During the operation of the car, a situation may arise in which the owner of a VAZ 2110 will need to adjust the clutch. It must be said that this procedure is not difficult to perform and even a beginner can handle it. Such a need may arise in a situation when the clutch drive begins to malfunction. This can occur when the friction disc is severely worn. Before performing work, you need to have an idea of how the clutch operates on this particular car model. If you study this thoroughly, then it is quite possible to adjust the VAZ 2110 clutch with your own hands. In this case, there is no need to visit a car service center.

Where is the clutch cable located?

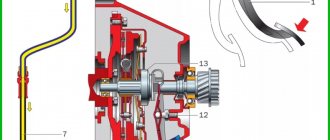

The location of the cable is the protective casing. Its ends are attached to the pedal and fork, which engages the clutch. If the discs wear out, the pedal travel increases. When the cable wears out, on the contrary, there is a decrease in the amplitude with which the pedal moves. This can lead to incomplete engagement or disengagement of the clutch.

How to change the clutch of a VAZ 2110

Having a foreign car in your own garage is very prestigious and cool, but even today hundreds of thousands of drivers are owners of domestically produced cars. Firstly, they are much cheaper compared to foreign cars, and secondly, they are economical to operate and repair. In addition, car markets are simply overflowing with a variety of spare parts and components for all VAZ models, both new and used.

Repairing a car, no matter what the breakdown, always requires an investment of money and effort. However, repairing or replacing spare parts with your own hands is much cheaper and more profitable. The clutch is a very important component of any car, so if you suspect that this particular part is faulty, you need to replace it immediately.

Replacing the VAZ 2110 clutch occurs as follows. First of all, you need to find an overpass or pit, or better yet, a lift.

The lack of a comfortable workplace will significantly complicate repair work and increase the duration of work.

You can raise the front of the car and fix it on special stands. Be sure to put chocks under the rear wheels. Only after the vehicle is installed in the workplace can you proceed to replacing the clutch.

Removing the air filter

- It is necessary to remove the negative terminal from the battery. This need is to prevent a short circuit in the wiring during repair work.

- Remove the air filter housing to gain access to the bolts that secure the transmission to the engine.

- Remove the protective caps from the front wheels and unscrew the locked nuts. You can do this with a core or chisel. It is also worth loosening the nuts on the left wheel. It will also have to be removed later.

- Raise the front of the car and place stands under it. Remove the front wheel (left).

Removing protection

- Then remove the long bolt that secures the anti-roll bar. Before doing this, you must remove the protection (if any).

- A very important stage is shifting the checkpoint. So that it can move freely, you need to remove the left mudguard, free the left ball joint from the bolts, and move the left strut to the side behind the wheel drive.

- Disconnect 2 connectors from the gearbox. On the right is a plate that is responsible for fastening the jet thrust. It originates from the lever, which changes gears. However, before disconnecting it, you need to notice the place for attaching the rod, so that there are no problems later and you don’t have to waste time adjusting the lever.

- After freeing the gearbox, you can remove its mounts to the engine. There are only 1 nut and 3 bolts.

Unscrew the pillows

- Then you need to unscrew the rear cushion, which serves to secure the gearbox and engine, then move the box. This must be done in such a way as not to lower the engine too much, so it is better to place some supports under it or jack it up.

- Similar manipulations need to be done with the box and only then move it to the required distance. When everything is ready, you can begin to unscrew the clutch basket and remove the release bearing.

- The best option would be to replace the entire clutch, including the release bearing.

Replace the clutch

The machine is reassembled in the reverse order. In this way, you can independently replace the clutch of a VAZ 2110 car. It is necessary to center the disk; it is best to use a special mandrel, or, if it is not available, a round piece of wood of suitable length and diameter. With proper disk alignment and tightening of all fastening bolts, the mandrel or round timber should be easily removed.

Step-by-step process for adjusting the clutch

The location of the clutch cable is the bottom of the pedal. Even a beginner can easily find it. How to adjust the pedal depends on how much travel it has. The length of the cable should be 12-13 cm. True, it can be increased to 16 cm. The pedal should “walk” in the range of 12 to 16 cm. If the travel indicators have different values, then adjustment of the VAZ 2110 clutch pedal travel is required .

To do this you need to do the following:

- In order to find the clutch cable, you need to open the hood. It is necessary to unscrew the nuts located on the clutch body. To avoid problems, they are treated with WD-40. After treatment, exposure must be maintained for 10 minutes. The nuts will come off much easier.

- Then the actual setup is carried out. One key unscrews the locknut, and the other makes adjustments. If you twist the nut in the direction where the tip is located, the pedal will increase its travel. If you rotate it in the opposite direction, this will lead to a decrease in pedal travel. In parallel with this, the pedal stroke is measured.

- After they reach 13 cm, sharply press the pedal several times. Then the measurement is repeated. Sometimes the progress can go wrong. Then the setting is repeated.

- The final step is to move the rubber bushing all the way.

During adjustment, there may be a deviation in one direction or another by a couple of millimeters. If after the work the pedal travel is still 17 cm, then most likely the basket will have to be repaired.

Pedal travel

This is where the whole process begins. The factory manual states that normal travel is about 13 centimeters.

Nut and locknut

But over time, the parameter increases as the driven disc lining wears out. This leads to the fact that the pedal rises slightly. Measuring the indicator is not difficult.

- Open the door leading to the driver's seat in the cabin.

- Squat down so you are close to the pedals.

- Place a regular ruler on the mat under the pedal, positioning it perpendicular to the clutch pedal.

- Measure the distance from the mat to the extreme point of the pedal, that is, the maximum distance.

- If the indicator is 16 centimeters or more, this indicates an urgent need for adjustment.

What to do if cable adjustment does not help

If the cause of the problem is a worn cable, then it simply needs to be replaced.

If the cable is faulty, then the clutch may simply fail during a trip. Then the possibility of an accident increases sharply. You can change it by doing the following:

- the nut that secures the torso to the bracket must be loosened with an open-end wrench;

- After this, the cable can be removed. They do this very carefully;

- then it is disconnected from the clutch fork;

- then the cable is disconnected from the pedal. To do this, remove the protective cover and lock nut. After this, the pedal can be removed;

- Assembly should be done in reverse order. During this process, it is advisable to lubricate the parts with lithol.

The clutch in a car works under constant intense load when traveling. Therefore, it is not surprising that it wears out over time. Therefore, it may be necessary to compensate for its wear. For this purpose, adjustments are made. It is not difficult to perform such actions. Any beginner can handle this task. Therefore, there is no need to send the car to a technical service. The exception, perhaps, is cases of acute lack of time. A car enthusiast simply has no time to do this.

Sometimes adjustment can correct the deficiency by compensating for clutch wear. But in some cases it is so large that the cable has to be completely replaced. If any signs of wear are detected, it is better not to rely on the Russian “maybe”, but rather to immediately change the clutch elements. This will prevent the risk of emergency situations, because the clutch may simply fail while driving. Then trouble cannot be avoided.

When adjustment is needed

You need to send the car to the garage and start adjusting the clutch system of your VAZ 2110 as soon as you notice signs of deviation from the normal operation of the unit.

The clutch greatly affects the performance of the entire car. What can we say, without it you will not be able to engage a single gear. Therefore, you will not be able to go anywhere.

The pedal may be too tight or fall apart at the slightest pressure. Both situations indicate that the clutch needs to be adjusted.

In general, the work is carried out in two stages:

- Clutch travel is checked;

- The setup itself is carried out directly.

But the first thing you should start with is studying the most important tool for repairing all components, assemblies and mechanisms of the VAZ 2110. Of course, we are talking about the instruction manual. Open it at the clutch section, study the main nuances, understand the essence of the unit, its design, operating principle, and then become familiar with the adjustment process.

Now we will talk about two main setup steps.

Functions and principle of operation of the clutch pedal

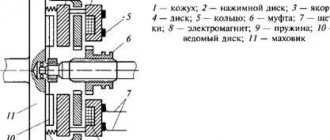

When you press the clutch pedal to the floor, the engine is disconnected from the gearbox - the clutch is disengaged. To start the car moving, you need to engage the clutch, that is, release the pedal. The clutch disc (consists of two discs) is splined on the gearbox input shaft (i.e., rigidly connected), and sandwiched between the basket and flywheel (engine) rings.

When you press the clutch pedal, the spring releases the ring on the basket, and it moves away from the flywheel. The clutch disc is released and rotates independently of the flywheel. That's it, change gears. We release the clutch pedal, the release bearing releases the spring, the rings converge, and the disc is clamped. Go.

How to adjust clutches on a VAZ-2112 with your own hands: video inside

One of the most basic elements of any transmission, including the VAZ-2112, is a mechanism designed to transmit torque from the crankshaft to the gearbox - the clutch. And after a certain mileage with the clutch drive, certain problems may arise.

The video below describes in detail the process of adjusting the clutch on a VAZ 2110-2112:

Diagnosis of clutch faults

You can check that the clutch is working properly like this.

- Put the car on the handbrake.

- Move the gearshift lever to the neutral position.

- Start the engine.

- Engage the gear and slowly release the clutch.

As a result, the car should stall. If this does not happen, the clutch needs to be adjusted.

The design of the VAZ 2109 friction clutch and its purpose

Any self-respecting motorist will study the design of the unit before adjusting the clutch on a VAZ 2109. This will help you approach the issue wisely and avoid mistakes.

In the photo: The process of tightening the clutch cable on a VAZ 2109 car

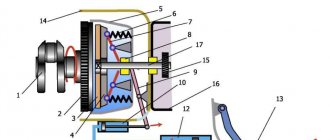

The mechanical drive design is simple and reliable. Compared to hydraulics, the cable requires minimal maintenance, and changing it is not labor-intensive. The mechanical drive consists of the following elements:

- Adjustable sheathed cable.

- Control pedal.

- Clutch release fork lever.

- Bracket for fastening the end of the cable sheath.

- Brake and clutch pedal bracket.

The mechanism serves to transmit force from the pedal to the release fork, which, in turn, removes the friction disc from the flywheel. Using a cable drive avoids major problems such as fluid leaks and periodic bleeding of air from the clutch control system. The weakest link in this chain is the cable, the quality of which at times leaves much to be desired. Therefore, replacing a cable on a Samara is a fairly common occurrence.

Meanwhile, the question of how to adjust the clutch on a VAZ 2109 car remains relevant for the cable mechanism. Setting standard values guarantees optimal tightness of the driven disk to the plane of the flywheel and basket when the clutch is engaged. The design also ensures complete separation (switching off) of the above parts from the passenger compartment through the pedal.

Eventually

In conclusion, it should be noted that there are some “homemade” ones who specifically move the release bearing away from the basket, explaining their actions by the fact that in this way they will be able to extend its service life. However, they will have to be disappointed - the bearing is unlikely to become more durable, but the petals of the diaphragm spring will gradually be milled by the untwisted bearing race. And, please note, we are not discussing the discomfort from increased pedal travel, which can result in much greater expenses than purchasing clutch elements.

On VAZ cars of the tenth family, regardless of engine size and type of gas distribution mechanism (8 or 16 valves), a mechanical clutch drive is used. Unlike classic Zhiguli cars, where a hydraulic clutch mechanism is installed, a cable drive is easier to maintain and cheaper . It has some disadvantages, but for engines of this size and power these disadvantages practically do not matter. The only thing that may require attention during operation is adjusting the VAZ-2110 clutch drive.

How the clutch works (briefly)

The clutch is controlled by a pedal located inside the car. Connection to the plug is made using a cable located in a protective casing. Let's imagine that the gearbox lever is set in the neutral position, and after the engine starts, the crankshaft begins to rotate. The basket presses the disc tightly against the flywheel. By pressing the pedal, we release the mechanism and torque is not transmitted from the engine to the gearbox; at this time, we engage first gear if we need to get underway, and smoothly release the clutch. The disk again begins to press against the flywheel, transferring torque from the engine to the gearbox and the car moves off.

If the force from the engine is suddenly transferred to the gearbox, the car will stall due to the load. The smooth operation of the mechanism allows you to extend the life of components.

In what cases will the mechanism need to be repaired?

When the clutch cable adjustment is done correctly, you need to find out if the clutch drive is working correctly. To do this, place the car on a level surface and put on the handbrake. We start the engine and engage first gear. Afterwards, you should start to smoothly release the clutch and try to drive the car. If the mechanism is adjusted correctly, the car will sit slightly on the rear and then stall. When the clutch pedal on a VAZ 2114 is completely released, the car remains standing still, this means that the disc is slipping. This occurs due to insufficient pressing force of the disc against the basket and flywheel. If this happens after adjustment, then the clutch requires repair.

In the opposite case, when you try to engage a gear, but it happens with great difficulty, this means that the clutch is driving. The disk has changed its shape so much that even with the clutch fully adjusted and the pedal pressed all the way, it is not released from the load and continues to keep the mechanism in tension. Before purchasing a new element, it is worth disassembling the mechanism and assessing the condition of the parts. If a complete replacement is required, except for the flywheel, such a kit costs about 3,000 rubles. Remember that when replacing the mechanism, it will also be necessary to properly tighten the cable so that the element works correctly.

The clutch often fails among motorists with an aggressive type of driving. To extend the operating time of the mechanism, it is enough to follow several rules:

- Drive smoothly;

- Do not keep the pedal half-pressed;

- Do not skid the car;

- Do not engage or disengage gear under load;

- Do not tow heavy trailers or vehicles;

- Do not over-switch.

It is also worth making adjustments in time, since in case of incorrect operation the circuit changes. There may be an increased load on the disk, it will start to burn and after that more serious problems appear. Try to feel your car, react in time to incorrect clutch operation and service it. Then it will serve you longer.

When to calibrate the clutch

To maintain a car in proper condition, it is worth carrying out timely diagnostics of its main elements, which include the clutch. It is worth noting that today there is no specific time frame or vehicle mileage after which it is necessary to adjust the speed shift control mechanisms, since the degree of wear may depend on the driver and the style in which he drives his car. The main signs that indicate the need to perform such a procedure may be the following:

- presence of clutch pedal failure;

- very fast or too slow response to lever pressing.