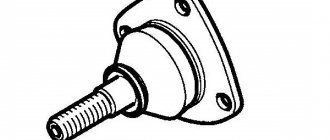

Ball joints are an important and indispensable part of a car's suspension, which connects the suspension arms and wheel hubs. This makes it possible to rotate and simultaneously turn left and right.

Previously, the role of ball joints in a car was performed by a pivot mechanism, this was the case until approximately the 60s of the last century. But this mechanism had many disadvantages, namely:

- fragility;

- heavy weight;

- it had to be constantly lubricated;

- ability to work only in the horizontal plane.

Therefore, with the advent of “balls” they completely replaced the “pivot”. There are several options for the location of supports in a car - two on top and two below, or only two supports on the bottom of the front suspension. And there are rear supports, they are installed in front-wheel drive cars with independent rear suspension.

The front wheels are able to turn because the upper supports support the steering knuckle. Modern technologies have made it possible to develop ball joints with a long service life, but this only applies to original parts. Unfortunately, there are now many handicraft spare parts on sale that are not of high quality. Naturally, the original hinges also fail and the reason for the rather downtime is wear. It occurs due to the friction that is created by changing direction and driving on uneven roads. The more the car travels along a bumpy road and the more often it turns, the faster the wear will be.

Absence or insufficient lubrication, as well as dirt, can accelerate wear. In passenger cars, ball joints have a sealed housing; this solution avoids constant maintenance. Some manufacturers additionally equip the supports with grease fittings to make it possible to add lubricant. It is added with a special syringe and allows you to increase service life by reducing the friction of the finger inside the support body.

Ball pins with a sealed housing do not have grease fittings (grease nipples), this prevents dirt from getting inside. Low friction in such supports is achieved thanks to a backing made of synthetic material. This affects the handling, it becomes light and this option is more preferable for front-wheel drive models.

When to change

- Remove the wheel.

- Clean the ball joints with a brush.

- Treat the connections with WD-40 (or equivalent).

- Using a “22” wrench, unscrew the nuts of the upper and lower supports by 1.5-2 turns.

- Install a specialized puller for ball joints.

- Usually the ball joints can be removed in one step (first the upper one, then the lower one). If the ball stays in place without applying force, you need to reposition it using a drift and hammer (hit the protrusions of the steering knuckle).

- After pressing out the ball joints of the VAZ 2107, it is worth removing the nut that secures the upper ball joint and remove it from the fist.

- This article may be of interest: Replacing brake fluid on a VAZ 2110 at home

The wear of ball joints largely depends on the intensity of driving, the loads being transported and the quality of the road surface. In addition to regular technical inspection at a service center, experts recommend inspecting the mechanism before a long trip or when a third-party knock appears in the wheel area.

Signs of replacing ball joints are:

- knocking while driving on an uneven surface at low speed;

- squeaking around the wheels when turning the steering wheel;

- unstable movement in a straight line;

- uneven tire wear.

Not every car enthusiast has a ball joint remover in their garage. In its absence, you can use a sledgehammer and a soft metal attachment. In this case, you will need to apply physical force to unpress the “finger”. You need to hit in a certain place, as indicated in the photo.

But it is worth considering that if the car is used for a long time, problems may arise with removing the “finger” in this way.

DETAILS: Changing the oil in a manual transmission Ford Focus 2 Complete step-by-step instructions

You should not delay the repair of ball joints, since the destruction of this mechanism while driving can lead to a serious accident. For replacement, you should choose components from a reliable manufacturer. Chinese fakes should not even be considered, despite the low price.

Symptoms of a problem

Obvious signs by which you can determine a malfunction of the ball joint:

- When driving on uneven roads or when driving at low speed, a characteristic knocking sound is heard in the area of the front wheel.

- When turning when the wheels are turned, you can hear a squeaking sound. It can be confused with noise from a wheel bearing.

- Uneven wear on car tires.

- When driving on a flat surface, the car wobbles from side to side, although the steering wheel remains motionless.

Useful : How to check a ball joint with your own hands?

If such malfunctions occur, it is necessary to diagnose the element. To do this, jack up the wheel from which the noise is coming, then insert a pry bar between the lever and the steering knuckle. We begin to swing the mount up and down. If the ball joint is faulty, then during such manipulations a knock will occur.

How to choose reliable and high-quality spare parts for repairs

For any repair, it is important to use high-quality components. You should not buy cheap fakes that will lead to breakdown after a short time. Many experts recommend using supports from. Here, high-strength steel is used for the ball “finger,” which is especially important. This element bears almost the entire load and the durability of the entire structure largely depends on its reliability.

Much depends on the manufacturing technology of components. Only large enterprises can use cross-wedge rolling, cold heading and other technologies that can significantly improve the quality of parts. You should not buy the cheapest ball joints made in China.

How to determine wear?

The lower and upper supports do not wear out at the same time, since the lower one bears more load and, of course, wears out more. To check how worn the ball pin is, you need to lift the wheel while supporting the lower arm. Then move the wheel up and down and determine if there is any runout. When rocking the wheel, it is possible to determine the presence of lateral play. If any of the problems are identified, the part must be replaced.

It is recommended to change the “balls” every 70,000 - 150,000 thousand km. This directly depends on where and under what conditions the machine is used. It is not safe to use faulty or heavily worn hinges. Most experts recommend replacing all hinges at once, for safety reasons and from an economic point of view.

Note: Check the wear of the “balls” before you want to lubricate them, because the lubricant will temporarily hide the gap and you will not see this moment.

Also check out

- To avoid turning your finger, you need to clamp the lever with a mounting tool.

- Remove the ball joint fasteners to the upper arm.

- Remove the ball.

- Clean the place where the ball joint sits on the lever (there should be no damage or cracks on it).

- Remove the sealing washer from the old ball joint and install it on the new one.

- Before installing the ball joint, you need to lubricate it with ShRB-4 or Litol-24.

- Install the boot and washer.

- Screw the ball onto the lever. Place it in your fist and tighten the nut.

- Unscrew the nut from the lower ball joint. Usually this causes the finger to start scrolling. To avoid this, it is necessary to create a lateral tension at the connection between the fist and the finger, for which a mounting is inserted in the gap between the brake shield and the fist. If there is no result in the gap between the fist and the lower arm, you should install an adjustable pin, and then use it to fix the pin.

- After the nut is unscrewed, you can raise your fist up. Place the key at “22” between the upper cavity of the fist and the lower lever.

- Remove the VAZ 2107 ball joint from the lever.

- Remove rust and dirt from the seat.

- Check the presence of lubricant in the lower part of the ball joint by unscrewing the plug with a “7” key. If there is no grease there, fill the ball with grease using a medical syringe without a needle.

- It will be interesting: Instructions for replacing the CV joint on a VAZ 2110 with your own hands

- Place the ball joint in place at the bottom of the lever and screw it to the knuckle.

- After this, we can say that replacing the ball joints with your own hands has been successfully completed.

DETAILS: Ford Focus 1 oil change Photo instructions for changing Focus 1 engine oil

Replacement of ball joints of VAZ 2107.

Replacement of the lower ball, like the upper one, is carried out using some tools, including a puller. At the same time, there is a certain scheme, taking into account which this procedure takes place.

- Removing the wheel.

- Cleaning the fastening elements of the VAZ 2107 support.

- Loosening the upper ball pin nut.

- Pressing a finger out of a fist. For this purpose, a VAZ ball joint remover is used.

- Unscrewing the fastening nut and dismantling it.

- Unscrewing the bolt securing the support to the lever.

- Dismantling the upper and lower ball with a cover and a pressure plate.

- Checking and replacing faulty parts.

- Reassemble the dismantled elements in the reverse order.

Upon completion of this work, you need to check the alignment angles of the front wheels.

When, during the diagnostics of the suspension, a faulty ball joint was identified, we are faced with the question of how to replace the ball joint on a VAZ 2107? I will answer it for you now. But before repairing, you need to decide on the tool. A long and painful replacement of ball joints on a VAZ 2107 without a puller is possible, because almost no one manages to do this without a puller. Or you can immediately buy a special tool and then I will show you how to use a VAZ 2107 ball joint puller.

We will look at how to dismantle the upper ball joint of a VAZ 2107 without a puller, and I will show how to remove the lower ball joint of a VAZ 2107 in a version with a device designed for this.

Replacing the upper ball joint of a VAZ 2107.

Replacement of VAZ 2107 ball joints occurs with the wheel removed. To remove the upper ball joint, for example, on the left side without a puller, we must perform the following actions: turn the steering wheel as far as possible to the left, loosen the ball nut, put something under the hub, so that when lowering the car from the jack, the hub fits tightly on this object, take a hammer and point it at the tide on the fist (just below the ball nut) and with a sledgehammer or an ax we hit the hammer sharply, but not too hard.

As soon as the pin comes out of the hub, unscrew the 3 bolts and dismantle the part.

But this case does not help in all cases. It happens that the ball simply rusts to the hub and there is no way to remove it except a puller.

Replacing the lower ball joint of a VAZ 2107.

Using a puller, the balls can be pressed out of the hub in less than 5 minutes. To do this, unscrew both ball pin nuts a couple of turns. Next, we insert the puller between the upper and lower ball pins and begin to unscrew the puller bolt as shown in the photo below.

DETAILS: Replacing the generator bearing on a VAZ 2114 Photo instructions on how to change the generator bearing on a VAZ 2114

Next, all we have to do is unscrew the bolts securing the balls to the arms and install new balls.

Assembly is carried out in reverse order.

During assembly, it happens that when you tighten the nut onto the ball pin, it begins to rotate. To avoid this situation, wipe the ball pin and its seat in the hub with a dry rag. And after inserting the ball into the hub, lightly but firmly hit the ball with a hammer a couple of times. After these procedures, the finger will not turn when screwing the nut.

It is most convenient to carry out repairs in an inspection pit or on a lift. This will ensure that you have a good overview for inspection and will have the necessary access to the mechanisms.

What tool will you need?

From the tool you will need:

- metal brush;

- solvent;

- a set of keys;

- puller for supports;

- adjustable wrench;

- medical syringe;

- lubricants.

The process of replacing ball joints on a VAZ 2114

Having prepared everything you need, you can begin replacing the VAZ 2114 ball joints. Follow the instructions and carry out the work step by step:

- Loosen the wheel nuts, then jack up the car and completely remove the wheel.

- Using a 17mm socket wrench, unscrew the ball joint to the knuckle. It is better to pre-treat the connection with WD-40, since most often these components are subject to severe corrosion.

- Using a 19mm socket, unscrew the nut securing the pin to the lower arm.

- We put the ball puller on the lever. How to remove a ball joint on a VAZ 2114 without a puller? You can try to knock out the finger with a heavy hammer. To do this, you need to hit the end of the lever. It would also be a good idea to lean against the pry bar at this moment to increase the load.

- Rotate the puller pin and squeeze the support out of the lever.

- We jack up the steering knuckle by the brake disc and pull out the support.

After this, the removal process is completed and you can begin installing the new part. For this we need:

- Insert the new support into the lever and tighten the nut.

- We remove the jack from under the brake disc and screw the bolts securing it to the knuckle. If the holes cannot be aligned, you can knock out the support a little with a hammer through a drift or wooden block.

- Tighten all fasteners. If you have a torque wrench, tighten the bolts to the knuckle with a force of 60 Nm, and the nut with 80 Nm.

- Then we put the wheel in place.

At this point, the process of replacing the ball is completed and you can begin checking. It’s enough just to ride around the site and follow the sounds. If they are missing, then the repair was carried out correctly.