The main purpose of the gearbox is to change the amount of torque. As a matter of fact, changing gears is possible only through the operation of the gearbox. The VAZ 2107 is equipped with five-speed manual transmissions, which are characterized by increased performance and long service life. The main element of the box is the input shaft, from which the car begins to move forward.

- How to remove the input shaft from the box

Photo gallery: main stages of work - Rejecting the input shaft

- How to determine bearing wear

- How to remove the old one

Video: replacing the input shaft bearing on a VAZ classic

Which bearings are better for a VAZ 2107 box?

Transmissions of classic models from AvtoVAZ are distinguished by good reliability, unpretentiousness and ease of maintenance compared to foreign models, and ease of repair. However, given the advanced age of even the youngest models, many may have problems not only with the body, electrical system and other parts, but also with the operation of the gearbox. Its system contains a large number of parts, the operation of which is of fundamental importance for the system as a whole. Among these components is the bearing of the input shaft of the VAZ 2107 gearbox. This small part is responsible for the operation of the gearbox shaft itself, which ensures smooth transmission of torque and changes in gear ratios.

Similar functions are performed by other bearings in the box: the output shaft and the intermediate shaft. These parts consist of particularly strong metal housings in the shape of a circle with a large number of moving parts in the form of metal hinges, which allow the shafts to freely perform their direct functions. During the installation process, a special lubricant is inserted into this part, which not only preserves the functional properties and performance of the unit, but also extends its service life.

At the same time, the reliability of these parts is quite high; they fail only with very high mileage or when critically high loads on the gearbox occur. In addition, such parts are subject to simple diagnostics. There are many different components on the market in the form of spare parts for VAZ cars. Spare parts are produced by both domestic companies and foreign brands. Sometimes the cost also varies significantly. However, in this particular case, the optimal solution would be to focus not on cost and manufacturer, but on the originality of the parts.

Therefore, the right decision would be to choose AvtoVAZ products or related companies that produced these products while the car was on the assembly line. This reduces the possibility of purchasing an unreliable counterfeit product. In addition, when choosing, you must strictly adhere to the standard dimensions of the part, which may differ significantly from foreign competitors, which will lead to the impossibility of installation and implementation in the gearbox.

Difference between 4-speed and 5-speed gearboxes

As noted, the VAZ-2105 was equipped with two gearboxes - 4 and 5 speeds. At the same time, they took the 4-speed version as the basis for creating a 5-speed gearbox and modified it a little. Therefore, the gear ratios of the five-speed gearbox up to 4th speed are identical, but the added 5th speed has a gear ratio of 0.82. That is, this direct box still has 4th gear.

Let's take a more specific look at the differences between the five-speed and the four-speed on the VAZ-2105, and there are several of them:

Since the 4-speed version was the basis for creating the 5-speed gearbox, it is quite possible to upgrade the 4-speed gearbox yourself at home, for which you should replace and add the specified gearbox components.

As for the control of the VAZ-2105 gearbox, the switching pattern is no different from the VAZ-2106 or any other modification with a 4-speed gearbox. In a 5-speed gearbox, to engage the last speed, it is enough to move the gearshift lever as far as possible to the right and push it forward, that is, in the direction opposite to the rear speed. Below are shown the switching diagrams for both gearbox modifications:

In general, the KPP-2105 is very reliable and can operate for a long time without any maintenance. In addition, it has good maintainability and repairs are not so difficult. Replacing the 2105 gearbox is usually done in case of wear of the bearing seats in the housing or if it is damaged - breakdown, cracks. In case of other breakdowns (wear or damage to gears, bearings, shafts, etc.), the functionality of the unit can be restored by replacing the broken elements. Also, replacement can be carried out in the case of installing a 5-speed modification instead of a 4-speed one, in the case where the unit was purchased as an assembly, and not only those elements that allow you to modernize the old gearbox.

But in any case, whether it’s a replacement, modernization or repair, nothing can be done while the gearbox is installed on the car. In any case, the unit will have to be dismantled, and you need to know how to remove the box.

Bearing numbers in the VAZ 2107 5-speed gearbox

To simplify the selection of wheel bearing data for the VAZ 2107 5 gearbox, special numbers are provided, which are specified in GOST. In accordance with these figures, various manufacturers are required to produce products in strict accordance with GOST, which includes not only physical dimensions, width, length, but also the composition of the materials used, various temperature conditions and operating tolerances. For these units the numbers 6-50706AU and 6-180502K1US9 are provided. The differences lie in the way parts are replaced. So, the first is carried out taking into account replacement without the need to disassemble the gearbox, the second - with such disassembly.

It is in accordance with GOST standards that the advantage of domestic manufacturers lies, since this standard was developed taking into account the specifics of the operation and loads of the gearbox in domestic conditions. Foreign analogues can use this standard in production, but in many cases they do not, providing the market with low-quality products. For the intermediate shaft, the bearing number according to GOST is 6-205KU, for the intermediate shaft 6-156704.

Operating principle and design of the secondary shaft of the gearbox?

The gearbox consists of many parts that are connected to each other, allowing them to interact and ensure reliable transmission of torque. Initially, the torque is transmitted from the clutch disc to the gearbox input shaft. The primary shaft has a short length and a common fastening device with the secondary shaft. However, there is no rigid mechanical connection between these two parts, and they rotate independently of each other. The third element of the transmission is the intermediate shaft, which is located under the primary and secondary shafts.

All these elements have a large number of gears, each of which, paired with the other, forms a gear ratio, and the pair, in turn, forms a gearbox stage. The intermediate shaft provides connection between the primary and secondary shafts through certain gear ratios. It is on it that the gear ratios change and, as a result, the gear changes when driving.

The output shaft plays a concluding role in the gearbox. It transmits the converted torque to the shank, and then it goes to the driveshaft of the car. Thus, the secondary shaft provides connection between the gearbox and the chassis of the car, and the level of its operation determines whether the car will move or not.

Bearing dimensions in the VAZ 2107 gearbox

The size of the parts is also regulated by law. Based on these values, the consumer can easily choose the desired product. At the same time, there is a high probability of avoiding counterfeit goods, the dimensions of which are often different. The diameter of the main shaft element is 30 mm, the height is 19 mm, and the outer diameter of the ring is 75 mm. The number of metal balls is also determined, which allows fixing and ensuring the mobility of the shaft itself in the amount of 7 units. A correctly selected VAZ 2107 input shaft bearing is the key to long and trouble-free operation of the entire unit.

Replacing bearings in a VAZ 2107 5-speed gearbox

Depending on the location of the facility, the methods of carrying out repair work within the system also differ. To perform them, the owner will need a lift, a bunch of keys, various types of screwdrivers, a hammer, and a small knife.

Replacing the input shaft bearing in a VAZ 2107

The procedure for removing the VAZ 2107 input shaft bearing occurs in several stages:

- Place the vehicle in neutral and remove the transmission cover and switch system.

- Then it is necessary to remove the starter, as it interferes with access to the box body, and together with it, disassemble the oxygen sensor and the catalyst / muffler connection.

- Next, move the box to the side and begin disassembling the bearing itself. To do this, you need to remove part of the housing with a screwdriver and pry the bearing housing itself into the core.

- Using gradual movements, begin to remove the part until it stops, then help yourself by hitting the screwdriver body with a hammer, slowly sliding and removing the part from the standard attachment.

Replacing the secondary shaft bearing in a VAZ 2107

The output shaft also requires several disassembly steps:

- After disassembling the gearbox, it is necessary to separate the part of the housing that hides this bearing on the output shaft.

- After this, using a special extraction key, rotate the part around its axis; you can use levers in the form of large keys, or pry the part off with a knife or screwdriver.

Replacing intermediate shaft bearings in a VAZ 2107 gearbox

For the intermediate shaft, the situation is similar to the actions with the input shaft, since there are no fundamental differences in the design and fastening of this part. Also, for progressive driving with slow sliding of the part around its axis, the block is removed from the standard holder.

How to remove the input shaft from the box

The gearbox must be installed on a flat surface so that nothing prevents its disassembly. Before starting work, it is important to clean the housing from dirt and liquid leaks so that debris does not accidentally get inside the housing.

The box looks like an elongated bell

To work you will need standard tools:

- set of wrenches;

- flat screwdriver;

- a thick bolt or a screwdriver with a powerful blade.

You need to pull the input shaft out of the gearbox strictly according to the regulations:

- Pull the oil level indicator out of the box body.

- Remove the bolt with flat washer and two nuts that hold the clutch cable bracket. Remove the cable mechanism from the gearbox.

- Unscrew the four bolts from the box cover and remove the cover.

- Unscrew the bolt with spring washer that secures one part of the input shaft.

- Before you start working with the input shaft, you will need to prevent the shafts from spinning among themselves. To do this, they need to be fixed: for example, insert a thick screwdriver between the teeth.

- Unlock the input shaft securing nut. It is very firmly planted and can take a long time to remove.

- After this, carefully pull the shaft out of the gearbox housing.

Photo gallery: main stages of work

Even after unscrewing the bolts, the cover will fit tightly to the body, so effort will be required to remove it

The most difficult stage of the work is when you have to unscrew this nut

The input shaft must be pulled out of the box very carefully so as not to damage both the shaft itself and adjacent elements

For further work, you will need to wipe all the mechanisms in order to be able to carry out troubleshooting.

Accordingly, installation of the input shaft into the gearbox is carried out in the reverse order of removal.

Rejecting the input shaft

When the car and gearbox are operating normally, the driver, as a rule, does not have any suspicions about the exhaustion of the shaft and its elements. However, if the car starts to “strange things”, for example, the gear does not work or the speed starts to switch on in an arbitrary order, then you need to make sure that the box and, in particular, the input shaft are working.

Rejection is carried out with the gearbox removed, since only in this way can you carefully examine all the shaft parts and determine their suitability for further use.

This gear can no longer be used and needs to be replaced.

The correct culling procedure is carried out according to the following scheme:

- Visual inspection of the input shaft for abrasions and deformations.

- General condition of the retaining rings and locking ring springs.

- Wear of splines.

- Scuffs and burrs on gears.

That is, a routine inspection of the mechanism allows you to determine the degree of wear of each element and, if necessary, replace them. It is important that the gears and the splined part of the input shaft do not have even the slightest damage, otherwise new parts will have to be installed.

Tips and recommendations for replacing bearings in a VAZ 2107 box

As basic advice, we can give recommendations on the selection of units for replacement. Foreign products are not always superior in quality to Russian products, which are produced according to strict government standards. Therefore, you should not focus on cost when purchasing. Also, when working on editing these details, you need to strictly follow the sequence of actions. A gearbox is a complex mechanism consisting of many components. And if the reassembly procedure is not followed or other parts are unintentionally damaged, the disassembly procedure will have to be repeated again.

For ease of use, you should always use a lift or pit in your garage. This will allow not only the replacement of parts, but also the prevention of other elements of the gearbox and the general condition of the gearbox. In addition, great attention must be paid to the moment of centering and tightening of parts. If the load increases, the life of the bearing decreases in proportion to the increase in load and, therefore, the bearing will need to be replaced at lower strokes. In addition, during the repair process it is necessary to use high-quality lubricants, since without them the bearing itself will have to run dry, which also significantly reduces its own service life.

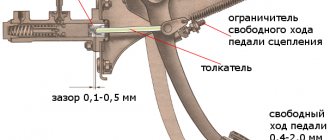

Where is the crankshaft bearing installed and what is it used for?

The bearing installed in the crankshaft flange is not part of the engine, but of the transmission. The main purpose of this assembly is to center and support the transmission input shaft - it serves as a front rotating support. Anyone who has ever installed a gearbox on a car is familiar with the crankshaft bearing - it is so difficult to get into its inner race with the shank of the input shaft. As for the high service life of the part, it can be explained simply. The fact is that the rolling unit only works when the clutch is depressed. The rest of the time, the crankshaft and gearbox input shaft rotate at the same frequency. Despite the low load, it is recommended to replenish the lubricant supply in the bearing when replacing the crankshaft rear oil seal, repairing the clutch, etc. This way you will delay the need for repairs for a long time.