airbag control module. Accelerometers are typically piezoelectric or variable capacitive sensors. The most common MEMS accelerometer in use today is the ADXL-50 from Analog Devices.

The author has come across the conclusions of complete idiomatic “non-reading” auto experts, in which they establish a malfunction of the shock sensor by visual inspection or organoleptic method. Their logic is limited to the primitive chain “there was a shock - the airbags did not work - which means the shock sensor is not working.” In fact, the testing procedures for such sensors are based on Gauss-Newton type algorithms (not approved by the Ministry of Justice, and therefore not recognized by state experts as scientific) and require special software and equipment. Examples of numerous tests can be viewed on YouTube, and if necessary, official regulations for testing and calibrating a specific sensor model can be found on the manufacturer’s website.

As the masses aimed at the elastic elements move relative to the sensor body due to acceleration, special plates attached to the masses move closer to other stationary plates. Changing the distance between the plates affects the sensor's capacitance, or ability to hold an electrical charge. This change in capacitance is easily measured and then converted into a change in voltage. The change in voltage is directly related to the inertial force due to acceleration, and the reading is interpreted by the airbag control module as acceleration. The control module's algorithm can determine whether airbag deployment is necessary based on its mathematical model of acceleration pulses over time.