Drive disc - clutch

The driving clutch discs are made of gray cast iron, and the driven discs are made of sheet steel.

The clutch drive disc is secured with a nut at the rear end of the fluid coupling turbine wheel hub. A stamped steel casing is attached to the disk, in which a pressure disk with nine pressure springs and three switching levers is installed. Between the drive disks there is a driven disk with spring linings, mounted on the splines of the gearbox input shaft.

In models released so far with the crankshaft parallel to the axis of the motorcycle, the engine crankshaft and gearbox shafts are also parallel; The clutch drive discs, as is common in cars, are connected to the crankshaft. The engine turns out to be low, but very wide (with horizontal opposing cylinders) and quite long. The generator and distributor are located at the front end of the crankshaft (see Fig. Access to the clutch, gearbox, shift mechanism and kick-starter mechanism is less convenient than with the arrangement shown in Fig.

To connect the flywheel to the clutch, special pins are installed on it or seating belts and threaded holes for fastening bolts are provided, or teeth are cut with which the teeth of the clutch drive disk engage.

| Switching the two-speed PTO drive. |

With an independent PTO drive (Fig. 100, b), the power flow from the engine branches behind the flywheel - one part goes through the driven clutch disk to the transmission, and the other from the driven clutch disk goes to the PTO.

The flywheel, cast from cast iron, serves to remove the pistons from their dead points, carry out auxiliary strokes, uniform rotation of the crankshaft, and also start the engine with a starter, for which a steel ring gear is pressed onto the flywheel rim. In addition, the flywheel is the driving disc of the clutch.

In case of wear, surface cracks, scuffing or warping of the working surfaces, the drive clutch discs are machined and ground until signs of wear are removed.

In order not to disturb the balancing during disassembly, the clutch housing is attached to the flywheel in accordance with the marks. For the ZIM engine, the crankshaft assembly with the fluid coupling (without the clutch drive disc) is subjected to dynamic balancing, with a permissible imbalance of 50 gcm. Before balancing, 6-65 liters of turbine oil are poured into the fluid coupling.

The operation of the clutch is as follows. At the beginning of the shock cycle, the dynamo and brake generators are turned off. The clutch drive disc is closed to the flywheel, and the driven disc is opened. The operator turns on the drive dynamo and spins the clutch flywheel.

The flywheel is cast from cast iron. It serves to remove the pistons from their dead points, carry out auxiliary strokes, uniform rotation of the crankshaft, and also start the engine with a starter, for which a steel ring gear is pressed onto the flywheel rim. In addition, the flywheel serves as the clutch drive disc.

Gray cast iron (GC) is liquid-melting, gives little shrinkage when solidifying, and can be easily processed by cutting. When heated, it retains hardness up to the melting point. It is used for casting cylinder blocks, piston rings, flywheels, clutch drive discs, gearbox housings, etc. Gray cast iron is marked with the letters SCH with a numerical designation indicating the strength of the cast iron.

The ZIM car has a hydraulic coupling installed between the clutch and the engine. The steel clutch body is stamped and welded in two halves and is bolted to the crankshaft flange in place of the flywheel. The coupling body contains impellers, which are hollow stamped rings with welded radial blades located in the bells. The pump wheel is attached to the housing and has 48 blades. The turbine wheel, which has 44 blades, is attached to the hub and connected to the clutch drive plate. The front end of the hub is mounted in a ball bearing fixed in the flange of the clutch housing, and the rear end rests on a roller bearing on the shank of the gearbox input shaft. The front end of this shaft is mounted in the coupling hub on two needle bearings.

Replacement

Not all car owners decide to replace the release bearing (TR) themselves. But if you are ready for this kind of work, then go for it.

VI components

Therefore, think twice before making a final decision. There is always the opportunity to contact a car service.

To work you will need the following set of tools and materials:

- Set of wrenches;

- Jack;

- Several durable bricks;

- New release bearing;

- Screwdriver Set;

- Container for draining transmission fluid;

- Clutch holder;

- Garage with a pit or lifting mechanism.

It is better to divide the entire replacement procedure into two main stages.

- Removing the gearbox.

- Bearing replacement.

Many people make the mistake of relaxing too much when they finally change the bearing. In practice, reassembly often causes more problems than dismantling work. Please take this into account.

Dismantling the gearbox

- Place the car over a hole or overpass.

- Lift the hood, remove the negative terminal from the battery and throw it aside.

- Disconnect the ground wire from the clutch housing.

- Use a screwdriver to remove the engine splash guard. To do this, you need to unscrew several screws that hold the mudguard to the elements of the side wings. For the VAZ 2109, a key size of 8 is used. Having removed all the screws there, remove the parts of the engine mudguard and put them away for now.

- Disconnect the transmission drive rod. To do this, use a 13mm wrench to loosen the clamp bolts. Next, use a screwdriver to separate the ends of the clamp and disconnect the element from the gearbox.

- Be sure to disable the reverse optics sensor.

- Place blocks or bricks under the rear wheels of the car to prevent the car from moving.

- Remove the front wheels by first loosening the bolts and lifting the front part of the body. After removing the wheels, place pre-prepared bricks under the body.

- Using a 17 wrench, unscrew the nuts securing the ball joint to the steering knuckle on both sides.

- The extension is moved to the side, and the fastening screws of the left extension to the vehicle's suspension arm are unscrewed.

- Using a 10 mm wrench, remove the fasteners of the lower clutch housing cover.

- Remove the transmission mounts. This is done as follows. Place supports or bricks under the engine and a jack under the box. Unscrew the mounting screws of the support to the body with a 17mm wrench. After removing the bolt, remove the support bracket by unscrewing several corresponding nuts.

- We proceed directly to dismantling the gearbox. Using a 19 wrench, unscrew the fasteners of the clutch housing to the cylinder block. Use a jack to lower the gearbox slightly and move it away from the engine. Lower until the input shaft begins to come out of the box.

- Enlist the support of a partner, since it is quite difficult to remove the gearbox alone.

- Make sure that the gearbox input shaft does not rest on the clutch spring petals. If you allow this situation to happen, you will simply damage them.

- Carefully place the gearbox on the supports, being careful not to hit it. Otherwise, repairs will cost much more than buying a new bearing.

Removing the gearbox

Removing a gearbox is a complex procedure that requires a lot of time, patience and skills. Therefore, without these, it is better not to undertake work with your own hands.

Single disc clutch diagram

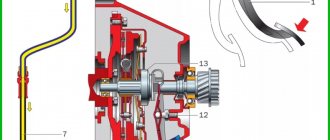

The flywheel is installed on the engine crankshaft. It serves as the clutch drive disc. Modern cars usually use a dual-mass flywheel. This flywheel consists of two parts connected by springs. One part is connected to the crankshaft, the other to the driven disk. The design of the dual-mass flywheel smoothes out jerks and vibrations of the crankshaft. The clutch housing houses the clutch components. The clutch housing is bolted to the engine.

The pressure plate presses the driven disk against the flywheel and, if necessary, relieves it of pressure. The pressure plate is connected to the housing (casing) using tangential leaf springs. Tangential springs, when the clutch is disengaged, act as return springs.

A diaphragm spring acts on the pressure plate, providing the necessary compression force to transmit torque. The diaphragm spring with its outer diameter rests on the edges of the pressure plate. The inner diameter of the spring is represented by elastic metal petals, the ends of which are acted upon by the clutch release bearing. The diaphragm spring is fixed in the housing. Spacer bolts or support rings are used for fastening.

The pressure plate, diaphragm spring and housing form a single structural unit, which bears the established name of the clutch basket. The clutch basket has a rigid bolted connection to the flywheel. Based on the nature of the work, there are two types of clutch baskets - push and pull. In a common push-action clutch basket, the petals of the diaphragm spring move towards the flywheel when the clutch is disengaged. In the clutch exhaust basket it is the other way around - the petals of the diaphragm spring move away from the flywheel. This type of clutch basket is characterized by minimal thickness, therefore it is used in cramped conditions.

The driven disk is located between the flywheel and the pressure plate. The driven disk hub is connected by splines to the input shaft of the gearbox and can move along them. To ensure smooth engagement of the clutch, damper springs are placed in the driven disk hub, acting as a torsional vibration damper.

Friction linings are installed on the driven disk on both sides. The covers are made from glass fibers, copper and brass wires, which are pressed into a mixture of resin and rubber. This composition can withstand temperatures up to 400°C for a short time. The driven disc linings may also have a higher thermal performance. On sports cars they install the so-called. ceramic clutch, the disc linings of which consist of ceramics, Kevlar and carbon fiber. Even more durable metal-ceramic linings that can withstand temperatures up to 600°C.

The clutch release bearing (common name: release bearing) is a transmission device between the clutch and the drive. It is located on the clutch rotation axis and directly acts on the diaphragm spring petals. The bearing is located on the release clutch. The movement of the clutch with the bearing is ensured by the clutch fork.

Typical breakdowns

The clutch can fail for several reasons:

Diaphragm springs are worn out;

To find the reasons for the failure of the clutch, you will have to disassemble it. But don't be afraid of this process. Even beginners can disassemble and return the unit to functionality if they study the instructions, design, and watch visual videos.

Driven disk of the clutch

Motorists magazine

Unfortunately, the use of the power unit (ICE) and gearbox is impossible without using the clutch. One way or another, the car will not be able to adequately respond to driver control, for example, when starting the car, or, worse, while stopping.

How does the clutch work?

Let's look at how the clutch works. Today, a dry, single-disc, constantly engaged clutch has become widespread. That is, it turns out that when the car is parked, or during constant driving (at a certain constant speed), the clutch is always engaged by default and works as a connection between the gearbox (manual or automatic) and the engine flywheel. It turns out that the principle of operation of the clutch is to constantly connect the flywheel of the power unit and the gearbox, and, if necessary, separate them.

Let's continue answering the question of how the clutch works. Let's see what happens when the clutch pedal is fully depressed. When the driver presses the clutch pedal, the force is transmitted through the drive to the release bearing, thus transmitting force to special release springs. And the entire working surface of the clutch is pressed away from the clutch disc. By releasing the disc on the input shaft, the gearbox stops rotation while the power unit continues to operate.

In conclusion, answering the question - how the clutch works, you should tell us what happens when the pedal is not pressed. When the clutch is in the operating positions, the splined coupling receives the input shaft. Under the influence of the release springs on the clutch pressure plate, full contact occurs, in which the flywheel is pressed against the clutch disc. Thanks to this, the torque generated by the engine is completely transmitted via the clutch disc to the gearbox.

- Flywheel;

- The lining of the clutch disc itself.

- Clutch basket pressure surfaces

The principle of operation of the clutch, which is constantly disengaged, is exactly the opposite of that described above. However, this type of clutch is not widely used, and therefore we will not dwell on a more detailed consideration of this issue.

The principle of operation of the clutch is that at certain moments it does not work, while the clutch is constantly engaged and works together with the flywheel and gearbox.

Operating principle of a double-disc clutch

The operating principle of different types of clutches is similar, as is their design. However, they function differently. Let's look at how a double-disc clutch works.

First of all, you should pay attention to the fact that a double-disc clutch is always used on heavily mechanically loaded vehicles. That is, when there is a heavy load on the car’s power unit and a stronger connection between the engine and clutch is needed

Such vehicles can be:

- Armored vehicles;

- Trucks;

- Heavy motorcycles;

- Sports cars.

A double-disc clutch works as follows: with the help of a release bearing, a force is generated that is transmitted to the release levers, which pull back the pressure plate. Then, the pressure disk is disconnected from the first driven disk, and the springs are pressed out. These springs disconnect the intermediate drive disk, which in turn moves away from the second, the friction disk.

Other spare parts for VAZ (Lada) 2108/2109

Having found out which clutch kits VAZ (Lada) 2108/2109 owners prefer to install, you can look at other popular spare parts for this car. In October 2022, the leaders on PartReview were:

- #1 KYB shock absorbers - 14% of votes.

- #1 FENOX brake discs - 20% of votes.

- #1 ATE Brake Pads - 13% of votes.

- #1 Lukoil motor oil - 11% of votes.

- #1 GISLAVED tires - 7% of votes.

You can also find out what VAZ (Lada) 2108/2109 owners chose among manufacturers of such spare parts as: Timing belt, Cooling radiator, Pump, Thermostat, Spark plugs, and others.

VAZ 2109: which clutch to choose and how to do it yourself

Today are no longer the days when the necessary part could only be found from a speculator, purchased at exorbitant prices on the market or through great connections. Then there was more confidence that the quality of the spare part would be 100 percent. Now there are a lot of different clutch kits for the VAZ 2109. “Which clutch to choose?” - this question is becoming more relevant than before. It is noteworthy that on a VAZ 2109 you can determine which clutch is better yourself.

VAZ 2109 when to change the clutch

On the modern market there are copies from different manufacturers, both domestic and foreign, thereby complicating the choice of truly high-quality clutch discs.

Note! Statistics show that most pressure and driven disks sold in markets and stores are of dubious quality, and sometimes you can even stumble upon counterfeits.

So, which clutch is better to buy and how not to make a mistake in your choice? First you need to figure out what today's manufacturers offer:

Firstly, this is a factory VIS clutch, also called “stock”. In principle, the product is not bad, it is supplied by the AVTOVAZ plant itself for assembling cars. It is not difficult to distinguish an original clutch from a fake; you just need to check the presence of laser markings applied to the discs themselves. In addition, you can send an SMS with an identification code and receive a response message confirming its uniqueness and quality.

VAZ 2109 clutch kit

Secondly, there is an imported line of products, this includes VALEO, LUK, SACHS and KRAFT clutches. Among such a variety, the buyer has to make a difficult choice. When choosing, it is not recommended to rely on beautiful packaging and name, since a primitive Chinese counterfeit of a certain brand may be sold.

What to choose

For example, some people prefer a Mercedes, while others prefer a Muscovite. In one case or another, supporters of a particular part, brand or company will find a lot of evidence in their favor. For the above reason, there is no need to compare and draw a conclusion about the best grip. As a rule, this is a matter of habit. Some people prefer a soft clutch, while others have a car with an automatic transmission, where the driver does not even know what the corresponding pedal is for.

VAZ 2109 soft clutch

One way or another, many consumers choose a clutch without taking into account advice and recommendations. They are guided solely by their own experience in operating a particular clutch. Let's look at the most famous brands of car clutch kits; you don't have to follow the recommendations, but it's still worth reading the information. The driver decides which clutch is more suitable: Valio, Kraft or Luk. Sometimes you even have to try all three brands in order to decide on the right part.

French or Korean Valeo

VAZ 2109 clutch drive

It is difficult for high-quality car parts to exist on the Russian market, since many people want to counterfeit them. This also applies to the Valio brand.

Note! A counterfeit of this brand can be immediately tracked by its relatively low cost, as well as by the quality of its constituent elements. Now on the modern market you can find French, Italian, Spanish and South Korean Valio clutch components. From France, of course, less.

Motorists who prefer this brand speak only positively about the products. This clutch is also called female, as it ensures easy and smooth operation.

VAZ 2109 clutch which one to choose

It should also be noted that it has good reliability and a significant service life. If the Valio clutch is used correctly and with care, then it will be enough for 150 thousand kilometers. The original discs are not afraid of overheating (this refers to the permissible limits), while the flywheel is characterized by practical eternity.

German meticulousness of the Luk clutch with high quality

VAZ 2109 clutch which is better

It is difficult to say how plausible the information offered is, but it is still taken into account. They conclude that today such a clutch kit is installed on every second car made in Germany and on every fourth car from another manufacturer. Of course, it is almost impossible to prove this; most likely, it is so. If we take into account the eternal formula of the marketing ratio of price plus quality, then this clutch fits well here.

The best clutch for VAZ 2109

A distinctive feature of the Onion clutch is the vibration damping characteristic of such a device. The corresponding conclusions can be drawn from the reviews of Russian motorists.

Note! Luk clutches are equipped with a special damping element for vibrations of the driven and pressure plate.

Kraft clutch

Best clutch VAZ 2109

Note! The downside, perhaps, is the short service life of the release bearing. As a rule, this will most likely directly depend on the driving style of the vehicle.

Clutch kits from Kraft reliably “sit” in their niche of the Russian car market. And this is not surprising, since the products are characterized by excellent quality despite their low cost. Which clutch to choose for your car will depend only on personal preference. Each of the purchased kits can be installed using a training video and photo completely with your own hands. Also, for ease of work, individual detailed instructions are included. Don't forget that the price should always correspond to the quality.

By the number of torque transmission streams

Based on this indicator, systems can be divided into:

- Single threaded. The most common option for installing a mechanism between a car engine flywheel and a transmission drive pulley is shown in the photo. The actual role of the drive pulley is performed directly by the flywheel. A driven pulley with friction clutches, mounted using special fasteners to the transmission shaft, is connected to the end of the device using springs. The main advantage is the versatility of such systems, which cannot be said about dual-flow ones.

- Double-flow. In fact, this type is a combination of two single-disk devices, and each of them is equipped with both driven and driving pulleys, which are compressed by means of specialized springs. The main disadvantage of the system is its lack of versatility - such mechanisms are used only on tractors and other agricultural machinery.

Let's summarize

From the above, we can conclude that the operation of replacing the release bearing of a VAZ 2113-2115 is not as labor-intensive as it might seem at first glance. The most important thing is to follow the above instructions and master all the listed tools.

If you doubt your abilities, it is better to entrust the work to professionals. The price for replacing a release bearing for a VAZ 2113-2115 is from 2000 to 3500 rubles. The price for the work is the same as for replacing the entire clutch.

The process of replacing the release bearing of a VAZ 2113-2115 is clearly shown in these videos:

Symptoms of malfunction

The clutch release bearing itself will tell you that its life is already at its limit or it has completely failed. Therefore, your task is to monitor the behavior of the car and promptly respond to emerging problems.

| Sign of breakdown | Peculiarities |

| The clutch pedal becomes hard to press | Initially, this only causes a certain discomfort, since you have to apply more force to change gears. But this phenomenon should not be ignored. Bearing needs to be replaced |

| Difficulty engaging first and reverse gears | This indicates that the bearing's life is gradually ending, and you urgently need to take action. If you don't do this, you will soon be unable to engage any of the gears in your transmission. |

| The car doesn't pull | There is a loss of efficiency and performance of the box. Consequently, it is not possible to change gears correctly and quickly. This makes maneuvers, overtaking and a banal increase in speed more difficult. |

| The car is slipping | This happens occasionally at first, and therefore almost every time you change gears. This symptom clearly indicates that it is time to send the car to a service station or garage for repairs. |

Old and new gearbox

If the release bearing is not replaced in a timely manner, the gearbox will soon fail, the clutch will not work, and this will lead to dire consequences.

Consequences of wear

If you have encountered such a phenomenon as wear of the clutch release bearing, then you probably often drive your own VAZ 2109. It is time and the many kilometers traveled that lead to such breakdowns.

If the bearing is not replaced in time, this will result in the following consequences:

- Any subsequent trip may be the last for the car;

- The clutch disc will overheat, which will lead to destruction of the lining;

- In addition to replacing the bearing, you will have to replace the entire clutch disc;

- It is not uncommon for the clutch to fail. If you hear an incomprehensible noise coming from the clutch system, then there is a problem with it.

How do you know if your clutch needs repair or replacement?

Signs that the clutch mechanism is worn out or faulty may include the following malfunctions:

- great effort when changing gears;

- extraneous noises that occur when the clutch is depressed;

- slippage;

- the clutch is not engaged at full strength.

If at least one of these signs is observed, you should conduct a diagnostic inspection of the mechanism or send the car for service. If repair turns out to be impossible, you will have to think about completely replacing the clutch with a new one.

When inspecting a new clutch kit, the closest attention should be paid to the basket. Even if one of its petals is uneven or crooked, you should immediately refuse the purchase.

Driven clutch disc (ferodo) - purpose, types, device

The clutch of a car is a unit that has a very important function - it ensures soft and painless gear shifting for the car.

What is the clutch driven disc used for?

The job of the clutch is to transfer torque from the engine to the transmission, to disconnect the transmission from the running engine for the time necessary for the driver to engage the desired gear in the gearbox and to ensure a soft (without shocks or shocks) connection of the transmission back to the engine. One of the main parts of the clutch is the driven disc.

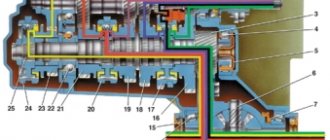

The driven disk has friction linings on both sides, thanks to which, due to the friction force, the driven disk receives rotation from the driving disk. There are also special cuts on the driven disk to avoid warping of the disk in case of strong heating, and there is also a device called a torsional vibration damper. The clutch driven disc is a complex part. It has its own hub, which is not rigidly connected to the disk. The hub has internal splines to connect to the transmission drive shaft splines, and it is mounted inside the driven disc itself. A torsional vibration damper is installed on one side of the driven disk. Friction plates are rivet-fastened to the damper and to the driven disk itself. Dampener disks and oil deflectors are installed on both sides of the hub flange and driven disk. Oil deflectors, damper discs and the hub flange are connected to each other with rivets.

Thus, the driven disk is free and can rotate at a certain angle relative to the hub. The damper disks, damper ring and driven disk have windows into which springs with support plates are inserted. The springs are pre-compressed, but not fully compressed. The rotation of the flywheel is transmitted to the clutch housing, and from it to the pressure plate. From the pressure plate, rotation due to friction is transmitted to the friction linings and to the steel disk of the driven disk, then through the torsional vibration damper springs to the damper disks, then to the hub flange, to the hub and through the splines to the gearbox drive shaft. With a sharp change in rotation speed, the damper springs are compressed and, as a result, torsional vibrations are somewhat reduced, which helps to avoid damage to gearbox parts.

How often should you change the clutch disc?

The clutch driven disc is a fairly strong unit, the task of which is to be able to withstand significant dynamic loads and compensate for the lack of sufficient clutch operating skills of an inexperienced driver. However, with intensive and not very careful use, the clutch driven disc gradually wears out, and certain malfunctions may occur. For example, friction linings may wear out or become damaged, the main steel disk may become deformed due to overheating, damper springs may break, and the hub splines of the driven disk may wear out.

It happens that the clutch driven disc wears out prematurely if errors were made when installing and adjusting the clutch. The durability of the clutch driven disc initially depends on the strength and load characteristics inherent in the design, on the quality of the components, and most importantly, on the skills and driving style of the car owner.

Under normal conditions, a high-quality clutch disc on any other car may require replacement no earlier than after a mileage of 100 thousand km. Wear of the clutch driven disc will certainly be indicated by clutch slipping, and a characteristic smell will appear in the cabin.

Posts 1 to 20 of 163

1 Topic by AlexeyG 2008-12-24 19:42:22 (2009-03-13 11:50:07 edited by maniboo)

- AlexeyG

- User

- Offline

- Registered: 2008-11-09

- Messages: 23

- Reputation: [ 0 | 0 ]

Topic: Clutch selection

It looks like the clutch is about to be replaced, there is a dip in 4th gear, periodically slips in 2nd, sometimes with interference on. transfers. I drive calmly and handle the clutch gently.

I don’t want to buy the factory kit, the reviews are not flattering about it.

A choice arose - to supply a cheaper kit - KRAFTTECH, or Valeo, LUK or SACHS.

I read a lot of reviews on the Internet, some say that the craft is a city, but it doesn’t go much in the region of 10-50 thousand km, some just squeak from it, about Valeo and other reviews are better, but you can easily run into a fake.

As I understand, the main problem with all current clutches is the release clutch.

And somehow 50 thousand is not enough for a clutch, although it is not known how the people who write about it drive.

Who will say what, who changed it, who installed what?

2 Reply from Driver 2008-12-24 19:57:35

- Driver

- User

- Offline

- Registered: 2008-12-08

- Messages: 460

- Reputation: [ 0 | 0 ]

Re: Clutch selection

They say SAX has good grip. Just be careful not to look at a fake. My car now has Kraft. Mostly I drive calmly, but sometimes I let the car go to shit. Once I set it on fire a little when I was dragging the “herring” up the mountain. The engine couldn't handle it and I had to play with the clutch a little. I don’t know how long the old owner drove it. I skated 50 thousand on it and have not yet found any signs of death.

3 Reply from AMX 2008-12-24 20:11:21

- AMX

- User

- Offline

- Registered: 2008-12-11

- Messages: 389

- Reputation: [ 0 | 0 ]

Re: Clutch selection

Craft - woof** +1. A friend put it on drain and it still spits.

Sachs (mine) - Very soft pedal - in traffic jams it’s just super, when compared with the same craft and VIS. But during dynamic driving it smells a little. It cost about 55 thousand. So far it’s normal, I think it’s enough for another 15 safely.

4 Reply from DAF 2008-12-24 20:11:55

- DAF

- User

- Offline

- Registered: 2008-11-19

- Messages: 33

- Reputation: [ 0 | 0 ]

Briefly about the Lada Samara torque transmission system

Before discussing which clutch is better on the VAZ 2114, it would be useful to consider the design features of the friction mechanism. The designers decided to abandon the classic hydraulic drive circuit for controlling the release fork, and developed a mechanical type drive based on a cable for front-wheel drive cars. Constructive nuances can be expressed in the following points:

- A single-disc dry clutch is a permanently closed type device.

- The shutdown process involves a diaphragm pressure spring.

- The driven disk is equipped with a torsional vibration damper.

- Cable clutch drive without gaps between the pressure spring petals and the bearing.

The Samara model is equipped with a clutch with a diameter of 190 mm (2109-1601085), Samara 2 has a clutch with a diameter of 200 mm (2110-1601085). New designs have softer dampers, which makes it possible to effectively smooth out uneven crankshaft rotation not only at idle, but also during load and engine braking. The owner can only determine which clutch is best to install on the VAZ 2114, and choose a high-quality kit from the mass of offers.

Subject to compliance with the operating rules, some copies work out their service life of up to 100-150 thousand km. If previously car owners preferred to buy exactly those clutch parts that had failed, in recent years there has been a change in priorities towards the purchase of kits. This is due to the increasing qualifications of our drivers; many have realized that comprehensive repairs are much more profitable financially.

Rating of the TOP 8 best clutches for VAZ

Among the wide range of clutch kits, we can highlight the most popular and high-quality ones.

Valeo

The leader in the question of which clutch is best to install on a VAZ is the product from Valeo, which is valued among motorists for its reliability, quality, and service life.

The product is more expensive than competitors, which is explained by good performance. Average mileage is 120 thousand km. Often the mechanism remains operational up to 200,000 kilometers. The disk can withstand severe overheating without breaking.

The safety factor of the set is 6000 rpm. The device works normally at 9 thousand. This indicator is important for owners of modified models.

The average cost of a kit for a VAZ-2114 and other models is 7-8 thousand rubles.

Source

Signs of malfunctioning parts

The release clutch can fail not only due to improper use, but also due to natural wear and tear. Knowing the operating principle of the device, you can determine its technical condition based on its characteristic symptoms. Typical symptoms of a malfunction are:

- The occurrence of extraneous noise when pressing the clutch pedal. The destruction of the node is accompanied by a grinding or loud crunch.

- Gear shift drive sticking. Sometimes it is impossible to turn on the desired speed.

- Excessively free play of the clutch pedal.

- Incomplete engagement or disengagement of the clutch. The situation may be accompanied by an unpleasant burning smell.

Additional signs of a breakdown are: increased fuel consumption, engine overheating, and jerky movement of the vehicle. The service life of the part is reduced due to dust and dirt getting into the bearing, increased temperature and lack of lubrication.

Signs of a defect cannot be ignored, because... This can lead to serious consequences when driving with a faulty transmission.

Control check

You can diagnose the condition of the squeezing device in the following way:

- Start the car engine. Listen to your work for any extraneous noise. If available, determine the location.

- Depress the clutch pedal. If an extraneous sound appears, the part will need to be replaced.

The bearing cannot be repaired. The problem is solved by replacing the defective part.

Consequences of malfunction

The element has sufficient strength, so it cannot fall apart instantly. However, there is no point in delaying the elimination of the defect, since failure leads to misalignment of the disks and uneven wear. As a result, problems will arise with the transmission, which will negatively affect the technical condition of the vehicle.

Signs of a faulty clutch

They talk about a malfunction of the clutch or its drive:

- Difficulty shifting gears;

- the enormous force required to depress the pedal;

- clutch slipping. This means that when the engine speed increases, the speed does not increase;

- pressing the pedal is accompanied by noise from the gearbox;

- moving away is accompanied by powerful shaking of the vehicle.

A break in the tip of the clutch cable cannot be foreseen, but in the latter case, you can move off simply by starting the engine with the starter while first gear is engaged, and you can switch from speed to speed without disengaging the clutch.

Repair work

If you decide to do everything yourself, follow the following sequence of actions.

- Drive onto an overpass or pit. This will make it more convenient for you to work.

- Raise the front of the car using a reliable jack and securely fix the nine.

- Remove the wheels.

- Disconnect the clutch housing ground and clutch cable. Next you will have to remove the transmission.

- To do this, remove the starter by disconnecting the wires, terminals and unscrewing the three mounting nuts.

- Disconnect the speedometer cable and reverse cable.

- Remove the brace fastenings to the suspension arms and move them to the sides.

- Disconnect the ball joints from the swing arms. To do this, you need to remove the cotter pin, unscrew the nut, and knock out the support pin. Then the two nuts are unscrewed and the hinge is disconnected.

- Using a pry bar, press out the tip of the inner CV joint. Be sure to plug the hole formed in the gearbox using improvised means, otherwise oil will begin to pour out of the gearbox.

- Remove the lower clutch housing protection. There are only 3 bolts holding it in place.

- Make supports from bars, bricks for the box and engine.

- Remove the rear supports.

- Unscrew the remaining fasteners and pull the gearbox horizontally. Be careful not to deform the pressure spring lobes with the input shaft.

Removal and inspection

- When unscrewing the mounting bolts, it is better to secure the driven disk with something. A regular large screwdriver will do.

- Be careful not to give out the driven disc and remove the clutch assembly.

- Examine the current condition of the parts. If mechanical damage is noticed on them, we recommend replacing them immediately.

The next step is to check the condition of the parts.

| Object to be checked | Peculiarities |

| Release bearing | Try to crank it up. If crunching or extraneous sounds occur, the part must be replaced. |

| Driven disk | Check it for signs of wear and damage on rubbing surfaces. Also, the rivets should be located at a depth of at least 0.2 millimeters, and the springs in the sockets should only be solid and tightly installed. Otherwise replacement |

| Basket | This is the pressure plate. Check it for damage or cracks on the working surface. Plus the condition of the flywheel is checked |

| Diaphragm spring | If there are cracks here, the petals dangle or are located in different planes, the part goes to scrap, and a new one is installed in its place |

Dismantling work

It is quite rare that individual components of the coupling are changed independently of the others. Mostly repairs involve replacing the assembly, which includes the pressure plate, release bearing and clutch driven disc.

Assembly of the unit is performed in reverse order. Just make sure that you choose really high-quality parts for replacement. For example, a normal quality clutch disc will cost about 1,000 rubles today. We do not recommend taking cheaper options.

Loading …

Replacement

Not all car owners decide to replace the release bearing (TR) themselves. But if you are ready for this kind of work, then go for it.

VI components

The main difficulty in replacing the gearbox is the need to dismantle the gearbox. Without this event, it will not be possible to replace the component.

Therefore, think twice before making a final decision. There is always the opportunity to contact a car service.

To work you will need the following set of tools and materials:

- Set of wrenches;

- Jack;

- Several durable bricks;

- New release bearing;

- Screwdriver Set;

- Container for draining transmission fluid;

- Clutch holder;

- Garage with a pit or lifting mechanism.

It is better to divide the entire replacement procedure into two main stages.

- Removing the gearbox.

- Bearing replacement.

Many people make the mistake of relaxing too much when they finally change the bearing. In practice, reassembly often causes more problems than dismantling work. Please take this into account.

Dismantling the gearbox

- Place the car over a hole or overpass.

- Lift the hood, remove the negative terminal from the battery and throw it aside.

- Disconnect the ground wire from the clutch housing.

- Use a screwdriver to remove the engine splash guard. To do this, you need to unscrew several screws that hold the mudguard to the elements of the side wings. For the VAZ 2109, a key size of 8 is used. Having removed all the screws there, remove the parts of the engine mudguard and put them away for now.

- Disconnect the transmission drive rod. To do this, use a 13mm wrench to loosen the clamp bolts. Next, use a screwdriver to separate the ends of the clamp and disconnect the element from the gearbox.

- Be sure to disable the reverse optics sensor.

- Place blocks or bricks under the rear wheels of the car to prevent the car from moving.

- Remove the front wheels by first loosening the bolts and lifting the front part of the body. After removing the wheels, place pre-prepared bricks under the body.

- Using a 17 wrench, unscrew the nuts securing the ball joint to the steering knuckle on both sides.

- The extension is moved to the side, and the fastening screws of the left extension to the vehicle's suspension arm are unscrewed.

- Using a 10 mm wrench, remove the fasteners of the lower clutch housing cover.

- Remove the transmission mounts. This is done as follows. Place supports or bricks under the engine and a jack under the box. Unscrew the mounting screws of the support to the body with a 17mm wrench. After removing the bolt, remove the support bracket by unscrewing several corresponding nuts.

- We proceed directly to dismantling the gearbox. Using a 19 wrench, unscrew the fasteners of the clutch housing to the cylinder block. Use a jack to lower the gearbox slightly and move it away from the engine. Lower until the input shaft begins to come out of the box.

- Enlist the support of a partner, since it is quite difficult to remove the gearbox alone.

- Make sure that the gearbox input shaft does not rest on the clutch spring petals. If you allow this situation to happen, you will simply damage them.

- Carefully place the gearbox on the supports, being careful not to hit it. Otherwise, repairs will cost much more than buying a new bearing.

Removing a gearbox

Removing a gearbox is a complex procedure that requires a lot of time, patience and skills. Therefore, without these, it is better not to undertake work with your own hands.

Replacing VP

To change the release bearing, follow the instructions.

- After dismantling the gearbox, you can examine the condition of the release bearing. Spin it by hand. If at the same time there are extraneous noises and crunching sounds, then it is obvious that the VP has lost its former performance and needs to be replaced.

- Using a screwdriver, remove the ends of the spring clip and remove the clutch release.

- Move the spring petals of the pressure ring and remove the release bearing from the clutch. To do this you will need to remove the holder.

- At this point, bearing dismantling can be considered complete, so install a new bearing instead of the old element.

- Before installation, make sure that the element is in good condition, rotates freely along its axis, there are no jams, there are no crunches or extraneous noises.

- Swap the old and new bearings. Insert the element into the coupling so that its protruding part is directed towards the coupling.

- Secure the bearing with the clutch holder. You need to hold the bearing in place.

- Take some regular motor oil and apply it to the shaft.

- Install the squeezer onto the shaft and secure the part with a spring.

- During the reassembly process, strictly adhere to all recommendations and maintain surgical precision.

How to replace the clutch - next steps

Remove the speedometer limit switch. All we have to do is turn off the cardan, which is located under the boot. Unscrew the stopper. They disconnected everything from above and unscrewed it, removing the clutch pedal cable.

Now you need to unscrew the rear airbag. The engine will hang, the box will tilt down a little. We unscrew the bolt securing the pillow to the side member and pull it to the side. Due to the fact that the engine is suspended, the box can flop around. We check that all the bolts have been unscrewed. Let's take a small montage. If you are removing the box for the first time, then place a board under it. Otherwise, without knowing the actual weight of the gearbox, you may drop it.

You will have to lower the engine a little, since the bracket does not allow the box to come out. With a slight movement of your hand, remove the box. Her weight is twenty kilograms. The problem was with the clutch, we see a half-dead release bearing, worn out petals that were sticking. Water got into the basket and there was rust.

Next, let's see how worn the clutch basket is. Here we see a leak of antifreeze from under the pipe. The wear on the clutch disc is visible. The car has traveled many kilometers, not 150 thousand, but more. The bolts all unscrew like clockwork.

Let's put another basket. Try to choose a clutch disc with a large number of springs and a clutch with a large number of petals, then everything will work smoothly. There is very little left to do to replace the clutch. Assembly is carried out in reverse order.

Replacing the clutch cable on a VAZ 21099

The more vulnerable link in the clutch, especially in urban traffic, is the cable - over time, the wires from which its core is woven begin to fray in places where it twists. By lifting up “against the grain” inside the shell, they interfere with the normal movement of the cable inside the shell. Therefore, the force required to depress the pedal increases over time.

When removing the old cable, start by loosening its tension by loosening the nuts securing the cable to the bracket at the checkpoint (Checkpoint is a point designed to control passage (visit) and entry into the territory of any facility)

, then disengage it from the fork.

Next, remove the cable end from the pedal. It is held on the axis of its lever by a special lock, which is simply removed with a screwdriver.

Adjustment of the cable tension is done with nuts that strengthen its sheath to the bracket. The clutch pedal, when the cable is adjusted correctly, must be placed flush with the other pedals.

Clutch kit VALEO or Luk

Luk spare parts have always been of high quality. They are made very well. I bought Luk for myself more than once. If you pick up Luk and another manufacturer, you will immediately understand the difference. I'm a taxi driver, so I only get out of the car to eat or sleep, so I always had a separate conversation about the quality of spare parts. The Luk clutch discs that I came across earlier were always equipped with reinforced springs - this is good;

the bearing is always perfectly lubricated; the release bearing does not need to be lubricated immediately when installing the clutch; Due to the frequently located petals, the squeeze is slightly softened, which reduces the load on the cable, bearing and fork. Take it, you won't regret it.

I have been working in the service department for a long time and have installed more than one Valeo clutch. I can say that the clutch is of the highest quality. Customers are always happy and note the smoothness and ability to withstand overheating. Valeo lasts for about 100,000 km. The price is certainly higher than competitors, but it's worth it.

But to get a quality part, you need to find the original.

Four years ago I installed a Luk clutch kit on a VAZ 21093, and they installed it for me at a service center. I went for a test and was pleased. Smooth starting, soft clutch pedal. I've been driving for 4 years now, I've covered 100 thousand km. and it never stank. I tore up, skidded, pulled on a cable, dragged trailers.

Everything is fine, it didn’t even fall a centimeter, it works flawlessly and without any complaints!

I can’t say that this clutch is excellent, there are better ones. I take it when I can't find anything else. There are no complaints about the appearance, everything is done well, conscientiously. During installation, everything falls into place without problems, no nuances are detected.

But when driving, the clutch slips and burns, the result of burning is felt for quite a long time. Clutch life also does not differ in duration.

The clutch is simply disgusting, I bought a creeper for Suzuki. In general, I skated 7000 km, so I don’t recommend it to anyone, it’s a waste of money.

I decided on LUK 06A141025H; I really liked how it was not too soft, but not too hard. The mileage is 15 thousand km, I start off without problems, nothing creaks.

I began to notice dips and jerks when shifting gears, I think that the clutch has reached its end, but replacement... the story is certainly not cheap. I went to the Kiavodov forum, read people’s opinions, and read an article on Drive Ru. In the end, I settled on the original clutch from Valeo, a French manufacturer of spare parts.

Now it has already driven 3000 times, there are no failures, everything seems to be normal.

I also have a Valeo clutch on my Kia. I bought it at a discount (the box was torn) with a good discount, so it was even cheaper compared to the competition. I drove 25 tkm, no problems.

I got tired of changing the clutch, so in 2.5 years I replaced the third clutch set. The store manager recommended a clutch kit from Luk! It’s good that everything comes included: the basket, the clutch disc and, not least, the clutch release from the same company!

While I've been driving for a month, first and second gears have become harder to engage, maybe the disc hasn't gotten used to the basket yet. In general, the gears shift smoothly, there are no slips, and it starts without jerking. Time will show.

I bought a VAZ 4, liked it very much, drove 50,000 km. It worked accurately and never failed. I changed the car to a “five” and installed Valeo there too, but it was enough for 5,000 km, I installed a new one, it was enough for 14,000 km. Now the third set has traveled 10,000 km and it also looks like it needs to be changed.

Perhaps this is a fake, I took it at the market. Be careful when purchasing this clutch.

Help others - tell us about your experience using the spare part.

Erases the disc. It squeaks like a garbage truck at speed, at a traffic light. Always .

Luk clutch discs only have 4 reviews. Perhaps you will add another one?

OEM Honda power steering fluid has its first review!

Khimik rust converters only have 10 reviews. Perhaps you will add another one?

GIGAWATT batteries only have 10 reviews. Perhaps you will add another one?

The UFI oil filter has only 10 votes! Do you recommend?

Voted FOR Gates drive belt on rating page

Voted AGAINST DAYCO drive belts on the rating page

Voted FOR Contitech drive belt on rating page

BFGoodrich tires have only 20 votes! Do you recommend?

There are already 15 manufacturers participating in the ranking of the best air conditioner radiators!

The crossbars are installed incorrectly - backwards. .

There are already 10 manufacturers participating in the auto rating of stabilizer struts for the Ford Focus!

There are already 5 manufacturers participating in the auto rating of fuel filters for Mazda 6!

There are already 5 manufacturers participating in the auto rating of oil additives for Opel Astra!

I've done 20,000 km and that's it. I bought it for 410 UAH. I won't buy it again. They also write that the company is cool. Ordinary shit. Okay h.

There are already 70 manufacturers participating in the ranking of the best radios!

There are only 9 manufacturers in the ranking of the best flame arresters. Perhaps you know of someone else?

Syntek is my favorite, because I not only use them as antifreeze, but also oil, and it is much better, even better than some.

Could it be a bad sensor? I installed denso and everything was fine [email protected] Fanto, .

There are already 25 reviews written on Motordetal-Kostroma.

There are already 40 manufacturers participating in the ranking of the best oil additives!

There are already 25 reviews written on GT Radial.

There are already 25 reviews written for INCI AKU batteries.

There are only 14 manufacturers in the ranking of the best crankshaft oil seals. Perhaps you know of someone else?

CTR tie rods already have 150 votes!

Voted FOR RAVENOL motor oil for Ford Focus on the auto rating page.

Other clutch kit comparisons

If this comparison does not satisfy your curiosity, then you can also find many others on PartReview.

For example, comparisons of VALEO clutch kits with such companies as: Sachs, KRAFT TECH, Hola, KRAFT, TRIALLI, VIS, Exedy, PILENGA, AISIN, TRIAL.

Comparisons of Luk clutch kits with such companies as: Sachs, KRAFT TECH, Hola, KRAFT, TRIALLI, VIS, Exedy, PILENGA, AISIN, TRIAL are also available.

In addition, you can find out who is better among other clutch kit manufacturers: VALEO or Sachs, VALEO or KRAFT TECH, VALEO or Hola, VALEO or KRAFT, VALEO or TRIALLI.

Recommendations

Comments 45

Take Native metal

Where else can I get the third one?

Does everyone on your collective farm talk like that? You must have a certificate. Or are you getting it? Are you writing from the hospital? Although it’s high time I gave it to you, judging by the comments.

I will decide for myself and did not ask for your opinion in my comments. I hope you know what to do with your opinion in such cases.

and your knowledge is already visible)))

I won’t lie, but from some clutch kit they immediately throw out the bearing. It’s just that when I was looking for a kit for myself, I often came across such reviews. I took the VIS kit for myself, it was the same (as on the left in the photo), I was immediately confused by the internal plastic sleeve. but they said everything was fine.

Yes, they throw it away from a lot of places, from luk too. I just played with the Visa one, I didn’t like it

I have it since 08, it has a rounded part that comes into contact with the petals. www.rain-auto.ru/images/goods/19690.jpg it seems like the production is less, the contact area is larger. but I didn’t find a domestic one. And I didn’t take all sorts of crafts and trials.

I don’t have any options anymore, I need to choose something from these two

I ordered it from Nizhny Novgorod through a transport company)) yes, just like that, I went to the local store, and there are all sorts of things there. According to the principle, they brought it and buy it. I wasn’t happy with this, especially if I had to change the clutch, it’s not like changing the wheel, you can’t climb there much) if you’re interested, here’s the blog entry www.drive2.ru/l/9243732/

Moreover, the onion bearing should cost about 2.5 rubles (judging by the price on the existential), which is how much I took from them and in the autodoc, they always only sell the original. and in regular stores they’ll sell you everything you want www.drive2.ru/b/2514649/

Well then, when I change it, I’ll ask the masters, otherwise the camp has been divided))

They’ll tell you what’s worse (so that you can come again)) I personally don’t like this bow in the photo. It’s kind of clumsy, with burrs. Maybe it’s just a photo from the Internet, and there’s another one in the store? So this company is not bad (I took the tension roller for myself). Until I get around to replacing the belt (Goetz), roller (ina/bow) and pump (tza).

Well, I’m taking my buddy to the service center, I bet he won’t say crap. And then along the way they are both normal, so you just have to choose, I don’t have any others in the store, Phenox and AvtoVAZ. I already have these

yes how to say. I also asked a friend at the service center to measure the compression. And I got distracted by going to the store to buy a set of timing sprockets. I come, and they have already measured it! Idk, I didn’t like it that much, I wanted to see the process in person. In two it says the norm, and in two it’s about 10. It’s no longer a cake, it’s necessary to invest. I ask how much? 23tr for everything! I don't know if it was invented or not. It’s not burning for me, but the oil is already leaking. I think the caps. But it’s a pain to change them to 16kl. And you need to take off the head. and I’m like, if I remove the head, then I’ll want to do everything else at the same time.

They’ll tell you what’s worse (so that you can come again)) I personally don’t like this bow in the photo. It’s kind of clumsy, with burrs. Maybe it’s just a photo from the Internet, and there’s another one in the store? So this company is not bad (I took the tension roller for myself). Until I get around to replacing the belt (Goetz), roller (ina/bow) and pump (tza).

And by the way, watch your belt, Gates is not the same anymore

hatch and all this nonsense, that it will fall apart)) it is made of very durable “plastic”

Release bearing Lada Granta

Release bearing Gearbox 2181, Clutch release clutch Gearbox 2181 - replacement in Lada Granta

Well, I was struck by the death of the release bearing with a mileage of 23 thousand km, also known as the clutch release clutch of the gearbox 2181. Judging by people's reviews, this bearing does not last more than 30 thousand km. In the evening everything was fine. The next day in the morning, while squeezing the clutch, I noticed that it was somehow not being pressed correctly, I thought, maybe it seemed, and after 20 - 30 km the clutch disappeared altogether.

With the car running, I could not turn on the first and rear, 3,4,5 turned on with difficulty, and after a while they did not turn on. But with the car turned off, all transmissions were switched on. Having opened the hood, I pulled the clutch fork, it dangled as desired in different directions, i.e. was not fixed. Having reached the garage under my own power (25 km), I began to find out the reason. I disassembled and removed everything unnecessary that interfered with removing the box. We unscrewed and separated the box from the engine and supports, hung it by the CV joints (in this position it is problematic to install it later, it is better to read a repair book). The problem became immediately clear - the release bearing had died. Among other release bearings, I chose a roughly similar one - the Priorov one, but it still needed to be installed somehow, and for it to still work. In the 2181 gearbox there is a release fork similar to a fork from a cornfield, based on this I decided to also buy a release bearing spring from a cornfield (or from a VAZ 2101) that secures the bearing to the fork.