Purpose of ball joints VAZ 2107

A ball joint (BJ) is an ordinary hinge built into the VAZ 2107 suspension and allows the wheel to move only in a horizontal plane. At the same time, it limits the possibility of wheel movement in the vertical direction.

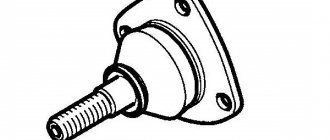

Ball joints on the latest versions of the VAZ 2107 have become more compact

Ball joints of the VAZ 2107 are very short-lived, so they have to be changed often.

Design of ball joints VAZ 2107

Previously, passenger cars did not have ball joints. They were replaced by bulky king pins that had to be lubricated frequently. The mobility of such compounds left much to be desired. This, in turn, negatively affected the car's handling. The designers of the VAZ 2107 abandoned the kingpins and installed ball joints. The first SHO consisted of:

- housings;

- ball pin;

- springs;

- anther

The finger was pressed into a fixed eye, fixed with a powerful spring and covered with a boot. This structure also needed to be lubricated periodically, but quite rarely (about twice a year). The lubricant on the pins had to be changed every week.

Modern ball joints do not use springs

Subsequently, the VAZ 2107 SHO was constantly improved:

- the spring disappeared from the structure;

- the steel boot was replaced with a plastic one;

- the fixed eyelet in which the finger was fixed became more compact and received a plastic external finish;

- SHOs have become non-separable, that is, practically disposable.

One driver I know assured me that he had found a great way to extend the life of plastic boots. Before installing new ball joints, he always applied a thick layer of silicone ointment to the boots, which car owners use to prevent the rubber bands on car doors from freezing in winter. From his words, it turned out that the anthers after such a procedure become practically “indestructible.” When I asked how an ointment intended for rubber could improve the quality of plastic, I was recommended to just try it and see for myself. Unfortunately, we never got around to it. So I leave it to the reader to check this driver’s find.

Reasons for failure of VAZ 2107 ball joints

The main reasons for SHO failure are as follows:

- Alternating shock load. As a result, the ball pin pressed into the suspension eye is destroyed. The support is designed in such a way that the shock loads on the pin ball are very high. When the quality of roads is poor, these loads increase manifold. In such conditions, even a high-quality SHO will not be able to fully exhaust its resource.

- Lack of lubrication. Under the influence of shock loads, the lubricant is gradually squeezed out of the SHO. In addition, over time, the lubricant loses its original properties.

- Anther destruction. The boot protects the hinge joint from dirt. If a crack appears in it, the dirt that gets into the joint turns into an abrasive material and grinds down the surface of the ball pin.

Dirt gets into the joint through a crack in the boot and wears down the surface of the ball pin.

Signs of malfunction of VAZ 2107 ball joints

The main symptoms of a VAZ 2107 SHO malfunction include:

- Extraneous sounds. While driving, a knocking or grinding noise begins to be heard from the wheel. This is especially pronounced on uneven roads at a speed of about 30 km/h and is usually a consequence of partial destruction of the ball on the support pin.

- Wheel rocking. When accelerating, the wheel begins to sway slightly in different directions. This happens due to the backlash that occurs in the SHO due to its wear. The situation is quite dangerous, and the backlash must be eliminated quickly. Otherwise, the wheel may turn at a right angle to the body at speed.

Play in the ball joint causes the front wheel to sway, which can spin out at speed. - Grinding and squeaking noise when turning the steering wheel left or right. The reason is the lack of lubrication in one of the SHOs (usually only one of the supports fails).

- Uneven wear on front and rear tires. This can happen not only due to faulty SHOs. The cause of uneven wear may be incorrectly adjusted camber and toe-in, insufficient or excessive air pressure in individual wheels, etc.

Auto repair school - Do-it-yourself car repair

May 24, 2016 VAZ 2101, VAZ 2102, VAZ 2105, VAZ 2106, VAZ 2107, Zhiguli, Classics by admin

UPD. 10/30/2016

The lower ball joint can be called the weakest and most capricious/problematic part of the front suspension of VAZ 2101-2107 Zhiguli cars . Owners of Classics Do you agree with me? I think we agree. Since the picture on the road - immobilized Zhiguli with the front wheel turned out, for example at an intersection or turn, is not uncommon. Therefore, it is better to check the condition of the front suspension regularly or unscheduled, at the first appearance of a creaking or knocking sound in the vehicle’s chassis. And if the technical inspection reveals wear of the ball joint, then it is better not to delay the repair. Since the ball coming out on the road is a serious problem! And, if it happens, then you will be provided with repairs on the roadway (you will not be able to replace the support on your own, without training and tools) with a call to the auto repairman to the scene (however, not every master will agree to work in the open air; there are those who refuse reasons) or transporting the car to a service station using a tow truck. Who needs such adventures? Moreover, even a novice motorist can easily replace the lower ball joint on VAZ-2101, VAZ-2102, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Zhiguli cars The main thing is to seriously prepare for work, that is, read this photo report to the end)))

Tool. In photo No. 1 you can see the main arsenal of tools, without which I, for example, will not undertake the replacement of the lower ball joint on the VAZ-2101, VAZ-2102, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107 cars . The main list, in addition to the wheel wrench, jack and VD-40, includes: socket and ring wrenches 13, open-end wrench 22, metal brush, sliding pliers and BALL JOINT PULLER for VAZ 2101-2107 cars. A ball joint remover is essential. I understand that it is not cheap and you can replace the ball joint without a puller (I will describe how to do this below), but believe me, working with a puller is much easier, more convenient and faster.

Spare parts. Everything is simple here. I personally recommend buying and installing only reinforced lower and upper ball joints . Since the stock ball joints have long been out of confidence. Yes, the ball pin can also be pulled out from the reinforced support, but this will be at least twice as difficult. And this is no longer enough. Next, I’ll go through the manufacturers whose ball joints inspire confidence: TRACK TRS SPORT (expensive, but the best and most reliable ball joints for Classics), AvtoVAZ , Kedr , Belebey , Belmag .

It is very good if the ball joint comes with fasteners (ball pin nut, three bolts with nuts and engravers). Let's look at photo 2. Why did I write “good”? Because manufacturers often supply ball joints to the market in two versions: with and without fasteners. With fasteners, the support is naturally more expensive. But, I advise you to still take it with fasteners (upon further reading, you will understand that this advice will be useful).

What else can I say about spare parts? Yes, here it is: the stock upper and lower ball joints for the VAZ 2101-2107 are externally different from each other. Therefore, during installation it is quite difficult to mix them up. What can not be said about the ball joints of the reinforced version. Therefore, manufacturers stamp the designations “B” (top) and “H” (bottom) on the supports. Let's look at photos 3 and 4. I think these signs are put up for a reason. Therefore, it will be correct to install the ball joints according to the designations.

There is one more addition))). Before installing the lower ball joint, regardless of the manufacturer, check for grease under the boot . This is not difficult to do on stock supports. On reinforced ones, you will have to tinker a little: using a screwdriver, remove the crimp ring securing the boot, remove the boot and check for the presence of lubricant (photos 5 and 6). If necessary, add lubricant; Litol-24 or ShRB-4 are suitable for these purposes. And, most importantly, do not overdo it when adding, since an excess of lubricant is just as bad as its absence. If you fill the boot with lubricant “to capacity”, then after installing the ball on the workplace, the boot will rupture immediately or after a very short time - this is 100%. Therefore, in this case, the saying “you can’t spoil porridge with butter” is not appropriate!

Detailed photo report describing the replacement of the lower ball joint on VAZ-2101, -2102, -2104, -2105, -2106, -2107, Zhiguli, Classic cars:

Let's get down to business. We put the car in “gear” and the handbrake. We install anti-roll stops under the rear wheels. Loosen the wheel bolts, jack up the car, finally unscrew the wheel bolts and remove the wheel. Do not forget to install insurance under the car body, for example, a wooden block or a removed wheel.

We twist the steering wheel to its extreme position (for example, if we are replacing the lower support on the left side, then we turn the steering wheel to the left).

Clean the ball joint with a metal brush. We spill WD-40 or brake fluid (photos 7 and 8).

Using a 22 wrench, unscrew the ball pin nut. It will not be possible to unscrew it completely due to the design of the steering knuckle. Again we spray the nut and thread of the ball stud with WD-40. Tighten the nut. Let's use VD-40 again. And unscrew the nut again. We repeat the “unscrew-wd40-tighten” process until the nut unscrews without effort (photos 9 and 10).

If you have a special puller for ball joints for VAZ 2101-2107 cars , then you can skip this paragraph. So it will talk about removing (unpressing the ball pin) the ball joint without a puller . And so, we take a sledgehammer and an extension (preferably made of soft metal, copper or aluminum). We begin to apply strong blows to the eye of the steering knuckle (photos 11 and 12). If you're lucky, two or three blows will be enough and the ball joint will be pressed out. If not, then you will have to be patient and time. And methodically tap the eyelet until the bitter end! The method works and allows you to achieve the desired result. At the same time, by swinging a sledgehammer, you can also warm up))).

If you have a puller, dismantling the lower ball joint is much faster and easier (photo 13).

After unpressing the ball joint pin, all that remains is to finally unscrew the fastening nut. At this point, work can go in one of two directions. In the first, the nut is easily unscrewed from the ball joint pin (the above-described “unscrew-wd40-tighten” process should serve as the key to success), you lift the steering knuckle up, and only a few moments remain until the end of the ball joint removal. Or, luck “turns its back on you” and events begin to move in the second direction. In a very “interesting” direction, where you have to fight with a stubborn nut. I even wrote a separate article on this topic. Therefore, if in your case the nut refuses to unscrew properly, I advise you to follow the link, read the article and emerge victorious in the battle with the nut))). True, in this case the nut will have a “cover” and the advice about buying a ball joint with fasteners will no longer seem useless!

The nut has been removed! The final part remains. Using keys 13, unscrew the fastening bolts of the ball joint to the lever (photos 14 and 15). We remove the support.

Remove dirt from the lower arm. We inspect the seat of the support on the lever for cracks and breaks (photo 16). If cracks are found, the lever should be replaced. If everything is ok, then install a new lower ball joint, be sure to lubricate the pin (nigrol, engine oil, lithol) and carry out the assembly in the reverse order (photo 17).

The work on replacing the lower ball joint on the VAZ-2101, VAZ-2102, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107 cars has been completed.

When using an article or photographs, an active direct hyperlink to the website www.avtorem.info is required!

Did you like the article? Share it on your page!

Diagnostics of ball joints VAZ 2107

You can make sure that the cause of the grinding or squeaking is the ball joint in various ways.

- Aurally. An assistant will be needed for this. Two people rock a car with the engine turned off, simultaneously pressing on both sides of the car's hood. If at the same time an uncharacteristic sound is heard from one of the wheels, the corresponding wheel is worn out or needs lubrication.

- Detecting the backlash of the sho. The wheel, on which the support has most likely failed, is raised with a jack by about 30 cm. An assistant from the interior presses the brake pedal as hard as possible. After this, you should forcefully rock the wheel, first in a vertical plane up and down, then to the right and left. When the brakes are locked, play will immediately appear. Even if it is insignificant, the SHO still needs to be changed.

To identify play in the ball joint, the wheel should first be rocked up and down, and then to the right and left. - Inspection of ball pins. This method is relevant only for the latest VAZ 2107 models, which have special inspection holes for monitoring ball pin wear without disassembling the support. If the pin wear is more than 6 mm, the ball joint should be replaced.

What to do if the upper ball joint nut rotates with the pin

Remove the hub from the lower pin. We pull it in our direction with our hand until it stops. We wedge the finger in the cone of the fist. It will be clamped, unscrew the nut completely.

Second option. We insert a pry bar between the pin and the edge of the lever. We are trying to move the pin away from the lever. We clamp the finger and unscrew the nut.

Video, if the nuts turn together with the ball pins, how to remove them:

How to replace ball joints without a puller

To press the ball joint pins out of the steering knuckle cones, you need to:

- Jack up the car under the beam, hang the wheel so that it and the lever “hang” in the air.

- Loosen the ball fastening nuts as described above

- We insert a pry bar, when replacing the lower ball joint, between the lever and the knuckle. We press it down, as if squeezing these two parts apart

- With the second hand we hit with a hammer with “bulging” eyes on the ebb of the fist, shown above in the screenshot. After some time, depending on the degree of souring of the ball pin in the cone, the pin will “fly out”

- For the top one we do the same. We insert the pry bar between the upper knuckle and the lever and hit it with a hammer until the ball joint pin pops out

The remaining operations are carried out according to the same scheme as replacement with a puller: preparation, cleaning, lubrication, etc.

Video - replacement without a puller:

Required tools and materials for DIY replacement

The table below shows the tools and materials that need to be prepared before replacing the ball joint on a VAZ 2107.

Table - Tools and materials required to replace ball joints

| Name | Note |

| Puller | Special for VAZ 2107 ball joints or universal, for example, fork type. In extreme cases, you can do without a puller by using a hammer |

| Metal brush and rags | For cleaning surfaces and fastenings |

| Penetrating lubricant | For example, WD-40 |

| Key | "at 7", "at 22" |

| Grease | Graphite, ShRB-4, Litol-24 or special for ball joints |

| adjustable wrench | Lasting |

| Hammer | Medium size for easy removal of ball joints |

| Scrap | Can be replaced with a mount |

| Jack | To lift the car |

| Balloon wrench | For removing and installing wheels |

Fork type puller

How to determine the malfunction?

There are several ways to determine the condition of the ball joints:

- With an assistant, we rock the car by pressing the front wings one by one. An uncharacteristic sound will come from the side where the balls are worn.

- Jack up the wheel and ask an assistant to press the brake pedal. We grab the wheel and try to swing it to the sides. When the wheel is locked, play is immediately felt.

- On the VAZ 2107 of the last years of production, holes appeared in the ball joints for diagnosing pin wear. To check the lower ball joint, insert the rod of a caliper into the hole as in the diagram below.

Parts selection

The main enemies of the upper and lower ball joints are not only water or dirt, but also low-quality materials. It is best to purchase spare parts made of steel, as they are the most durable and wear-resistant. Any auto store will tell you which companies produce such parts. Also, reviews of other VAZ 2107 car owners can help you in your choice. Most of them recommend paying attention to domestic manufacturers, since cheap Chinese analogues can fail at any time.

- pressure plate;

- ball pin cover;

- upper ball pin.