Similar articles

13 comments on “Vaz 2114 replacement of fuel hoses. It is necessary to replace the fuel pipe of the VAZ 2115 in the figure "

There is no need to remove anything unnecessary there.

I just need a hole, it’s more convenient. In the summer I removed the tank at 99, as far as I remember, this one hangs freely there and you don’t have to remove the tank, I could be wrong.

This is a melted filter and tubes suitable for it can be replaced without removing the tank

There is no need to remove it, you just need to unscrew the tank fastenings from the fuel filter side, and tilt the tank, and then calmly change the tube

It all depends on the length of the tube that goes above the tank, if it’s long, then you don’t need to remove anything, if it’s short, then you understand that it’s not going to fit you well.

you don't have to take it off

install a Volgov remote and you don’t need to change anything at all

So are you going to change the tube before the filter?

What does 99 have to do with it, your fuel system is completely different

Don’t remove anything, if you change the tube itself, then change it before the filter

You can do it without removing it!

Alexander, despite the fact that the pipes are located in the same way

Modern engines have replaced carburetors with injectors. The VAZ 2114 engine was no exception. His fuel pump was mounted directly into the fuel tank. Design features make it possible to create a pressure in the fuel rail of up to 8 atm, as well as to carry out work with a productivity of up to 80 liters per hour.

At the same time, the fuel pump does not like contaminants that are present in the fuel. Plus, you absolutely cannot start the engine idling if the tank is empty. A failed pump will not allow the engine to even start.

The entire fuel system of the VAZ 2114 consists of:

- Fuel module;

- Fuel filters;

- Fuel injectors;

- Fuel line;

- Fuel supply control system;

- Injector ramp.

The fuel module, in turn, includes the following units:

- Gasoline pump;

- Float;

- Fuel level sensor;

- Primary filter mesh.

How to replace the fuel rail on a VAZ 2113-VAZ 2115?

Note! On cars of the Samara 2 family, different engines were installed and different fuel rails were also installed, but don’t pay much attention to this, and even if you have a ramp of a different type (on engines 21114 there is a ramp like the one shown in the pictures below), then the principle of removing it is practically is identical to other ramps (In this article we are looking at replacing the fuel rail of the 2111 engine) and therefore, by turning on your head and studying this article in detail, you can replace this ramp on your car!

Removal: 1) Before proceeding to removal, release all the pressure in the system using a screwdriver and the fitting that is present on the fuel rail (For more details on how to do this, read the article: “Relieving pressure on a VAZ”), after the pressure will be released from the system, you can proceed to the replacement itself, first disconnect the wire block and the connector between each other that goes to the injectors (see photo below), it is located next to the fuel pressure regulator, look more carefully and you will find it immediately , by the way, as soon as these things are disconnected from each other, remove the fuel pressure regulator itself from the rail (For information on how to do this, read the article: “Replacing the fuel rail pressure regulator on a car”).

Note! Before disconnecting the wires, it is advisable to remove the minus terminal from the battery so that no short circuit occurs. If you do not know how to remove the terminal from the battery, then in this case, study point one in the article entitled: “Replacing the battery on a VAZ”, which is located on our website!

2) Now unscrew the nut securing the fuel pipe to the side of the ramp (Indicated by a red arrow) and then disconnect the tube from the ramp, once it is disconnected, inspect the o-ring on its tip (Indicated by a blue arrow) which should be in normal condition and not in no case should there be any defects on it (cracks, tears, or the ring should not lose elasticity, in other words, make sure it is not hardened), if necessary, replace it with a new one.

3) Next, using a “5” hex wrench, unscrew the two hex head bolts (see photo 1), which secure the fuel rail to the brackets; after unscrewing, carefully remove them and do not lose the washers, which are located under the bolt heads, and in completion, carefully remove the ramp, but only it must be removed at the beginning at an even angle so that the injectors are not damaged, that is, the fuel injectors fit into the holes, if you immediately begin to pull the ramp to the side, the injectors will simply bend and break due to this, so at the beginning Carefully, without changing the lines to the top, remove the fuel rail and only after that tilt it as convenient for you and pull it out together with the injectors from the place where it is located.

Note! If, when removing the ramp, it happened that the injector remained sitting not on the ramp itself, but in the hole into which it goes, then in this case the clamp that holds this injector must be replaced and the sealing ring of this injector must also be replaced, by the way, in more detail how to replace these clamps and O-rings on the injectors, read the article to which the link is given above, and this article is called: “Replacing fuel injectors on cars”!

Installation: The new ramp is installed in its place in the reverse order of removal; before installing from the old ramp, remove all the injectors and transfer them to the new ramp, and also leave all the latches in good working order, over time they will weaken and you have to replace them with new ones.

Additional video clip: So that you can clearly see the process of replacing the ramp, in this case, study the video that is located just below, it shows the whole example on the 2111 engine, this is an engine with a volume of 1.5 liters, 8 valves, used on cars of the Samara, Tenth family family and family Samara 2.

https://www.youtube.com/watch?v=Jv7kL96omLI

Features of the engine power system 11183 (1.6i)

Receiver

engine 11183 (1.6i) is made of plastic.

Engine Intake Module 11183 (1.6i):

1 – flange with an o-ring for fastening the throttle pipe; 2 – receiver with o-rings for connection to the inlet pipeline

Engine Fuel Module 11183 (1.6i):

1 – inlet pipe (for supplying fuel to the pressure regulator); 2 – outlet (discharge) pipe; 3 – module cover; 4 – fuel level indicator sensor; 5 – intake chamber; 6 – module cover guide

Fuel pump

combined with a fuel level indicator sensor and a fuel pressure regulator into a single unit -

a fuel module

(often called an electric fuel pump). Fuel from the pump (through the outlet pipe of the fuel module) enters the fuel filter. Purified gasoline is again supplied through the fuel line and through a tee to the inlet pipe of the fuel module, and then supplied to the fuel rail.

Engine fuel pressure regulator 11183 (1.6i):

1 – hole for dumping excess fuel; 2, 4 – sealing rings; 3 – holes for supplying fuel to the regulator; 5 – body; 6 – terminal for connecting the regulator to ground

Fuel rail for engine 11183 (1.6i) complete with injectors:

1 – diagnostic fitting; 2 – fuel rail; 3 – fitting for connecting to the fuel line; 4, 5, 6 and 7 – nozzles

Excess fuel is released through the pressure regulator into the tank. The fuel pressure regulator is installed in the fuel module cover.

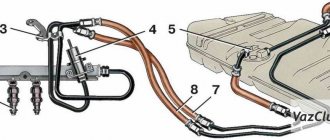

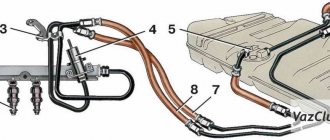

Engine power supply diagram 11183 (1.6i):

1 – nozzle; 2 – fuel rail; 3 – diagnostic fitting; 4 – adsorber; 5 – check valve; 6 – throttle unit; 7 – gravity valve; 8 – safety (two-way) valve; 9 – separator; 10 – fuel line tubes connecting the fuel module to the fuel filter; 11 – fuel module; 12 – fuel filter; 13 – filler pipe; 14 – fuel tank; 15 – fuel line connecting the fuel module to the fuel rail; 16 – metal fuel pipe; 17 – connecting hose; 16 – fitting for connecting the fuel rail to the fuel line

The process of uninterrupted fuel supply is carried out by a fuel device, which ensures the flow of the required amount of combustible materials into the engine when the vehicle is moving.

The structure of the VAZ 2114 fuel system

Analysis of cars selling fuel rail for VAZ (Lada) 2114 in Moscow

- Audirazbor Rating: 5.0

/5 – 4 ratings - Mytishchi district, Dmitrovskoe highway, Gribki settlement, uch. 15A.19

- +7

- Rating: 4.6

/5 – 10 ratings

- Rating: 3.9

/5 – 11 ratings

- Rating: 4.4

/5 – 8 ratings

- Rating: 4.0

/5 – 11 ratings

- Rating: 4.4

/5 – 8 ratings

- Rating: 4.2

/5 – 10 ratings

- Rating: 4.1

/5 – 8 ratings

- Rating: 4.6

/5 – 7 ratings

- Rating: 4.5

/5 – 6 ratings

- Rating: 4.5

/5 – 4 ratings

- Rating: 4.5

/5 – 6 ratings

123…34

Popular companies

- Best Auto Parts 4.4

/5 – 8 ratings - Butyrskaya street, 86Bs7

- +7,,

- 4.1

/5 – 8 ratings

Pressure check

If the pump is working properly, but the engine begins to operate intermittently, you should check the fuel pressure in the system. For this you will need:

- pressure gauge (can be a tire gauge with a measurement limit of 5–7 kPa);

- petrol-resistant hose with a diameter of 10–12 mm and a length of 50–80 cm;

- two clamps for a hose of the appropriate diameter;

- Phillips screwdriver;

- nipple cap;

- dry rag.

In addition, the presence of an assistant is desirable.

The verification procedure is as follows:

- In the engine compartment on the engine fuel rail, locate the pressure measuring fitting (on the right side).

- Remove the plastic cap (plug) from the fitting.

Find the pressure fitting and remove the cap from it

- Using the nipple cap, unscrew the spool valve from the fitting. When unscrewing the spool valve, fuel may spray out of the fitting. To remove it, use a dry cloth.

When unscrewing the spool valve, fuel may spray out of the fitting.

- Place one end of a gas-resistant hose onto the fitting and secure the connection with a clamp. Connect the other end of the hose to the pressure gauge fitting and also tighten the clamp.

Connect the pressure gauge to the fitting using a hose and clamps

- Ask an assistant to turn on the ignition. Wait a few seconds and watch the meter readings. If the pump is working properly, the pressure gauge should show a pressure of 2.8–3.2 kPa for engines with a volume of 1.5 cm3 and 3.7–3.9 kPa for engines of 1.6 cm3. If the pressure is noticeably higher, the pump is faulty.

WHAT GASOLINE TO POUR IN THE VAZ-2114?

This topic has become overgrown with various conjectures and speculations, but we will try to put everything in its place.

The technical data sheet of the fourteenth indicates that the car engine requires AI-95 gasoline, and there is no reason not to trust the manufacturer’s recommendations.

Another thing is that many car owners, over their long driving experience, have accumulated rational doubts about the existence of any serious differences between 95 and 92 gasoline. Adding fuel to the fire was the recent statement by the chief engineer of the Moscow oil refinery, A. A. Abrosimov, that we do not make 95-grade gasoline in our country, and everything that is sold under its guise is either 92-grade or unknown fuel brought from somewhere.

As evidenced by reviews from VAZ 2114 owners who use exclusively 92-octane gasoline, there were no problems with the car during its service life due to fuel, and they see no point in using a more expensive analogue. However, the final decision about what to pour into the fourteenth is yours.

Checking the electrical circuit

At the beginning of the diagnosis, you should check the electrical circuit of the fuel pump. To do this you will need:

- car tester (multimeter);

- crosshead screwdriver;

- two pieces of wire about 2 m long.

Checking the electrical circuit is carried out in the following order:

- Turn on the ignition without starting the engine. When the key is in the first position, a click should be heard, characteristic of turning on the relay, followed by a slight whirring of the pump electric motor. If there is no click, the relay is faulty or is not receiving power. If there is a click, but no buzzing, the wiring coming from the relay or the pump motor itself is faulty.

- Under the glove compartment, find an additional mounting block consisting of three relays and three fuses. The pump relay is located in the middle, and the fuse is located to the left of it. Remove the fuse from its socket, test it with a multimeter, and if the result is negative, replace it. When replacing the fuse, please note that it is rated for a maximum of 15 A.

The relay and fuse for the fuel pump on the VAZ 2114/2115 are located in the mounting block under the glove compartment.

- Set your multimeter to voltmeter mode. Connect one probe of the device to the relay terminal to which the pink wire fits, and the second to the car body. Turn on the ignition. The device should show the on-board network voltage in the range of 11.7–12.4 V. If there is no voltage, the problem may be a broken wiring or a malfunction of the ignition contact group. In this case, it is better to contact an auto electrician. If power is supplied, check that the relay is working. With the ignition on, use a screwdriver or a piece of wire to close the contacts to which the pink and gray wires go. This closes the circuit bypassing the relay. If the fuel pump works, replace the relay.

- Be sure to check the connection of the pump's negative wire to ground. Often it is the lack of “ground” that causes interruptions in the operation of the fuel pump. Remove the plastic trim from the center console near the parking brake handle. Under it there is a “negative” wire of the pump, screwed to the body with a self-tapping screw. Unscrew it, clean the contacts, screw it back and repeat the test.

Fuel pressure regulator VAZ-2114: signs of malfunction, repair. Fuel system VAZ-2114

All engines with an electronic fuel injection system are equipped with devices that maintain the required fuel pressure in the fuel line. In the VAZ-2114 power unit, this function is performed by a special regulator. It is thanks to this that gasoline is supplied under pressure to the injectors in the required quantity, depending on the operating mode of the engine.

In this article we will talk about what the VAZ-2114 fuel pressure regulator is, how it works and where it is located. In addition, we will consider its possible malfunctions and methods for eliminating them.

PRINCIPLE OF OPERATION OF THE SYSTEM

The fuel system of the VAZ 2114, in comparison with foreign cars, is made quite simply, thanks to which a high level of its reliability and endurance has been achieved. The 2114 has an injector for injecting gasoline into the combustion chambers. The presence of an injector provides for a complex fuel dosing system, for which the ECU controller (electronic control unit) is responsible.

The VAZ 2114 fuel pump is driven electronically. The injection moment itself is calculated thanks to sensors that determine the location of the car’s crankshaft. When the fuel pump is turned on, the fuel is supplied through the transport system to the filters, where it is cleaned of impurities, and after the filters - to the fuel rail.

The fuel rail is the part of the intake manifold in which gasoline and gas are mixed in a ratio of 1 to 15 (an increase or decrease in the amount of gas can be adjusted manually, but the optimal gasoline consumption is observed precisely at the above ratio). Next, the mixture is supplied to the injectors, after which it enters the combustion chambers.

Diagnostics of removed injectors

- Activate the battery by connecting the negative terminal.

- Connect the fuel supply pipe and power supply block to the removed ramp.

- Install the ramp in such a way that equal containers can be placed under each nozzle.

- An assistant is needed to turn the starter. The containers will be filled with fuel and poorly functioning injectors or those that are completely out of order will be revealed as the containers are filled.

- It is better to immediately replace a nozzle that is not working with a new one; washing the old one will not eliminate the problem for a long time. The same goes for sealing gaskets and power supply terminals.

- If the block is faulty, the injector will not function.

When diagnosing yourself, do not forget about fire safety!

How to properly check RTD

In order to independently check the pressure in the system, and therefore the correct operation of the regulator, you need to take a pressure gauge, the maximum pressure in which is up to 10 atmospheres. You should not use a device with a larger scale, as its readings will have a serious error. It connects between the fitting and the fuel pipe:

- first turn off and cool the engine;

- locate the fuel rail under the hood;

- remove the plug from the fuel pressure fitting;

- unscrew the fitting nipple using a spool valve;

- wipe the surfaces if fuel splashes appear under the influence of residual pressure;

- pull a hose with a diameter of up to 9 millimeters onto the fitting and secure it with a clamp;

- Connect the second hole of the hose to the pressure gauge.

Signs of injector failure

In fact, there are quite a lot of reasons why injectors may not work well. And the most common symptoms are described below: • Difficulty starting the engine in any weather; • The engine is running unsteadily; • The engine stalls at idle; • High crankshaft rotation speed at idle speed; • Loss of power, poor response to the accelerator pedal; • When you press the gas, shocks or dips may appear; • High gasoline consumption; • If the nozzle is dirty or damaged, it should be replaced or cleaned. There is no point in repairing it. It should also be noted that today injectors cannot last even 100 thousand km.

Which injectors are better to install on a VAZ-2114

The VAZ-2114 model can be equipped with different injectors from different manufacturers. Depending on this, durability and their cost also differ. It is recommended to buy not domestic parts, but from other companies, for example, GM, BOSCH, SIEMENS

.

Also, the choice of injectors also depends on the working volume and the number of valves. For 16-valve engines, the performance of such parts will be different than for the 8-valve version. If the parts are selected incorrectly, then most likely, gas mileage will be higher or the car will lose power. If we talk about choice, then preference should be given to the BOSCH brand at number 0280158502

. This is the serial number that is suitable for an 8-valve engine with a volume of 1.5 liters.

Injectors fail not only because of their quality; their performance is largely affected by fuel that contains a lot of dirt or large fractions. Cleaning injectors at service stations will not be cheap. Therefore, if you do not check and clean it yourself, then you should think about whether it might be easier to buy new parts and replace them.

Removing the fuel rail and injectors on VAZ 2115 (2113, 2114) 8 cells. - video

Components of the device

The VAZ 2114 fuel system includes:

- fuel mixture storage tank;

- gasoline pump;

- several types of filters;

- pipelines for transmitting flammable liquids;

- ramp with 4 nozzles;

- pressure regulator;

- cap on the tank neck.

The steel fuel tank serves as an object for storing fuel; it contains a high-pressure pump and a fuel availability indicator controller, which transmits a signal to the control panel. The pump has a coarse filter that prevents large particles of debris, rust and various impurities from entering the fuel system.

There is a fine filter near the tank; this unit guarantees thorough cleaning of the flammable liquid from the main line to the nozzles.

The injectors are placed on the fuel rail, which securely fastens them to the engine. Fuel injection is carried out using the system control unit. The pressure regulator controls the level of fluid injection between the inlet hose and the ramp line. The excess combustible mixture is returned back through the nozzles, along a separate tank drain line.

The temperature of the fluid that performs the reverse stroke increases by 6-14 degrees, this happens because the fuel circulates under the base of the machine and the blazing engine, and also rubs against the walls of the hose.

This circulation of the combustible mixture increases the temperature of the total liquid in the tank. Fuel vapors appear, which, according to a certain pattern, enter the fuel container and do not escape into the atmosphere; the fuel injection system ensures the safe capture of evaporation, destroying the vapors during engine operation.

Before carrying out repairs or preventative actions on the power system, it is important to reduce the pressure inside the unit. To prevent fuel spillage when removing the wires, it is important to secure the ends of the hose with microfiber.

The vehicles are equipped with a VAZ 2114 fuel supply system, which effectively supplies fuel at various inclinations of the vehicle, as well as when the liquid level in the tank is low.

Symptoms of RTD malfunction

A faulty VAZ-2114 fuel pressure regulator does not pose a critical threat, but its failure disrupts the stable operation of the engine. Symptoms of RTD failure may include:

- difficult starting of the power unit;

- unstable crankshaft speed at idle;

- reduction in engine power characteristics;

- loss of dynamics;

- the occurrence of “dips” when pressing the accelerator pedal;

- increase in fuel consumption.

Having discovered the listed signs of an RTD malfunction, you should diagnose the device and determine the cause of the failure.

Features of the 2111 (1.5i) engine power system

Location of elements of the 2111 (1.5i) engine power supply system in the engine compartment:

1 – receiver; 2 – vacuum supply hose to the fuel pressure regulator; 3 – throttle unit; 4 – fuel rail; 5 – fuel pressure regulator; 6 – air supply hose to the throttle valve; 7 – adsorber; 8 – air filter; 9, 10 and 11 – hoses of the crankcase ventilation system; 12 – throttle valve drive cable; 13 – diagnostic fitting

Pressure in the fuel line VAZ 2114

The pressure in the fuel line of an injection engine is an important parameter - if it is low, normal injection by injectors into the cylinders of an internal combustion engine (ICE) will not be ensured. And its high degree is also dangerous - fuel can flood the entire engine compartment, and then a fire will occur.

Car owners may have a question about how to check the pressure in the fuel rail, within what limits should the readings be, what is used to check it, and how to determine what may be faulty in the fuel line? So, in order.

First you should know how the fuel system (TS) works and what elements it consists of. The vehicle includes (elements in order, starting from gasoline intake to its direct injection):

- Gas tank (in the VAZ model 2114 it is located under the bottom of the trunk);

- Electric fuel pump (located in the gas tank);

- Coarse filter (represents a mesh that is located on the intake part of the pump);

- Fine filter (located immediately after the gas tank, located below the trunk, between the rear of the muffler and the fuel tank);

- Fuel rail or rail (TR), it distributes gasoline among the cylinders, it can be steel, aluminum or plastic;

- Injectors (there are four on model 2114);

- Fuel pressure regulator (it maintains the required gasoline pressure in the system for normal injection through the injectors into the cylinder).

All elements are connected to each other by a fuel line, and in the entire chain, after the pressure regulator (RDT), there is also a return hose through which excess gasoline is discharged into the tank. After the ignition is turned on, fuel passes through the system to the injectors (therefore, there is pressure in the system even when the ignition is on), and when the engine starts, the electronics send a command to the injectors, and gasoline enters the cylinders.

How and with what to check the pressure in a vehicle

They check the pressure in the fuel rail of the VAZ 2114 with a pressure gauge - it is most convenient to connect it on the ramp, and not somewhere else in the line. At the rear of the ramp, in the direction of travel of the car, there is a fitting with a thread and a valve, closed with a plastic cap. When measuring, the pressure gauge adapter is screwed onto the fitting. The pressure gauge is easy to assemble yourself. For this you will need:

- The measuring device itself with an arrow - a tire pressure gauge with a maximum reading limit of 6 to 10 kgf/cm² is suitable;

- A piece of gasoline hose 50-70 cm long;

- A fitting for checking the pressure, which will be screwed into the ramp;

- Two clamps.

We assemble all the elements, tighten the clamps, and the pressure gauge is ready for use. That's it, now you can take measurements. To do this you will need tools:

- Wheel valve cap.

- Thin screwdriver or metal pin;

- A wrench with a fitting size (usually 17 mm):

- Pressure gauge.

To measure the pressure in the fuel rail, you need to:

- Turn off the engine, turn off the ignition;

- unscrew the cap, relieve pressure in the VAZ 2114 fuel rail by pressing the valve with a thin screwdriver;

- Unscrew the spool with the valve using the wheel valve cap. A rag will come in handy - when you dump it, fuel will spray out of the valve. To relieve pressure, you need to press the valve smoothly, releasing the pressure;

- secure the pressure gauge fitting with a wrench to the rail. Now you can start the internal combustion engine and measure the pressure in the fuel rail.

What should be the indicators in the VAZ 2114 gasoline line?

There are several modes in which you will need to check the pressure in the VAZ 2114 fuel rail in order to judge vehicle malfunctions. Make a measurement:

- When the ignition is turned on;

- At idle;

- On re-gassing of internal combustion engines;

- When the ignition is turned off.

The readings should be approximately like this:

- With the ignition on, approximately 3 kgf/cm²,

- During operation at idle speed from 2.8 to 3.2 kgf/cm²,

- When the engine speed increases, it can drop to 2.3-2.5 kgf/cm², when releasing the gas it returns to a reading of about 3 kgf/cm²,

- After stopping the engine, the pressure should drop very slowly. A rapid drop indicates a malfunction of the RTD.

Too low pressure in the fuel rail indicates that:

- The performance of the fuel pump has decreased,

- The fine filter is clogged,

- The RTD is faulty.

If the filter becomes clogged, the fuel injector rail also becomes clogged. In order to clean the vehicle of debris and dirt, it is necessary to remove the fuel rail and clean the injectors.

These parts are cleaned efficiently in car services where there is special equipment. The equipment includes a stand where they can be tested for injection performance. The clogged elements are then cleaned in the bathroom using ultrasound.

Removing the ramp to clean the injectors

You can clean the injectors yourself, but you will have to remove the rail in any case. Typically, car enthusiasts use a special liquid to clean carburetors.

PRINCIPLE OF OPERATION OF THE MAIN ELEMENTS OF A FUEL UNIT

Fuel system VAZ 2114

CONTAINER FOR STORING COMBUSTIBLE MATERIALS

It is made of steel, consists of two firmly welded parts, the neck through which the fuel enters is connected to the tank with a rubber pipe and secured with clamps.

GASOLINE PUMP

This tool with an electric mechanism is located in a tank with a fuel mixture level indicator. Its actions are coordinated by the engine control box, through a special pump relay, which supplies fuel through the line to the injectors. At idle or when the engine is completely turned off, the pressure is maintained due to the action of a one-way lock, which is located near the unit itself.

The VAZ 2114 power system has a fuel pressure regulator and injectors. The voltage is supplied to them from the battery through the main relay. Thus, the amount of driving fluid is indicated by the duration of the pulses, which are generated by the engine control unit and transmitted to the injectors.

RAMP

Located on the intake manifold, it includes a fuel control element and a pressure valve with a spring-loaded diaphragm. It, in turn, divides the regulator body into 2 parts: the fuel part regulates the pressure of the combustible mixture, the air part, due to the rarefaction of the air, raises the membrane and produces constant fuel pressure readings in the rail.

When the engine starts, the vacuum behind the damper decreases, the diaphragm closes the power system valve, so the pressure increases. When the vacuum is maximum, then the fuel pressure decreases. The regulator is not dismountable, so if it fails, it is replaced with another one.

FUEL MIXTURE CONTROL SENSOR

The pump module has a float, which is located in the tank cavity. When the position of the float changes, the resistance of the unit changes proportionally. According to a certain signal, the fuel quantity indicator on the dashboard displays the presence of fuel in the system.

Why does the sensor often fail?

Due to:

- fragility of the case;

- frequent temperature changes;

- condensation formation in the tank;

- when using a low-quality combustible mixture;

- oxidation of contacts when sealing is broken.

That is why it is so important to carry out preventive maintenance on time, clean the unit, change contacts in order to prevent its destruction. Changing a device is not that easy. Many markings are original and unique, which means that the services of professionals will be required, which are also not cheap.

HOSES AND PIPES

Such irreplaceable products guarantee uninterrupted circulation of flammable liquid from the container to the main line and nozzles, and if there is excess, they transfer the residual liquid back to the tank. The pipelines are located on the bottom of the vehicle, they need to be carefully checked, cleaned, inspected for integrity, various deformations identified and promptly eliminated in order to avoid fuel leakage, as well as poor transmission to the injectors.

Another function of the pipelines is the transfer of fuel vapor from the tank to the activated carbon section, where waste is collected when the engine is turned off. After it is started, the electromagnetic device is triggered and the vapors escape into the engine, where they are destroyed.

HIGHWAY

The design of the VAZ 2114 fuel system includes a main line that guarantees the supply of fuel to all injectors. Today, the fuel pressure regulator is placed in the tank and is not located on the line; there is also a service valve, which performs the function of eliminating air after a technical inspection of the vehicle.

The fuel injection system of the VAZ 2114 includes an uninterrupted mode for collecting fuel vapors, and the gravitational unit located in the device helps prevent fuel from leaking when the vehicle is in an emergency position.

When the engine's air consumption is high, the system is purged more intensively. The filter element is made of durable paper material, after which the air moves through the mass air flow sensor and moves into the intake hose, which leads to the throttle assembly.

Thus, the operation of the fuel fluid supply mode of an engine with a fuel injection system on a VAZ 2114 car occurs.