The cost of fasteners for the VAZ-2114 front suspension extension, commonly known as “crab,” in Russia varies from 275 per piece to 1,750 rubles per set. Depending on the modification required.

The bracket is one of the most important components of the car's chassis. Complete or even partial wear of a part seriously affects the vehicle's handling. That is why, when diagnosing a “disease,” service station mechanics advise eliminating the malfunction as soon as possible. The “sore” is unpleasant, but, as can be seen from the price tags, it is not fatal.

Crab on VAZ 2114: operation and replacement

Very often, on cars produced by AvtoVAZ, a malfunction occurs such as a breakdown or even complete destruction of the front suspension brace fastening.

The crab on the VAZ 2114 is no exception (this is what many drivers call this fastener). The main reason for such frequent breakdowns is the material from which the crab is made, namely various aluminum alloys (like silumin). If, while driving, a car touches high protruding elements - stones or bricks, with its brace fastening, then in most cases this leads to the destruction of the latter.

It would seem, why did the designers choose this particular material, since crab 2114 could have been made of steel? The answer here is quite simple - this element is made fragile specifically in order to save other, more important and expensive elements of the car suspension when it collapses.

Is it possible to drive with a faulty crab?

In most cases, driving with a faulty brace fastening is impossible. This is caused by the fact that the wheel on the damaged side becomes simply uncontrollable, and movement even at a minimum speed turns out to be extremely difficult.

If the crab is completely broken, you should stop driving the car until it is repaired, and if the breakdown occurs far from home, then call a tow truck.

Cracked crab VAZ 2114

Sometimes a slightly different situation happens - it seems that the mount is not damaged, and the car is driven normally, but at the same time a knocking sound is periodically heard from one of the wheels (especially clearly when going over uneven surfaces).

This may be caused by the fact that the fit of the fasteners on the crab itself has worn out (due to the fact that it is made of fragile material) and backlashes have appeared.

This is very easy to check - you just need to put the car on an overpass or hang it on jacks, and then inspect the mount. If it turns out that backlashes have indeed appeared, then the crab should be immediately replaced with a new one.

Driving a car with a worn-out crab that has strong play can lead to its spontaneous destruction even without colliding with an obstacle (which is extremely dangerous, as it can happen when driving at high speed).

How to replace the crab with a new one?

If signs of wear or damage are detected, it may be necessary to replace the crab with a VAZ 2114. This is quite simple to do and can be done by every car enthusiast.

The only thing you will need is the presence of an inspection hole or overpass and a minimum set of tools:

- jacks;

- shoes;

- flat screwdriver;

- set of heads with ratchet;

- 24mm wrench.

Replacing the crab VAZ 2114

The entire replacement procedure is performed in the following order:

- We install the car in the pit.

- We install the shoes under the rear wheels.

- We hang the front on jacks.

- We dismantle the protection and front bumper.

- Take a 24mm wrench and unscrew the rod nut.

- Unscrew the 3 bolts securing the crab.

- We remove the destroyed crab.

Dismantling the crab VAZ 2114

After this, we take a new bracket and mount the VAZ 2114 crab in exactly the same sequence, but in reverse order. As you can see, everything is quite simple and does not require much time. If necessary, the entire replacement procedure can be performed even on the road (provided there is a suitable place for this).

What to consider when choosing a new crab?

As stated previously, all front brace brackets are designed to be frangible to ensure the safety of more critical parts when impacted by obstacles.

At the same time, all crabs currently on the market can be divided into the following groups according to the materials from which they are made:

- silumin;

- magnesium-aluminum;

- steel.

New crab VAZ 2114

While the first two types of crabs work on the same principle (they break apart in an accident and differ only in their weight and strength), steel crabs work somewhat differently. They are made of a powerful metal base with a welded steel strip that serves as a traction mount.

The fragile element in this case is the weld - if damaged, it bursts and the entire bracket is divided into two parts.

This design is more reliable (for example, it will not burst while tightening the bolts, which sometimes happens with low-quality crabs), but you should understand that it will “work” only with a strong impact. A collision with insufficient energy to fracture a weld may well be sufficient to damage other suspension components.

Replacing VAZ 2109 crabs with your own hands

Crab – bracket securing the car suspension brace

A common problem with “nines” is the destruction of the bracket that secures the front suspension brace of the car, which is located under the front bumper. Replacement of the VAZ 2109 crab is necessary in case of its destruction, in case of accidental bumping into a high stone or curb, as well as cracks due to “fatigue” of the metal. It is made of a rather fragile aluminum alloy silumin, which is easily destroyed upon impact. When the “crab” is destroyed, it is necessary to replace the VAZ 2109 crab, since the front end of the lever loses its fastening, hangs freely in the air, and no longer holds the front wheel of the car in the desired position.

What does this threaten?

As a result of a breakdown, the wheel begins to move backwards or forwards. Further use of the car is simply impossible. If this happens far from populated areas, you can only call a tow truck. Most often, two types of breakdown occur - complete destruction or separation of one bolt, together with a nut, and the threads of the remaining two nuts are stripped. There are also two ways to deal with such a breakdown: perform the entire repair procedure yourself or seek help from a specialized automotive workshop .

Tools

Since we are going to solve the problem ourselves, we select the right tool:

- Liquid key (aka WD-40)

- Open-end spanners “24” and “17” (preferably heads with a knob)

- Pipe for reinforcement

- Get ready for the fact that a grinder and welding may come in handy

Let's get started

The brace bracket began to be called a “crab” because of the four existing holes for bolts, giving it some resemblance to a claw. You can determine if a crab is broken by the characteristic “crack” that appears in the front of your car. You can look at its condition and determine the scale of the destruction without even lifting the car. We choose the first solution - replacing the crabs on a VAZ 2109 yourself, it’s much cheaper and not presents particular difficulties:

Replacing a crab on a VAZ 2115 with your own hands - step-by-step instructions

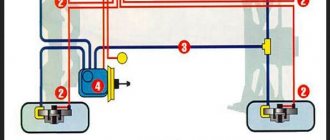

A fairly common “sore” of many models of the VAZ family is a faulty or damaged front suspension extension fastener, or in common parlance, a “crab”. The crab holds the front suspension brace located under the front bumper.

Often, the destruction or malfunction of the crab occurs due to the fragility of the product itself, which is made of silumin or another aluminum-based alloy. The crab usually crashes on high rocks, a curb, or other elevation that the driver did not notice.

The question of why it was necessary to make a power part from such a fragile metal worries many “victims”. The answer is actually quite simple. With its fragility and rapid destruction in the event of an impact, the crab saves more important and expensive parts such as a “TV” or a spacer.

A broken or cracked crab is a pretty big problem if you find yourself far from home and a service station. The fact is that in the event of complete destruction, you most likely will not be able to get home even at a very low speed. Due to the fact that the front end of the lever remains unattached and simply hangs in the air, the wheel becomes uncontrollable and begins to move either backwards or forwards. As you understand, in this case the only way to get home is by carriage.

It should be noted that a malfunction of the crab does not always manifest itself in the form of a completely immobilized car; it often happens that the fastener itself is absolutely intact, while knocking noises are heard while driving over uneven surfaces. It’s quite simple to check whether it’s a crab; you just need to drive into a “pit” or lift the car on a lift. The presence of play indicates wear in the fastener and requires immediate intervention and replacement of the faulty crab.

Cost and features of brands

Let's start with, which specializes in the production of spare parts for the national automobile industry. Products are certified. Quality standards are maintained in accordance with the standards adopted in the Russian Federation. Brackets of this brand are made by stamping and welding from sheet steel. The bushing material is polyurethane, whose safety factor is higher than that of rubber analogues. The strength of the adhesive connection virtually eliminates separation from the metal even under extreme loads. The “Sitek Profi” variety has increased body strength and rigidity of silent blocks. Estimated cost – 1250 rubles per set.

Products from Autoproduct, designed to replace standard brackets, not only improve vehicle handling, but also reduce the load on the body. They increase the rigidity of the suspension mounting points and allow you to set the caster to more than 2 degrees. Approximate price: 1750 per pair.

Under maximum loads, which means frequently occurring bumps, holes, potholes and other unevenness of the road surface, the “CS-20 DRIVE” mounts will give the motorist the opportunity to control the stability of the vehicle and the separation of the wheels from the highway.

Compound:

- Imported three-component poured polyurethane, including prepolymer “CS3516-B”.

- Mixed compounds of polyols "CS3516-65A" and catalyst "CS3516-C".

The part is an original development for the CS-20.

Advantages:

- Improved controllability.

- Wear resistance.

- The service life is several times longer than rubber analogues.

The described benefits remain at any time of the year. Temperature range: from -60 to +140 degrees Celsius. Price – 650 per unit. At the same time, the standard Tolyatti one has a range from 344 to 383. Polyurethane fasteners from the PIK company cost from 394 to 438 rubles. Sports “crabs” “Tehnomaster” will be sold to you for 1 thousand 350 rubles - a pair. Among the stated advantages are increased rigidity and improved controllability of the machine. Due to the installation of bushings of smaller diameter.

If we talk about more budget options, the reinforced Inter-auto bracket sells for 275 rubles apiece. Weight 535 grams. Dimensions 15*13*7 centimeters.

From all of the above, we can conclude that on average standard mounts cost from 275 rubles per unit. High-strength sellers estimate 650-900.

Crab VAZ 2114 signs of malfunction Replacing the crab on a VAZ 2115 with your own hands - step-by-step instructions

A fairly common “sore” of many models of the VAZ family is a faulty or damaged front suspension extension fastener, or in common parlance, a “crab”. The crab holds the front suspension brace located under the front bumper.

Often, the destruction or malfunction of the crab occurs due to the fragility of the product itself, which is made of silumin or another aluminum-based alloy. The crab usually crashes on high rocks, a curb, or other elevation that the driver did not notice.

The question of why it was necessary to make a power part from such a fragile metal worries many “victims”. The answer is actually quite simple. With its fragility and rapid destruction in the event of an impact, the crab saves more important and expensive parts such as a “TV” or a spacer.

A broken or cracked crab is a pretty big problem if you find yourself far from home and a service station. The fact is that in the event of complete destruction, you most likely will not be able to get home even at a very low speed. Due to the fact that the front end of the lever remains unattached and simply hangs in the air, the wheel becomes uncontrollable and begins to move either backwards or forwards. As you understand, in this case the only way to get home is by carriage.

It should be noted that a malfunction of the crab does not always manifest itself in the form of a completely immobilized car; it often happens that the fastener itself is absolutely intact, while knocking noises are heard while driving over uneven surfaces. It’s quite simple to check whether it’s a crab; you just need to drive into a “pit” or lift the car on a lift. The presence of play indicates wear in the fastener and requires immediate intervention and replacement of the faulty crab.

In this article you will learn how to replace a crab on a VAZ 2115 at home if it malfunctions. The work is simple and does not require special skills or tools, the main thing is to follow the sequence of actions.

How to replace a crab on a VAZ 2115 with your own hands - step-by-step instructions

- We drive into the pit, put the car on the handbrake, install wheel chocks, and jack up the front end.

- We dismantle the protection and remove the front bumper.

- Using a “24” wrench, unscrew the rod nut.

- After this, you need to unscrew the three bolts securing the crab to the platform and remove it

- We install the new crab in place and fasten it with bolts.

- Further assembly is performed in reverse order. Before tightening the fastening bolts, lubricate them with graphite or, in extreme cases, with polish, this will make your life easier in the future.

That's all I wanted to say! As you can see, there is nothing difficult in this work. Now you know what a crab is, why it breaks and how to replace it if it malfunctions. Thank you for your attention and see you again at VAZ Repair.

Front arm

Replace the silent blocks on the front suspension arm of a VAZ 2114 with your own hands. To do this, try to strictly adhere to the instructions we offer.

- Place the car on the inspection hole.

- Remove the engine protection, if equipped.

- Unscrew the bolt nuts from the front arms.

- Using a 17 key, remove the fasteners of the front stabilizer strut, which secures it with the lever.

- Knock out the bolt.

- Loosen the wheel bolts, jack up the car and remove the wheels.

- Use a 24mm wrench to remove the brace nut. To avoid having to exert enormous force, first clean the fastener with a wire brush and treat it with WD40. This should help completely unscrew this nut.

- Then remove the two ball joint bolts from the steering knuckle to remove the arm.

- Problems often arise with this nut. It is rarely possible to remove it easily. A good way out of the situation is to remove the lever with a crab and a stretcher. To do this, slightly loosen the extension nut near the crab and remove the three bolts securing the crab and the body. Now remove the entire assembly and, in a more comfortable position, begin to unscrew the problematic nut. The most extreme method is heating or using a chisel.

- You managed to remove the lever. First of all, replace the silent block of the extension. Dismantling the old element is carried out using the most ordinary chisel. Be sure to clean the lugs and take a new suitable silent block.

- It's up to the vice. The silent blocks are pressed one by one into your lever. It is usually not possible to seat the element completely, so the lever should be placed on a flat floor or a sturdy table. The silent block must be installed using a hammer. A few accurate and fairly strong blows should be enough.

- Using the method without using a vice is very risky. Such measures are resorted to either by self-confident specialists or by those who do not mind experimenting with their car.

- Now we change it on the front lever. The first priority is to get rid of the old silent block. If it was completely broken, you just need to remove the bushing and remove the remaining rubber elements of the silent block from the eyes.

- If this method is not relevant, the silent tape will have to be pressed out. You already have a puller.

- The new element is pre-treated with water diluted with any soap, dish gel or simple liquid soap.

- Use the press-in tool to place the new part in its rightful place.

- The fastening bolts should be tightened gradually. The silent block can be twisted at the same time, so try to hold it with a screwdriver.

- Alas, the process of replacing silent blocks on the front lever is much more complicated than in the case of a stretcher.

Replacing VAZ 2109 crabs with your own hands

Crab – bracket securing the car suspension brace

A common problem with “nines” is the destruction of the bracket that secures the front suspension brace of the car, which is located under the front bumper. Replacement of the VAZ 2109 crab is necessary in case of its destruction, in case of accidental bumping into a high stone or curb, as well as cracks due to “fatigue” of the metal. It is made of a rather fragile aluminum alloy silumin, which is easily destroyed upon impact. When the “crab” is destroyed, it is necessary to replace the VAZ 2109 crab, since the front end of the lever loses its fastening, hangs freely in the air, and no longer holds the front wheel of the car in the desired position.

Clutch Lada Kalina

The exhaust system caused trouble. By the sixth ten thousand, the muffler pipe broke off - as smooth as a knife, it was cut off close to the bracket. There are high vibration loads here, the pipe is weakened by corrosion - where else can it break? As soon as the pipe was replaced, the resonator leaked. And while changing it, they found a more serious malfunction: the honeycomb filling of the converter dangles and rattles in the body of the catalytic manifold. It is natural to assume that it has already been partially destroyed - and this promises new adventures. However, the test showed that the “aging coefficient” of the neutralizer is still half the critical value, and toxicity is normal. And we reasoned: the car is Euro III, which means we’ll wait until the self-diagnosis turns on the warning light, then we’ll think about replacing it.

What does this threaten?

As a result of a breakdown, the wheel begins to move backwards or forwards. Further use of the car is simply impossible. If this happens far from populated areas, you can only call a tow truck. Most often, two types of breakdown occur - complete destruction or separation of one bolt, together with a nut, and the threads of the remaining two nuts are stripped. There are also two ways to deal with such a breakdown: perform the entire repair procedure yourself or seek help from a specialized automotive workshop .

Let's get started

The brace bracket began to be called a “crab” because of the four existing holes for bolts, giving it some resemblance to a claw. You can determine if a crab is broken by the characteristic “crack” that appears in the front of your car. You can look at its condition and determine the scale of the destruction without even lifting the car. We choose the first solution - replacing the crabs on a VAZ 2109 yourself, it’s much cheaper and not presents particular difficulties:

- First, we purchase a new crab and a set of bolts for it; on old ones, the threads may be torn off

- First, we roll the car onto a pit or overpass

- Then you need to put the car on the “handbrake” (parking brake) and support the rear wheels with “shoes” (or wooden blocks to prevent it from rolling away)

- Raise the front of the car with a jack

- Remove the bottom protection and bumper

- During work, you need to remove the stretcher, if you don’t remove it, then you need to make sure that it does not interfere with you

Bolts securing the crab to the platform

- First, unscrew the remaining mounting bolts, if they did not come out of the “crab” when the car hit

- Remove the spacer washers one by one

- We recommend that you immediately count the number of washers removed from each hole and remember the order in which they were installed

- When screwing on the new “crab”, first do not forget to put all the removed adjusting washers in their places; install the washers in the reverse order

- Then we screw in the bolts of the crab VAZ 2109, securing the brace bracket in place

- We tighten them with force, but without fanaticism, so as not to tear them off

- This completes the replacement of the crab for the VAZ 2109, but it doesn’t always turn out to get off so easy

- It happens that the platform breaks along with the stretching bracket

We buy spare parts

When, having unscrewed the bracket, you discover that a crack has formed on the platform, do not rush to replace the platform, the crack can be welded. Sometimes, however, it becomes necessary to replace not only the bracket, the bolts on the crab VAZ 2109 and the platform to which it was attached also suffered ( and it happens that both platforms or both brackets, left and right):

- Then in the car store we purchase a reinforced plate to which nuts are welded to attach the “crab”

- When choosing, special attention should be paid to the quality of the welded nuts, since your safety when driving your car depends on this.

- If there is no particular choice, and the nuts were welded to the plate with one welding point (or two), then you need to independently weld all the nuts in a circle in order to strengthen their fastening to the plate

- Be sure to purchase new bolts for the VAZ 2109 crabs so that microcracks or other defects do not surface later

- When choosing traction brackets, you should carefully choose not only the material from which it is made, but do not forget about the thickness

- The best option for installation would be a silumin bracket with maximum rib thickness

- Since it is stronger than the factory one, however, it will not damage the “TV” or the spacer during a strong impact

- The cast iron bracket is stronger than the silumin one, however, cast iron is also fragile and cracks when impacted, and besides, it can damage the spacer and the “TV”; the instructions do not solve this issue for you

- It is worth paying special attention to the strength of the rubber cushion and its clip - the more powerful they are, the longer the part will work

- We recommend choosing a crab that has a polyurethane cushion

- You should not take an inexpensive one (the low price is alarming), or without packaging, we remind you about possible counterfeits!

- And don’t forget that there are right-handed and left-handed brackets and platforms; when replacing, this is of great importance

What influences price formation?

The cost of the “crab,” like any other component, depends on the cost of its production and the markup set by the seller. However, the costs of each enterprise, car dealership or online resource are calculated differently. Based on this, even identical fasteners do not have a fixed cost. For example, a set of “crabs” of the “Sevi Expert” brand can cost either 587 or 924 rubles. Intermediate options range around 650 rubles. Then everything depends on the availability of goods in the warehouse and delivery time.

It is no secret that the final amount in the check is influenced by the manufacturing technology of spare parts. Catalogs are full of names of various manufacturing companies. Each, in pursuit of a client, tries to maintain the ratio of price and quality.

Replacement of pads

If welding the platform does not make sense (the thread of the nut or the nut itself is broken, the bolt securing the VAZ 2109 crab is broken), then a grinder and welding will be needed here.

Tip: When starting to replace the site, be sure to close the radiator, and if welding is performed from the passenger seat, then also close the generator from sparks. There is no need to remove them; this is an additional and unnecessary waste of time and money (if the repair is carried out at a service station).

Let's move on to actions:

- Attach the plate and mark the places for future cuts

- Using a grinder, remove the old platform, rusty metal and clean the areas around the cuts; when welding, it is important that the metal is clean

- Before performing welding work, you need to remove both terminals from the battery

- Weld the plate firmly

- The quality of the seams is important here; it must be good, since the part operates under conditions of increased loads, so it makes sense to entrust this work to an experienced welder

The bracket is screwed to the overcooked platform, although the quality of the seams leaves much to be desired, and they were clearly too lazy to clean them

- To prevent your car from looking like in the photo, after completing the welding work, you should clean the seams and, to increase protection against rust, coat the surfaces with anti-rust (for example, Tamak) and cover with primer

- Attach the stretcher (if you removed it), screw the bracket into place, tightening each bolt of the VAZ 2109 crab (again, carefully, do not break the bolts) Then attach the bumper (see Removing the front bumper of the VAZ) and the lower protection

- In the future, when operating the car, it is recommended to check the brackets after each strong impact.

- It is recommended not to drive with a broken (split, cracked) “crab” unless absolutely necessary (this is dangerous for the health and life of people around you and for you too). Faulty (damaged, cracked) “crabs” discovered in time should certainly be replaced with new ones as soon as possible

- This measure will help save your money, as well as your health and life. Replacing the brackets is complete, everything is simple and completely doable on your own.

If you find an error, please select a piece of text and press Ctrl+Enter.

It all started with the fact that a strong beating began to be heard from the right wheel when driving on an uneven road, on gravel. I checked the wheel for horizontal play. Well, I think either the ball was broken, or art. The bearing Having driven like this for a month, I decided to take it apart and see what it was, because the beating was already quite boring, and when driving fast, not the most pleasant thoughts come =) I took it apart, knocked, tugged, twisted, kicked, didn’t understand anything) ) I called a friend from the neighboring garage, the operation was repeated and again no one understood anything) In general, without thinking twice, I went and bought a TRACK ball (I constantly buy their products, so far only good reviews) and a ball puller. I arrived, took off the wheel, pressed the ball joint, took a new one and then realized that I didn’t know how to press it back o_0