Several ways to bleed the brake system

Let us remind you that bleeding the brakes is very important for accident-free situations on the roads; keep an eye on the ABS brake bleeding system. Bleeding ABS brakes is possible in several ways, and their implementation depends on the design of the entire complex. There are two ways to remove air from the brake system, but in any case, you will need an assistant. The process of bleeding a brake system with ABS cannot be considered labor-intensive or complicated.

Method No. 1

After completely disabling the ABS system, you need to do the following:

- First, you need to bleed the unit farthest from the master cylinder - the rear wheel on the right side. You need to put one end of the hose on the fitting, and lower the other end into a bottle of brake fluid. You need to have an assistant behind the wheel who will press the brake with your foot. And press until the air is completely removed.

- While the assistant holds down the gas pedal, you need to unscrew the fitting. After the liquid or air stops flowing, you must immediately tighten the fitting. This operation must be repeated several times if bubbles still come out of the working cylinder.

- Then you can move to the rear left wheel and do the same actions.

- After this, we move to the right front caliper, and finish pumping the brakes on the left front caliper.

- When each slave cylinder has been bled, it's time to look at how much fluid is in the expansion tank. The main thing is not to allow the brake fluid to completely drain from the reservoir, because then air will enter the system.

Method number 2. Using a special pump, bleed the brakes

If it is possible to connect a pump, then you can use this method to pump the brakes, but you will also need a partner for this. It is imperative that after the brake bleeding process is completed, before leaving, you need to check the tightness of the system and the absence of leaks. Check the brake fluid level.

- To bleed the right rear cylinder, you need to put a hose on the fitting on one side, and on the other side, also put the hose in a bottle with brake fluid. Then you need to unscrew the fitting about 1.5 turns.

- The assistant will also press the brake pedal and turn on the engine. The attached pump will create pressure in the brake line and expel all the air. After the bubbles stop flowing into the bottle, you just need to turn off the engine.

- The rear left wheel is pumped a little differently. The hose is attached to the fitting and lowered into the liquid, and the drain must be unscrewed 1 turn.

- Turn on the engine and when the bubbles enter the bottle of liquid, you will need to press the brake pedal about halfway, after which you need to quickly tighten the fitting.

- Then you can release the pedal and turn off the engine.

- The main thing is to add brake fluid to the reservoir on time.

- When bleeding of the brakes has come to an end, you need to tighten all the fittings, screw on the cap on the reservoir and reconnect all previously disconnected connectors. Look under the bottom and check how tight the pipelines, fittings and cylinders are. And if nothing leaks anywhere, then everything is fine with the car and you can drive safely. Good luck in completing the solution to the problem of bleeding brakes with ABS.

Advice from experienced car owners

VAZ 2107 bleeding the brakes

We found out how often the brake fluid is changed. Below are some warnings for experienced drivers:

- replace based on the manufacturer's recommendations;

- mix TFs within the same class (it’s better to always use the same one);

- – follow the instructions;

- there should be no H2O;

- if contaminated, prompt replacement is required;

- in a car without ABS, do not allow the fuel fluid level to reach a critically low level when pumping;

- do not create excess pressure in the expansion tank;

- Wipe the tank only with a cloth (water is prohibited).

When deciding to change the solution, take into account the mileage and condition of the car’s brakes. Don't forget the car manufacturer's recommendations. The shelf life of the brake fluid is limited, and it must be renewed.

If you prefer to contact a specialized service station, use Uremont. Here you will quickly find a car service suitable for your location, read reviews from aggregator visitors and receive a response to your application in an average of ten minutes.

It is convenient to clarify questions about cost in a special chat with representatives of partner car services. We work for Russia, Kazakhstan and Belarus. We provide technical support around the clock.

Is it possible to mix brake fluids?

Important! Is it possible to mix brake fluids? Due to the fact that DOT 5 uses different chemicals that are found in DOT 4 and DOT 3. Therefore, DOT 5 should not be mixed with DOT 4 or DOT 3

Also, if the operating instructions for a particular car say that brake fluid other than DOT 5 cannot be used, then DOT 3 and 4 cannot be poured into the brake system of such a car.

How often should you change the brake fluid in your car?

The frequency of TJ replacement depends on the following factors:

- type of brake system;

- operating conditions of the vehicle;

- brake fluid class;

- composition (the basis on which the fuel fluid is produced).

For most cars, the service interval for replacing brake fluid is 40 thousand km, if the temperature in the system does not consistently rise above 150 degrees. For sports cars and premium cars, it is recommended to completely change the brake fluid every 20 thousand km. More information about the terms of use and the procedure for replacing brake fluid can be found in the car’s operating instructions.

Experts believe that it is undesirable to simply add brake fluid from time to time. Even if most of the fluid is renewed, its properties will differ from those of a completely replaced fluid. The same applies to mixing formulations of different brands and classes.

Sometimes the color of the fluid may indicate the need for replacement. Optimally, if the glycol liquid is light yellow or light brown, the silicone-based composition is dark red. It is worth replacing the fluid completely or contacting a service technician if the color has changed significantly, the liquid has become cloudy, or sediment has appeared in it. Delay threatens breakdown.

How to change the TJ?

- Open the tank.

- With a slight movement, unscrew the fittings involved in bleeding on the brake cylinders of a certain circuit and pull the rubber hose onto them.

- Place the ends of the hose in a container of water and completely pump out the fluid from the system using the brake pedal.

- Pour new fluid into the reservoir until clean fluid comes out of the hose.

- Tighten the fittings and pump the fluid by pressing the pedal to remove air from the system. As soon as liquid without air begins to emerge from the hoses of all four tubes, the hoses are removed and the reservoir cap is returned to its original place. The calipers and cylinders are replaced in the same way.

If you are not sure about the correctness of your own actions to replace the brake fluid, contact specialists at the official service centers of FAVORIT MOTORS Group of Companies. Experienced technicians will quickly and efficiently diagnose the system and perform all necessary work in accordance with the manufacturers’ recommendations. Don't risk your safety, turn to professionals!

Sources

- https://oooyuma.ru/uhod-za-avtomobilem/skolko-nuzhno-tormoznoj-zhidkosti-dlya-zameny.html

- https://etlib.ru/blog/610-skolko-tormoznoj-zhidkosti-nuzhno-dlya-zameny

- https://favorit-motors.ru/articles/obsluzhivanie-i-remont/zamena-tormoznoj-zhidkosti/

- https://autostuk.ru/skolko-tormoznoj-zhidkosti-nuzhno-dlya-zameny.html

- https://nahybride.ru/hodovaya-chast/zamena-tormoznoj-zhidkosti-svoimi-rukami

- https://zen.yandex.ru/media/uremont/kak-chasto-nujno-meniat-tormoznuiu-jidkost-v-avtomobile-5c98956b3bbd5d00b3568ec3

ABS bleeding sequence

- First, we look for and remove the fuse in the fuse block that is responsible for the operation of the anti-lock braking system.

- Next, we jack up and remove one front wheel, and look for the brake wheel cylinder (BWC) fitting.

- After this, we put a hose on the fitting (from the hydraulic level, for example).

- Open the fitting one turn.

- One presses the brakes all the way and holds it in that position.

- Now turn the ignition key to turn on the hydraulic pump (the ABS indicator lights up on the instrument panel).

- The second person watches how air is removed through the hose and, after removing the air, tightens the fitting.

- We release the pedal only after tightening the fitting.

- Now, how do you know that all the air has escaped from the ABS? This shows the ABS icon on the dashboard, if it goes out after removing the air and tightening the fitting, then all the air has escaped.

The correct sequence for bleeding the ABS system

There is a specific order for properly bleeding an ABS system: right front wheel, then rear, then rear right, and then rear left wheel. If during such work the fuel fluid leaks out of the system, it is necessary to fill the system with new fluid. And to do this, you need to know what fluids can be mixed and how much brake fluid is needed for replacement.

Sequence of operation for the front wheels:

- Turn off the ignition (key position “0”).

- Remove the terminals from the brake fluid reservoir.

- Take a bottle with a small amount of brake fluid and a hose. We lower one end of the hose into the liquid, put the second on the fitting and open the fitting with an open-end wrench. It is advisable to use a transparent hose from the hydraulic level so that you can see whether air bubbles are coming out or not.

- Press the brake pedal and hold it in this position.

- The second person (at the wheel) looks to see if the air is coming out, and after the air bubbles have stopped coming out, he closes the fitting with a key.

How to bleed rear wheels with ABS:

The procedure differs for pumping the rear wheels. After the front wheels, the rear right wheel should be pumped in the following sequence:

- We also put the hose into the bottle of liquid and into the caliper fitting.

- Depress the brake pedal all the way.

- Turn the ignition key to position “2”.

- Hold the brake pedal until the hydraulic pump completely expels the air bubbles.

- Close the fitting and release the brake.

For effective bleeding, when working with the brake system of the rear left wheel, the procedure must be adjusted. Namely:

- As in other cases, put on the hose and unscrew the caliper fitting 1 turn. When pumping with the rear left wheel, the brake does not need to be applied immediately.

- Turn the ignition key to start the hydraulic pump.

- After the air comes out, press the brake pedal halfway and close the fitting.

- Next, release the brake and wait for the hydraulic pump to turn off.

- Turn off the ignition.

- We connect the disconnected connector of the TJ tank.

Main signs of GTZ breakdowns

Lada LadaThe main task of this unit is to uniformly distribute the working fluid of the hydraulic system along the contours. Therefore, the slightest imbalance leads to a decrease in braking efficiency.

To determine the condition of the master cylinder or the need to replace it, experts advise paying attention to factors such as:

- readings of the warning lamp on the dashboard;

- brake oil leaks;

- cracks on the body

If at least one of these signs is detected, repairs should be started immediately. It is possible, of course, to partially restore defective parts, but practice shows that it would be more rational to install a new assembly.

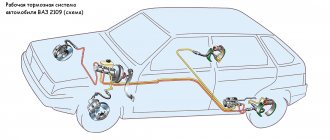

Scheme for pumping brakes on a VAZ-2110

The brake system of the VAZ-2110 has two circuits operating in a diagonal pattern. This dictates the procedure for removing air from the system. When performing work, it is necessary to follow the following pumping sequence:

- Right rear wheel.

- Front left.

- Rear left.

- Front right.

The procedure for bleeding the brake system of the VAZ-2110 and modifications.

Necessary materials

Before you start bleeding, you need to stock up on brake fluid for topping up.

We stock up on brake fluid of a certain brand, and if the brand is not known to us, we prepare for its complete replacement.

It is important to remember that the liquid must be the same brand that was used previously. If we are not sure what kind of brake fluid is poured into the VAZ-2110 system, it is better to play it safe and replace it completely. Otherwise, when mixing fluids of different types, clots may form in the system, which will damage the brakes.

Also for work you will need a transparent container half filled with liquid, a hose for the fitting about 40-50 cm long, a socket wrench with a cut out segment (union wrench).

Bleeding the brakes with an assistant

An assistant will be needed. Go.

- Open the lid of the fluid reservoir and add it to the maximum allowable mark.

Add brake fluid to the reservoir.

Remove the protective cap from the fitting of the right rear wheel.

Block the "sorcerer" if necessary.

We put the hose on the fitting, connect it to the container and pour brake fluid into it.

We bleed the remaining brake mechanisms in order of priority.

Next, we bleed the brake mechanisms of the remaining wheels, according to the bleeding order.

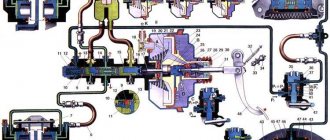

Anti-lock brake system (ABS) device

When braking, ABS regulates fluid pressure in the working cylinders, preventing the wheels from completely locking. Thanks to this, the braking distance is reduced and the driver continues to control the vehicle’s trajectory even during intense braking on snow, sand or wet asphalt.

The principle of operation of the abs system. Video:

The anti-lock braking system includes the following parts:

- Control block. Electronics that change pressure by opening and closing bypass valves. It analyzes information about wheel rotation. When the wheel stops, the valve partially relieves pressure and the pad presses less.

- Sensors that control rotation speed. The devices are mounted on wheel hubs and operate due to the Hall effect. They transmit information to the ECU.

- Hydraulic block. It consists of hydraulic accumulators, solenoid valves for inlet and outlet, an electrically driven pump and damping chambers.

Conclusion

After carrying out repair and maintenance work on critical components of the car, before driving, you must first check the tightness of the system and the operability of the vehicle components.

ABS - Anti-lock Braking System is a system against wheel locking during heavy braking. Thanks to the fact that ABS prevents the car from skidding along the road, safety increases in emergency situations. The anti-lock braking system will operate correctly if the system is not air-filled.

Watch this helpful video. Tests show that even a working ABS system turns off at the end of the braking distance, so you still need to modify it with your foot.

The Lada brake system is responsible for the safety of the driver and passengers of the vehicle, so it needs to be checked regularly. The serviceability of the brake pads should be checked at least once a month.

2304-3-20-03

The fastest filling, as a rule, occurs in the case of a bottle in which the hose coming from the brake cylinder of the front left wheel is lowered. As soon as there is about 200 ml of liquid in the bottle of the front left wheel, wrap and tighten the fitting of the local cylinder. We repeat the same with the front right wheel. We complete the process on the rear axle - here 200-250 ml of liquid should pass through each fitting.

That's it, the brake fluid replacement is complete. All that remains is to make sure that all fittings are tightened tightly. We put on the protective caps, check the fluid level in the master cylinder reservoir - and off we go.

Types and types of ABS anti-lock systems

Based on the number of control circuits, there are three types of anti-lock braking systems:

- single-channel - when one wheel is blocked, all four are released;

- two-channel - triggering occurs based on data from the best (high-threshold) or worst (low-threshold) wheel;

- four-channel - each wheel is adjusted separately, which ensures maximum braking efficiency.

Important! Modern cars are equipped with four-channel systems.

Depending on the location of components and maintenance features, there are three types of ABS:

- with components (hydraulic module, valves, accumulator and pump) located in a single unit;

- with components spaced in the form of different units;

- with optional SBC and ESP systems.

Despite the complicated design, it is quite possible to replace ABS brake fluid yourself.

Useful tips

How to bleed ABS brakes on Priora, Kalina and Honda Civic correctly? To prevent the work from causing harm to your car, and you don’t have to take it to a car service center, you should remember a few rules. Self-replacement of brake fluid for Lada Priora. Step-by-step writing of the work with illustrations.

Firstly, you do not need to turn on the ignition for more than 15-20 seconds. Otherwise, this will lead to failure of the electric pump. Secondly, it is necessary to take breaks between pumping the wheels. After all the air (aired mixture) has come out of one wheel, you should not immediately move to the second. You need to wait about 5-10 minutes until the air in the system completely disappears.

- Why does the electric power steering turn off on a Kalina? Replacing the electric power steering control unit

- Fuse block Kalina 2, its diagram, assignment of all fuses and relays (21925, 21927 Lux)

- Vaz Kalina tire sizes - Size tables

- How to tighten the handbrake on Kalina or replace its cable

Adjusting the handbrake of Lada Priora with your own hands

We turn the adjusting nut clockwise, thereby tightening the handbrake cables. The full stroke of the handbrake lever should be from 2 to 4 teeth (clicks). When the handbrake is adjusted correctly, with the handbrake lever lowered, the wheels should rotate freely. After adjustment, use the locknut to fix the adjusting nut.

This completes the replacement of the rear pads on the Priora and the adjustment of the handbrake. If you have any questions, ask them in the comments.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

How to bleed ABS brakes correctly and quickly

The procedure for bleeding the brakes is influenced by the design of the system, the location of components and the presence of additional electronic modules. You need to start by relieving the pressure in the hydraulic accumulator. To do this, you need to turn off the ignition (it is not necessary to start the engine) and pump the pedal.

Read how to bleed ABS brakes and stock up on the following materials, parts, accessories and tools:

- spanner;

- a rubber (possibly plastic) hose with a diameter corresponding to the thickness of the fitting tip;

- brake fluid;

- container (necessarily transparent) into which you will drain the old brake fluid.

You cannot do without an assistant who must press the pedal on command. You will perform manipulations with the fittings that ensure the removal of liquid.

Bleeding ABS brakes, where the components are located in one unit, differs little from the standard procedure. The only thing you need to do is turn off the system by pulling the fuse. This method works on domestic Ladas.

You can take advantage of the built-in pump. Then you will have to pump with the ignition on or even with the engine running. The procedure for bleeding the brakes starts with the right front cylinder and looks like this:

- disconnect the terminal of the level control sensor fixed on the expansion tank cover;

- remove the cover;

- open the brake reservoir;

- fill the reservoir to the brim with brake fluid;

- put the hose on the tip of the fitting;

- lower the end of the hose into a container to collect liquid;

- open the fitting by turning it a quarter or half a turn;

- to activate electronic systems, turn on the ignition;

- release the brake;

- wait until the pump expels the airy mixture;

- release the brake pedal;

- Tighten the fitting with a wrench.

The brake bleeding scheme is no different on any car. First, air is removed from the “far” circuit (for “left-hand drive” cars it is on the right), then from the “near” circuit.

Important: When bleeding, keep an eye on the brake fluid level. If it falls below the minimum, the system will fill with air. Then the work has to be done again.

To bleed a system with components located in different places, a diagnostic tester is needed. It connects to the car and allows you to control electronic components using a smartphone or computer. In this case, you will also have to unscrew the fittings and drain the airy liquid. However, no manipulation of the pedal is required. Instead, the valves and electric pump must be activated using the appropriate menu items. This way you can bleed the systems on the VW Passat B6 and other modern cars.

What is car ABS

ABS (Anti-lock Braking System) is an anti-lock braking system that prevents the wheels from locking during emergency braking.

The main task of ABS is to regulate the speed of rotation of all wheels. This is done by changing the pressure in the car's brake system. The process occurs using signals (pulses) from each wheel sensor that enter the ABS control unit.

See:

How the anti-lock braking system works

The contact patch of the car's wheels is relatively stationary to the road surface. To remove air from the system, it is necessary to bleed the brakes. From the brake pedal. Threshold covers are installed for the purpose of protection. As we can see, remove the threshold and replace it. According to physics, the wheels are affected by the so-called. static friction force.

Taking into account the fact that the static friction force is greater than the sliding friction force, ABS effectively slows down the rotation of the wheels at a speed that corresponds to the speed of the car at the moment of braking.

At the moment the braking begins, the anti-lock braking system begins to constantly and quite accurately determine the rotation speed of each wheel and synchronizes it.

Anti-lock braking system device

Here are the main components of ABS:

- sensors installed on the wheel hubs of a car: speed, acceleration or deceleration;

- control valves installed in the line of the main brake system. They are also components of the pressure modulator;

- ABS electronic control unit. To ensure effective and safe braking in the grant with external brakes on. Its task is to receive signals from sensors and control the operation of valves.

Alternative Brake Fluid Change Method: Our Pump-and-Hold Answer

Who hasn’t heard shouts of “download and hold” somewhere in garages, and even at mediocre services? Surely the men are pumping the brakes. Replacing brake fluid is a well-known procedure. Have you ever wondered how they fill the system with it at car manufacturing plants? Let's try to apply the factory operation in civilian conditions.

Industrial approach

At the factory, the entire brake system is completely empty, but its design is such that the fluid reservoir is located on the main brake cylinder in the engine compartment, at the very top. A little lower is usually the ABS unit (who has it), and then the brake pipes go to the front and rear wheels. There, in wheel brake mechanisms, cylinders of different designs can be used. But one feature unites all of them: a bleeder fitting is always located at the very top of the cylinder. It is also sometimes called an air release valve.

At the factory, a special fitting is put on the neck of the reservoir, through which brake fluid fills the system under pressure. The worker below opens the bleeder fittings on the wheel cylinders one by one. Air is first forced out of them, and then brake fluid flows. All. The fitting can be screwed on. By repeating this operation with all the wheels of the car, we obtain a fully charged and functional braking system. All that remains is to disconnect the filling nipple from the neck of the tank installed on the master brake cylinder and tighten the tank cap.

The question arises, can an ordinary car owner use the same method? If you have repaired the brake system and replaced hydraulic components, or are bleeding the system because you suspect there is air in it, I usually recommend doing a classic “pump and hold” bleed. More intensive passage of liquid in the tubes and cavities of the cylinders is guaranteed to displace air bubbles.

Don't try this at home?

What if, in accordance with the maintenance regulations for our car, we decided to simply replace the fluid? For some every two years, for others every three. And this is where the method of flushing the system with new brake fluid comes to our aid. We take advantage of the fact that the fluid reservoir is located high, and the fluid simply drains down to the working cylinders under the influence of gravity. The main advantage of the proposed method is that it does not require an assistant.

Brake fluid should be purchased with a reserve (at least 1 liter). It is interesting, by the way, that almost all passenger cars, regardless of their size, increased cross-country ability, the presence of ABS systems and other differences, have a brake system capacity of about half a liter. Please note that the replacement occurs by stirring, so you need to pour a slightly larger amount of liquid through the system. Stock up on 1 liter of brake fluid from any manufacturer (they are all compatible). DOT-4 is the most common brake fluid used in the vast majority of cars. It has to be replaced due to its high hygroscopicity - the ability to absorb moisture from the air and, as a result, lose its performance characteristics.

So, replacing the brake fluid yourself will require placing the car on an inspection ditch or overpass and providing free passage between the place from where you can refill the brake fluid reservoir in the engine compartment and the brake cylinders of all four wheels.

We work in stages

Use a rubber bulb or syringe to pump out the brake fluid from the reservoir. Add new fluid to the top edge. To speed up the process (to release fluid from all cylinders at once), it is advisable to select four pieces of tubes that fit tightly onto the bleeder fittings of all cylinders. We lower the free ends of the tubes into small transparent bottles.

Alternative solution to the issue

The owner's manual for a vehicle with ABS may discuss the presence of a drain fitting in the design of the anti-lock module. To maintain a similar system, a compressor or a homemade installation in the form of a pear and a converted brake water reservoir cap may be useful. Developing a replacement in this case looks much simpler:

- remove the used liquid from the container and fill it with new one;

- bleed all four brake cylinders in the traditional way according to the scheme discussed by the manufacturer;

- install instead of the “brake reservoir” cap a special adapter for the compressor or a home-made installation;

- connect a hose to the drain fitting of the anti-blocking module and unscrew it 1 turn;

- make the pressure about 1 BAR;

- identify the end of the release of old water and bubbles;

- relieve pressure.

In the process of replacing used brake water with the newest one in a system with ABS, the following notes should be taken into account:

- constant control over the water level in the tank is required: a drop below the low mark (MIN, Low) is not allowed;

- The permissible operating time of the hydraulic pump is 2 minutes; if it is exceeded, turn off the ignition and allow the unit to cool for 5-10 minutes.

- before draining the water, you need to “discharge” the system by pressing the brake pedal more than 20 times;

- It is strictly prohibited to pour used liquid or a composition that has stood for a long time in an open container;

- When you turn on the ignition and the drain plug is open, you should be prepared for a sudden release of water.

Summary

You can change the water without the help of others only on cars with a hydraulic accumulator and valves combined into one unit. List of required equipment:

- a syringe with an extension tube or a bulb;

- transparent containers;

- transparent tube 20-30 cm long;

- open-end wrenches set to “8” or “10”.

Briefly about the procedure for replacing brake water in a car with ABS on your own:

- change the composition in the tank with a new one;

- bleed the left and right front brake cylinders;

- bleed the rear right cylinder with the brake pedal depressed and the pump turned on;

- bleed the rear left cylinder with the brake pedal released and the hydraulic pump turned on;

- check the system for tightness.

If there is a drain fitting on the ABS module, you should bleed all 4 brake cylinders in the traditional way according to the scheme discussed by the factory, and then “drive” the ABS unit with excess pressure supplied from outside.

Source

How to properly bleed the brakes

First of all, look in the car manual to see in what sequence the pumping is carried out. If no recommendations are given, then the procedure is carried out in the form of English Z.

What you will need

You should invite an assistant who will press the brake pedal on command.

A rubber hose, a set of spanners, brake fluid and a container for draining it are also prepared.

Do-it-yourself replacement of brake fluid on a Lada Priora

Replacing brake fluid (BF) on a Priora must be done every 45-50 thousand km or once every three years if the car is rarely used and you have not reached 45 thousand. It is necessary to fill the Priora brake system with glycol fluid (FMVSS 116 not lower than DOT-3).

Before replacing the brake fluid, it is necessary to check the tightness of all connections and the brake system as a whole.

To work you need to prepare:

- Brake fluid (recommended by the manufacturer);

- Key to "8";

- A syringe or bulb for pumping out the old brake and a piece of tube, preferably transparent (for putting on the fitting);

- Dishes for draining fuel fluid;

- Rags;

- You will also need an assistant.

A few words about safety precautions

- Be careful when handling brake fluid as it is toxic.

- Avoid contact of TJ with skin and eyes.

- Do not allow brake fluid to come into contact with plastic or rubber products or paint surfaces.

- If liquid gets on any of the above, wipe them immediately using a clean cloth.

Note: Brake fluid is hygroscopic (capable of absorbing moisture and various substances from the air), so reuse or filtering is prohibited. TJ can only be stored in a closed container.

Step-by-step instructions - how to replace brake fluid on a Lada Priora

1. Raise the rear wheels and unlock the rear brake force adjuster by placing a screwdriver between the piston and the plate. When you're done, don't forget to take out your screwdriver.

2. Unscrew the plug of the GTZ tank.

3. Using a syringe or bulb, you need to pump out all the brake fluid, then pour in new fluid to the top of the reservoir.

4. Clean the right rear valve fitting from dirt, then remove the rubber cap from it. Place the rubber tube prepared earlier on the fitting and lower its end into an empty container.

5. The assistant’s task is to get into the car and pump the brake pedal 4-5 times, then press and hold it.

6. At this time, you are under the car and unscrew the air release valve with a key “8” by about 1.5-2 turns, generally a little until the old brake fluid flows from the hose. It will be significantly different from the new one in its characteristic dirty color. At the same time, the pedal will begin to smoothly fall to the floor. Your task is to quickly tighten the valve as soon as the liquid stops flowing through the tube.

7. Constantly monitor the liquid level in the tank; it should not fall below the minimum level; top up with clean fuel fluid to the upper level in time.

Follow all the steps described above until clean brake fluid flows from the hose. This way you will drive out the old fluid and pump in new fluid in its place. After you are done with the rear right wheel, move on to the other one, next you need to bleed the left front brake. Next, you should replace the fuel fluid on the rear left and front right fittings.

If mistakes were made during the replacement and the brake system became airy, you need to bleed the brakes, as described here.

How many TJs are contained in VAZ models?

Most often, quite practical and inexpensive Dot 4 liquid is poured into the cars of the Volzhsky Automobile Plant. The systems of classic models (from VAZ-2101 to VAZ-2107) do not contain so much of it - 0.55 liters, but more modern Ladas (VAZ-2114, “Kalina”, “tenth” family) already require a whole liter of brake fluid. However, if you plan to flush the system, it is better to purchase a little more liquid than required. One and a half liters will be enough, but since packaging is done only in liter containers, it is better to take two such packages.

It is also useful to know that most of the liquids used (in particular Dot 3 and Dot 4) cannot be stored open for too long: a maximum of two years!

The brake system is one of the important systems in a car, because without brakes it is impossible to imagine a single trip, even the shortest one. The brake system is made up of many parts, but the blood in its veins is brake fluid. We choose high-quality brake fluid for the VAZ 2110. Why do you need to change the brake fluid? Brake fluid is used under difficult conditions, as a result of which, even during quiet driving, it can heat up to +150-180`C.

New high-quality brake fluid copes with its duties without difficulty. But during operation it inevitably absorbs moisture, which causes the boiling point to decrease. As soon as the brake fluid collects a large amount of water, it can already boil at 145-160`C. What causes “vapor blocking of the brakes” is when, due to a sharp expansion of the formed bubbles, part of the liquid is squeezed out into the reserve tank, and when the pedal is pressed, the liquid remaining below cannot create the required pressure, i.e.

K. Saturated with bubbles, and the pedal falls through. How to check the condition and level of brake fluid? The brake fluid level is checked by the level on the barrel. The condition of the brake fluid is determined by its color.

If it is darkened or has a rusty color, then it should be replaced. How long does it take to change the brake fluid in a VAZ 2110? According to the regulations, after 45,000 km or 3 years, whichever comes sooner. Which brake fluid to choose for VAZ 2110? Brake fluid, like fuel and lubricants, should be purchased from a trusted brand and in trusted places, this way you will protect yourself from purchasing a low-quality product.

When choosing, you can rely on survey results or comments. What type of brake fluid should I choose for the VAZ 2110? Brake fluid is classified as DOT 3, 4, 5 and 5.1. DOT 5.1 (glycol base) on road sports cars where the thermal stress on the brakes is significantly higher. DOT 5 (silicone) is practically not used on conventional vehicles.

Glycol-based brake fluid absorbs water and attacks paint. Silicone brake fluid does not absorb water or corrode paint, but does require good brake bleeding. Otherwise, all the moisture in the hydraulic system will accumulate in one place and can cause localized corrosion in the hydraulics. Brake fluid compatibility All brake fluids are interchangeable in nature. That is, DOT 3, 4, 5 are interchangeable.

1, and DOT 5 only with itself. How to replace brake fluid in a VAZ 2110? You can change the brake fluid according to the instructions. So, let’s vote and leave reviews about the brake fluid for the VAZ 2110-12. Which brand of brake fluid did you choose? What type of brake fluid do you use? What brake fluid was used before? After how long do you change the brakes?

>

Step by Step Actions

The nuances of pumping depend directly on the ABS model. The location of individual components and the presence or absence of additional modules affect the order of the procedure.

The preparatory stage is the same regardless of the car brand. Turn off the ignition and press the brake pedal intensely several times.

Pumping using the example of Lada Granta

The car is placed on an overpass or driven into a pit. This is necessary so that you do not have to remove the disks for free access to the working surface. Next, turn on the ignition to open the solenoid valves. Start the procedure with the right rear wheel.

To bleed the brakes you need:

- Disconnect the wires from the tank cap;

- remove the cover;

- pour brake fluid into the reservoir (as much as will fit);

- remove the cap;

- use a spanner wrench to loosen the tension on the fitting;

- the prepared hose is connected to the tip of the fitting;

- place the second end of the hose in a container for waste liquid;

- press the brake pedal several times;

- fix the pedal in the lowest position and hold it;

- use a key to open the fitting;

- wait until the liquid has completely drained (at this moment the brake pedal will “fall” to the floor);

- close the fitting;

- pump the pedal again and repeat the procedure until the liquid flowing from the hose no longer contains air bubbles;

- tighten the fitting;

- remove the hose;

- reinstall all parts.

The process is repeated on each wheel in order of priority.

Bleeding the brakes of Lada Priora

The process of bleeding the ABS brake system for the Lada Priora is similar to the previous one. When bleeding the front wheels, the discs are removed, providing better access to the working surface.

After completing the process, you should not immediately drive out onto the road. First, they check the functionality of the system in a safe area, eliminating leaks and failures of the pedal.

How to properly bleed ABS brakes

For some reason, drivers are not afraid to fix a braking system without ABS on their own, but if an anti-lock braking system is installed, then many have difficulties. Actually bleeding ABS brakes and doing it correctly is not that difficult, although there are differences and things to know. And, you also need to know that each car with ABS has its own differences in pumping and replacing the fluid.

Anti-lock braking system ABS: types, types

Depending on the type and type, ABS is classified into:

- One scheme of operation of the ABS system is when all the devices that make up the ABS are located in one unit. That is, the hydraulic valve block, hydraulic accumulator and pump are located in one unit.

- The second ABS scheme is when the component devices (hydraulic valve block, hydraulic accumulator and pump) are located in different places. In this type of braking system, in addition to the ABS module, there is also an ESP module and an SBC module.

Whether you can bleed it yourself depends on the type of brake system in your car.

If the car has a system of the first type, then it is easy to properly pump the ABS.

If the car has a system of the second type, then one cannot cope without a scanner; it needs to be pumped to a service center for maintenance.

- Sensors (installed on the hubs). When replacing rear wheel hubs, as well as some front ones, you may notice special recesses for sensors. They are engaged in transmitting data about the speed of movement.

- Control valves (installed in the brake system). Serve to change the pressure in the system.

- The electronic unit. Receives speed information from sensors and adjusts control valves.

To achieve a good result, you will need an assistant, with whom you first need to bleed the line of the front wheels, then the rear ones.

Important! There may be high pressure in the system, up to 180 atmospheres, so you must first relieve the pressure.

You can bleed, that is, reduce the pressure by discharging the pressure accumulator. To discharge the pressure accumulator, you need to turn off the ignition and press the brake pedal many times (about 20 times).

After this, you need to disconnect the tank connectors. If suddenly, while driving, in a front-wheel drive car, bad sounds begin in the area of the front wheels: grinding, crunching sounds, then these are most likely signs of a CV joint malfunction.

ABS bleeding sequence

- First, we look for and remove the fuse in the fuse block that is responsible for the operation of the anti-lock braking system.

- Next, we jack up and remove one front wheel, and look for the brake wheel cylinder (BWC) fitting.

- After this, we put a hose on the fitting (from the hydraulic level, for example).

- Open the fitting one turn.

- One presses the brakes all the way and holds it in that position.

- Now turn the ignition key to turn on the hydraulic pump (the ABS indicator lights up on the instrument panel).

- The second person watches how air is removed through the hose and, after removing the air, tightens the fitting.

- We release the pedal only after tightening the fitting.

- Now, how do you know that all the air has escaped from the ABS? This shows the ABS icon on the dashboard, if it goes out after removing the air and tightening the fitting, then all the air has escaped.

The correct sequence for bleeding the ABS system

There is a specific order for properly bleeding an ABS system: right front wheel, then rear, then rear right, and then rear left wheel. If during such work the fuel fluid leaks out of the system, it is necessary to fill the system with new fluid. And to do this, you need to know what fluids can be mixed and how much brake fluid is needed for replacement.

Sequence of operation for the front wheels:

- Turn off the ignition (key position “0”).

- Remove the terminals from the brake fluid reservoir.

- Take a bottle with a small amount of brake fluid and a hose. We lower one end of the hose into the liquid, put the other on the fitting and open the fitting with an open-end wrench. It is advisable to use a transparent hose from the hydraulic level so that you can see whether air bubbles are coming out or not.

- Press the brake pedal and hold it in this position.

- The second person (at the wheel) looks to see if the air is coming out, and after the air bubbles have stopped coming out, he closes the fitting with a key.

How to bleed rear wheels with ABS:

The procedure differs for pumping the rear wheels. After the front wheels, the rear right wheel should be pumped in the following sequence:

- We also put the hose into the bottle of liquid and into the caliper fitting.

- Depress the brake pedal all the way.

- Turn the ignition key to position “2”.

- Hold the brake pedal until the hydraulic pump completely expels the air bubbles.

- Close the fitting and release the brake.

For effective bleeding, when working with the brake system of the rear left wheel, the procedure must be adjusted. Namely:

- As in other cases, put on the hose and unscrew the caliper fitting 1 turn. When pumping with the rear left wheel, the brake does not need to be applied immediately.

- Turn the ignition key to start the hydraulic pump.

- After the air comes out, press the brake pedal halfway and close the fitting.

- Next, release the brake and wait for the hydraulic pump to turn off.

- Turn off the ignition.

- We connect the disconnected connector of the TJ tank.

This video shows how to bleed anti-lock brakes on Audi A4, Audi A6, Volkswagen Passat B5 and others.

FAQ

- Literally, ABS (Anti-lock Brake System) stands for an anti-lock braking system, which is used during emergency braking, when you have to suddenly and suddenly press hard on the brake pedal in order to avoid a collision with an obstacle. Presumably we can say that this is an additional device in the car that helps to hold the road by alternately releasing the wheels from braking at a frequency of several times per second.

- One of those who first came up with such a system was Heinz Lieber in 1964, but the first working example of ABS was made by Hans Scherenberg. And already 8 years later, Bosch used this anti-lock braking system on luxury Daimler-Benz cars. However, at that time she was very huge compared to what she is now, weighing almost 7 kilograms.

How does ABS work?

The principle of operation of the anti-lock system is to alternately create pressure in the brake circuits and the pressing force of the brake pads to the disc. This is done with a special pump, supplying brake fluid from the hydraulic unit to the working brake cylinders or blocking its flow with electric valves.

Triggering occurs cyclically in 3 phases. Based on data from the sensors, the ABS control unit issues commands to: hold, release or increase the brake fluid pressure in the circuit of the brake cylinder of a certain wheel.

When the control unit has created braking force to the point where there is a danger of blocking, the inlet valve of the valve body closes. Then, provided that the exhaust is also blocked, the force is applied to the working brake cylinder of the caliper. Then, in order for the pads to press out, the exhaust valve opens so that the fluid flows into the pressure accumulator and the wheel can spin. And in order for the pressure to be released faster, the liquid is pumped into the damping chamber in the opposite direction (at this moment vibration appears on the pedal). After which the cycle is repeated, the electronics of the ABS unit close the magnetic exhaust valve and open the intake valve to again create pressure in the circuit. The system turns on when the vehicle speed exceeds 10-15 km/h; if it is lower, it should not work.

The point of the work is to keep the wheels on the verge of blocking, allowing them to spin and slow down at the same time, regulating and distributing the braking force across the wheels on which the sensors are installed.

How does ABS affect automatic transmission?

On many modern cars, the ABS unit is connected to the automatic transmission, and if there are problems with it, the car may behave differently depending on the type of problem (the speedometer will stop working, the car will be blocked for diagnostics, the emergency mode of the automatic transmission will turn on, etc.).

How do ABS sensors affect? Indirectly. They transmit speed data directly to the wheels to provide the necessary performance indicators for the gearbox. Making it possible to use various additional motion functions with a certain differential difference between the speeds of rotation of the wheels on different axles or sides of the car and the shafts of the box itself. If the connection from the sensors to the ABS unit or to the transmission control unit is broken, or incorrect data is received, the automatic transmission goes into emergency mode. This protection is triggered at speeds over 40 km/h.

Related terms

- Caliper

- Speed sensor

- Vacuum brake booster

Bleeding the hydraulic brake system

We pump the brakes to remove air from the hydraulic drive after it has depressurized when replacing the master cylinder, wheel brake wheel cylinders, hoses, tubes, as well as in case of replacing the working fluid or when the brake pedal becomes “soft”. We remove air from the system when the engine is not running, first from one circuit and then from the other in the following sequence: – the brake mechanism of the right rear wheel; – brake mechanism of the left front wheel; – brake mechanism of the left rear wheel; – brake mechanism of the right front wheel. If air gets into one of the circuits, it is enough to bleed only this circuit, and not the entire hydraulic drive. Before pumping, check the level of working fluid in the brake system hydraulic reservoir and, if necessary, add fluid (see “Checking the fluid level in the brake hydraulic reservoir,” page 42). We bleed the brakes with an assistant. If the rear wheels are suspended... ...insert a screwdriver between the lever and the plate spring of the pressure regulator in the hydraulic drive of the rear wheel brakes, fixing the regulator piston in the recessed position. We clean the brake bleeder fitting of the right rear wheel from dirt...

...and remove the protective cap from it. Use a spanner wrench or an “8” socket to loosen the tightening of the bleeder fitting. We put a hose on the fitting, and immerse its free end in a container partially filled with working fluid. An assistant should vigorously press the brake pedal all the way 4-5 times and keep it pressed.

Using the “8” wrench, unscrew the bleeder fitting 1/2–3/4 turn. In this case, liquid with air bubbles will flow out of the hose, and the brake pedal should be pressed all the way. As soon as the liquid stops flowing out of the hose, tighten the fitting and only after that can the assistant release the pedal. We repeat pumping until air bubbles no longer appear in the liquid coming out of the hose. We remove the hose, wipe the bleeder fitting dry and put a protective cap on it. We pump as described above...

...brake mechanism of the left front wheel. Similarly, we bleed the brake mechanisms of the other circuit. When pumping, you need to monitor the fluid level in the brake hydraulic reservoir and add fluid if necessary. If, when you press the brake pedal, you feel its “softness” and increased travel, it means there is air left in the system. In this case, we repeat pumping until the pedal becomes “hard”, i.e., when pressed, go no more than half the distance to the floor. If air cannot be removed, check the tightness of connections, pipelines, hoses, master and working cylinders. We tighten leaking connections, replace faulty main and working cylinders (see “Brake system”).

Recommendations

It is worth remembering that actions related to bleeding the brakes are carried out in certain situations. As a rule, such a procedure is necessary when air pockets form.

They inevitably arise during operation of the brakes, and sooner or later they will still have to be pumped.

However, there are other factors that can force a car enthusiast to undertake such a procedure prematurely.

The most common reasons are:

- Brake system repair. If repair work is carried out involving intervention in the brake complex, then it is best to carry out its prevention in the future, since air masses will almost certainly penetrate the system;

- Depressurization of brake lines. Over time, oil hoses and tubes inevitably wear out, crack, or simply become obsolete. After replacing the listed elements that have become obsolete, bleeding the brakes is mandatory;

- Replacing the working fluid. When such an action is carried out, the procedure for cleaning all brake lines must be carried out without fail;

- Drop in working fluid level. If such an indicator drops to a critical level, then this is a clear indicator of a system malfunction. In such a situation, urgent intervention is necessary, and pumping as the final stage is a prerequisite.

As is clear from what is described above, in the presence of ABS, the procedure for bleeding the brakes changes somewhat. This happens because such a device makes adjustments to the operation of the brakes.

It is designed specifically to prevent the wheels from locking when braking. This is achieved by adjusting the intensity of wheel movement by changing the pressure in the system.

ABS performs its functions through the following components:

- An electronic control unit responsible for receiving and analyzing data coming from sensors. He also regulates the brake valves;

- Sensors mounted in wheel hubs. They read information regarding the rotation of the wheels and send it to the block described above;

- Brake valves integrated into the pressure modulator and brake line. They adjust the intensity of braking.

This is how the standard anti-lock braking system works.

Possible mistakes

In order for the procedure to be effective and not lead to new problems, you should know common mistakes. The most common ones include:

- mixing two different brake fluids;

- reducing the fluid level in the system to critical;

- pressure too high.

If you mix two brake fluids with different parameters, the rubber seals are damaged. The system becomes clogged with clots and stops working.

When the fluid level in the reservoir is too low, air gets into the brake system and it fails. Also, do not use excessive force when pumping. The recommended pressure in the tank is 0.8 atmospheres. If excessive pressure is created, the tank will leak.