Nowadays, the rapid development of technology contributes to the discovery of more practical and environmentally friendly inventions. Manufacturers of diesel fuel systems are constantly improving their units. If earlier the injectors were controlled, let’s say, mechanically, then later electrical elements appeared in the control of the fuel system. This made it possible to more accurately monitor and control the injection system. But the injectors themselves still remained a purely mechanical product, and their response speed depended on the parameters of the dynamic operation of these mechanical components.

In electromagnetic injectors of the first generations, the fuel supplied to the cylinder was divided into preliminary and main doses. But the injection system turned out to be more effective, where during one working stage of the injector, the fuel is divided into the maximum possible number of microportions.

To do this, it was necessary to increase the response speed of the control and actuator mechanisms of the injector. For this purpose, a piezoceramic nozzle was designed, which operates four times faster than a traditional electromagnetic one.

Typical defects in the operation of diesel engines with piezo injectors

Considering the specific design of this type of injectors, they add their own specific ones to all the “sores” of traditional electromagnetic ones.

Basically, they manifest themselves in this way: the car does not start well (does not start at all); stalls under load; troit; stalls at idle; when under load, traction is lost; the appearance of bluish smoke at idle and black under load.

The reasons for such defects in the operation of a car can be varied, but quite often we see the root cause in the injectors. Therefore, if you find such symptoms on your diesel engine, first of all undergo computer diagnostics. It is inexpensive and will help you save a good amount of money in your case.

If the diagnostics determines a loss (excess) of pressure in the system, a short circuit on the injectors, or a significant imbalance in the operation of the cylinders, then first pay attention to the injectors. Often this is where the cause of these problems lies.

Failure of piezo injectors and impact on engine operation

The piezo injector does not hold pressure - the precision part of the switching valve is damaged. As a result, the car has difficulty starting. It may also stall under load.

The injector is shorted to ground - the insulating layer of the piezoelectric element is damaged. In this case, the car does not start at all, or starts and after a short period of time stalls right at idle. Sometimes, with such a breakdown, the car stalls only under load. Most often we encounter such a defect on Trafic 2.0, less often on cars of the Volkswagen and Audi groups.

Sprayer failure . There are basically two options here: either the sprayer pours, or it jams in the closed position. In the first case, a weakly flowing atomizer produces light smoke at idle, which completely disappears under load. It appears on non-working nozzles after removing the particulate filter. Cars from the Mercedes group love to smell such light smoke, less often Audi and Crafter.

If the sprayer pours heavily (open wedge), then there will be more smoke. Black smoke also appears in the load, which is accompanied by a knocking noise. But such a defect has so far been observed very rarely.

When wedge is closed, the car idles (the wedge is felt more when there is low pressure in the system).

Depressurization of the drain line - mechanical damage to the elements of the drain line, failure of the check valve of this line. With such a breakdown, the car starts and runs, but stalls under light load. Quite often we see such damage on Trafic 2.0.

Insufficient capacity of the piezoelectric element (or weak resistance) - the piezoceramic element has failed. If this happens on one injector, then the car will fail. If the piezoelectric element loses capacity on several injectors, then the car may lose traction.

Repair cannot be changed

From a service point of view, the main feature of piezo injectors is the high complexity of repairs, which require special equipment. In some cases, repair is completely impossible. At the same time, the piezo injectors themselves are very demanding on the quality of the fuel, its composition and degree of purification, and if these levels are reduced, they quickly fail.

Piezo injectors for passenger car engines are produced by companies such as Bosch, Delphi, Denso and Siemens. But they are in no hurry to give this market to third-party repair services, offering a complete replacement. This component is quite expensive: depending on the brand and model, a piezo injector can cost from 16,000 to 40,000 rubles. Therefore, repairs, the average cost of which is half or less than the price of a new injector, are in demand. But not every service can do it.

The control valve most often fails. In this case, the part is manufactured with high precision and dimensions at the micron level.

Difficulties begin from the moment of diagnosis, which cannot be carried out in a garage workshop. For example, an overflow test, when tubes with cups are connected to the drain fittings into the return line, in a system with piezo injectors simply cannot be done like that, since there must be a pressure back-up “in the return”.

As servicemen say, the most vulnerable is the control valve, which fails most often. Moreover, it is one of the most important components - its malfunction can lead to failure of the entire nozzle. The valve is either replaced entirely or restored by grinding and lapping the working edge of the valve itself and the working edge of the valve seat. But this is not easy to do. The valve has a very high, precision manufacturing accuracy with measurement parameters at the micron level. For example, the collar at the top of a valve plug is about one hundred microns wide (one tenth of a millimeter), and there must be a certain chamfer angle. And the more accurately the factory parameters are reproduced, the easier it will be to configure the nozzle and the longer its service life will be.

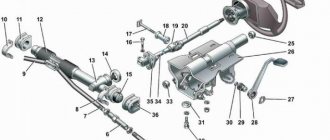

Piezo injector structure

Section of a piezoelectric nozzle : 1 – drain line; 2 – electrical connector; 3 – piezoelectric element; 4 – high pressure channel; 5 – hydraulic cylinder; 6 – mating pistons; 7 – switching valve (multiplier); 8 – throttle plate; 9 – spray needle; 10 – over-needle chamber; 11 – exhaust throttle.

The piezoelectric injector can be divided into three parts:

control , hydraulic and actuating parts.

At the top we have the piezo element, her main “secret weapon”. In the middle is a hydraulic cylinder (another innovation) and a switching valve. And below we have a sprayer and a throttle plate (spacer). Now let's take a closer look at these nodes

Piezo element

This is a composite piezoelectric crystal (30-40 mm long), which consists of ceramic plates welded together. When an electrical impulse is applied to it, it is capable of expanding by 80 microns in 0.1 ms. This is quite enough to apply a force of 6300 N to the nozzle needle. To enhance efficiency, palladium and zirconium are added to its structure. The interesting thing is that it consumes electricity only when voltage is applied. And when the electrical voltage is turned off, it regenerates this energy.

Operating principle of a piezoelectric injector

The operation of the nozzle control valve is based on the well-known piezoelectric effect, which is used, for example, in the design of gas lighters. A button that a person presses with force with a finger deforms the working element made of a special material - dielectric. The deformation creates a charge that is used to ignite the gas.

In addition to fuel injectors, the piezoelectric effect is used in the design of the knock sensor and the intake absolute pressure (MAP) sensor.

Piezoelectric injectors use the so-called inverse piezoelectric effect. Voltage is applied to the dielectric, which contributes to the deformation of the material. The valve stem is connected to the dielectric, which rises when current is supplied to the nozzle.

Hydraulic cylinder and switching valve (multiplier)

The hydraulic cylinder body is located inside the shock-absorbing spring. The cylinder body contains two conjugate (depending on each other) pistons. The space between them is filled with fuel, which, thanks to the valve in the drain line, is under pressure up to 10 bar. The fuel here acts as a pressure absorber. The hydraulic cylinder mediates between the piezoelectric element and the switching valve.

The switch valve (multiplier) is a valve that switches between low pressure areas (in the nozzle cavity around the hydraulic cylinder) and high pressure, which is located above the throttle plate and is connected to the over-needle chamber.

Features of operation of piezoelectric injectors

The use of such a precision mechanism as a piezoelectric injector in engines allows achieving peak performance. For the same reason, the fuel used in a car should not contain even the smallest impurities. When dirt gets in, the injectors fail almost instantly. The cost of piezoelectric injectors ranges from 10 to 15 thousand rubles, and repairs will cost approximately half of this amount.

Nozzle and throttle plate

The sprayer is somewhat different from the classic version. But the principle of its operation is similar to the atomizer of an electromagnetic injector - fuel under high pressure is injected simultaneously from the upper and lower sides of the needle. This allows you to keep the nozzle in the closed position.

A throttle plate is located above the atomizer . It is equipped with holes through which fuel communicates between the high pressure channel, the nozzle and the switching valve chamber.

The principle of operation of a piezo injector

At rest, the spray needle, under the influence of high pressure on both sides simultaneously, is in the closed position. When an electrical impulse is applied to the piezoelectric element, it expands. The piezoelectric crystal, expanding, pushes the elements of the hydraulic cylinder.

The hydraulic cylinder, in turn, acts on the switch valve and opens the exhaust throttle channel, through which fuel flows under pressure from the over-throttle chamber. In this case, the pressure above the needle drops, and the fuel in the under-needle chamber, which is under high pressure, raises the nozzle needle, and injection occurs.

That's all. But the main trick is that this whole series of processes occurs at very high speed. This is the main advantage of piezo injectors.

Advantages of piezo injectors

- speed and frequency of operation

- number of injections per injector operating cycle

- fuel dosage accuracy

- reduction of engine noise

- nozzle operation at high pressures

- environmental friendliness

As mentioned above, the speed of the piezo injector allows the fuel supply to be divided into a large number of micro-doses: first, several preparatory injections occur, then the main one and after that the so-called post-injections.

Fuel injection occurs in such a way that a small amount of fuel enters the cylinder - pilot injection (about 1.5 ml). It enriches and warms up the fuel-air mixture, smoothly preparing the system for the main fuel supply. This achieves uniform pressure distribution in the combustion chamber. The more such pre-injections , the softer the combustion occurs, and, accordingly, the quieter the engine runs.

After this, a large dose of fuel is supplied, which plays a major role in creating the fuel-air mixture. At the end of the combustion cycle, the remaining fuel is burned using post-injections . This reduces the toxicity of exhaust gases. Also, fuel supplied in this way at the end of the injector operating cycle helps to clean and regenerate the particulate filter.

Why are fuel injectors needed?

In the photo: Electromagnetic injectors of a diesel engine

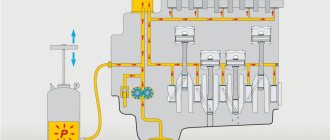

Electrohydraulic injectors

This type of injector combines two previous technologies and is fully adapted for use on diesel engines. The high pressure in the fuel system is equalized by the fact that pressure on the needle occurs from above and below. Thus, the same pressure is formed in the upper chamber and in the lower one. But into the lower chamber, fuel enters through a narrow channel, increasing the time for balancing the pressure in the two chambers.

In the photo: Electro-hydraulic injectors of a diesel engine

When the solenoid valve is activated, due to equal pressure - no more power is required, the needle opens access to the nozzle and allows fuel from the lower chamber to enter the cylinder. But the upper chamber is directly connected to the fuel line and fills quickly, increasing the pressure on the needle. After closing, the lower chamber is filled with fuel through a narrow channel and the pressure is equalized.

Injectors have proven to be a reliable mechanism, effective when used on any engine, but are used on modern diesel engines. Since, on gasoline systems, electromagnetic injectors are sufficient. In addition, electrohydraulic injectors are used in engines with a direct fuel injection system into the cylinders.

Piezoelectric injectors

Piezoelectric injectors are the most modern invention used in the mass production of modern diesel engines equipped with a direct injection system into the cylinders. According to the principle of operation. They completely replicate electrohydraulic injectors, with the only exception - not an electromagnet, but a piezoelectric crystal is used as a valve drive.

Development prospects

Thanks to the latest developments, it is possible to use up to seven injections per injector stroke. Due to this, new opportunities emerge for increasing engine power, reducing engine noise and creating conditions for more precise control of exhaust gases.

Today, manufacturers are developing common rail systems with operating pressures up to 2500 bar. The maximum pressure in such injectors is achieved not in the fuel rail, but in the injector itself. They are equipped with a small hydraulic pressure booster and two electromagnets for precise control of the torque and amount of fuel supplied. This will increase the injection pressure and the efficiency of the fuel system.

We are looking forward to seeing these injectors in our workshop...

What's the result?

The piezo injector is a high-tech component, originally intended to be replaced entirely and difficult to repair. But life dictates its own rules - services have appeared that have learned how to restore these parts so that the client is satisfied. All that remains is for non-original manufacturers to have their say and start producing analogues. And also to the manufacturers of original piezo injectors themselves, offering proprietary restoration technologies and spare parts for repairs.

Alexey Zubikov, head of development of the Bosch Diesel Center / Service network in Russia, Transcaucasia and Central Asia:

— To repair piezo injectors in Bosch Diesel Service workshops, the company does not yet have the technology, and kits of special tools and spare parts are not ready. At the moment we can only carry out diagnostics of injectors of this type. It is planned that we will begin providing repair services for piezo injectors in 2017–2018.

Source