The engine does not start the first time; it stalls not only at idle, but also when revving up. The reason is that the mass air flow sensor does not correctly read the amount of air entering the engine and transmits the wrong voltage to the ECU, which, in turn, generates a distorted cyclic voltage to the injectors. The cylinder will receive a rich or lean mixture. The engine will begin to puff, explode, stall, etc. due to overeating or undereating fuel. If the engine actually consumes 50 kg. air per hour, and a faulty mass air flow sensor shows a flow rate of 40 kg/hour, then the ECU calculates the amount of fuel per 40 kg. air, resulting in a lack of fuel. The mixture is poor, the car does not pull, the driver presses on the trigger, and the result is increased fuel consumption.

The mass air flow sensor DMRV, on engines of the ZMZ 406 family, is located between the air filter and the throttle valve. The mass air flow sensor is designed to convert the air flow (flow) entering the engine into DC voltage.

The mass flow sensor contains a sensitive element, in the form of a film or thread, through which an electric current passes and heats it to a constant temperature. The passing air flow through the mass air flow sensor cools it, but the ECU begins to increase the heating current to the initial, specified level. The heating current of the film or filament of the air flow sensor is proportional to the air flow. In parallel, the mass air flow sensor converts the heating current into a DC output voltage.

The mass air flow sensor never fails completely. A working MASS AIR FLOW SENSOR, on most cars on which BOSH mass air flow sensors are installed, when the ignition is on, should produce a voltage equal to 0.996 Volts; at a voltage above 1.04, it begins to negatively affect engine operation. But the mass air flow sensor installed on engines of the ZMZ 406 family is not suitable for this verification method. Let's try other methods for finding a faulty mass air flow sensor.

Pinout of the MAF contacts manufactured by Siemens 5WK9-7014: 1- (+12v) 2- (+5v from the ECU) 3- (signal) + to the contact in the ECU 4- (DTV) 5- (ground)

Pinout of MAF contacts manufactured by Siemens 5WK9-635: film MAF 20.3855 installed on ZMZ 406 with MIKAS-7.1 in version 241.3763-31 1- (ground from ECU) 2- (+12v) 3- (signal) + to contact in ECU 4 - (mass) 5- not used

We will carry out the test for a five-pin Siemens 5WK9-7014 mass air flow sensor.

Before removing the sensor to check, we will determine whether 12 volts are supplied to it. To do this, turn on the ignition, connect the negative wire of the voltmeter to the ground of the car, and connect the positive wire to the 1st terminal of the mass flow sensor. Carefully look at the designation indicated on your original sensor, since on the engines of the ZMZ 406 family the plant installed several types of mass air flow sensors, both film and filament, and they are in no way interchangeable. https://www.chiptuner.ru/content/gaz_spec_m7/

Let's assemble a simple circuit for a five-pin mass air flow sensor. We connect 12 volts - the voltmeter should show 1.3 - 1.4 Volts, and when the switch is briefly closed, the voltmeter shows 8 Volts.

(Video of incorrect operation of a film 4-pin mass air flow sensor on a ZMZ 406 engine.)

Screenshots of auto diagnostics in different operating modes of the UMZ 4216 Euro 4 engine with a mileage of 10 thousand km.

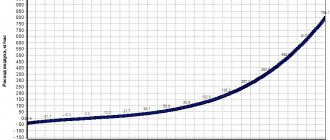

MAF ADC data in Volts

Air flow sensor data in kg/h

If it is not possible to buy a new sensor, you can wash it with 96% medical alcohol. Pour alcohol into a clean container and immerse the air flow sensor there and soak for 24 hours, periodically removing it for better circulation. When finished, simply dry it in natural conditions and put it in the car.

Air, you are powerful air, you drive away flocks of clouds, do something for the people, blow the damn one out of the country “inpropart”

What to do if your car has symptoms of a “dead” air flow sensor? Before going to a service station or store for a new expensive sensor, try checking it yourself.

ishachok › Blog › All about the signs of a malfunction of the mass air flow sensor.

Considering the importance of the function of the mass air flow sensor in the productive and long-term operation of the propulsion system, it is necessary to promptly begin diagnostics when the first symptoms of a malfunction of the mass air flow sensor occur.

During the operation of the vehicle, the propulsion system constantly operates in various modes. Each internal combustion engine mode implies the formation of an optimal air-fuel mixture. The mass air flow sensor plays an important role in creating the fuel mixture by transmitting the mass air flow rate to the electronic control unit. The main function of the device is to determine the amount of air flow that enters the cylinders of the engine system. Despite the importance of the sensor function in the vehicle system, the analyzer itself has a fairly simple device and an understandable operating principle.

The proper function of the mass air flow sensor guarantees optimal operation of the engine system. As you know, the determining factor in the characteristics of engine performance is the correct formation of the fuel mixture. This is why a faulty sensor entails such unfavorable consequences.

The analyzer has a rather fragile design and can be damaged even when cleaning the surface with a special composition. Since the analyzer constantly operates in difficult conditions, it often malfunctions due to mechanical damage or thermal exposure. It is impossible to repair a damaged sensor, therefore, if a malfunction of the analyzer is detected, it is necessary to promptly begin replacing the mass air flow sensor.

The symptoms of a malfunctioning mass air flow sensor are quite obvious and it is quite difficult not to notice damage to the analyzer.

- Signs of DMRV malfunction. -Difficult function of the propulsion system at idle. -Deterioration in acceleration dynamics. -An arbitrary increase or decrease in engine speed. -Difficulty starting the car.

A modern car, if equipped with the appropriate equipment, will independently indicate a malfunction of the mass air flow sensor. But, in order to recognize the error code, you will need an appropriate device. Therefore, in order to diagnose the sensor in detail, you will have to turn to professionals. In most cases, this is not necessary, since replacing the sensor is a fairly simple and affordable procedure.

You can finally check the condition of the sensor only after replacing it. Depending on the characteristics of the propulsion system, to replace it you will need to purchase an analyzer suitable for your car model. To identify the product code, you should refer to the original manufacturer's instructions or have the old sensor with you if you purchase a new one. Timely replacement of the air analyzer will help restore the function of the internal combustion engine and avoid large-scale breakdowns.

There are several common recommendations for increasing the service life of the mass air flow sensor.

1. The first reason for analyzer failure is excessive clogging of the air filter. Therefore, to avoid damage to the sensor, you should promptly pay attention to the condition of the air filter and replace it if necessary.

2. The second reason for device failure is oil clogging, which occurs due to wear of the piston rings. In this regard, regular replacement of piston group seals will save you from problems with the mass air flow sensor.

Source

Tags: dmrv 3110 thread

Comments 8

no green red some yellow with black stripes

There is a 6 pin DMRV pinout, my wires are completely different colors

They wanted to cheat you out of money in the service department! I don't visit them anymore. You can calcinate the thread yourself by briefly applying 12 volts to the 4th leg, but there is no particular point in this. When the ignition is turned off, the ECU itself burns the thread for cleaning. If the sensor is working and the air flow rate is normal 12-13 kg, then there is no point in tinkering with it - there is no need to interfere with its work, and if it already shows the weather on Mars, then there will be no point in burning it, most likely the sensor will need to be replaced. I consider it barbaric to water the mass air flow sensor with all sorts of crap like slurry to clean the carburetor. There is also electronic filling, or, in extreme cases, pure alcohol. Can you imagine what kind of deposits after this slurry will be on the thread when the burning is completed?

It seems to me that it is useless to clean it; it’s easier to buy a new one

You supply 12 volts to some contact and you can clean it manually) but is there any point? When you turn off the ignition, the thread from the signal from the block itself heats up) so they wanted to trick you)

According to swarm of information, there is a simple diagram of how and what to connect it to so that all the crap goes away from it!

I DON’T BELIEVE IN THIS SHIT. YOU’LL ONLY THROW OUT YOUR MONEY AND STILL GO FOR A NEW ONE. WHEN I CAME OUT, I BUYED A NEW ONE.

probably in order to stupidly rip off the money, and this is the most favorite activity in the service))

source

Signs of a DMRV malfunction

When the internal combustion engines that modern cars are equipped with operate, a fuel-air mixture is burned, for the formation of which, as you can easily guess from its very name, it is necessary to mix fuel with air, and in strictly defined proportions. Accordingly, the systems that are responsible for the formation of this substance must accurately “know” the consumption of each of its components at every moment of operation of the power unit. The value of this indicator for one of them helps to determine the mass air flow sensor (MAF). It should be noted that it is present in the design of only injection engines, and if drivers notice signs of a malfunction of the mass air flow sensor, then it should be checked and, if necessary, replaced.

Video “Features of diagnosing an oxygen sensor”

The nuances that should be taken into account when checking the lambda probe are described in the video below (the author of the video is the AndRamons channel).

Mass air flow sensor GAZ, UAZ with engine. ZMZ 406.

Temperature sensor for cars GAZ 3110 Volga, 3302 Gazelle.

MAF sensor GAZelle, Volga, Sobol, dv 406, UAZ Patriot;.

CARGEN AX506 gas block, UAZ mass flow sensor.

MAF GAZ dv.406 Cartronic HFM 62C/11 (20.3855)

Air flow meter gaz gazel sobol volga 2.3 2. Bosch 0.

Why do you need a mass air flow sensor?

What does a mass air flow sensor look like on a car?

The mass air flow sensor is an important sensor located directly behind the engine air filter, or more precisely, just between it and the throttle assembly. It is designed so finely that it allows you to accurately measure the flow rate of only air that is well cleared of mechanical impurities

During operation, the mass air flow sensor transmits signals to the electronic engine control system, which are processed and interpreted as the volume of air that is supplied to form the fuel-air mixture. For normal operation of the power unit, the volumetric ratio of liquid fuel (gasoline, diesel fuel) and air in it should be close to 1x14. If this proportion is violated, then either a significant loss of engine power or excessive fuel consumption occurs (these, by the way, are the main signs of a malfunction of the mass air flow sensor). The information received by the ECU from the sensor that determines the mass air flow helps to avoid this.

The mass air flow sensor measures the amount of air that enters the fuel rail per unit time. It transmits this data to the ECU, which instantly calculates the amount of liquid fuel that needs to be supplied to form the mixture, and gives the appropriate “instructions” to the engine devices responsible for this. Thus, if, for example, you press the accelerator pedal, more air immediately begins to flow, the mass air flow sensor instantly detects this, sends data to the computer, which increases the supply of gasoline or diesel fuel in the appropriate proportion. If the amount of air decreases, then the volume of liquid fuel supply decreases.

From a design point of view, there are three types of such sensors that are actively used:

Mass air flow sensors built on the basis of a pitot tube are considered obsolete and are not used in the newest engine models. They are so-called vane flowmeters, the main elements of which are plates connected to potentiometers and softly fixed to the axes. Changing their position under the influence of air flow, they act on the potentiometer, which changes its electrical resistance.

Mass air flow sensors with hot-wire type meters are quite expensive, although they are very effective. They are equipped with special heat exchangers consisting of two platinum filaments, which are heated by passing electric current. One of them is blown with a flow of air, the second remains a control one, and based on the difference in the current passing through them, the ECU calculates the amount of air supplied to form the fuel mixture. Mass air flow sensors with film meters are considered the most modern. According to their principle of operation, they are almost similar to hot-wire anemometers, only they do not use platinum threads, but ceramic elements coated with platinum.

Where is it located and what is it used for?

This is a small car part that will be difficult for inexperienced car enthusiasts to find. We open the hood of the car and move our eyes from the air filter to the engine. It is located in front of the intake manifold; you will see a plastic insert in the gap in the air duct with wires.

It is not by chance that he is in this place. It measures the amount of air sucked in by the engine so that the electronic control unit can properly prepare the air-fuel mixture. If the mass amount of air is small, then less fuel needs to be supplied and vice versa. Otherwise, the mixture will be lean or rich. Which will lead to unstable operation of the power unit.

Main symptoms of a malfunctioning mass air flow sensor

A malfunction of the mass air flow sensor, as noted above, leads to either an over-enrichment or a depletion of the fuel mixture with gasoline or diesel fuel, which negatively affects the functioning of the engine and can lead to serious damage. Most often, malfunctions of the mass air flow sensor are associated with a clogged air filter: the air is poorly cleaned, and the mechanical particles contained in it get into the sensor, which is the cause of its failure. It should be noted that mass air flow sensors are non-repairable devices, and if they fail, they must be replaced with new ones.

Practice shows that the main signs of a malfunction of the mass air flow sensor are as follows:

Of course, all the signs may also appear during other vehicle malfunctions, but in any case, if at least one of them is detected, this is a good reason to visit a service station. However, you can check the mass air flow sensor for malfunctions yourself, without contacting service station specialists.

Characteristics and features of the mass air flow sensor

The mass air flow sensor is a hot-wire element. It is used to measure the volume of air flow entering the engine, which allows you to determine the required volume of fuel for injection. The device is mounted between the air filter and the throttle line.

The main task of the sensor is to maintain the temperature of the temperature-sensitive sensitive component at a certain level. In particular, we mean a thermistor made in the form of a platinum-iridium filament. More modern devices are considered film devices because they use a thread as a sensing element instead of a thread.

Mass air flow sensor for Gazelle car

This element must be heated to a set temperature, which must be higher than the ambient temperature. The air flow that passes through the filament in any case affects the dissipation of thermal volume. The larger the volume of air that enters the system, the better the cooling and the lower the temperature. Eventually, the level of resistance or temperature on the filament begins to change and in order to return it to its previous state, current begins to flow through the device. By the way, current can be used to determine the incoming air volume, but in fact it is not current that is used, but voltage.

What you need to know about the device to connect wires

dialing mode

If you plan to test the wiring in your apartment, you need to know several fundamentally important facts about multimeters. First of all, it is worth noting that you can check the wire with the simplest device. An inexpensive Chinese model with minimal capabilities is quite suitable.

But at the same time, it is most convenient to use a device that has the dialing function itself. In order to set the device handle to the appropriate position, you need to turn it in the direction of the diode icon (as an option, an image of a sound wave can additionally be applied). This means that when checking the integrity of the wire, a sound signal will sound when the contacts are closed.

But the presence of sound is completely optional for testing wires with a multimeter. The fact that the circuit is broken will be indicated by a unit on the display, indicating that the resistance level between the probes is higher than the measurement limit. If there is no damage in the area under study, the resistance value will be displayed on the screen, which ideally should tend to zero (subject to operation in short-distance household networks).

Devices and symptoms of malfunction of the ZMZ 406 coolant temperature sensor

On Gazelle cars with a ZMZ 406 engine, two sensors with different purposes are installed. The first is responsible for transmitting information about the temperature of the internal combustion engine to the electronic unit, while the second simply informs the driver.

The device of the DTOZh sensor is quite simple and is a thermistor that supplies electrical impulses to the ECU if the ambient temperature changes.

Coolant temperature sensor (DTOZH) ZMZ 406

Despite its simplicity, the sensor very often fails and the following signs will tell you about it:

You probably realized that a failure of the coolant temperature sensor can cause a lot of trouble, so if it fails, it is recommended to replace it.

How to check the mass air flow sensor for serviceability

There are several basic methods for checking the mass air flow sensor, which allow you to verify its malfunction.

Checking the mass air flow sensor in motion

The easiest way to diagnose a flow meter is to analyze the operation of the engine when the sensor is forcibly turned off. The check proceeds as follows:

Checking the mass air flow sensor with a multimeter

You can diagnose a problem with the sensor using a multimeter. To do this, you must first understand the design of the device and its “pinout,” that is, the wiring of the wires on the board. There are 4 wires coming out of the mass air flow sensor. Depending on the MAF model and manufacturer, their colors may vary, but in most cases they are as follows:

To check the mass air flow sensor, the multimeter must be set to constant voltage measurement mode and set the limit to 2 Volts. Next, you need to turn on the ignition, but do not start the engine. Once this is done, connect the multimeter's red lead to the sensor's signal input (yellow wire) and the black lead to ground (green wire). This can be done without “exposing” the wires by inserting the probes of the diagnostic device through the rubber seal of the connector.

Based on the measurement results, conclusions can be drawn about the state of the sensor:

Some modern on-board computers allow you to view the voltage on the mass air flow sensor. In such situations, you can do without a multimeter.

Visual inspection of the mass air flow sensor

Experienced motorists can determine a malfunction of the mass air flow sensor by its appearance. The first step is to remove the mass air flow sensor, and then inspect it carefully. Signs of a malfunction are liquid getting into the air pipe and the mass air flow sensor (or the presence of mechanical damage).

Most often, liquid may end up in the sensor for the following reasons:

The easiest and most reliable way to diagnose problems with the mass air flow sensor is to replace it with a working device. For example, you can remove a suitable working sensor from another car, install it and make sure that engine operation has stabilized. In such a situation, you can immediately go buy a new sensor without diagnosing it with a multimeter or other methods.

In modern diesel and gasoline injection engines, it is very important to maintain a constant composition of the combustible mixture, regardless of operating modes. The mass air flow sensor (MAF) plays a key role in solving this problem. Read all about the mass air flow sensor, its types, design, operation and repair in the article.

gasoline vapor recovery in gasoline engines, exhaust gas recirculation system in diesel engines, etc. Types and design of mass air flow sensors The first injection engines were equipped with mechanical air flow sensors, but today they have been replaced by more modern and efficient devices. Currently, hot-wire anemometer sensors are used, which, with a fairly simple device, have high efficiency and measurement accuracy. The operation of these sensors is based on a simple principle. The sensor has a measuring (sensitive) element that is constantly maintained in a heated state (hence the word “thermo” - heat). This element is blown by a flow of air (hence the second part of the name - “anemometric”, it comes from the ancient Greek word “anemos”, which means “wind”), as a result of which it is cooled. Moreover, the more air passes through the element, the more it cools. At different temperatures, the element has unequal e

In modern diesel and gasoline injection engines, it is very important to maintain a constant composition of the combustible mixture, regardless of operating modes. The mass air flow sensor (MAF) plays a key role in solving this problem. Read all about the mass air flow sensor, its types, design, operation and repair in the article. gasoline vapor recovery in gasoline engines, exhaust gas recirculation system in diesel engines, etc. Types and design of mass air flow sensors The first injection engines were equipped with mechanical air flow sensors, but today they have been replaced by more modern and efficient devices. Currently, hot-wire anemometer sensors are used, which, with a fairly simple device, have high efficiency and measurement accuracy. The operation of these sensors is based on a simple principle. The sensor has a measuring (sensitive) element that is constantly maintained in a heated state (hence the word “thermo” - heat). This element is blown by a flow of air (hence the second part of the name - “anemometric”, it comes from the ancient Greek word “anemos”, which means “wind”), as a result of which it is cooled. Moreover, the more air passes through the element, the more it cools. At different temperatures, the element has unequal e

Possible controller malfunctions and ways to eliminate them

Several malfunctions may occur in the operation of the device:

- The sensitive element of the sensor - film or thread - is damaged. Typically, this problem occurs due to wear and tear. It is theoretically possible to repair such a regulator, but in reality it can take a lot of time and effort. Therefore, many car enthusiasts simply change the mass air flow sensor.

- The flow meter is clogged. This problem usually occurs as a result of prolonged use of the sensor. Clogging of the device, especially when constantly using the car in city mode, is a completely normal situation. The problem can be resolved by cleaning the flow meter or replacing it.

- Another malfunction is damage to the contacts or their oxidation. Damage can occur as a result of long-term operation of the flowmeter in vibration conditions, and oxidation can be caused by high humidity or long-term operation. In any case, you can try to repair the damage to the plug, but if that doesn’t work, the connector can always be replaced. As for oxidation, this problem can be solved by cleaning the contacts. An iron construction brush or a toothbrush can be used for this.

- Damage to wiring. It’s not exactly a malfunction of the flow meter itself, but if a break occurs in a section of the electrical circuit, the device may stop working. Accordingly, this will also affect the performance of the motor (the author of the video is the Simple Opinion channel).

What symptoms indicate a malfunction of the flow meter:

- an indicator appeared on the dashboard indicating the need to check the engine;

- the car began to consume more fuel;

- at idle speed the engine is unstable, the speed itself constantly fluctuates;

- the car takes more time to gain speed, the dynamics decrease;

- engine power as a whole has become weaker;

- Due to a non-working flow meter, the driver may encounter difficulties starting the engine, in some cases it is not possible to start it at all.

Replacing the mass air flow sensor ZMZ-406

The mass air flow sensor is a thermopneumatic flow meter IVKSH 407282000, installed in the intake system after the air filter.

The sensor determines the amount of air entering the cylinders while the engine is running.

A platinum thread is stretched in the sensor body. During operation, it heats up to a temperature of 150°C.

The air flow passing through the sensor body takes away more heat from it, the higher the air flow rate.

Based on the amount of electrical power expended to maintain a given filament temperature, the electronic unit calculates the mass flow of incoming air.

Since the cooling of the filament is affected by the temperature of the air itself, a thermistor is installed in the sensor housing, changing its resistance in accordance with the temperature of the air flow entering the system.

Based on its readings, the electronic unit makes adjustments to the operation of the filament heating electrical circuit, thereby compensating for temperature changes caused by changing weather conditions.

The control system informs the driver about the occurrence of a malfunction in the mass air flow sensor circuit by turning on the KMSUd indicator lamp, the fault codes are entered into the memory of the electronic unit (see “diagnostics of the control system”), and the engine will be switched to standby mode.

1. Disconnect the wire from the negative terminal of the battery.

2. Disconnect block 1 from mass air flow sensor 3. Loosen the clamps, disconnect the air supply hoses 2 and remove the sensor 3.

3. Install the new sensor in reverse order.

Using an awl to pry the spring clamp of the block, disconnect the sensor connector.

Using a screwdriver, loosen the screws of the clamps.

We remove the mass air flow sensor from the air ducts.

We put short pieces of thin polyvinyl chloride tube onto the pins of the electrical connector.

By inserting 7-8 mm exposed ends of the wires into them, we assemble the circuit shown in the figure.

When connecting the wires to the sensor, you need to follow the profile of the end of the connector.

Electrical circuit for checking the mass air flow sensor

We take voltmeter readings with the device switch turned off.

For a working sensor, the voltage at pins “2” and “3” should be 1.3-1.4 V

Turn on the switch for a short time and take voltmeter readings.

For a working sensor, the voltage at pins “2” and “3” should increase to approximately 8 V.

The platinum thread becomes red hot.

A faulty sensor must be replaced.

Install the mass air flow sensor in reverse order.

Checking the regulator for functionality

Diagnostics of the flow meter is carried out using a voltmeter:

- First disconnect the battery. Use a screwdriver to pry up the spring clamp of the block, and then disconnect the flow meter plug.

- Use a screwdriver to loosen the clamps and remove them.

- Remove the controller, then install pieces of polyvinyl chloride tube onto the contacts of its connector.

- Install the ends of the wires into these sections, as shown in the diagram, approximately 7-8 mm. When connecting, you should be guided by the profile of the end of the plug.

- Now you need to take the tester readings with the device switch turned off. If the controller is working properly, then the voltage level on its pins 2 and 3 should be about 1.3-1.4 volts.

- Then the switch should be turned on for a short time, while the tester readings are checked again. If the device is working properly, then the voltage value at its contacts should increase to 8 volts or around that. At the same time, you will notice that the sensitive element on the device (if it is a thread) has warmed up to red. If the diagnostics showed different values, then the flow meter must be replaced. The assembly procedure is carried out in reverse order.

Photo gallery “We check the mass air flow sensor ourselves”

Description of the oxygen sensor

A lambda probe or oxygen sensor is mounted in the Gazelle exhaust system. This device is used to measure the volume of oxygen in exhaust gases. By design, the device is equipped with a built-in heating element, which allows you to quickly warm up the controller to ensure its normal operation. The readings taken by the lambda probe are used to adjust the fuel supply, check the condition of the engine, as well as the exhaust gas neutralization system.