We get rid of vibration and extraneous sounds of the Niva transfer case forever

The characteristic howl and hum of the transfer case on VAZ-21213 cars, alas, is familiar to many owners of such cars. Let’s figure out what is the reason for these problems, and most importantly, how to get rid of them without using “collective farm” methods, such as additional noise reduction.

Content

- Let's understand the terminology.

- We study problems and repair methods. Vibration and how to deal with it.

- We remove the howl and hum.

- We remove the possibility of oil leakage.

- Niva (LADA 4×4)

Understanding the terminology

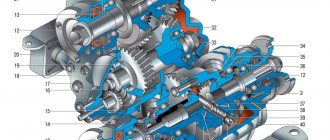

Let's start by diving into the materiel. Transfer case (TC) is a separate unit of an all-wheel drive vehicle, which provides multi-mode power distribution from the engine to the front and rear axles.

Externally, this is a mechanism located under the bottom of the car, in the body of which a multiplier (divider) is placed in series to obtain an intermediate gear ratio in the transmission and a splitter of one power flow into two. It is with the help of this device and its controls (levers) that go into the vehicle interior that the LADA 4×4 driver selects the all-wheel drive operating mode.

The RK directly connects the front driveshaft and the intermediate shaft (shaft) with the vibration damper to the vehicle’s gearbox. As is probably already clear from the description, this element is connected to the rear axle of the car via a rear propeller shaft.

We study problems and repair methods.

Any car owner definitely doesn’t need to be told why howling and humming are bad. Vibration of the transfer case on a Niva at low speed is quite common. The driver, of course, gradually gets used to many extraneous sounds in the car, but the noise level is high enough to make it impossible to carry on a conversation with passengers while traveling. Due to excessive noise pollution, you will inevitably have to deal with the problem.

Vibration and how to deal with it.

The main reason for the occurrence of unnecessary sounds is multi-frequency vibrations of the components of the transmission. In general, the vibration of the transfer case on a Niva is one of the most common cornerstones that other car owners are forced to fight (or put up with) constantly.

- Check the cushions (supports) on which the power unit, gearbox and other parts are attached to the body, including the muffler. Any worn-out pad or rubber band can easily cause excessive shaking of the iron and accompanying rumble. It is better to replace worn silent blocks and pillows immediately.

- Be sure to pay attention to the intermediate shaft (inlet shaft). If you see signs of “fatigue” - change the elements that have become unusable, or the entire part!

Perhaps this is the most complete set of measures that experienced auto mechanics advise when the transfer case on a Niva hums and vibrates!

Removing the howl and hum

We will assume that we have dealt with the vibration, but an equally significant problem remains - how to remove the howling of the transfer case on the Niva. Vibrations of the mechanism are not always the only reason for the appearance of extraneous irritating sounds. And the characteristic noise of the transfer case, alas, is one of the “trademark” shortcomings of one of the best domestic SUVs.

- The first thing you should pay attention to is the levers. It is better to immediately replace them with silent ones - with anti-resonance bushings inside. They won’t eliminate all the noise, but they will definitely extinguish some of it.

- The result will be even better if you install a small-module transfer case - with front and rear covers equipped with double-row bearings. In 2010, AVTOVAZ introduced new double-row bearings for output shafts in order to get rid of backlash and runout, as well as extend the life of the seals and, in general, increase the reliability of the mechanism. Here logic is man’s friend: less shaking and hesitation means higher service life and reliability.

Removing the possibility of oil leakage

In an effort to resolve the question of how to get rid of the howling of the transfer case, even before the 2010 update, the manufacturer began assembling this mechanism using silicone sealant instead of cardboard gaskets. And he introduced an improved crankcase ventilation system with an open breather, which was located under the hood. Again, the reliability of the vehicle when passing fords has increased slightly, and most importantly, the load on the seals has also decreased.

We mention them again to point out that the fewer vibrations and shocks, the longer it will not take to detect an oil leak on the transfer case housing due to deteriorated seals. Moreover, the flange in the RC covers can cause noise - during operation, the bearing seats are simply broken.

We hope that the steps listed above will become complete step-by-step instructions on how to eliminate transfer case noise on a Niva.

A universal remedy that will definitely eliminate the noise of the transfer case?

For people who do not want to spend a lot of time modifying the components of their SUV, there is a proven solution. A fairly reliable universal option for how to remove the howling of a transfer case on a Niva, one might say, know-how from the SV-PARTs company, is the installation of a steel four-satellite differential.

Chevrolet Niva 2003 Logbook Eliminating cardan vibration

After driving for a couple of days with a vibrating CV joint on the rear axle, I realized that I need to do something, otherwise it shakes so much that I really want to go to the toilet after the trip) It won’t take long to lose weight.

I decided to test it by swapping the front and rear universal joints. At the same time I stretched the rear axle shank, but the nut was loosened almost one turn. The backlash of the shank was immediately reduced by 2 times.

I went to test it and lo and behold. The vibrations have disappeared. More precisely, of course, they are there at the same 60-100 km/h, but they are so little noticeable that they are felt only visually by the vibration of the gear shift knob.

It’s still not clear what the matter is. Whether in an unscrewed shank, in an unbalanced new CV joint, or a complete set of looseness of the car, which has a greater effect on the CV joint than on the spider. For now, I decided to leave it like this, in front of the CV joint, in the back of the cross, although the rear one is also due for replacement soon, the cross is moving a couple of mm. But for now let's ride. Maybe we’ll save up for the second CV joint, but for the sake of interest we’ll save up for the Saratov one.

Niva Chevrolet transfer case alignment

Determining the causes of vibration and centering the transfer case

We remember the vehicle speed and engine speed at which vibration occurs in the transfer case mounting area.

With the car stationary, move the gearbox and transfer case levers to neutral and start the engine. We set the crankshaft speed corresponding to the vehicle speed at which vibrations occurred. If vibration persists, check the condition and fastening of the power unit supports.

If no vibrations are detected, repeat the previous test by engaging direct transmission in the gearbox. If vibration appears this time, the intermediate shaft is faulty (the flanges are loose, the hinge is stuck, the elastic coupling is cracked, etc.).

If there are no vibrations, accelerate the car slightly above the marked speed and move the gearbox and transfer case levers to the neutral position. The causes of vibration in this case are an imbalance of the center differential, front or rear driveshafts, or jamming of their hinges.

We also check the fastening of the transfer case to the body: the condition of the rubber-metal supports (tears and peeling of rubber are unacceptable), the tightening of the nuts, the absence of fatigue cracks on the body.

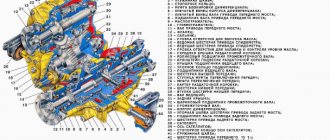

Before centering the transfer case, we check the condition of the power unit supports and the correct installation (the centering washers of the engine mounts must fit into the corresponding holes in the side brackets). We install the transfer case on the car without fully tightening the nuts securing the brackets for its suspension.

By moving the transfer case in the longitudinal, transverse and vertical directions (tightening or loosening the nuts of its fastening), we achieve a minimum and uniform gap between the flanges of the intermediate shaft and the drive shaft of the transfer case (the flanges must be at the same level and parallel to each other).

We fill the gap between the body floor and the supports with adjusting shims and align the centering belts of the flanges, slightly moving the transfer case forward (by the amount of the gap between the flanges). Finally tighten the nuts securing the transfer case supports.

Balancing the transfer case on the Niva. By popular demand.

Aligning the NIVA Transfer Case Without a lift 3 Ways to Center the NIVA Transfer Case

How to adjust the transfer case on a Niva and help from ZELLO

Transfer case alignment Niva Chevrolet 2123

how to adjust the transfer case on a field video

Centering of the Niva transfer case.

Chevrolet Niva Vibration. Checking the leak. 3rd support. Vibration of Chevrolet Niva transfer case. Causes

Using a transfer case on a Chevrolet Niva.

Balancing the transfer case in the field

August 30, 2016

This operation can help remove vibration, or at least it will be interesting and educational, like this miracle car. As practice has shown, this does not save you from replacing cardans with worn splines and broken crosspieces on an old car, but on a new one with good cardans and bearings on the shafts it helps. AS A CONSEQUENCE, THE TRANSFER LEVER NO LONGER CONVULSES, even on a Niva with high mileage. Take steel wire

1 mm, plasticine or hot glue as desired. We put the box and transfer case in neutral. We are looking for a helicopter bolt on the shaft donut from the gearbox side (important!) that corresponds well with the CV joint nut on the transfer case side. (On a helicopter there are 3 bolts on the CV joint and 4 nuts, but one pair is the same). Remove the speed sensor.

We fasten the wire and bend it so that when rotating it does not touch the gearbox lever housing. We bring the ends of the wires together at the point where we decided to start (leave a 1-2 mm gap) and rotate the structure. Our task is to rotate the ends of the wire nose to nose EVERYWHERE.

For this, all means are good: we bore the transfer case fasteners (for rotation), put washers under the supports, where there is no need to remove the washers. A big THANK YOU for the idea and advice to the honorary grower of the city of Goryachy Klyuch Vladimir Shubin!

Chevrolet Niva L › Logbook › Balancing cardans and transfer case on Chevrolet Niva

Causes of vibration and how to deal with it Reading our forum, you often come across a cry from the heart: “Help - vibration.” In this regard, I decided to share my thoughts on the fight against vibration and talk about how I finally defeated it.

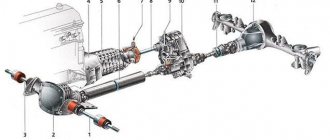

1. Imbalance of cardans. The reason is still not the most common. An imbalance in a normal cardan appears only if it is bent or if it is repaired, or the crosspiece or flange is replaced. In addition, an imbalance appears after, due to wear of the spline or crosspiece bearing, as well as wear of the transfer case or axle bearing, the cardan is displaced from the axis of rotation under which it was balanced.

2. Tight rotation of the crosses.

Usually drivers do not think about this, but in the case of tight rotation of the crosspiece, the force expended on this rotation is transmitted to the suspension elements of the units, and from them to the body. I won’t draw vectors, but the tighter the crosspiece, the more the transfer case deviates on its pads. And since with each revolution the crosspiece turns first in one direction, then in the other, then, accordingly, the vibration frequency is 2 times higher than the frequency of rotation of the cardan. A symptom of this particular problem is a hum, very similar to the hum of a bridge.

For example, I thought that my RZM.3 would soon “bend.” Large angles of crossing of the cardan flanges. The literature says: the drive must be “homokinetic”, this means that both flanges must be parallel to each other. In fact, this is ideal. In any case, deviations should be minimal. With proper alignment, the Niva turns out to be about 5-7 degrees (measured with a school protractor with a weight, so the accuracy is plus or minus a bast shoe).

Chevrolet Niva BlackHunter Logbook vibration resonance at 80 mph

So, let's talk about vibration in a shriv with cross driveshafts.

Given: vibration when accelerating at 20-40-60-80 km/h. Vibration only appears under load - either in floor-to-ceiling mode, or when the trunk and interior are fully loaded. At 80 km/h there is almost always vibration. At higher speeds there is silence.

Another feature is the complete absence of vibration on a cold car, that is, for the first 5-10 km there is no vibration. Then it gradually appears. Hence the conclusion - something is heating up: rubber bands in the rods, a donut, gearbox cushions or manual transmission...

Moreover, what is remarkable is that you press on the gas, a vibration appears, you release the gas a little and press again - the vibration disappears. Without load and in neutral, there is no vibration in the manual transmission.

1. To begin with, I replaced the jet rods with stock ones - the vibration almost disappeared, but gradually appeared again.

2. I removed the rear driveshaft - there is absolutely no vibration.

3. I buy and install two new Belkard universal joints. The vibration has decreased, but still appears in resonance.

4. Replaced the RPM and RZM with new ones - nothing has changed.

5. I adjusted and centered the position of the manual transmission, lowered the manual transmission by 2 mm - the vibration decreased further, but it appeared again in resonance.

6. Swap the cardan shafts - no changes.

7. I bought and installed adjustable reaction rods on silent arms 2108, lengthened the lower rods by about 5 mm - there is almost no vibration, but after running 10-20 km in the city or 50 kilometers on the highway it appears at 20 km/h in the floor-to-ceiling mode and at 80 km/h, the more the trunk is loaded, the rougher the vibration.

8. I replaced the tired gearbox support - no changes.

Basically, all that remains is to replace the transfer case cushions and the blower shaft, as I feel that the reason is somewhere there. Plus lengthen the lower links a little more so that the REM and manual transmission flanges lie in the same plane.

It seems to me that the rear cardan aligns the plane of rotation of the flanges, while the manual transmission bends on the cushions and the front cardan ends up outside the plane of the flanges, hence the misalignment of the cardans, which generates vibration.

Carry out a major overhaul of the unit

The latest and most effective method only applies to old transfer cases. But there are also shortcomings in the units of new cars. All of them can be eliminated by careful troubleshooting and fine-tuning of the unit.

The car must be inspected in the pit. Check the play in the shafts and, if necessary, modify or replace. Unfortunately, the assembly of this car is fraught with many errors that may emerge immediately or a little later.

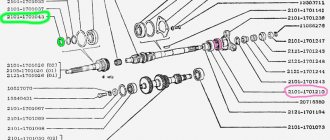

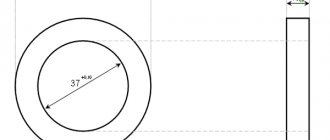

Specifics. Flanges and helicopters.

The results surprised even us, although it seems that nothing in this car should surprise us anymore. The photo shows the gearbox flange, also known as the transfer case flange. And it seems like a rotation part with an even number of splines and an even number of holes. But you can’t “take” an AvtoTAZ so easily. This part has a landing diameter (along the splines) and a mating plane. We made a device from the transfer case output shaft. We very carefully centered them for axial runout, and clamping the flanges, as we do on transfer cases and gearboxes, began to check them for runout of the end plane. The results are depressing. 20% of products DO NOT have runout. There were flanges where the runout reached 0.5 mm. To avoid doubts about spare parts, we removed the flanges from the conveyor machines, the result was the same. On checkpoint “helicopters” the picture is exactly the same.

Why does Niva Chevrolet vibrate?

First, you need to make sure that the vibration of the car occurs in the transmission units, and not on the mount of the power unit. To do this, set the gearbox and transfer case levers to the neutral position, and the engine speed is brought to those at which vibration was detected. If vibration occurs again, the reason lies in the engine or gearbox mounts.

Rubber-metal products delaminate over time and lose their elastic properties. If the vibration disappears, then the intermediate shaft and driveshafts are suspect.

The condition of the intermediate shaft is assessed with direct transmission engaged (IV speed). The vibration transmitted to the car body comes from hinges, elastic couplings or flanges. To check the beating of the cardans, it is necessary to accelerate to the test speed, or even better, to a speed slightly higher than the one at which vibration of the Chevrolet Niva was detected. Then the gearbox and transfer case levers are moved to neutral, and the car starts to coast. Only the cardan shafts work. The problem has not been resolved - the shafts are definitely unbalanced.

The last reason for a car to shake while driving may be a misaligned transfer case. This especially happens after transmission repairs. You should immediately check the condition of the engine and gearbox mounting mounts. If the cushions are worn out, there is no point in centering the transfer case.

Troubleshooting Methods

Some manipulations can be performed independently, without the services of a sometimes expensive car service.

However, the quality of spare parts for domestic cars leaves much to be desired, so, say, having bought a Chevrolet Niva driveshaft, no one receives a 100% guarantee that the problem will be solved.

But many people prefer to take risks by purchasing new parts.

The engine and gearbox mounts must be periodically monitored. If the car is operated in harsh conditions, then the load on these components increases significantly. The Chevrolet Niva driveshaft must be balanced, but only with a certain runout tolerance. Some drivers send the driveshaft for restoration, while others prefer to buy a new one.

A certain amount of vibration can be eliminated if you replace cardans with crosspieces with cardans with CV joints.

In this case, you will have to make minor changes, since the shank flanges are not identical. Finally, you can center the transfer case yourself if you loosen its fastening and, moving it along the plane, achieve such a position that the gap between the flanges is minimal. This refers to the flanges of the transfer case drive shaft and the intermediate shaft.

The truth about Niva cardan shafts

Vibration and noise are one of the problems of Niva -21213, 21214 and Niva CHEVROLET - 2123.

However, there may be several reasons for these troubles:

- malfunction of the vehicle's running system;

- transmission malfunction,

- gearbox malfunction

- transfer case malfunction.

Often the cause of everything is vibration, which appears at speeds from 75 km/h to 90 km/a consequence of an imbalance of the driveshafts.

How to eliminate vibration:

- remove the driveshaft from the car

- check the condition of the crosspieces (the driveshaft crosspiece should move with little effort in all directions of tilt; if the crosspiece does not bend when tilted in one direction or another, then it must be replaced).

- When replacing the crosspiece, be sure to check the lubricant in the roller bearing caps (we recommend using CASTROL LMX synthetic lithium grease).

- Inspect the cardan spline joint. To check the splines, it is enough to try to simultaneously rotate the halves of the driveshaft in different directions around their axis (the free play in the splines should be no more than one millimeter). If the spline part is damaged or there is more play in it, the driveshaft must be replaced.

If no faults are found when checking the driveshafts, the vibration may be caused by improper installation of the transfer case.

How to fix:

To adjust the installation of the transfer case between the driveshafts, it is necessary

- hang the car so that the wheels of the car do not touch the ground (in this case, free access to the transfer case mounts must be provided)

- inspect the transfer case mounts (for cracks, chips and damage in the metal part and in the bushings)

IMPORTANT: When removing the transfer case, pay special attention to the intermediate shaft located between the transfer case and the gearbox. The procedure for checking the intermediate shaft crosspiece is similar to checking the crosspieces on the propeller shaft.

- When all checks are completed, hang the transfer case on the mountings without fully tightening the mounting nuts. After this, ask an assistant to accelerate the hanging car to 80 km/h and carefully, so as not to get your hands into the rotating parts of the transmission, tighten the transfer case mounting nuts until the end.

To reduce vibration, you can replace the cardan shafts “on the cross” with cardan shafts on CV joints. They usually cost more than cross-type ones, but they are actually less susceptible to vibration.

Cars NIVA-2121, 21213, 21214 and NIVA CHEVROLET 2123 could be equipped from the factory with driveshafts from different manufacturers. If it is necessary to replace the crosspieces, it is important to know the manufacturer of the cardan, since the crosspieces have different sizes and are not interchangeable.

Cardans of JSC "KARDAN".

2121-2201012-02 Rear universal joint (thin splined, thick pipe, VAZ cross).

Fits:

Niva-2121,21213,21214,2131 and on NIVA CHEVROLET 2123 (both in front and behind there is one).

2121-2203012-04 Front universal joint (thick splined, thin pipe, VAZ cross).

Fits:

Niva-2121,21213,21214,2131

Cardans Türkiye TIRSAN.

2121-2201012-02 Rear cardan (thin spline, thick pipe, 27mm TRIALLI cross).

Fits:

Niva-2121,21213,21214,2131 and on NIVA CHEVROLET 2123 (both in front and behind there is one).

2121-2203012-04 Front universal joint (thick splined, thin pipe, 27mm TRIALLI cross).

Fits:

Niva-2121,21213,21214,2131

Cardans in Belarus are produced by the plant in Grodno, JSC BELKARD.

2121-2201012-02 Rear cardan (thin splined, thick pipe, Moskvich cross).

Fits:

Niva-2121,21213,21214,2131 and on NIVA CHEVROLET 2123 (both in front and behind there is one).

2121-2203012-02 Front cardan (thick splined, thick pipe, Moskvich cross).

Fits:

Niva-2121,21213,21214,2131

Factory driveshafts are properly balanced

Who is to blame and what to do?

I think that the first question is rhetorical))) But let’s try to answer at least “why this is so.” I am a mechanical engineer by education and work, production technology is at an average level, so I turned to a military plant technologist for advice. How it should be: the workpiece is made with a press, rough processing is carried out with allowances, a thermal treatment is made, the part is processed completely according to the “main and landing” dimensions. How it was done: the last stage was removed. After heat treatment, the part warps and does not come out clean. Or it is placed on a cylindrical mandrel during finishing processing, which cannot be done. Since with this design, everything is centered on the splines.

The answer to the second question. We buy a box at the factory containing 100 “semi-finished” flanges wrapped in oil paper, drag them to the lathe, set up the “finishing fixture” and finish the entire batch.

Which cardans are best installed on a VAZ 2123?

The most popular among Shniva owners are cardan shafts from the following manufacturers:

- Tirsan Kardan is a manufacturing enterprise in Naberezhnye Chelny, specializing in the manufacture of driveshafts for AvtoVAZ vehicles and other Russian automobile plants;

- SiM (Sickle and Hammer) is a Saratov plant producing transmission components, CV joints, cardans and camshafts;

- Belkard is a Belarusian enterprise that produces spare parts for buses, trucks and passenger cars. Among other things, this company produces reinforced splined cardans for Shnivy.

We get rid of vibration and extraneous sounds of the Niva transfer case forever

Let's start by diving into the materiel. Transfer case (TC) is a separate unit of an all-wheel drive vehicle, which provides multi-mode power distribution from the engine to the front and rear axles.

Externally, this is a mechanism located under the bottom of the car, in the body of which a multiplier (divider) is placed in series to obtain an intermediate gear ratio in the transmission and a splitter of one power flow into two. It is with the help of this device and its controls (levers) that go into the vehicle interior that the LADA 4×4 driver selects the all-wheel drive operating mode.

The RK directly connects the front driveshaft and the intermediate shaft (shaft) with the vibration damper to the vehicle’s gearbox. As is probably already clear from the description, this element is connected to the rear axle of the car via a rear propeller shaft.

We study problems and repair methods

Any car owner definitely doesn’t need to be told why howling and humming are bad. Vibration of the transfer case on a Niva at low speed is quite common. The driver, of course, gradually gets used to many extraneous sounds in the car, but the noise level is high enough to make it impossible to carry on a conversation with passengers while traveling. Due to excessive noise pollution, you will inevitably have to deal with the problem.

Vibration and how to deal with it

The main reason for the occurrence of unnecessary sounds is multi-frequency vibrations of the components of the transmission. In general, the vibration of the transfer case on a Niva is one of the most common cornerstones that other car owners are forced to fight (or put up with) constantly.

- Check the cushions (supports) on which the power unit, gearbox and other parts are attached to the body, including the muffler. Any worn-out pad or rubber band can easily cause excessive shaking of the iron and accompanying rumble. It is better to replace worn silent blocks and pillows immediately.

- Be sure to pay attention to the intermediate shaft (inlet shaft). If you see signs of “fatigue” - change the elements that have become unusable, or the entire part!

- Examine the condition of the driveshafts. The “old” version of the cardan allows you to service (repair) the part, for example, by replacing broken crosspieces. In the case of CV joint driveshafts, you will have to replace a completely non-functional element. As for driveshafts on constant velocity joints (CV joints), this design is more expensive, but it has an undeniable advantage - it is easy to dismantle and install back, and this operation does not disturb the balancing of the driveshafts.

- It would be a good idea to pay attention to the placement of the transfer case. If an additional (third) RC mount is installed, unscrew it from the box; there is no need to unscrew it from the body. Set the transfer case to neutral, start the car and in fourth gear, rev it up to about 3-4 thousand revolutions. It must stabilize and, as they say, find its place. Turn off the car and secure the mechanism.

Perhaps this is the most complete set of measures that experienced auto mechanics advise when the transfer case on a Niva hums and vibrates!

Removing the howl and hum

We will assume that we have dealt with the vibration, but an equally significant problem remains - how to remove the howling of the transfer case on the Niva. Vibrations of the mechanism are not always the only reason for the appearance of extraneous irritating sounds. And the characteristic noise of the transfer case, alas, is one of the “trademark” shortcomings of one of the best domestic SUVs.

Removing the possibility of oil leakage

In an effort to resolve the question of how to get rid of the howling of the transfer case, even before the 2010 update, the manufacturer began assembling this mechanism using silicone sealant instead of cardboard gaskets. And he introduced an improved crankcase ventilation system with an open breather, which was located under the hood. Again, the reliability of the vehicle when passing fords has increased slightly, and most importantly, the load on the seals has also decreased.

We mention them again to point out that the fewer vibrations and shocks, the longer it will not take to detect an oil leak on the transfer case housing due to deteriorated seals. Moreover, the flange in the RC covers can cause noise - during operation, the bearing seats are simply broken.

We hope that the steps listed above will become complete step-by-step instructions on how to eliminate transfer case noise on a Niva.

A universal remedy that will definitely eliminate the noise of the transfer case?

For people who do not want to spend a lot of time modifying the components of their SUV, there is a proven solution. A fairly reliable universal option for how to remove the howling of a transfer case on a Niva, one might say, know-how from the SV-PARTs company, is the installation of a steel four-satellite differential.

Practice shows that it eliminates up to 90% of noise. Perhaps, if you also follow the previous recommendations, then the total effort will be enough to find comfort and peace behind the wheel of your favorite car.

There is a difference? What transfer cases are on different modifications of the Niva?

One more point should be paid attention to: is there a difference for different modifications of the Niva car.

Niva (LADA 4×4)

The VAZ-21213 (Niva), and with it the VAZ-21214, LADA 4×4 URBAN and other small-scale vehicles assembled on their basis, are equipped with a single transfer case, only taking into account the updates and improvements introduced by the plant in 2009-2010.

Chevrolet Niva

Here you need to take into account that the transfer case of the VAZ-2123 car, which the Niva actually is, has exactly the same device as similar units on an ordinary VAZ SUV.

But the Chevrolet Niva, as you know, has a different control mechanism - it uses a single transfer case lever, not two. Gears are switched lengthwise, and the locking is switched across. At the same time, it was initially installed with a different clutch (Valeo) and small-module RK with single-row or double-row bearings. And the car left the factory with a transfer case control lever with a built-in damper, which removed excess noise in the range of 4-5 thousand revolutions of the power unit.

So, regarding the discussion on the topic “the causes of vibration and howling in the transfer case on a Chevrolet Niva and how to eliminate it?” The advice we gave above is quite appropriate.

SV-PARTS recommendations

We would like to point out that the assortment of the SV-PARTS online store has everything to solve issues with the transfer case, even complete units for Niva 4×4 (VAZ 2121) and Chevrolet Niva. We also recorded a short video to help car enthusiasts so that you don’t have to waste a lot of your time

Watch, comment and conquer new horizons off-road with us!

Possible causes of increased gearbox noise

| GENERAL INFORMATION |

1) Select a section of road with a smooth asphalt surface to reduce the noise created when tires roll and the level of resonance noise in the car interior.

2) After driving the vehicle, warm up all components of the vehicle to normal operating temperature.

3) Write down the vehicle speed and the number of the gear engaged at which an increase in noise is observed.

4) Check for noise when the engine is idling and the vehicle is stationary.

5) Determine in which driving mode there is increased noise.

5a) Acceleration - smooth or sharp.

5b) Uniform movement - movement of a car at a constant speed at a small opening angle of the throttle valve on a horizontal road.

5c) Engine braking - driving a vehicle with the gear in gear and the throttle valve partially or completely closed.

5d) In all of the above modes.

Bearing noise

Final drive bearing noise can easily be confused with wheel bearing noise. Since the final drive bearings are preloaded, their noise should not be noticeably reduced when the gearbox is running and the suspended drive wheels are rotating. The characteristic feature of wheel bearing noise is that it continues when the car is coasting in neutral in the gearbox. Since the wheel bearings do not have preload, their noise is noticeably reduced when the suspended wheels rotate.

Brinelling

Brinell bearings are characterized by clicking or knocking sounds, the frequency of which is approximately half the speed of rotation of the wheel, since the rollers move more slowly.

Brinelling is a consequence of the action of large forces that press the rolling elements (balls or rollers) into the bearing ring. In this case, indentations are formed on the ring track. Brinelling is observed when the bearing ring is pressed onto the shaft journal or into the crankcase seat, if the force is applied through the race with the rolling elements and the second ring. Brinelling is also caused by vibration acting on the housing part in which the bearing or rotating shaft is installed. An external sign of brinelling is the presence of small dents on the surface of the bearing treadmill, making it look like a washboard. The operation of a defective bearing is accompanied by strong low-pitched noise.

Laping

Laping is caused by small abrasive particles of scale, sand, corundum, etc. materials that are carried by oil. These particles cause wear on the raceways and rolling elements of bearings. A defective bearing may have significant play but operate smoothly. The cause of lapping is the operation of the car on contaminated oil.

Jamming

Bearing jamming occurs when large foreign particles enter the treadmill. These particles can jam the rolling elements and cause one of the bearing rings to rotate. Excessive preload on tapered bearings can also cause them to seize.

Pitting, or pitting of rolling surfaces, is a consequence of normal fatigue wear under prolonged exposure to cyclic contact stresses. Pitting can also be a consequence of improper installation of the bearing or develop after the introduction of solid foreign particles into contacting surfaces.

Spalling, or scaly spalling and cracking of the rolling surfaces, is a consequence of overloading or improper installation of the bearing (misalignment, misalignment of rings or excessive preload).

Shaft balancing

The procedure is necessary after replacing crosspieces or minor damage to the driveshaft. It is performed on a special balanced stand with sensors and control surfaces.

Important! At home, using it will not be possible to achieve the required accuracy in selecting loads. Therefore, balancing should be performed in a specialized service station.