How the car clutch works

Issue No. 6: adjusting the clutch pedal and changing the oil

The clutch is one of the car components designed to establish a connection between the engine and the transmission of the car. This complex part is necessary for adjusting speed modes (gears) and torque, which increases the smoothness of the machine when starting to move. In the absence of this component, a colossal load will be placed on the car’s gearbox, which can cause wear or immediate failure. To operate the clutch correctly, you need to know about the structure and operating principle of this mechanism, as well as have information about its possible breakdowns.

Device

A modern clutch consists of the following elements:

1. Pressure disk. This part is the basis of the clutch assembly. It is a round-shaped basket to which several springs are connected. The engine flywheel is connected to the base of the pressure plate, transferring torque from the gearbox directly to the motor. The disc springs have a rounded shape and are directly involved in the interaction of all the main clutch elements.

2. Driven disk. The driven disk suppresses unnecessary noise, sounds and vibrations during gear shifting using the transmission. It consists of such parts as a damper spring, a coupling, a convex base and friction linings. Damping is carried out inside linings consisting of a carbon fiber or ceramic composite with soundproofing properties. The driven disk fits into the splines of the gearbox shaft and, with the help of damper springs, moves freely along them when changing the speed mode.

3. Release bearing. A release bearing, which is a rounded pressure pad, is attached to the protective conical tube of the engine's primary propeller shaft. With its help, the drive system is activated. It performs its actions through pulling or pressing movements.

4. Drive system. The drive transmits torque from the car's engine to its wheels. Depending on the transmission method, mechanical, electrical and hydraulic drive systems are distinguished. In a mechanical system, all transportation occurs using a cable located in the inner part of the conical shaft tube. The electrical system carries out transmission under the action of a built-in electric motor, which is located next to the shaft cable.

The electric motor is activated when you press the pedal. The hydraulic drive system has the most complex operating principle. It transmits torque through a high-pressure tube. When you press the car pedal, a specialized piston begins to press on the brake fluid, creating high pressure in this area. Using a tube, it is transmitted to the working cylinder, which activates the release fork.

Torque is transmitted through it.

5. Clutch pedal. This component is located inside the car. It is connected to the clutch using a number of fasteners and assemblies. The pedal operates the drive system.

Operating principle

The clutch action is based on the variable movement of the drive disc. It attaches to the flywheel of the motor. To achieve maximum strength, the structure is held together with a pressure plate. The driven disk is located between the pressure pad and the motor flywheel. The flywheel is influenced by the pressure plate springs. As a result of the pressure, the cable is activated, which transmits the pressure through the high-pressure tube to the release fork. As a result, the torque is transmitted to the gearbox and gear shifting occurs.

Depending on the structure of the structure, there are 2 types of clutch, differing in their operating principle:

1. Wet friction clutch. The main difference between this type of clutch is the presence of an oily environment in which all components of this part interact. The driven disk moves through translational movements and weakens the compression between the gearbox shaft and the pressure plate, causing a change in speed. The oily liquid cools all components and allows greater torque to be transmitted than in a dry environment. Wet friction clutches are most often used in motorcycles and mopeds.

2. Dry friction clutch. This type of clutch operates all components in the absence of fluids. It is used in most passenger cars with manual transmission. It has less high efficiency, but is much cheaper than a wet friction clutch.

Operating principle

VAZ vehicles use a single-plate dry closed clutch with a diaphragm-type pressure spring, for which the operating position is engaged.

New clutch VAZ 2114

The clutch includes the following components:

- body-protection;

- bearing switch;

- main shaft roller bearing;

- pressure disk;

- compression spring;

- flywheel;

- secondary friction disc;

- scale;

- crankcase;

- transmission main shaft;

- plug switch;

- second bushing-switch;

- toggle switch;

- fixation bolt to the flywheel.

The operating principle of this mechanism is as follows. After pressing the clutch pedal of the VAZ 2114, the drive moves the fork, which acts on the clutch bearing. The bearing, in turn, presses on the diaphragm spring of the pressure disk. As a result of the impact, the spring petals bend towards the flywheel, and its outer edge moves away from the pressure plate, thus releasing it. The transmission of torque from the running engine to the transmission stops.

Clutch drive VAZ 2114

After releasing the pedal, the pressure disk again comes into contact with the driven disk, and through it, with the flywheel. In this case, the transmission of force is resumed (as you can already guess, the moment of rotation itself is transmitted due to the friction force).

How to deal with a tight clutch pedal

Experts' recommendations for removing, installing and adjusting rear doors on the Lada Granta

Most drivers do not want to put up with this state of affairs and try in every possible way to improve the performance of the clutch.

Among the most common recipes for dealing with a tight pedal are the following:

- Replacement of the basket and all clutch assembly elements with a known quality product. The best option would not even be a new Valeo, but the assembly recommended by the manufacturer. Often, for many car enthusiasts, the situation became a revelation when, after replacing cool branded baskets with conventional Russian options, the clutch pedal turned from extremely tight to an option with a comfortable level of effort;

- It is considered cheaper and more accessible to pack all rubbing surfaces with lubricant. To gain access to blind lubrication points, there is a diagram indicating drilling locations, where transmission oil is subsequently pumped with a syringe or oiler;

- Replacing the cable with a stronger model, regularly filling brake fluid or engine oil with a syringe under the casing. If spindle or similar oil still gives a good effect, pouring brake fluid or WD-40 is pointless and useless. They only contribute to the destruction of the outer sheath of the cable.

Important! All of the above methods, to one degree or another, can effectively deal with a tight clutch pedal. The first recipe will be the best and most effective. In addition to cable drives, hydraulic systems also suffer from similar problems.

But, unlike the cable, due to the high force on the clutch release fork, the cylinder cuffs are destroyed first, and brake fluid leaks

In addition to cable drives, hydraulic systems also suffer from similar problems. But, unlike the cable, due to the high force on the clutch release fork, the cylinder cuffs are destroyed first, and brake fluid leaks.

The video shows what a stiff clutch pedal is and how to fix the problem:

- How to adjust clutch pedal free play

- Replacing the coolant pump

- Operating principle of the contact ignition system

- Device for a contactless car ignition system

When pressing the clutch pedal we definitely have to apply some kind of force, but there are situations when it is pressed too hard. In such a situation, we are dealing with the problem of a tight clutch pedal. There may be several reasons for such a breakdown. The most common of them are sticking of the lever or cable, wear of the fork bearing. So, in order to restore the correct functioning of the pedal, you first of all have to deal with the so-called symptom of the breakdown (or what led to the breakdown).

So, if the clutch pedal becomes stiff as a result of wear on the fork bearing, then when you press the pedal, you will hear some rumbling, which indicates that the release bearing has already served its purpose and needs to be replaced with a new one.

The mechanisms developed in our time are designed to cover long distances (more than 1,300 thousand km), if the driver regularly diagnoses them and the necessary replacement of worn parts.

But if the system is treated carelessly, then it will serve you no more than 50 thousand km. In large trucks, problems can also arise with new, not yet ground-in elements.

You also need to check if everything is in order with the release bearing; it may be damaged and this may cause problems with pressing the pedal. It is also worth checking the diaphragm spring, which is located on the pressure plate, for damage. If you are well versed in your car, then you can perform this type of check yourself, but for a better result, you should still contact the service station workers.

There may also be a problem of incomplete shutdown of the mechanism. In such a situation, the driver of the car should feel a certain grinding noise when engaging the gear. This is due to the fact that the disc is not able to come off the pressure plate normally. To fix this breakdown, it is also better to turn to professionals.

A situation where the device is not completely turned off is possible due to a number of reasons, such as:

- the cable has been adjusted incorrectly;

- the driven disk becomes jammed;

- the system unit is not assembled properly;

- disk warping occurs;

- deterioration of the shutdown mechanism.

A stiff clutch pedal is considered a fairly common breakdown of the system as a whole. In such a situation, it is pressed very hard. To differentiate the source of the breakdown, you should contact a specialist, especially if the breakdown occurred after the installation of a new kit.

A little about the history of the creation of the Soviet SUV

Initially, the UAZ 469 was developed as an all-terrain military vehicle, which was intended to replace the older GAZ -69 model. The car was developed from the mid-60s, and began to be mass-produced in 1972; its further modification was the UAZ-3151 (produced since 1985). The civilian modernized version was the UAZ-315195 Hunter. Three years ago, the Russian Ministry of Defense completely refused to supply UAZ, switching to other types of SUVs. Although UAZs have proven themselves in the army as reliable, unpretentious vehicles, they are very outdated.

The familiar Loaf model

The UAZ 3303 commercial truck became a further modification of the famous “loaf”, a family of cars from the Ulyanovsk plant, including the very first UAZ 450. It began to be mass-produced back in 1958. The car became the first independent development of the plant, based on the components and assemblies of the GAZ-69 and GAZ-21. The very first tests exceeded all the designers' wildest plans; the car confidently overcame even snow cover 50 cm deep, and also drove along a tank track with a load of a ton of weight. The development of the SUV began in the mid-50s, prototypes appeared a month later.

Since the GAZ 69 had an unsuccessful wheelbase, the new car had to use a carriage layout, which was developed in two modifications:

- a truck with a wooden body;

- all-metal van.

To ensure the necessary rigidity of the body, ribs were developed on the roof of the van, which visually resembled a loaf of bread. In the mid-late 80s, the “loaf” underwent modernization, the engine remained old, but boosted to 90 horses. The SUVs were equipped with an improved dual-circuit braking system and a vacuum clutch release amplifier, and the bridges were also modernized. The names have changed once again.

Adjustment instructions

Adjusting the clutch cable of the Lada Granta

The Lada Priora is equipped with a clutch cable with a ratcheting mechanism. The cable is backlash-free and does not require adjustment, but manufacturers recommend this be done during every maintenance.

Clutch cable

To adjust the cable on the Lada Priora, you need to prepare a screwdriver and a ruler. The procedure then consists of the following steps:

- To perform work, you must open the hood.

Engine compartment of Lada Priora First, you should disconnect the mass air flow sensor and remove the air filter.

Engine compartment without air filter

- After this, a cable will be visible, at the end of which there is a plastic clip.

- Before adjustment, it is necessary to set the cable to its original position: overcoming the resistance of the spring, push the cable clamp forward until it stops in the direction of movement of the car.

- This clamp should be pulled towards you and the distance between it and the plug should be measured, it should be 27 mm.

We measure the distance using a ruler - The distance is adjusted by turning the tip counterclockwise. In this way, an increase in distance can be achieved.

- Twist the clamp until the distance is 27 mm. Accuracy is very important here.

- Now you can release the cable and place it in the fork.

- After completing the steps, you need to get behind the wheel and press the pedal three times until it stops.

- Then again you need to measure the distance, it must be exactly 27 mm, otherwise we adjust until the desired distance is achieved.

- Next, you should insert the tip into the groove of the mechanism fork and release it. Thanks to the spring, the tip driver clamp is installed without any gap.

- After adjusting the cable, you need to return everything to its place, start the engine and check the operation of the mechanism.

After adjustment, the clicks disappear and the clutch release pedal operates softer.

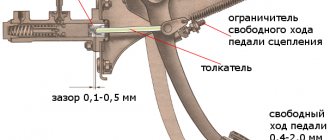

Clutch pedals

When the clutch pedal travel is large, the clutch is not completely disengaged, so it still comes into contact with the flywheel of the power unit. When the stroke is low, the driven disk does not turn on completely, which leads to slipping and loss of torque.

You should measure your pedal stroke if the following symptoms occur:

jerks appear when starting to move; noise and shock when shifting gears; the pedal gets stuck.

The symptoms described indicate that the mechanism requires adjustment. You can diagnose its operation on Priora yourself. To do this, start the engine, slowly release the PS and start moving. If, when the PS is released, the car immediately begins to move, this means that there is no free play. If the car does not budge even with the pedal fully released, then its travel exceeds the norm. The brake pedal should be at the same level as the brake pedal. In this case, its full stroke will be in the range of 125-135 mm. Fluctuations up to 160 mm are possible.

We measure the free play of the pedal

When making adjustments, loosen the first cable adjusting locknut located in the engine compartment on the bracket.

Locknuts for adjusting free play

By tightening the second locknut, the distance and stroke of the PS are adjusted. Thus, the desired result is achieved. After completing the procedure, the first locknut is tightened.

If you adjust so that the brake pedal is located above the brake pedal, then the clutch will barely leave the floor. If it is lower, it will set almost at the very end. If the PS is located too high, the basket wears out faster. The ideal option is that the brake and clutch pedals should be at the same level.

In order to extend the life of any mechanism, you should use it carefully. You should not constantly keep your foot on the PS; it is better to place it on the left on the floor. During each technical inspection of the Lada Priora, it is recommended to monitor the free movement of the PS and the clarity of gear shifting and, if necessary, make adjustments.

Methods for solving the problem

If the clutch pedal fails while driving a car, then there are not many ways to solve the problem. We recommend that you familiarize yourself with all the methods so that in the event of a corresponding breakdown you know how to behave.

Replacing the cable

To replace the cable, you will need the cable itself, as well as wrenches and pliers. It is advisable to use a spanner or open-end wrench, this will be much more convenient.

But if you don’t have a box and open-end wrench on hand, you can also use a regular wrench:

- Open the hood of your car. In the engine compartment you need to find the very place where the cable is attached to the tip. Since a break occurred, most likely the tip remained in the installation location, and the cable itself was dangling. You need to remove the tip using a wrench.

- Then get inside the car and disconnect the cable directly from the clutch pedal. Remove the cable.

- Take the new cable and install it in place of the old one, the entire assembly occurs in the reverse order.

- You need to measure the free code of the pedal, and then adjust the installed element. The free play should be no more than 3 cm, and the total should be no more than 14.7 cm. The accelerator travel is adjusted using the nuts on the end of the cable in the engine compartment.

1. Unscrew the fastening nuts

2. Remove the locking bracket

3. Adjust the new cable

If the spring breaks

If the return spring bursts, the procedure will be different. To replace, you will need the spring itself; if you do not carry it with you, you will have to go to the nearest spare parts store.

How to change a spring:

Open the hood and use a wrench (it’s more convenient to use a spanner) to unscrew the cable nut

You need to extract it. Carefully, so that the remains of the old return spring do not fall apart, remove them. Please follow all safety rules. Take the new part and install it in place of the old one

This also needs to be done carefully, since in this case it is very easy to damage your hand or fingers. Then reinstall the cable. Tighten the nut. After this, adjust the free and overall travel of the pedal. Start the engine and try to drive it.

1. Unscrew the fastening nut.

2. Remove the spring and replace it with a new one

How to get to the service station on your own?

Of course, it will be better for the driver if this breakdown occurs near his home, then you can consider yourself lucky. But if this happened on the road, and the nearest service station is not so close that you could push the car to it, then this is already a problem. But there is a way out of every situation, so if the clutch pedal fails, you can still get to the nearest service station, and now we’ll tell you how.

To drive in first gear - if you need to restore the pedal's functionality, you can do the following:

- The gearshift lever must be moved from neutral to first gear. In this case, the gas must be released.

- Start turning the key in the ignition. When the engine tries to start, apply gas, but do it so that the car does not stall.

- When the car starts to move, do not try to change to the next gear. This is fraught with breakdown of the gearbox, and its repair, believe me, will cost more than calling a tow truck.

In general, the same method allows you to start moving at second speed.

But before you do this, check out some important points:

- When the pedal fails, do your best to stop the car on a downhill slope or on a straight road without the car rolling backwards.

- Warm up the engine before driving.

- Before you start moving, carefully consider your entire route, because you need to take into account all the nuances. This includes the number of intersections, traffic lights, where you should turn from and where, and so on. It will be more convenient to drive only on the main road, so that you don’t have to stop to let other cars pass.

- Turn on the warning lights (hazard warning lights).

- Avoid unnecessary maneuvers and remember that no one knows about this problem except you. It’s better to stop once again and repeat the procedure than to create more serious problems for yourself.

- If you are not sure that you can cope with such a task on your own, then maybe it makes sense to call a tow truck or tow the car to a service station?

We recommend: Features of adjusting and setting the ignition of the VAZ-2106

How does the clutch work?

Experienced drivers are well aware of the design and principle of operation of the clutch. But among beginners, not everyone can boast of such knowledge. Therefore, before talking about malfunctions, it makes sense to understand what they are.

Model...

The physical principle on which the operation of the coupling is based is the presence of frictional force between the contacting surfaces. A simplified model of this device can be represented as two coaxial disks, a master and a slave. One of them can move under the action of a control lever. The first is connected to the drive. The second one is connected to the transmission.

When starting to move, the driver “squeezes the clutch” and the discs separate. The slave is motionless, i.e. the clutch is in the "disengaged" position. Then the driver engages first gear, adds gas and gradually releases the pedal. The disks are getting closer. At some point, their surfaces begin to contact each other, but still with slipping.

Therefore, the slave also begins to rotate, but its torque is less than that of the master. Next, the first disk is pressed more tightly against the second, slippage decreases, and the driven one rotates faster and faster. After the disks are completely pressed against each other, the slippage is zero and the angular velocities are the same. The clutch is engaged.

...And in reality

Compared to the physical model described above, the car clutch will be more complex. Although the principle of operation is the same. The main nodes are:

- Basket. Screwed to the flywheel. In its center there are pressing petals, and on the inside there is a movable pressure disk.

- Driven disk on the gearbox shaft. In its center there are damper springs in a circle. On one side there is a flywheel, on the other there is a basket.

- Movable release bearing. Makes the petals bend.

If the clutch is engaged and the motor is connected to the transmission, the pressure plate presses the driven one against the flywheel. When the driver presses the clutch pedal to turn it off, the bearing bends the petals. The discs move apart. The connection between the motor and the transmission is interrupted.

When the pedal is completely released, the pedal returns to its original position. The friction planes again touch one another and remain in this state, imparting torque from the engine to the gearbox. That. The car's clutch is a normally engaged mechanism.

General characteristics of UAZ 469 and UAZ 3303

The UAZ 469 SUV received a durable and torsionally rigid body mounted on a spar frame. The engine is common for the USSR and the Russian Federation: an in-line four, with a volume of 2.5 liters UMZ-451MI, its power was initially 75 horsepower, after modernization in 1985 the car received a more powerful UMZ-417 engine. A very useful feature of the car is the use of low-quality fuel, in particular A72/76 gasoline.

Early versions of the car used a clutch without a hydraulic booster.

Initially, the four-speed gearbox did not have synchronizers, but in the last gears this shameful defect was eliminated. The Jeep had a two-stage transfer case without an intermediate shaft. The seven-seater SUV consumed up to 16 liters of low-octane gasoline per 100 kilometers. The car allows you to transport up to 600 kg of payload, taking into account 2 passengers and towing a trailer weighing 850 kg.

Having received the new UAZ-3151 marking, the jeep was slightly modernized:

- the clutch was now hydraulically driven;

- more reliable cabin heating;

- safety steering;

- new lighting fixtures;

- windshield washer;

- new drive axles;

- dual circuit brakes.

For driver convenience, the brake and clutch pedals are suspended. According to the modern classification, the UAZ 3303 is a fully commercial off-road vehicle with acceptable efficiency. The Jeep has been modernized many times over its history, which has further improved its performance characteristics. So, from the mid-80s, the Ulyanovsk Automobile Plant began producing the UAZ 3303. The car had compact dimensions and an on-board platform. The designers completely left all-wheel drive from earlier models.

Due to the fact that the all-metal double cabin of the UAZ 3303 allows free access to the engine, which is located below, under the passenger compartment, it is very convenient to repair the engine in this case, especially in bad weather. And in winter, the cabin is well heated thanks to heat transfer from the power unit, so the car is very pleasant to operate in northern latitudes. Previously, the UAZ 3303 platform was mainly wooden, but recently the plant has completely switched to an all-metal side.

The basic version of the car does not have power steering, but for an additional fee you can purchase a car equipped with it. The latest versions have a more powerful UMZ engine of 112 horsepower, which, paired with a well-proven UAZ gearbox, allows you to feel confident on any off-road terrain.

Signs of a bad clutch

Clutch problems can affect the overall technical condition of the car and affect the safety of both the vehicle itself and other road users.

Symptoms of malfunctions:

If the clutch pedal is mechanically driven, then the reasons are as follows:

- malfunctions in the clutch pedal mounting mechanism;

- failure of the mechanical clutch engagement drive;

- deformation of the clutch fork;

- failure of the release bearing;

- failure of fork mounting bushings;

- wear or deformation of the clutch spring petals;

- jamming or jamming of the cable in the braid.

Hard hydraulic clutch pedal, reasons:

- fluid leakage from the hydraulic circuit or presence of air in the system;

- failure of the release bearing guide;

- failure of the hydraulic piston of the release bearing;

- malfunction of the clutch basket (deformation or wear of the spring);

- failure of the working cylinder (damage to the cuffs).

Let's summarize

If the check shows that the free play is normal, but you doubt your competence in adjusting the unit, contact a service station. Incorrect settings can cause rapid clutch failure. If you want to complete the work yourself, you can find the necessary information on the vehicle manufacturer’s website or in its service book

It is important to complete the work in a timely manner so as not to get into an unpleasant situation on the road. Monitor the service life of clutch parts, for example, the service life of the driven disc is 100 thousand kilometers

But, if a motorist has an aggressive driving style, it can decrease by 2-3 times.

Causes of a tight clutch pedal on a Lada Granta car and ways to eliminate the problem

Problems with a hard lever arise both on new cars and on models with an impressive mileage. Depending on the age, the nature of the problem can vary - from a banal drive wedge to serious problems with the unit connecting the engine and gearbox.

What's the matter

Often a tight clutch pedal on a Lada Granta occurs for the following reasons:

- Mediocre performance of the diaphragm spring.

- Fork jamming.

- Release bearing jamming.

- Scratches on the surface of the cable in the working braid.

- The cable is distorted in the mounting bracket to the interior pedal assembly.

- Wedging of the driven disk.

On vehicles with a long service life, cracks may appear in the bearing drive fork and on the release support guide. The accumulation of dirt in the assembly also cannot be ruled out. Damage to the cable clamp bracket should also not be discounted.

For your information. All of these problems can result from the manufacturer allowing defective parts to be installed.

How to troubleshoot

There is no point in immediately positioning the unit connecting the box and the engine as faulty. The cost of a new set of spare parts in the form of a basket, driven disk and release bearing is high, and there will be no 100% certainty that there is a problem with this module until a thorough diagnosis of the drive has been carried out.

Problems with the drive part

In 80% of cases, the culprit of a tight clutch pedal on a Lada Granta car is one of three:

- The rope is unraveled.

- Corrosion or dirt in the cable jacket.

- Lack of lubrication on the fork shaft.

On a note. Checking the serviceability of the cable part is quite simple. Just squeeze the pedal and throw it. The return stroke of the lever must be fast and continuous. More detailed diagnostics are performed with the cable disconnected. The operation takes more time, but gives a clear answer to the question. You can check both the condition of the cable and its ease of movement along the jacket.

However, there are often cases when it is enough to add lubricant to the jacket, and the pedal assembly shows proper operation. As lubricating products you can choose:

- Transmission or engine oil (fill in a syringe with a needle).

- Emulsion of silicone origin in cans.

- WD-40.

The need to lubricate the fork shaft will be indicated not only by tight movement. When a command is given to the unit, a creaking sound will also be heard from under the hood. You can deal with this kind of malfunction using the following method:

- Remove the engine air filter along with the housing.

- Pry off the plastic bushing of the fork.

- Spray with silicone lubricant or WD-40.

Problems with the clutch assembly

When installing a new basket, difficult behavior of the part is inevitable. The effect disappears after 500-1,000 km in mixed mode. If the normal functioning of the unit is not restored after running-in, an unofficial set with an increased leaf spring stiffness was probably purchased. Then there is only one way out - buy a proven set and change it again.

Wear or deformation of the Lada Granta clutch fork also causes tight pedal travel and subsequent discomfort. In this case, it is necessary to act as quickly as possible, since the presence of critical defects can damage the module at the most inopportune moment.

Substandard behavior of the Granta pedal assembly is a malfunction that should be eliminated as soon as possible. The issue may be either in the drive, which here is a cable drive, or directly in the unit connecting the engine and the gearbox.

Most often, the problem lies in an unraveled cable or its limited mobility in the jacket. This problem can be eliminated by replacing the cable and/or lubricating it with oil, silicone or WD-40. The fork shaft often needs lubrication.

Less commonly, the problem is caused by a deformed or cracked fork. Wear on the leaf spring can radically change the amount of force required to release the pedal. A new clutch can also cause it to feel stiff.

What to pay attention to

There are certain signs that the clutch on the Lada Grant has failed and action needs to be taken

It is worth paying attention that if the car has just been purchased, the pedal will be pressed quite easily. If this requires great effort, then this is the first indication that the clutch needs to be adjusted or replaced.

It is also worth paying attention to the appearance of extraneous squeaks at the moment when the driver presses the pedal. In addition, it should not twitch when the car owner does not touch it.

Most often, car enthusiasts are faced with the fact that the pedal travel becomes too tight. It is worth considering in more detail the reasons for this problem.

Verdict

Substandard behavior of the Granta pedal assembly is a malfunction that should be eliminated as soon as possible. The issue may be either in the drive, which here is a cable drive, or directly in the unit connecting the engine and the gearbox.

Most often, the problem lies in an unraveled cable or its limited mobility in the jacket. This problem can be eliminated by replacing the cable and/or lubricating it with oil, silicone or WD-40. The fork shaft often needs lubrication.

Less commonly, the problem is caused by a deformed or cracked fork. Wear on the leaf spring can radically change the amount of force required to release the pedal. A new clutch can also cause it to feel stiff.

source

The positive aspects of SUVs

SUVs such as UAZ 469, UAZ 3303, UAZ 3909 and other cars of the Ulyanovsk Automobile Plant have shown their high cross-country ability, which for many citizens of our country is a top priority, especially during spring thaw or deep snow in winter in rural areas.

Thanks to all-wheel drive and high ground clearance, a harmonious combination of engine power and transmission, it was possible to create unpretentious all-terrain vehicles that work well in harsh winters and hot summers.

It should be noted that these cars were tested by designers in different field conditions for years. And the fact that SUVs made in the USSR were in great demand in the world leaves no one in doubt. They were supplied to all continents; 100 foreign countries appreciated the quality of Soviet technology.

The clutch pedal is hard to press, causes and DIY repairs

Not long ago I noticed that in order to depress the clutch pedal in my car, I now need to put in twice as much effort. I found the reason...

Hello, anyone who has driven old VAZ cars understands what a tight clutch pedal is. And it wasn’t a breakdown at all, it was like that from the factory...

But when such a problem occurs in newer cars, even a VAZ 2110, not to mention foreign cars, this is a malfunction that needs to be eliminated.

Now I will try to clearly explain why the clutch pedal becomes tight and how to repair the problem with your own hands.

I want to say right away that there are two types of clutch drive: cable-based and hydraulic. 1st is simpler, but such malfunctions most often occur with it. Below is a diagram of how a cable clutch works.

Let's figure out when and by what signs we can draw a conclusion that something is wrong.

-To depress the clutch pedal, you need to apply a lot more force.

-When you press and release the clutch pedal, you hear strange sounds such as squeaking or the like.

-The clutch pedal began to move not smoothly, as before, but jerkily.

-The pedal stroke decreases with almost every press.

These are signs that can be seen in the clutch pedal.

With the last sign, everything is simple, if the pedal travel decreases, the clutch fork is very likely cracked, get ready, if you do not immediately replace the fork, the clutch will soon disappear completely.

To change the fork, sometimes you have to remove the entire gearbox, but on cars like the VAZ 2107-06, you can do this without removing the gearbox.

Clutch fork burst

If you hear a creaking noise, it often happens in combination with the pedal not moving smoothly, perhaps the cable is simply worn out or dirt has gotten under the jacket (rubber protection of the cable).

To check this, remove the cable completely, pull it out of the jacket and make sure it is in good condition. Next, simply pour oil into the cable jacket, maybe machine oil. Has the problem gone away? Great, that means the rest of the clutch assembly parts are working properly.

pouring oil under the clutch cable jacket.

If this procedure does not lead to any positive results, the reasons may be the following:

The fork is worn and sticking. Treated by replacing the plug. If it is possible to replace the fork without removing the gearbox. If you need to remove the gearbox to replace the fork, it is advisable to change the clutch assembly so that you do not have to remove the box several more times. So, I will continue to list the faults.

The release bearing is worn out, it may be intact, it just jams. If there is no extraneous noise when the clutch pedal is depressed, but when you release the pedal, quite a loud noise appears, it may be the release bearing that is making noise. Although it is possible that the noise is coming from the gearbox input shaft bearing.

Perhaps there is difficulty moving the piston in the cylinders (worker or main). This happens most often due to dirt getting in there. But it's not as likely as:

Worn clutch basket. It is its petal part. Over time, it begins to bulge, and in order to squeeze the pedal, you now need to make more effort. If you change the basket, be sure to change it with the disk. And also remember that expensive spare parts are certainly more durable, but when it comes to the clutch basket... the paddles there are hard, which means it’s more difficult to press the pedal. I advise you to purchase original spare parts.

Clutch basket

These are the most common malfunctions in the operation of a cable clutch.

In a hydraulic drive, I advise you to first look at the cylinders, and then carry out diagnostics further.

Thank you for your attention, I hope the article “The clutch pedal is hard to press, reasons and DIY repairs” was interesting and useful

Let's sum it up

Taking into account the above information, it becomes clear that there are many reasons why the clutch pedal is tight or the clutch is hard. In the process of troubleshooting, you should step by step check the pedal mechanism itself, and then move on to the clutch elements, cables, rods, etc.

Ignoring this rule often leads to the fact that a tight or hard clutch pedal can come as a surprise to the driver while on the road. The clutch pedal also fails, the clutch may not “grab”, etc. To avoid such unforeseen breakdowns, the quality of the clutch must be checked at every scheduled maintenance.

How to adjust the clutch pedal, what adjustment is needed for: clutch functions, clutch pedal adjustment (free play and total travel).

How to bleed the clutch, why it is necessary to perform the procedure. When to pump the clutch: signs. How to bleed the clutch yourself.

Car clutch: purpose, types, design, principle of operation. Frequent clutch malfunctions in the vehicle transmission system, signs of problems.

Types of clutch drive. If the clutch pedal falls, the clutch has become soft, problems have arisen with the clutch: causes and repair of major faults.

The clutch pedal has fallen: why does this happen? The main reasons why the clutch pedal fails, what should the driver do if the clutch fails.

Car clutch and design overview: clutch pressure plate, driven disc, release bearing. Types of clutch drives on manual transmissions and manual transmissions.

Source