The starter is one of the main links in the ignition system. The correct operation of this unit is responsible for starting the internal combustion engine. Reasons why the mechanism may fail: problems with the solenoid relay, discharged battery, opening of the ground contacts, ignition malfunction, violation of the integrity of the electrical wiring, etc. We will discuss the development mechanism, fault diagnosis and methods for eliminating them in more detail in the article.

No sound is heard when turning the key

We can say that this is the saddest sign. It means that power is not supplied to the starter rotor winding. In the best case, the solenoid relay has failed, which closes the power contacts and connects the starter gear to the crankshaft. At worst, the brushes wear out. In this case, you cannot do without completely disassembling the mechanism. If the car does not start, the first thing to look for is the starter.

If the battery charge is zero, you will not hear any sounds from the starter. However, the first sign of such a problem will be the complete absence of incandescence of the lamps. In many cases, charging the battery is sufficient. Replacing the starter is very rare, as it is easy to repair. Replacement is carried out in extreme cases, when the housing is destroyed or cracks appear on it. If there is no voltage supplied to the windings, then most often the solution is to replace the solenoid relay.

The mechanism does not function on a hot engine

The answer to the question of why the starter does not turn when hot lies on the surface. The bushings expand during engine operation, the unit begins to “wedge”, or it fails. As a rule, this problem occurs in cars with high mileage. Let's look at why this happens in the table.

| Cause of malfunction | Solution |

| Wear of standard bushings | Replacement |

| Bad contacts | Clean, tighten, treat contacts |

| Reducing the insulation resistance of the stator winding | Replace winding |

| Oxidized contact plates in the relay | Clean or replace |

| Foreign particles in the starter housing | Clean up |

| Brush assembly wear | Cleaning the brushes or replacing the unit |

The starter rotates but does not turn the crankshaft

If the car does not start, the starter rotates, but the flywheel does not turn, then several malfunctions may occur. The first is the destruction of the bendix. It is based on an overrunning clutch, which allows the gear to rotate in only one direction. Any destruction of this mechanism leads to the fact that torque is not transmitted to the flywheel.

The second reason is the destruction of the teeth on the flywheel crown. A breakdown is not a pleasant thing, since replacing this element involves removing the gearbox on all cars. The third reason is a broken timing chain or belt. A sign of this is excessively rapid rotation of the starter rotor and crankshaft. There is no large load created by the valve mechanism. But this breakdown does not apply to the starter, so we will keep silent about it.

The battery is dead

So, have you checked the high voltage wire clamps, battery terminals and found nothing? Still don't know why your car won't start? Your car's battery is probably dead. If you have wires for "lighting up", you can find another motorist who will agree to help you "light up" your car. If your car was started by another car, have your car's battery diagnosed by a mechanic. It may be time to get a new battery.

If the starter clicks

Problems with starting the engine can occur at any time of the year, but most often they appear in winter, when it is cold. The fact is that the battery loses its capacity when the ambient temperature drops. Consequently, it cannot provide the necessary power to the power mechanisms, which include the starter. And if the battery charge is low, the starter will not be able to turn over; clicks of the solenoid relay will be heard, the contacts of which will not even be able to close.

It is worth noting that the current consumption of this unit is very large - during cranking it can reach a value of 50-80 Amperes. And with a short circuit it even jumps to 700-800 Amperes. This happens when the crankshaft turns tightly or cannot be rotated at all. Consequently, in cold weather, when the oil becomes thicker, cranking becomes more difficult, the current drains, and the battery drains much faster.

Why does the engine rotate inefficiently?

There are times when the starter works, but does not turn the engine with the required force. Let's list the situations when this happens:

- When using oil that does not correspond to the temperature conditions. The lubricant thickens and prevents the crankshaft from rotating. It is necessary to replace the lubricant with one regulated for the given weather conditions.

- Low battery charge. Does not provide energy for effective rotation. The battery needs to be recharged or replaced.

- In case of a malfunction of the brush assembly. It is necessary to check the contacts of the brushes and the tightening force of the tips going to the part.

Dashboard lights go out when you turn the key

If this malfunction occurs, the starter will need to be completely rebuilt. And sometimes even the engine, since a breakdown can be hidden there too. The reason for this behavior is a short circuit in the starter windings. This also happens due to the fact that the crankshaft is jammed and is unable to rotate, or the starter housing is destroyed and the rotor is not aligned. As a result, the car will not start. The reasons lie in the fact that power is supplied to the windings.

If you try to apply voltage to the starter for a long time by turning the key, the contacts will burn out. This will only increase the cost of repairs. The thing is that the positive power wire comes from the pull-in relay directly from the battery. There are no degrees of protection, so when a short circuit occurs, all systems are almost completely shut down. If the starter does not respond to turning the ignition key and the lights go out, then the problem is a short circuit.

The mechanism makes clicks but does not rotate

When the starter clicks once, but does not start the engine, this means that the unit requires repair. You need to try to start the car again. If it doesn't work, then it's probably the following:

- Bendix is broken;

- the starter winding is broken;

- a short circuit has occurred;

- the solenoid relay is faulty;

- brushes are worn out.

In this case, you need to replace the parts.

Checking the starter and retractor relay

To check, you need to make sure that the battery has a sufficient charge level, the flywheel crown is intact, and the timing belt is not torn. First you need to check if the solenoid relay is working. To do this, disconnect the thin wire from it. Connect an incandescent lamp to it, connect its second terminal to the negative of the battery. When you turn the ignition key to the extreme position, the lamp should light up.

The starter does not respond to turning the ignition key if there is a break in the solenoid relay winding. If the lamp does not light, then look for a fault in the lock. If the lamp is on and the relay core does not retract, then there is a winding break. There is no point in doing repairs; it is easier to replace the retractor completely. To check, you can also short-circuit the two relay terminals using a screwdriver. You just need to do this with the neutral speed on.

Why doesn't the starter work?

A car starter is an electric motor that is powered by a battery and is designed to start a gasoline or diesel engine. For this reason, this device is prone to both mechanical failures and problems in electrical power circuits or problems in the contact area. If the car's starter does not respond to turning the key in the ignition and does not make sounds (for certain problems, the starter clicks or buzzes), then the check should begin with the following:

- determine the full charge of the battery;

- carry out diagnostics of the ignition switch contact group;

- check the traction relay (retractor)

- check the performance of the bendix and the starter itself;

The ignition switch contact group can be checked very quickly. To do this, just insert the key and turn on the ignition. The lighting of the lights on the dashboard will clearly indicate that the contact group is in working condition, that is, you should look for problems in the ignition switch only if the indicated lights on the dashboard do not light up after turning the key.

In the case of a suspected battery, it will be enough to turn on the headlights or headlights, and then evaluate the lighting of the light bulbs on the dashboard, etc. If these energy consumers light up very dimly or do not turn on at all, then there is a high probability of a deep discharge of the battery. You should also check the battery terminals and the ground connection to the body or engine. Insufficient or no contact at the terminals or ground wire will result in severe current leakage. In other words, the starter will not have enough power from the battery to start the engine.

Special attention should be paid to the “negative” wire, which comes from the battery and is attached to the car body. A common problem is that ground contact may not disappear constantly, but with a certain frequency. To eliminate it, it is recommended to disconnect the ground at the point of attachment to the body, clean the contact well, and then try to start the engine again.

To check the battery on a car with your own hands, you need to remove the negative terminal, after which the voltage at the battery outputs is measured with a multimeter. A reading below 9V will mean that the battery is low and needs to be charged.

The presence of characteristic clicks from the starter when trying to start the engine, which are also accompanied by a noticeable decrease in brightness or complete extinction of the lights on the dashboard, indicates that the solenoid relay is clicking. The specified relay can click both in the case of a discharged battery, and as a result of malfunctions of the retractor or starter itself.

We also recommend reading the article about why the starter clicks but does not turn the engine. From this article you will learn about possible malfunctions that cause the traction relay to click instead of starting the engine, as well as how to check the car starter yourself.

How to remove the starter

To remove the starter, you will need one 13mm wrench. However, on some cars it is necessary to use a 13mm socket with a cardan and an extension. Removing the VAZ 2101-2107 starter turns out to be problematic, since the lowest nut is located in an inconvenient place. Many owners of these car models simply do not tighten the nut during assembly. In fact, the fasteners do not suffer from this. But in rare cases it can cause deformation of the body.

On VAZ cars of later models, for example, 2108-21099, there is no such drawback. All nuts can be unscrewed even with a spanner. However, in the case of using injection injection, inconveniences of a different kind arise - the air filter gets in the way. Removing it from the rubber cushions is problematic, so it is better to remove the starter from below. It can be easily removed on carburetor models in the same way.

Seat belts not fastened

Believe it or not, some cars won't start unless the seat belts are securely fastened. Safe, yes, but nevertheless, the owners of such cars are very upset and angry because of such a setting. So before you scold your car for not wanting to start, fasten your seat belts. Your car may be equipped with this unusual feature. By the way, you can disable it by reconfiguring your computer.

Disassembling the starter

It does not matter at all whether the Iskra starter or some other is used in the engine starting system. They are disassembled almost identically, since the design is identical for all. After removing the device from the car, it is advisable to clean it from dust and dirt. Then, using 8 or 10 wrenches, as well as screwdrivers, unscrew the two nuts that secure the back cover. Below it is the end of the rotor.

Do not rush to disconnect the starter parts, as there is a retaining ring on the rotor. You first need to remove it, after which you unscrew the two bolts located on the same diagonal. It is worth noting that there may be minor differences between two different starter models. After this, carefully separate the starter into three parts. The rotor should remain in the front cover. To remove it completely, you will need to remove the retaining ring and the bendix.

Battery contacts are dirty

If you see some kind of whitish, greenish tint around the battery terminals, then the connection of the high voltage wires to the battery may be weak. Carefully remove the clips from the battery (plate is acidic) and clean the battery terminals with a suitable tool (such as a metal cleaning brush). If you don't have a tool handy, try tapping each battery terminal with a car key of some kind to knock some dirt and residue off the contacts. Then repeat the engine starting process again.

What elements need to be changed?

When carrying out a major overhaul of the starter, you need to change almost all of its elements. There is a bronze bushing in the back cover, which helps transfer power to the rotor winding. If not everything, then a lot depends on her condition. With a large gap between the rotor and the bushing, the transmission of electricity occurs much worse, therefore, a large amount of current will be lost.

How to replace the flywheel crown?

This is the most difficult malfunction, since its elimination results in the need to remove the gearbox. Such a process is quite complex. Especially in cases where the box has never been removed or was dismantled a long time ago. Typically, a sign of such a breakdown is a metallic grinding noise that comes from the flywheel. Removing the crown itself and installing a new one takes a little time.

In some cases, you don't even need to purchase a new one. All you have to do is remove the old one, turn it over and put it back in place. But installation may cause some difficulties. First you need to warm the crown over an open fire. After this, it is simply placed on the flywheel. As the metal cools, it contracts and the joint becomes very strong. However, there is nothing to worry about if the car does not start. You already know what to do with the starter and its systems. Don’t forget to carry out maintenance on time, then there will definitely be no “surprises”.

Author:

Maxim Markov

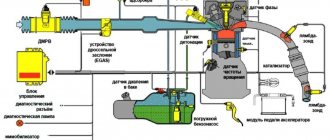

One of the most common car problems is the inability to start the engine. There may be several accompanying signs - when igniting, you can hear clicks in the starter or complete silence, slow rotation of the starter and, accordingly, the crankshaft. There can be quite a few reasons, and they are not always directly related to it. To better understand why the starter does not respond to turning the ignition key, it is necessary to study the engine starting circuit in more detail.

There is no fuel in the car

This is the most common problem faced by millions of car enthusiasts. The fuel level is the first thing you should check, no matter how funny it may sound. After all, you may well not have noticed that the car’s fuel level is at zero. Yes, it may look stupid, but believe me, very often this is the reason the engine fails to start. So if this happens to you, go to the gas station. Here is a simple solution to the problem.

What is a starter

The starter is a DC electric motor combined with a retractor relay, which ensures its start and rotation of the crankshaft. In order to turn the crankshaft at a rotation speed that ensures the start of the working cycle, it is equipped with a motor of sufficiently high power, measured in kilowatts, and the required current for its operation can reach hundreds of amperes. Therefore, like any electromechanical device, the starter is subject to both electrical and mechanical failures.

How does the engine start?

When the driver turns the ignition key, electric current is supplied to the solenoid relay. It moves the bendix until it engages with the teeth of the engine flywheel and at the same time closes the contacts of the starter itself, causing the crankshaft to rotate.

As soon as the engine cycle starts, the ignition key is returned to the “ignition” position, the bendix is retracted and the gears are disengaged. The mechanical circuit is quite simple, but all its components must work flawlessly, otherwise the engine will not start.

Starter operating principle

The whole process proceeds cyclically, the time period of passage is 3-4 seconds.

The actions of one cycle can be divided into three stages:

- Connecting the gear to the flywheel;

- Direct start of the motor;

- Uncoupling the gear from the flywheel.

Immediately after turning the key in the ignition, electric current from the battery flows to the relay, setting the Bendix in motion. It engages the flywheel, which closes the circuit. As a result, voltage is supplied to the motor, increasing the rotor torque. Its transmission to the shaft of a car engine, through coupling with the flywheel, gradually increasing due to the ignition of several portions of the fuel mixture, leads to the final start of the engine. After this, the starter is turned off and will not be used for anything else.

Starters in cars with diesel and powerful engines are reinforced with gearboxes. This is an element with several gears that increases the voltage many times over.

The use of gearboxes provides a number of advantages:

- increased efficiency;

- consumption of weak electric current;

- works even at very low battery levels.

Recently, hybrid starters with generators have gained widespread popularity.

Malfunction of the ignition switch contact group

Power is supplied to the starter after the contact group in the ignition switch is closed. To check, simply turn on the ignition. If the indicator lamps on the panel light up when you turn the key, then it is in good working order. If not, then the ignition switch itself is faulty. In addition, the key from the “starter” position must return to the “ignition” position on its own. If this does not happen, then the ignition switch will need to be replaced.

Diagnostics and troubleshooting

Before repairing the ignition system, you need to find out exactly what needs to be repaired; this is why the check is carried out. First, the spark plugs are diagnosed , as well as the ignition timing - whether it is installed correctly or not. It is also possible that the reason lies in a damaged or failed distributor cap. If it is damaged, then it must be replaced in any case, since the insulation has already been damaged, and it will not be possible to restore it.

Any wires in the engine compartment must be well secured; if you notice that one of the sections of the circuit has worn out, then it should be replaced. If there are traces of brake or engine fluid, fuel or other liquids on the wires, they must be wiped dry and the problem of moisture ingress must be solved. If there is damage to any wires, including high-voltage ones, the cables must be replaced; in an emergency, in order to get to the nearest store, they must at least be insulated. As for the coil diagnostics, it is carried out using a tester - an ohmmeter, and the values obtained during the diagnostics must be compared with those indicated in the service book.

We have already written in more detail about diagnosing spark plugs in this article. If the problem is a lock failure, then before replacing it, you can try to repair the device. To do this, you will have to completely remove and disassemble the mechanism, identify damaged elements and replace them.

Battery condition

When the battery is discharged, a characteristic sign will be clicking noises from under the hood when trying to start the engine, which is produced by the retractor relay, as well as slow rotation of the crankshaft.

This occurs because with the low voltage supplied by a dead battery, the relay cannot be fully retracted and its core is thrown back by the return spring and the starter clicks. In addition, a low battery will be indicated by dim lights from the side lights and headlights, and after turning the key, the instrument lighting will go out almost completely.

When the battery is normally charged, the voltage at its terminals should be 12-12.4 volts. The voltage is measured with a multimeter. If it is below 11 volts, then starting will be difficult, in addition, the state of charge will not be enough to provide a large starting current.

No contact

Poor contact in any part of the circuit can lead to the fact that there is current, but the starter does not turn the crankshaft. Particular attention should be paid to reliable contact with the “ground”, which is the car body. The negative wire from the battery to the body must be securely connected at both fastening points, the contact terminals must be cleaned and securely fixed. You should also pay attention to the “negative” wire connecting the car body and engine - after all, the starter is attached directly to the engine cylinder block and voltage drops when the ignition is turned on are unacceptable here.

What you need to know about electronic security problems

If, when you turn on the ignition, only some of the indicators on the instrument panel turn on, this may also be due to malfunctions of the SZ, although it is less likely. If we talk about malfunctions in the operation of the electronic SZ, then, as in any other case, malfunctions in its operation primarily affect the functioning of the power unit.

- The ignition does not turn on. When everything is bad, the system simply won't start.

- The engine starts, but with great difficulty. Sometimes the driver has to turn the starter for several minutes intermittently to start the engine. Ultimately, if the spark plugs are not primed, the engine will still be able to start.

- Loss of power from the power unit. When trying to accelerate, the driver may feel a dip; the car does not pick up speed. Such signs are especially obvious when driving uphill, in particular when driving in low gear.

- Unstable engine operation at idle. The engine may stall for no reason (the author of the video is Ramil Abdullin).

Starter bushings

Another reason could be worn copper-graphite bushings on which the rotor rests. One of them is pressed into the rear housing cover, where the brushes of the electric motor itself are located, and the front end of the rotor rests on a bushing, which is pressed into a hole in the clutch housing or in the starter housing itself, if the structure is closed.

The first option has almost gone out of use, because the bushing located in the clutch housing quickly breaks, the rotor begins to rotate misaligned and quickly becomes unusable. The second option is widespread almost everywhere, and bushings in this version are much more durable.

However, they also wear out over time and play appears, which eventually leads to jamming.

Your car is fine, but the fob/key doesn't work

The reason your engine won't start may have nothing to do with your car at all. It is quite possible that the battery in your key fob has run out. Check your vehicle's manual to find out how to start your car in this situation, or have your dealer diagnose the key/fob (in case the key has failed).

Starter related problems

The main reasons are related specifically to the starter. There are quite a few elements susceptible to malfunction:

- Solenoid relay malfunction

- Contacts burning

- Bendix malfunction

- Gear wear

- Winding short circuit

The retractor relay moves the bendix until it engages with the flywheel. When the relay gets stuck, it stops moving and this is enough for the starter not to respond. To check, it is necessary to apply voltage directly to the power contacts. If it works, then that's the reason.

Poor operation of the solenoid relay, which causes it to click, is often caused by burning of the contacts. A very large current passes through them, so if they burn out, it is necessary to disassemble the relay and clean the contacts. However, this measure is only temporary, since these contacts are treated from the factory with a special coating, which wears off over time, and cleaning the contacts will only accelerate the wear process.

Bendix may also be the cause of the problem. To check it, you also need to close the contacts on the power relay. If the bendix is working properly, the rotor will rotate together with the bendix, but here it will be necessary to check the engagement of the gear with the flywheel. In addition, it is necessary to pay attention to the condition of the gear teeth and ring gear on the flywheel.

If they are worn or partially licked off, they may be slipping and not engaging well with each other. This malfunction will manifest itself in the form of a crackling sound when starting the engine or its free rotation without engagement with the flywheel. To ensure that the Bendix is working, the starter must be removed and manually checked for ease of movement of the gear.

Another reason may be a short circuit in the winding. In this case, even when voltage is applied directly to the starter contacts, it will remain silent. Removal and disassembly can confirm a short circuit.

Other reasons why the starter may not respond when the ignition is turned on

In some cases, there have been malfunctions in the operation of automobile anti-theft systems (car alarms, immobilizers). Such systems simply block the supply of electric current to the starter after the security mode is removed. At the same time, the diagnostics shows the full functionality of the battery, power contacts and other elements of electrical equipment that are involved when starting the engine from the starter. For an accurate determination, it is necessary to directly supply power from the battery to the starter, that is, bypassing other systems. If the starter works, then there is a high probability of failure of the car's anti-theft system or immobilizer.

The next item to check is the solenoid relay. If it breaks, the starter can:

- be completely silent, that is, do not make any sounds after turning the key to the “start” position;

- hum and crank, but do not turn the engine;

- click repeatedly or once without cranking the crankshaft;

Bendix and retractor

The above symptoms will indicate that the fault is localized to the solenoid relay or the bendix does not engage the flywheel. Note that in the case of Bendix, a more characteristic sign is that the starter crunches and does not turn the engine. Another common sign of a bad starter is that the starter buzzes but does not turn the engine.

To check the traction relay, voltage must be supplied from the battery to the power terminal of the relay. If the engine starts to turn over, then the retractor starter is obviously faulty. A frequent breakdown is the burning of the contacts. To eliminate it, you will need to remove the relay to clean the nickels. After cleaning, you must still be prepared to quickly replace the traction relay, since in the factory the contact pads are covered with special protection that resists burning during operation. Stripping will mean that the specified layer is removed, as a result of which it is difficult to predict the moment when the retractor coins will burn again.

Now let's turn our attention to the starter bendix. Bendix is a gear through which torque from the starter motor is transmitted to the flywheel. The Bendix is mounted on a single shaft with the starter rotor. To better understand, it is necessary to understand how a starter works. The principle of operation is that after turning the ignition key to the “start” position, current is supplied to the solenoid relay. The retractor transmits voltage to the starter winding, resulting in the engagement of the bendix (gear) with the flywheel ring gear (flywheel ring gear). In other words, two gears are combined to transmit the starter torque to the flywheel.

After the engine starts (the crankshaft begins to rotate on its own) with a working starter, the key in the ignition switch is thrown back, and electric current no longer flows to the traction relay. The lack of voltage causes the retractor to disengage the bendix from the flywheel, as a result of which the starter stops spinning.

Wear of the Bendix gear means that there is no normal connection with the flywheel ring. For this reason, a cracking sound may be heard when starting the engine, and the starter may spin freely without engaging and buzzing. A similar situation arises if the teeth of the flywheel rim are heavily worn. The repair involves disassembling the starter to replace the bendix and/or removing the transmission to replace the flywheel. To check the bendix yourself, you will need to close two power contacts on the traction relay. The electric current will bypass the relay, which will determine the rotation of the starter. If the starter rotates easily and hums, you should check the quality of engagement of the bendix with the flywheel.

Starter bushings

A frequent breakdown is also the malfunction of the starter bushings. The starter bushings (starter bearings) are located at the front and rear of the unit. These bearings are necessary to rotate the starter shaft. As a result of wear on the starter shaft bearings, the traction relay clicks, but the starter does not spin itself and does not crank the engine. This malfunction is as follows:

- the starter shaft is not in the correct axial position;

- the primary and secondary windings also close;

This situation can lead to windings burning out and power wires melting. Sometimes a short circuit occurs in the vehicle's electrical circuits, which causes a fire. In the case when the starter clicks but does not spin itself, you cannot hold the key in the “start” position for a long time. It is recommended to make several short attempts to start, as there is a chance that the shaft will be able to return to its place.

Please note that even after a successful start of the internal combustion engine, the starter will require mandatory and immediate repairs to replace the bearings. Remember, jamming of the starter shaft can lead to a short circuit and fire. We also add that a starter with problem bushings can work absolutely properly when cold, but refuse to turn when hot.

If the starter does not turn over when hot or turns the engine poorly after warming up, then you need to:

- Check the battery, battery terminals and power contacts. If the battery is in good condition and was 100% charged before the trip, but then discharged, then you should check the alternator regulator relay, alternator belt, tension roller and the alternator itself. This will prevent battery discharge and subsequent undercharging while driving;

- then you should pay attention to the ignition system and fuel supply system, check the spark plugs. The absence of comments on the operation of these systems, which is accompanied by the fact that the starter turns poorly when the battery is charged, will indicate a malfunction of the starter.

We also recommend reading the article on how to properly charge a car battery with a charger. In this article, you will learn about the basic requirements and recommendations for properly charging the battery, as well as how to charge the battery without a charger.

Please note that the device gets very hot together with the engine in the engine compartment. Heating of the starter leads to thermal expansion of certain elements inside the device. After repairing the starter and replacing the bushings, the indicated expansion occurs with the starter bearings. An error in selecting the required bushing sizes can lead to jamming of the shaft, as a result of which the starter does not spin or spins very sluggishly on a warm engine.

Other reasons

Another reason for poor performance may be a faulty relay. It is almost always located in the mounting block and switches the voltage supply to the solenoid relay. If it malfunctions, the starter will not show signs of life if all other components are in full working order. To check, just listen to his work. When triggered, it always clearly clicks (the contacts inside it close). If it is silent, it means it needs to be replaced.

The operation can be blocked by an immobilizer or a security alarm installed on the car. They can be connected to the ignition or starter circuits and, when arming, simply open the starting circuit so that the starter does not respond to turning the key. To check, you should try to bypass it by connecting it directly to the battery. If it works, then the reason may be precisely these security systems.

Thus, there are quite a few reasons why the starter does not respond to the ignition key or clicks, but all of them can be diagnosed and identified using a comprehensive and consistent approach.

Why doesn't the battery light come on when the ignition is turned on? List of trivial problems

Car enthusiasts often wonder why the battery light does not light up when the ignition is turned on. This is a fairly common problem. And almost everyone has encountered such a manifestation of a malfunction in the car’s energy system. And it’s one thing if such a malfunction occurs in the summer and 100 meters from the house. Such a breakdown is much more dangerous in cold weather on a country road, especially at night. Therefore, you need to know the causes of the problem, as well as how to fix it. There are several reasons for a light bulb to fail. You'll have to check all the options, fortunately it's not difficult. Basic electrical knowledge is sufficient.

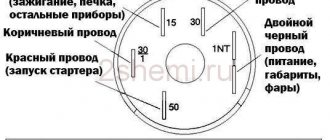

Why doesn't the battery light come on when the ignition is turned on? There may be several reasons for this behavior of the light bulb. Some of them are harmless, others indicate serious problems. Below we will look at the most likely reasons for this phenomenon. To troubleshoot, you will need a multimeter and a color wiring diagram of the car.

The lamp has burned out. A fairly common cause of this problem is the failure of the lamp. This is perhaps one of the simplest breakdowns, but it is not always harmless. It is advisable to replace the light bulb as quickly as possible. If there are problems with it, you will not be able to identify the problem with the generator in a timely manner. Which will lead to the battery being discharged at the most inopportune time. Thus, driving with a burnt-out lamp is highly not recommended.

You should also consider the design features of your car. Most generators have a built-in resistance. This allows you to generate energy even when the charge control lamp is burnt out. On some cars, the lamp itself plays the role of resistance. This can be found on some modifications of the VAZ 2112, as well as many old foreign cars. In this case, when the light bulb burns out, the generator stops producing current. If your car has this structure, you should always have a spare lamp.

Fuse A broken fuse may be the cause of a dashboard lamp failure. In this case, several devices usually fail at once. If such a symptom appears, you just need to check the fuse. It is located in the mounting block. You can find it using the diagram on the block cover. To check, the fuse is removed from the mounting block.

The easiest way is to install a known good fuse. If this is the reason, then the light should light up when the ignition is turned on. You can also check the fuse by measuring the resistance with a multimeter.

The whole process is described in detail in the article “How to check a fuse in a car with a multimeter.”

Circuit Failure If a light bulb does not light up, there may be a problem with the circuit supplying it. There are several nuances here:

- Problems with contacts. Quite a common problem. Usually appears after winter. During the cold season, moisture accumulates on the connectors, which causes the formation of oxides. The contact becomes significantly worse, as a result, the light bulb stops working. Typically, this problem manifests itself extremely unstable. One time it doesn't light up, the next time it works as usual. Clean all connectors and treat them with grease intended for this purpose;

- Circuit break. To identify the problem, you need to check the circuit using a multimeter. Perhaps there was a break somewhere. Find the faulty area and replace it;

- Relay problem. Some car models have a relay that controls the battery charge light on the panel. If this relay fails, the lamp will not light up. To check, use a multimeter to measure the voltage at the positive terminal of the relay. If there is a problem with the generator, the voltage will be less than 6 V; if the voltage is higher, the relay is faulty. It needs to be replaced. In detail about this, we wrote an article “How to check the generator regulator relay?”.